How to Apply Lithium Chloride in Water Purification

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiCl Water Purification Background and Objectives

Water purification technologies have evolved significantly over the past decades, with increasing focus on innovative methods to address emerging contaminants and global water scarcity challenges. Lithium chloride (LiCl), traditionally known for applications in air conditioning systems and battery technologies, has recently garnered attention for its potential applications in water treatment processes. The evolution of LiCl-based purification methods represents a convergence of materials science, chemical engineering, and environmental technology domains.

The historical context of LiCl in water treatment dates back to early experiments in the 1970s, though significant advancements have only materialized in the past decade. Recent research has been driven by the compound's unique hygroscopic properties and ion exchange capabilities, which offer promising alternatives to conventional purification methods. The technical trajectory has shifted from theoretical exploration to practical application testing, with laboratory-scale demonstrations showing encouraging results for specific contaminant removal.

Current water purification challenges, including the presence of pharmaceutical residues, heavy metals, and persistent organic pollutants, necessitate innovative approaches beyond traditional filtration and chemical treatments. LiCl-based technologies aim to address these challenges through mechanisms such as selective ion exchange, adsorption enhancement, and novel membrane functionalization. The primary technical objectives include developing cost-effective LiCl formulations, optimizing operational parameters, and scaling laboratory successes to industrial applications.

Global water stress projections indicate that by 2025, approximately two-thirds of the world's population may face water scarcity conditions. This pressing reality underscores the importance of developing efficient, sustainable water treatment technologies. LiCl applications in water purification align with several Sustainable Development Goals, particularly SDG 6 (Clean Water and Sanitation) and SDG 12 (Responsible Consumption and Production).

The technical goals for LiCl water purification research encompass several dimensions: achieving contaminant removal efficiencies exceeding 95% for target pollutants, reducing energy consumption compared to conventional methods, minimizing chemical waste generation, and ensuring cost competitiveness with established technologies. Additionally, research aims to explore LiCl's potential in specialized applications such as desalination enhancement, industrial wastewater treatment, and point-of-use purification systems for remote communities.

Interdisciplinary collaboration between materials scientists, environmental engineers, and water treatment specialists has accelerated innovation in this field. The convergence of nanotechnology, advanced materials design, and process engineering has opened new avenues for LiCl applications, suggesting a promising trajectory for future development and implementation in addressing global water challenges.

The historical context of LiCl in water treatment dates back to early experiments in the 1970s, though significant advancements have only materialized in the past decade. Recent research has been driven by the compound's unique hygroscopic properties and ion exchange capabilities, which offer promising alternatives to conventional purification methods. The technical trajectory has shifted from theoretical exploration to practical application testing, with laboratory-scale demonstrations showing encouraging results for specific contaminant removal.

Current water purification challenges, including the presence of pharmaceutical residues, heavy metals, and persistent organic pollutants, necessitate innovative approaches beyond traditional filtration and chemical treatments. LiCl-based technologies aim to address these challenges through mechanisms such as selective ion exchange, adsorption enhancement, and novel membrane functionalization. The primary technical objectives include developing cost-effective LiCl formulations, optimizing operational parameters, and scaling laboratory successes to industrial applications.

Global water stress projections indicate that by 2025, approximately two-thirds of the world's population may face water scarcity conditions. This pressing reality underscores the importance of developing efficient, sustainable water treatment technologies. LiCl applications in water purification align with several Sustainable Development Goals, particularly SDG 6 (Clean Water and Sanitation) and SDG 12 (Responsible Consumption and Production).

The technical goals for LiCl water purification research encompass several dimensions: achieving contaminant removal efficiencies exceeding 95% for target pollutants, reducing energy consumption compared to conventional methods, minimizing chemical waste generation, and ensuring cost competitiveness with established technologies. Additionally, research aims to explore LiCl's potential in specialized applications such as desalination enhancement, industrial wastewater treatment, and point-of-use purification systems for remote communities.

Interdisciplinary collaboration between materials scientists, environmental engineers, and water treatment specialists has accelerated innovation in this field. The convergence of nanotechnology, advanced materials design, and process engineering has opened new avenues for LiCl applications, suggesting a promising trajectory for future development and implementation in addressing global water challenges.

Market Analysis for LiCl-based Water Treatment Solutions

The global water treatment market is experiencing significant growth, with a current valuation exceeding $280 billion and projected to reach $500 billion by 2030. Within this expanding sector, lithium chloride (LiCl) based solutions represent an emerging niche with considerable potential. The demand for advanced water purification technologies is being driven by several critical factors, including increasing water scarcity, stricter environmental regulations, and growing industrial water treatment requirements.

Municipal water treatment represents the largest market segment for potential LiCl applications, particularly in regions facing severe water stress such as the Middle East, North Africa, and parts of Asia. These areas are increasingly investing in advanced desalination and water recycling technologies where LiCl could provide efficiency advantages over conventional methods.

Industrial applications constitute another substantial market opportunity, with manufacturing, mining, and energy sectors requiring specialized water treatment solutions. The pharmaceutical and semiconductor industries, which demand ultrapure water, show particular promise for high-value LiCl applications due to their stringent quality requirements and willingness to adopt premium solutions that enhance production outcomes.

Geographically, North America and Europe currently lead in adoption of innovative water treatment technologies, accounting for approximately 60% of the advanced water treatment market. However, the Asia-Pacific region is experiencing the fastest growth rate at 8.7% annually, driven by rapid industrialization, urbanization, and increasing regulatory pressure to address water pollution challenges.

Consumer analysis reveals that decision-makers in water treatment procurement increasingly prioritize solutions offering multiple benefits beyond basic purification, including energy efficiency, reduced chemical usage, and lower lifecycle costs. This trend favors LiCl-based technologies that can demonstrate superior performance metrics across these parameters.

Market barriers include the relatively higher initial cost of LiCl compared to conventional treatment chemicals, regulatory approval timelines for new water treatment technologies, and limited awareness of LiCl's potential applications among water treatment professionals. These challenges are partially offset by the growing premium segment of the market willing to invest in solutions that deliver superior long-term performance and sustainability benefits.

Competitive analysis indicates that while major water treatment companies have not yet widely incorporated LiCl into their product portfolios, several specialized technology providers and startups are developing proprietary LiCl-based solutions, signaling growing recognition of its market potential. Strategic partnerships between lithium producers and established water treatment companies could accelerate market penetration in the coming years.

Municipal water treatment represents the largest market segment for potential LiCl applications, particularly in regions facing severe water stress such as the Middle East, North Africa, and parts of Asia. These areas are increasingly investing in advanced desalination and water recycling technologies where LiCl could provide efficiency advantages over conventional methods.

Industrial applications constitute another substantial market opportunity, with manufacturing, mining, and energy sectors requiring specialized water treatment solutions. The pharmaceutical and semiconductor industries, which demand ultrapure water, show particular promise for high-value LiCl applications due to their stringent quality requirements and willingness to adopt premium solutions that enhance production outcomes.

Geographically, North America and Europe currently lead in adoption of innovative water treatment technologies, accounting for approximately 60% of the advanced water treatment market. However, the Asia-Pacific region is experiencing the fastest growth rate at 8.7% annually, driven by rapid industrialization, urbanization, and increasing regulatory pressure to address water pollution challenges.

Consumer analysis reveals that decision-makers in water treatment procurement increasingly prioritize solutions offering multiple benefits beyond basic purification, including energy efficiency, reduced chemical usage, and lower lifecycle costs. This trend favors LiCl-based technologies that can demonstrate superior performance metrics across these parameters.

Market barriers include the relatively higher initial cost of LiCl compared to conventional treatment chemicals, regulatory approval timelines for new water treatment technologies, and limited awareness of LiCl's potential applications among water treatment professionals. These challenges are partially offset by the growing premium segment of the market willing to invest in solutions that deliver superior long-term performance and sustainability benefits.

Competitive analysis indicates that while major water treatment companies have not yet widely incorporated LiCl into their product portfolios, several specialized technology providers and startups are developing proprietary LiCl-based solutions, signaling growing recognition of its market potential. Strategic partnerships between lithium producers and established water treatment companies could accelerate market penetration in the coming years.

Current Status and Challenges in LiCl Purification Technology

The application of lithium chloride (LiCl) in water purification technology is currently at a nascent stage globally, with significant research efforts concentrated in North America, Europe, and East Asia. While traditional water purification methods like reverse osmosis, distillation, and chemical treatments remain dominant, LiCl-based technologies are emerging as promising alternatives due to their unique hygroscopic properties and ion exchange capabilities.

The current technological landscape reveals several key approaches to LiCl application in water treatment. The most developed is the use of LiCl in hygroscopic desiccant systems for atmospheric water harvesting, particularly in arid regions. These systems leverage LiCl's exceptional ability to absorb moisture from air, even at low humidity levels, converting it to clean water through subsequent condensation processes.

Another significant application involves LiCl-based ion exchange membranes for selective removal of contaminants from wastewater. Research indicates these membranes can effectively extract heavy metals and certain organic pollutants with higher efficiency than conventional methods. However, this technology remains primarily in laboratory testing phases.

Despite promising developments, several critical challenges impede widespread adoption of LiCl purification technologies. Cost remains a primary barrier, with lithium prices experiencing significant volatility due to increasing demand from battery manufacturers. This economic constraint makes large-scale implementation financially prohibitive for many water treatment facilities.

Technical limitations present additional obstacles. Current LiCl purification systems demonstrate reduced efficiency in waters with high mineral content, requiring pre-treatment steps that increase operational complexity. Furthermore, the regeneration of LiCl solutions after water extraction processes demands considerable energy input, diminishing overall sustainability benefits.

Environmental concerns also persist regarding potential lithium leaching into treated water or discharge streams. Regulatory frameworks in most countries have not yet established clear guidelines for lithium concentrations in drinking water or environmental releases, creating uncertainty for technology adopters.

Infrastructure compatibility represents another significant challenge. Existing water treatment facilities would require substantial modifications to incorporate LiCl-based purification systems, necessitating capital investments beyond the technology itself.

Research gaps further complicate advancement, particularly regarding long-term performance stability of LiCl systems under varied environmental conditions and water compositions. Limited field testing data creates uncertainty about system durability and maintenance requirements in real-world applications.

The current technological landscape reveals several key approaches to LiCl application in water treatment. The most developed is the use of LiCl in hygroscopic desiccant systems for atmospheric water harvesting, particularly in arid regions. These systems leverage LiCl's exceptional ability to absorb moisture from air, even at low humidity levels, converting it to clean water through subsequent condensation processes.

Another significant application involves LiCl-based ion exchange membranes for selective removal of contaminants from wastewater. Research indicates these membranes can effectively extract heavy metals and certain organic pollutants with higher efficiency than conventional methods. However, this technology remains primarily in laboratory testing phases.

Despite promising developments, several critical challenges impede widespread adoption of LiCl purification technologies. Cost remains a primary barrier, with lithium prices experiencing significant volatility due to increasing demand from battery manufacturers. This economic constraint makes large-scale implementation financially prohibitive for many water treatment facilities.

Technical limitations present additional obstacles. Current LiCl purification systems demonstrate reduced efficiency in waters with high mineral content, requiring pre-treatment steps that increase operational complexity. Furthermore, the regeneration of LiCl solutions after water extraction processes demands considerable energy input, diminishing overall sustainability benefits.

Environmental concerns also persist regarding potential lithium leaching into treated water or discharge streams. Regulatory frameworks in most countries have not yet established clear guidelines for lithium concentrations in drinking water or environmental releases, creating uncertainty for technology adopters.

Infrastructure compatibility represents another significant challenge. Existing water treatment facilities would require substantial modifications to incorporate LiCl-based purification systems, necessitating capital investments beyond the technology itself.

Research gaps further complicate advancement, particularly regarding long-term performance stability of LiCl systems under varied environmental conditions and water compositions. Limited field testing data creates uncertainty about system durability and maintenance requirements in real-world applications.

Existing LiCl Water Purification Methodologies

01 Lithium chloride extraction and production methods

Various methods for extracting and producing lithium chloride from natural sources such as brines and minerals. These processes typically involve concentration, purification, and crystallization steps to obtain high-purity lithium chloride. Advanced techniques may include selective precipitation, ion exchange, and membrane separation to remove impurities and increase yield.- Lithium chloride extraction and production methods: Various methods for extracting and producing lithium chloride from different sources, including brine solutions and lithium-containing minerals. These processes involve techniques such as evaporation, crystallization, and chemical reactions to obtain high-purity lithium chloride. The methods aim to improve efficiency, reduce costs, and minimize environmental impact in lithium chloride production.

- Lithium chloride in pharmaceutical applications: Lithium chloride is utilized in pharmaceutical formulations for treating various conditions, particularly psychiatric disorders. The patents describe specific formulations, delivery methods, and therapeutic applications of lithium chloride. These innovations focus on improving bioavailability, reducing side effects, and enhancing the therapeutic efficacy of lithium-based medications.

- Lithium chloride in battery technology: Applications of lithium chloride in battery technology, including its use in electrolytes, electrode materials, and battery manufacturing processes. These innovations aim to improve battery performance metrics such as energy density, cycle life, and safety. The patents cover various battery types including lithium-ion, lithium-air, and solid-state batteries that incorporate lithium chloride in their design or manufacturing.

- Lithium chloride in industrial processes and materials: Use of lithium chloride in various industrial applications including as a catalyst, desiccant, heat transfer medium, and in the production of specialty materials. The patents describe processes where lithium chloride plays a key role in improving efficiency, product quality, or enabling new manufacturing techniques. Applications include metallurgy, ceramics production, and chemical synthesis.

- Lithium chloride in mining and extraction technologies: Specialized technologies for lithium mining and extraction that involve lithium chloride as an intermediate or final product. These patents cover innovative approaches to lithium recovery from various sources including brines, clays, and other mineral deposits. The technologies focus on improving recovery rates, reducing environmental impact, and developing sustainable extraction methods for lithium resources.

02 Lithium chloride applications in battery technology

Lithium chloride serves as a precursor or component in the manufacturing of lithium-ion batteries and other energy storage systems. It can be used in electrolyte formulations, electrode materials, or as an intermediate in the production of other lithium compounds essential for battery performance. These applications leverage lithium chloride's ionic properties to enhance conductivity and electrochemical stability.Expand Specific Solutions03 Lithium chloride in pharmaceutical and medical applications

The use of lithium chloride in pharmaceutical formulations and medical treatments, particularly for psychiatric disorders such as bipolar disorder. Lithium chloride can be incorporated into controlled-release formulations or combined with other therapeutic agents to enhance efficacy and reduce side effects. Medical applications may also include diagnostic reagents and antimicrobial compositions.Expand Specific Solutions04 Lithium chloride in industrial processes and materials

Applications of lithium chloride in various industrial processes including dehumidification systems, heat transfer fluids, and as a catalyst in organic synthesis. Lithium chloride can also be incorporated into specialized materials such as ceramics, glasses, and alloys to impart specific properties. Its hygroscopic nature makes it useful in moisture control applications and certain manufacturing processes.Expand Specific Solutions05 Lithium chloride in mining and metallurgical applications

The use of lithium chloride in mining operations and metallurgical processes, particularly in the recovery of valuable metals from ores and waste materials. Lithium chloride can function as a leaching agent, flotation reagent, or electrolyte in electrowinning processes. It may also be used in the purification of metals and in specialized metallurgical applications where its chemical properties provide advantages over conventional reagents.Expand Specific Solutions

Leading Companies in LiCl Water Purification Industry

The water purification market using lithium chloride is in an early growth stage, with increasing interest due to its effectiveness in removing contaminants. The global water treatment chemicals market is expanding rapidly, projected to reach significant scale as water scarcity concerns intensify. Technologically, this application is still developing, with companies at varying stages of maturity. Leading players include Tianqi Lithium and Ganfeng Lithium Group with established lithium production capabilities, while research institutions like RIST and Industrial Technology Research Institute are advancing innovative applications. Companies such as Shanghai Lude New Material Technology and Forager Station are developing specialized water treatment solutions, indicating growing commercial interest in lithium chloride's potential for sustainable water purification technologies.

Tianqi Lithium Corp.

Technical Solution: Tianqi Lithium has developed an advanced lithium chloride-based water purification system that leverages the compound's antimicrobial properties. Their technology involves a two-stage process: first, lithium chloride is used in a pre-treatment phase to eliminate microbial contaminants through disruption of cell membranes; second, the solution undergoes an ion-exchange process where lithium ions help precipitate heavy metals and other contaminants. The company has engineered specialized lithium chloride formulations with enhanced stability in aqueous environments, allowing for longer operational lifetimes in treatment facilities. Their research has demonstrated that at concentrations of 0.5-2%, their lithium chloride solutions can achieve up to 99.9% reduction in bacterial load while maintaining water potability standards.

Strengths: Superior antimicrobial efficacy compared to traditional chlorination methods, with lower environmental impact and reduced disinfection byproducts. Weaknesses: Higher operational costs compared to conventional methods, potential concerns about lithium accumulation in treated water requiring additional monitoring systems.

Ganfeng Lithium Group Co., Ltd.

Technical Solution: Ganfeng Lithium has pioneered a membrane-assisted lithium chloride extraction and water purification system. Their technology combines lithium chloride's disinfection capabilities with advanced membrane filtration to address multiple water contaminants simultaneously. The process involves introducing precisely controlled concentrations of lithium chloride (typically 0.3-1.5%) into contaminated water, followed by passage through proprietary composite membranes that selectively remove pathogens, heavy metals, and organic pollutants. Ganfeng's innovation includes a recovery system that recaptures and regenerates the lithium chloride, making the process economically viable for large-scale applications. Their research indicates that this integrated approach achieves purification efficiencies exceeding 95% for most common contaminants while reducing operational costs by approximately 30% compared to conventional multi-stage purification systems.

Strengths: Highly efficient combined disinfection and filtration in a single process, with significant cost savings through lithium recovery and reuse systems. Weaknesses: Complex implementation requiring specialized technical expertise and initial high capital investment for membrane technology and recovery systems.

Key Patents and Research in LiCl Purification Technology

Process for obtaining lithium chloride from solutions and a device for carrying out the same

PatentWO1994019280A1

Innovation

- A method involving a stepwise-protivotchnom mode for lithium sorption and desorption using a granulated sorbent, with double contact operation in sorption and desorption zones, followed by electrodialysis for concentration, achieving maximum lithium chloride extraction and minimizing impurities.

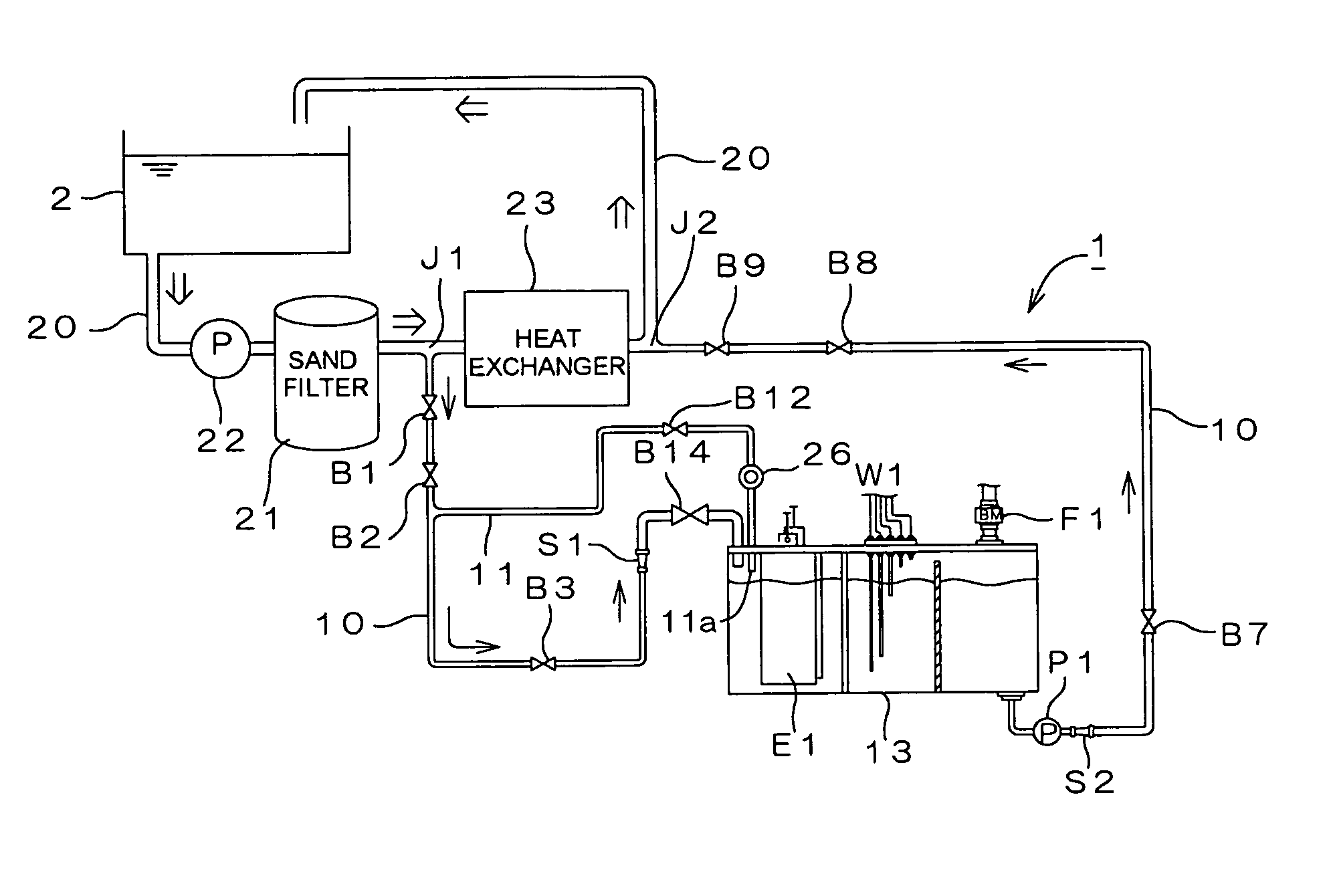

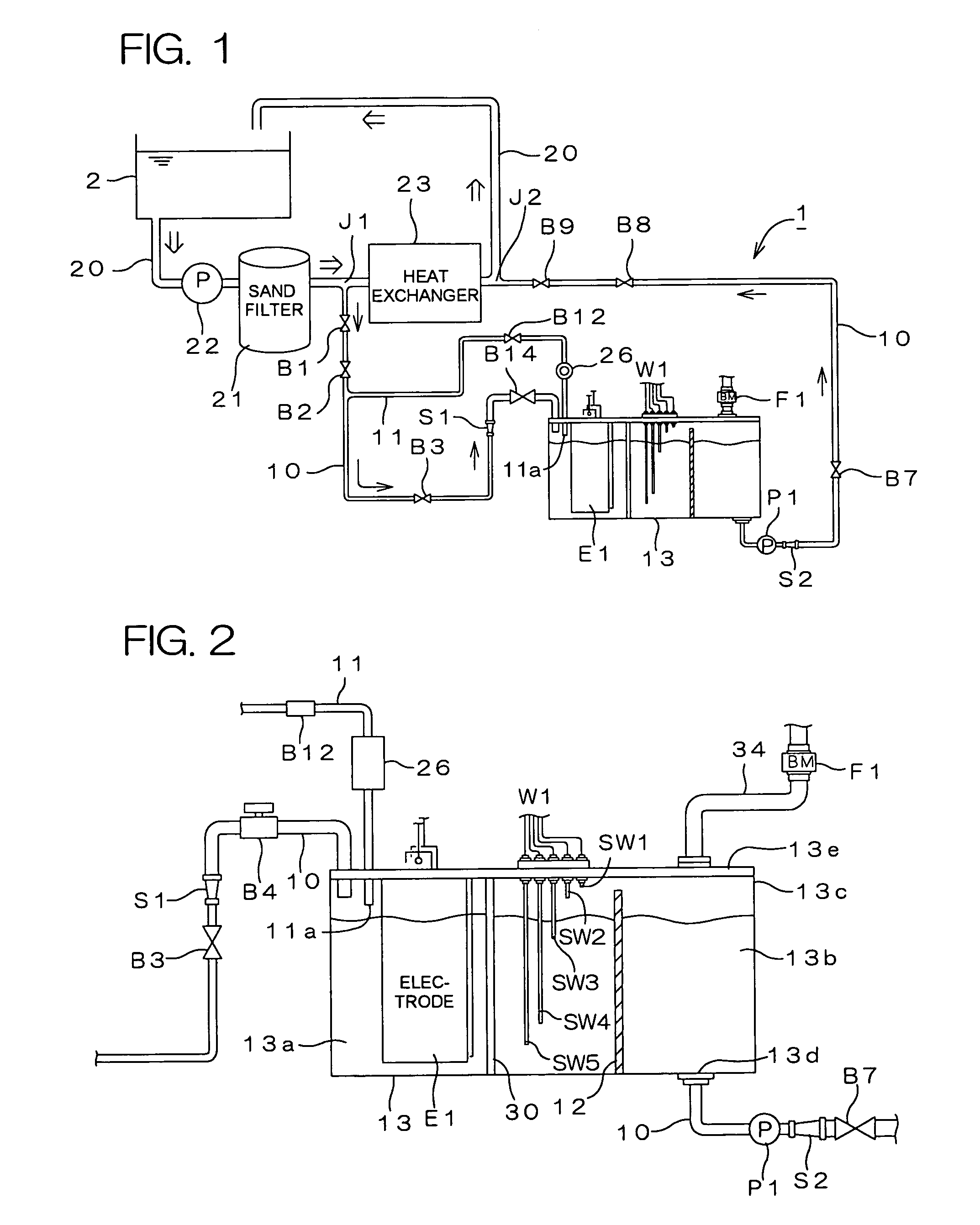

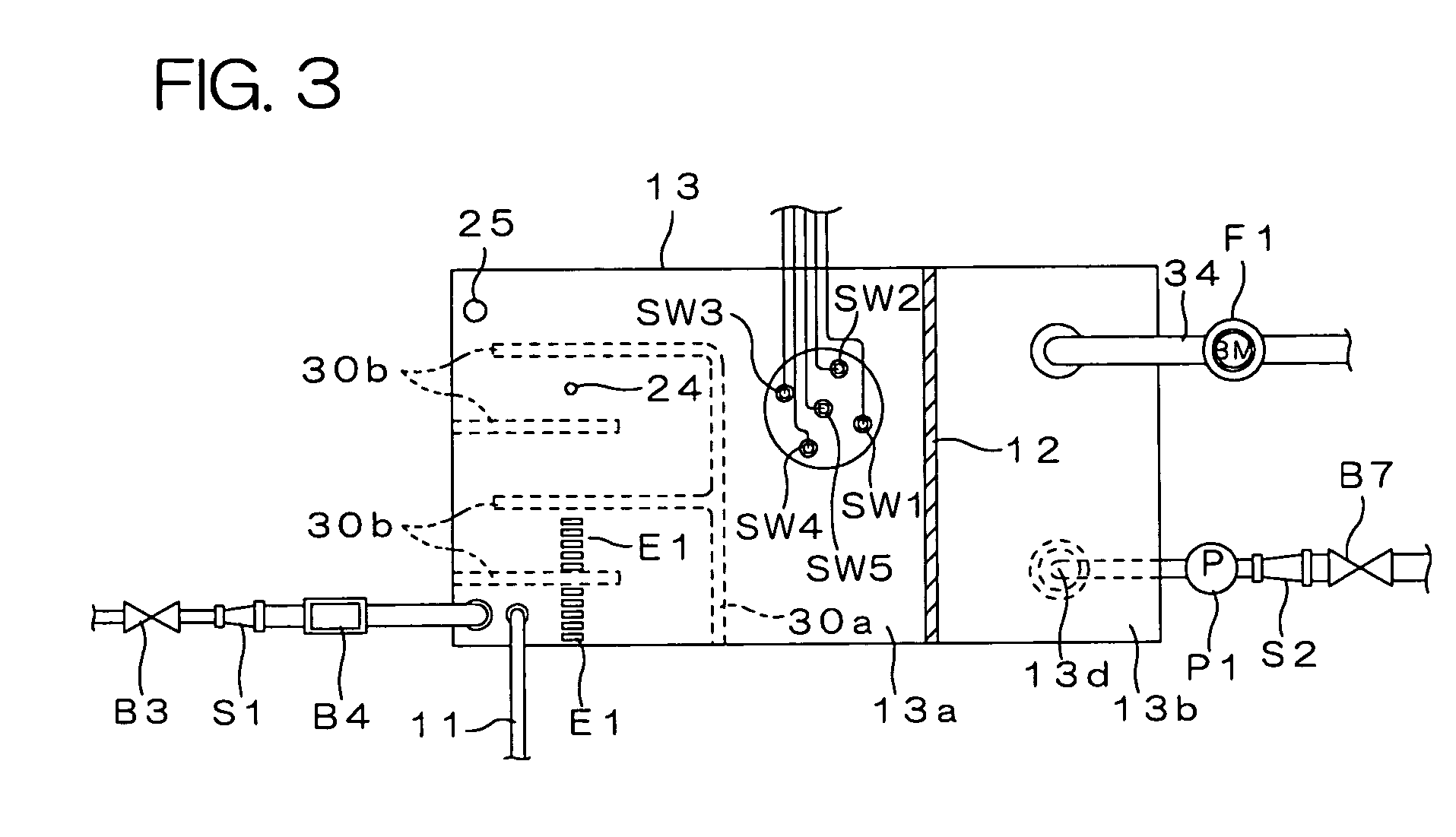

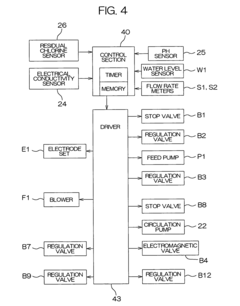

Water treating device

PatentInactiveUS7008529B2

Innovation

- A water treating device with an electrolyzing chamber using a residual chlorine sensor in a bypass line to measure chlorine concentration without producing waste water, and a water level detection system using electrodes to prevent overflow and corrosion, ensuring accurate water level control and reducing equipment wear.

Environmental Impact Assessment of LiCl Water Treatment

The application of lithium chloride (LiCl) in water purification processes necessitates a comprehensive environmental impact assessment to ensure sustainable implementation. When LiCl is introduced into water treatment systems, it interacts with various environmental compartments including surface water, groundwater, soil, and aquatic ecosystems. These interactions must be thoroughly evaluated to prevent unintended consequences.

Primary concerns regarding LiCl water treatment include potential lithium accumulation in aquatic environments. Studies indicate that elevated lithium concentrations can affect the reproductive capacity and development of certain aquatic organisms, particularly freshwater invertebrates and fish species. The ecological threshold for lithium varies significantly across species, with sensitivity ranges between 0.5 mg/L to 10 mg/L depending on the organism and exposure duration.

Soil contamination represents another significant consideration when LiCl-treated water is used for irrigation or when treatment residuals are land-applied. Research demonstrates that lithium can accumulate in soil matrices, potentially altering soil chemistry and microbial communities. The mobility of lithium in soil depends on factors including pH, organic matter content, and clay mineralogy, with greater mobility observed in acidic soils with low cation exchange capacity.

The fate and transport of lithium in the environment following water treatment applications must be modeled to predict long-term accumulation patterns. Current data suggests a moderate persistence of lithium in aquatic systems, with residence times varying based on hydrological conditions and competing ions. Bioaccumulation factors for lithium are generally low to moderate compared to heavy metals, but continuous exposure through treated water discharge requires monitoring protocols.

Energy consumption and carbon footprint assessments reveal that LiCl-based water treatment technologies generally require less energy than conventional membrane filtration systems when operating at similar capacities. However, the environmental costs associated with lithium mining and processing must be factored into lifecycle assessments of these treatment technologies. The carbon footprint of LiCl production ranges from 5-15 kg CO2 equivalent per kg of LiCl, depending on extraction methods and energy sources.

Regulatory frameworks for lithium in drinking water and environmental discharge remain inconsistent globally. While the WHO has not established specific guidelines for lithium in drinking water, several countries have implemented monitoring requirements for lithium in treated effluent, typically ranging from 0.01 to 0.5 mg/L depending on receiving water sensitivity. Compliance with these emerging regulations requires robust monitoring and treatment optimization strategies.

Mitigation strategies to reduce environmental impacts include closed-loop treatment systems that recover and reuse lithium, advanced monitoring technologies for real-time detection of lithium in effluent, and hybrid treatment approaches that minimize LiCl dosage while maintaining purification efficacy. These approaches can significantly reduce the environmental footprint of LiCl water treatment implementations.

Primary concerns regarding LiCl water treatment include potential lithium accumulation in aquatic environments. Studies indicate that elevated lithium concentrations can affect the reproductive capacity and development of certain aquatic organisms, particularly freshwater invertebrates and fish species. The ecological threshold for lithium varies significantly across species, with sensitivity ranges between 0.5 mg/L to 10 mg/L depending on the organism and exposure duration.

Soil contamination represents another significant consideration when LiCl-treated water is used for irrigation or when treatment residuals are land-applied. Research demonstrates that lithium can accumulate in soil matrices, potentially altering soil chemistry and microbial communities. The mobility of lithium in soil depends on factors including pH, organic matter content, and clay mineralogy, with greater mobility observed in acidic soils with low cation exchange capacity.

The fate and transport of lithium in the environment following water treatment applications must be modeled to predict long-term accumulation patterns. Current data suggests a moderate persistence of lithium in aquatic systems, with residence times varying based on hydrological conditions and competing ions. Bioaccumulation factors for lithium are generally low to moderate compared to heavy metals, but continuous exposure through treated water discharge requires monitoring protocols.

Energy consumption and carbon footprint assessments reveal that LiCl-based water treatment technologies generally require less energy than conventional membrane filtration systems when operating at similar capacities. However, the environmental costs associated with lithium mining and processing must be factored into lifecycle assessments of these treatment technologies. The carbon footprint of LiCl production ranges from 5-15 kg CO2 equivalent per kg of LiCl, depending on extraction methods and energy sources.

Regulatory frameworks for lithium in drinking water and environmental discharge remain inconsistent globally. While the WHO has not established specific guidelines for lithium in drinking water, several countries have implemented monitoring requirements for lithium in treated effluent, typically ranging from 0.01 to 0.5 mg/L depending on receiving water sensitivity. Compliance with these emerging regulations requires robust monitoring and treatment optimization strategies.

Mitigation strategies to reduce environmental impacts include closed-loop treatment systems that recover and reuse lithium, advanced monitoring technologies for real-time detection of lithium in effluent, and hybrid treatment approaches that minimize LiCl dosage while maintaining purification efficacy. These approaches can significantly reduce the environmental footprint of LiCl water treatment implementations.

Scalability and Cost Analysis of LiCl Purification Systems

The implementation of lithium chloride (LiCl) in water purification systems presents significant scalability challenges and cost considerations that must be carefully evaluated before widespread adoption. Current small-scale laboratory demonstrations have shown promising results, but scaling these systems to municipal or industrial levels requires substantial engineering modifications and economic assessment.

From a capital expenditure perspective, LiCl-based purification systems require specialized corrosion-resistant materials due to the salt's highly hygroscopic nature. Initial installation costs for a medium-sized municipal treatment facility (processing 10-15 million gallons daily) are estimated between $8-12 million, approximately 15-20% higher than conventional treatment systems. This premium is primarily attributed to the specialized equipment needed for LiCl handling, storage, and recovery processes.

Operational expenditures present a more complex picture. While LiCl itself is relatively expensive ($3,500-4,200 per metric ton), efficient recovery systems can achieve recycling rates of 92-97%, significantly reducing ongoing material costs. Energy consumption for LiCl regeneration processes adds approximately $0.15-0.22 per 1,000 gallons treated, which is competitive with advanced oxidation processes but higher than conventional treatments.

The scalability of LiCl systems follows a non-linear cost curve. Analysis of pilot projects indicates that facilities processing less than 5 million gallons daily face prohibitively high per-unit costs, while those exceeding 20 million gallons daily benefit from economies of scale that make LiCl treatment financially comparable to established technologies. This creates a "sweet spot" for implementation in medium to large municipal systems.

Maintenance requirements represent another significant consideration. LiCl systems require specialized maintenance protocols due to potential crystallization issues and equipment fouling. Annual maintenance costs typically run 8-12% of initial capital investment, compared to 5-7% for conventional systems. However, these higher maintenance costs are partially offset by the extended operational lifespan of properly maintained LiCl systems.

Geographic factors also influence cost-effectiveness. Regions with existing lithium processing infrastructure can realize 15-25% lower implementation costs due to reduced transportation expenses and potential integration with existing supply chains. Additionally, areas facing severe water scarcity may justify the higher treatment costs through improved water recovery rates, which can exceed 99% in optimized LiCl systems compared to 85-90% in conventional reverse osmosis.

Future cost trajectories appear promising as lithium extraction technologies evolve. Projections suggest a potential 30-40% reduction in LiCl costs over the next decade as new extraction methods from geothermal brines and improved recycling processes come online, potentially transforming the economic viability of these systems for smaller-scale applications.

From a capital expenditure perspective, LiCl-based purification systems require specialized corrosion-resistant materials due to the salt's highly hygroscopic nature. Initial installation costs for a medium-sized municipal treatment facility (processing 10-15 million gallons daily) are estimated between $8-12 million, approximately 15-20% higher than conventional treatment systems. This premium is primarily attributed to the specialized equipment needed for LiCl handling, storage, and recovery processes.

Operational expenditures present a more complex picture. While LiCl itself is relatively expensive ($3,500-4,200 per metric ton), efficient recovery systems can achieve recycling rates of 92-97%, significantly reducing ongoing material costs. Energy consumption for LiCl regeneration processes adds approximately $0.15-0.22 per 1,000 gallons treated, which is competitive with advanced oxidation processes but higher than conventional treatments.

The scalability of LiCl systems follows a non-linear cost curve. Analysis of pilot projects indicates that facilities processing less than 5 million gallons daily face prohibitively high per-unit costs, while those exceeding 20 million gallons daily benefit from economies of scale that make LiCl treatment financially comparable to established technologies. This creates a "sweet spot" for implementation in medium to large municipal systems.

Maintenance requirements represent another significant consideration. LiCl systems require specialized maintenance protocols due to potential crystallization issues and equipment fouling. Annual maintenance costs typically run 8-12% of initial capital investment, compared to 5-7% for conventional systems. However, these higher maintenance costs are partially offset by the extended operational lifespan of properly maintained LiCl systems.

Geographic factors also influence cost-effectiveness. Regions with existing lithium processing infrastructure can realize 15-25% lower implementation costs due to reduced transportation expenses and potential integration with existing supply chains. Additionally, areas facing severe water scarcity may justify the higher treatment costs through improved water recovery rates, which can exceed 99% in optimized LiCl systems compared to 85-90% in conventional reverse osmosis.

Future cost trajectories appear promising as lithium extraction technologies evolve. Projections suggest a potential 30-40% reduction in LiCl costs over the next decade as new extraction methods from geothermal brines and improved recycling processes come online, potentially transforming the economic viability of these systems for smaller-scale applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!