How to Optimize Humidity Control with Lithium Chloride

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Chloride Dehumidification Technology Background and Objectives

Lithium chloride (LiCl) has emerged as a significant material in humidity control systems, with its history dating back to the early 20th century. The hygroscopic properties of lithium chloride were first commercially exploited in the 1930s for dehumidification applications, marking the beginning of its technical evolution. Over subsequent decades, this technology has undergone substantial refinement, transitioning from basic absorption systems to sophisticated desiccant-based solutions that offer precise humidity control across various environments.

The fundamental principle behind lithium chloride dehumidification lies in its exceptional ability to absorb moisture from air. With a deliquescence relative humidity of approximately 11% at standard conditions, lithium chloride can effectively reduce ambient humidity to significantly low levels, outperforming many conventional desiccants. This property has positioned LiCl as a premium solution for applications requiring stringent humidity control.

Recent technological advancements have focused on enhancing the efficiency and sustainability of lithium chloride dehumidification systems. The integration of renewable energy sources for regeneration processes, development of composite materials to improve absorption capacity, and implementation of advanced control algorithms represent key evolutionary trends in this field. These innovations aim to address the growing demand for energy-efficient humidity management solutions across industrial, commercial, and residential sectors.

The global emphasis on energy conservation and indoor air quality has further accelerated research into optimized lithium chloride systems. Current development trajectories indicate a shift toward hybrid systems that combine the strengths of lithium chloride with complementary technologies, creating more versatile and efficient humidity control solutions. Additionally, miniaturization efforts are expanding the application scope to include portable and embedded systems.

The primary technical objectives for lithium chloride dehumidification optimization encompass several dimensions. First, enhancing energy efficiency through improved regeneration methods and reduced operational energy requirements. Second, extending service life by mitigating issues related to crystallization and corrosion. Third, developing more environmentally sustainable formulations that maintain performance while reducing potential ecological impacts. Fourth, improving control precision to enable dynamic response to varying humidity conditions.

Furthermore, cost optimization represents a critical objective, as traditional lithium chloride systems often involve higher initial investments compared to conventional alternatives. Achieving cost parity through material innovations and manufacturing process improvements would significantly expand market penetration across diverse applications, from pharmaceutical manufacturing to data centers and precision manufacturing environments.

The fundamental principle behind lithium chloride dehumidification lies in its exceptional ability to absorb moisture from air. With a deliquescence relative humidity of approximately 11% at standard conditions, lithium chloride can effectively reduce ambient humidity to significantly low levels, outperforming many conventional desiccants. This property has positioned LiCl as a premium solution for applications requiring stringent humidity control.

Recent technological advancements have focused on enhancing the efficiency and sustainability of lithium chloride dehumidification systems. The integration of renewable energy sources for regeneration processes, development of composite materials to improve absorption capacity, and implementation of advanced control algorithms represent key evolutionary trends in this field. These innovations aim to address the growing demand for energy-efficient humidity management solutions across industrial, commercial, and residential sectors.

The global emphasis on energy conservation and indoor air quality has further accelerated research into optimized lithium chloride systems. Current development trajectories indicate a shift toward hybrid systems that combine the strengths of lithium chloride with complementary technologies, creating more versatile and efficient humidity control solutions. Additionally, miniaturization efforts are expanding the application scope to include portable and embedded systems.

The primary technical objectives for lithium chloride dehumidification optimization encompass several dimensions. First, enhancing energy efficiency through improved regeneration methods and reduced operational energy requirements. Second, extending service life by mitigating issues related to crystallization and corrosion. Third, developing more environmentally sustainable formulations that maintain performance while reducing potential ecological impacts. Fourth, improving control precision to enable dynamic response to varying humidity conditions.

Furthermore, cost optimization represents a critical objective, as traditional lithium chloride systems often involve higher initial investments compared to conventional alternatives. Achieving cost parity through material innovations and manufacturing process improvements would significantly expand market penetration across diverse applications, from pharmaceutical manufacturing to data centers and precision manufacturing environments.

Market Analysis for Advanced Humidity Control Solutions

The global market for advanced humidity control solutions has witnessed significant growth in recent years, driven by increasing awareness of indoor air quality and its impact on health, comfort, and industrial processes. The humidity control market was valued at approximately $3.2 billion in 2022 and is projected to reach $5.1 billion by 2028, growing at a CAGR of 6.8% during the forecast period.

Lithium chloride-based humidity control systems represent a specialized segment within this market, primarily valued for their exceptional hygroscopic properties and efficiency in maintaining precise humidity levels. This segment is experiencing accelerated growth due to increasing demand from pharmaceutical manufacturing, food processing, and advanced electronics production sectors where precise environmental control is critical.

The pharmaceutical industry constitutes the largest end-user segment for advanced humidity control solutions, accounting for 28% of the market share. This is primarily due to strict regulatory requirements for manufacturing environments and the need to maintain product stability. The electronics manufacturing sector follows closely at 23%, driven by the expansion of semiconductor fabrication facilities where even minor humidity variations can significantly impact yield rates.

Geographically, North America and Europe currently dominate the market with combined market share of 58%, attributed to stringent regulatory frameworks regarding indoor air quality and the presence of major pharmaceutical and electronics manufacturing hubs. However, the Asia-Pacific region is emerging as the fastest-growing market with 9.2% annual growth, fueled by rapid industrialization in China, India, and Southeast Asian countries.

The market for lithium chloride-based solutions specifically is projected to grow at 7.5% annually, outpacing the overall humidity control market. This growth is driven by increasing recognition of lithium chloride's superior performance in applications requiring precise humidity control between 15-60% relative humidity ranges, particularly in critical environments like cleanrooms and laboratories.

Customer demand patterns indicate a clear shift toward energy-efficient solutions that offer precise control capabilities while minimizing operational costs. End-users are increasingly willing to invest in premium solutions that demonstrate measurable energy savings and reduced maintenance requirements over traditional systems. Market surveys indicate that 72% of industrial customers prioritize energy efficiency and precision control over initial acquisition costs.

Competitive analysis reveals that the market remains moderately fragmented, with the top five players controlling approximately 42% of the global market share. Recent merger and acquisition activities suggest a trend toward market consolidation as larger HVAC companies seek to expand their technological capabilities in specialized humidity control solutions.

Lithium chloride-based humidity control systems represent a specialized segment within this market, primarily valued for their exceptional hygroscopic properties and efficiency in maintaining precise humidity levels. This segment is experiencing accelerated growth due to increasing demand from pharmaceutical manufacturing, food processing, and advanced electronics production sectors where precise environmental control is critical.

The pharmaceutical industry constitutes the largest end-user segment for advanced humidity control solutions, accounting for 28% of the market share. This is primarily due to strict regulatory requirements for manufacturing environments and the need to maintain product stability. The electronics manufacturing sector follows closely at 23%, driven by the expansion of semiconductor fabrication facilities where even minor humidity variations can significantly impact yield rates.

Geographically, North America and Europe currently dominate the market with combined market share of 58%, attributed to stringent regulatory frameworks regarding indoor air quality and the presence of major pharmaceutical and electronics manufacturing hubs. However, the Asia-Pacific region is emerging as the fastest-growing market with 9.2% annual growth, fueled by rapid industrialization in China, India, and Southeast Asian countries.

The market for lithium chloride-based solutions specifically is projected to grow at 7.5% annually, outpacing the overall humidity control market. This growth is driven by increasing recognition of lithium chloride's superior performance in applications requiring precise humidity control between 15-60% relative humidity ranges, particularly in critical environments like cleanrooms and laboratories.

Customer demand patterns indicate a clear shift toward energy-efficient solutions that offer precise control capabilities while minimizing operational costs. End-users are increasingly willing to invest in premium solutions that demonstrate measurable energy savings and reduced maintenance requirements over traditional systems. Market surveys indicate that 72% of industrial customers prioritize energy efficiency and precision control over initial acquisition costs.

Competitive analysis reveals that the market remains moderately fragmented, with the top five players controlling approximately 42% of the global market share. Recent merger and acquisition activities suggest a trend toward market consolidation as larger HVAC companies seek to expand their technological capabilities in specialized humidity control solutions.

Current State and Challenges in LiCl-based Humidity Control

Lithium chloride (LiCl) has emerged as a significant material in humidity control systems due to its exceptional hygroscopic properties. Currently, LiCl-based humidity control technologies are deployed across various sectors including HVAC systems, pharmaceutical storage, food preservation, and precision manufacturing environments. The global adoption of these systems has been steadily increasing, with particularly strong implementation in regions experiencing extreme humidity fluctuations.

The fundamental mechanism of LiCl-based humidity control relies on its ability to absorb moisture from the surrounding air when humidity levels rise above the equilibrium point, and release moisture when ambient humidity falls below this threshold. This natural property enables passive humidity regulation within a defined range, making it an energy-efficient solution compared to conventional mechanical dehumidification systems.

Despite its advantages, several significant challenges impede the optimization of LiCl-based humidity control systems. The primary technical limitation is the phenomenon of deliquescence, where LiCl absorbs excessive moisture and forms a liquid solution, compromising its structural integrity and functional efficiency. This phase transition occurs at approximately 11% relative humidity at standard temperature, restricting operational parameters.

Another critical challenge is the corrosive nature of LiCl solutions, which can damage metal components in humidity control systems, necessitating the use of corrosion-resistant materials that increase manufacturing costs. Additionally, the regeneration process of saturated LiCl requires substantial energy input, diminishing the overall energy efficiency benefits of these systems.

Performance consistency presents another obstacle, as LiCl's moisture absorption capacity diminishes over repeated cycles, requiring periodic replacement or regeneration. This degradation is accelerated in environments with airborne contaminants that can react with LiCl and alter its hygroscopic properties.

From a geographical perspective, LiCl-based humidity control technologies have seen varied adoption rates. North America and Europe lead in research and implementation, while Asia-Pacific regions, particularly China and Japan, are rapidly advancing in manufacturing and deploying these systems. The Middle East and tropical regions, where humidity control is particularly challenging, represent emerging markets with significant growth potential.

Recent technological advancements have focused on addressing these limitations through composite materials that incorporate LiCl into porous matrices to prevent deliquescence, development of encapsulation techniques to mitigate corrosion issues, and integration with renewable energy sources to power regeneration processes more sustainably.

The fundamental mechanism of LiCl-based humidity control relies on its ability to absorb moisture from the surrounding air when humidity levels rise above the equilibrium point, and release moisture when ambient humidity falls below this threshold. This natural property enables passive humidity regulation within a defined range, making it an energy-efficient solution compared to conventional mechanical dehumidification systems.

Despite its advantages, several significant challenges impede the optimization of LiCl-based humidity control systems. The primary technical limitation is the phenomenon of deliquescence, where LiCl absorbs excessive moisture and forms a liquid solution, compromising its structural integrity and functional efficiency. This phase transition occurs at approximately 11% relative humidity at standard temperature, restricting operational parameters.

Another critical challenge is the corrosive nature of LiCl solutions, which can damage metal components in humidity control systems, necessitating the use of corrosion-resistant materials that increase manufacturing costs. Additionally, the regeneration process of saturated LiCl requires substantial energy input, diminishing the overall energy efficiency benefits of these systems.

Performance consistency presents another obstacle, as LiCl's moisture absorption capacity diminishes over repeated cycles, requiring periodic replacement or regeneration. This degradation is accelerated in environments with airborne contaminants that can react with LiCl and alter its hygroscopic properties.

From a geographical perspective, LiCl-based humidity control technologies have seen varied adoption rates. North America and Europe lead in research and implementation, while Asia-Pacific regions, particularly China and Japan, are rapidly advancing in manufacturing and deploying these systems. The Middle East and tropical regions, where humidity control is particularly challenging, represent emerging markets with significant growth potential.

Recent technological advancements have focused on addressing these limitations through composite materials that incorporate LiCl into porous matrices to prevent deliquescence, development of encapsulation techniques to mitigate corrosion issues, and integration with renewable energy sources to power regeneration processes more sustainably.

Current LiCl Humidity Control Implementation Methods

01 Lithium chloride as a humidity control agent

Lithium chloride is widely used as an effective humidity control agent due to its hygroscopic properties. It can absorb moisture from the air and maintain specific humidity levels in enclosed environments. This property makes it valuable in various applications where humidity control is critical, such as in storage facilities, laboratories, and industrial processes. The compound can be used in different forms including solutions and solid matrices to achieve desired humidity regulation.- Lithium chloride as a humidity control agent in desiccant systems: Lithium chloride is widely used as an effective desiccant material in humidity control systems due to its strong hygroscopic properties. It can absorb moisture from the air, making it suitable for applications requiring low humidity environments. These systems often incorporate lithium chloride solutions or solid forms into dehumidification equipment for industrial, commercial, and residential settings. The hygroscopic nature of lithium chloride allows it to maintain specific relative humidity levels in controlled environments.

- Humidity control devices incorporating lithium chloride: Various devices and apparatus designs incorporate lithium chloride for humidity control purposes. These include specialized containers, chambers, and equipment that utilize lithium chloride solutions or solid forms to regulate moisture levels. The designs often feature mechanisms for air circulation, regeneration of the desiccant material, and monitoring of humidity levels. These devices find applications in storage facilities, manufacturing environments, laboratories, and other settings where precise humidity control is critical.

- Lithium chloride in combination with other materials for enhanced humidity control: Combining lithium chloride with other materials can enhance its humidity control capabilities or provide additional functionalities. These combinations may include other salts, polymers, or carrier materials that improve absorption capacity, regeneration efficiency, or physical stability. Such composite materials can offer advantages like reduced corrosivity, improved handling characteristics, or extended service life while maintaining effective humidity control properties. These formulations are particularly useful in specialized applications requiring specific performance characteristics.

- Lithium chloride humidity control in specific industrial applications: Lithium chloride humidity control systems are employed in various specialized industrial applications where precise moisture regulation is essential. These include mining operations, chemical processing, pharmaceutical manufacturing, and food preservation. In these contexts, lithium chloride-based systems help maintain product quality, prevent equipment corrosion, ensure process stability, and create safe working environments. The implementation may involve customized solutions designed to meet the specific requirements of each industrial setting.

- Advanced technologies and improvements in lithium chloride humidity control: Recent technological advancements have improved the efficiency and effectiveness of lithium chloride-based humidity control systems. These innovations include automated monitoring and control systems, energy-efficient regeneration methods, and novel material formulations. Smart sensors and digital controls allow for precise humidity regulation with minimal energy consumption. Additionally, research has focused on reducing environmental impact and improving the sustainability of lithium chloride desiccant systems through optimized designs and operational parameters.

02 Humidity control systems incorporating lithium chloride

Various systems have been developed that incorporate lithium chloride for humidity control purposes. These systems include dehumidifiers, air conditioning units, and specialized humidity control devices. The designs typically feature components that allow lithium chloride to interact with air, absorbing moisture when humidity is high and potentially releasing it when conditions are dry. These systems often include mechanisms for regeneration of the lithium chloride solution to maintain its effectiveness over extended periods of use.Expand Specific Solutions03 Lithium chloride in energy storage and conversion applications

Lithium chloride is utilized in various energy-related applications that involve humidity control. These include certain types of batteries, fuel cells, and energy storage systems where moisture levels must be carefully regulated. The compound helps maintain optimal operating conditions by controlling humidity levels, which can affect the efficiency and lifespan of these energy systems. Some applications involve lithium chloride as part of composite materials or electrolytes where its hygroscopic properties contribute to overall system performance.Expand Specific Solutions04 Manufacturing processes using lithium chloride for humidity control

Various industrial manufacturing processes utilize lithium chloride for humidity control. These include production of pharmaceuticals, electronics, textiles, and food products where specific humidity levels must be maintained. The compound can be incorporated into production lines through specialized equipment that regulates moisture content in the manufacturing environment. This helps ensure product quality, prevent moisture-related defects, and maintain consistent production conditions throughout manufacturing operations.Expand Specific Solutions05 Lithium chloride in environmental and agricultural applications

Lithium chloride finds applications in environmental monitoring and agricultural settings where humidity control is important. It can be used in systems designed for greenhouse humidity regulation, soil moisture management, and environmental testing equipment. The compound's ability to maintain specific humidity levels makes it valuable for creating controlled environments for plant growth, seed storage, and agricultural research. Some applications involve lithium chloride solutions or impregnated materials that help maintain optimal growing conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Humidity Control

The lithium chloride humidity control technology market is in a growth phase, characterized by increasing demand for efficient moisture management solutions across various industries. The market size is expanding due to applications in HVAC systems, pharmaceutical storage, and electronics manufacturing. Technologically, the field shows moderate maturity with established principles but ongoing innovation. Key players include LG Chem and Samsung SDI, who leverage their battery expertise for humidity control applications; Boveda, which has specialized in two-way humidity control solutions; and Daikin Industries, applying its climate control knowledge. Research institutions like RIST and University of Tokyo are advancing fundamental science, while companies like Fuji Electric and Sharp focus on integrating humidity control into smart systems, indicating a competitive landscape balanced between established corporations and specialized technology providers.

LG Chem Ltd.

Technical Solution: LG Chem has developed an advanced humidity control system utilizing lithium chloride as the primary desiccant material in their environmental management solutions. Their technology incorporates a proprietary lithium chloride impregnation process for high-performance absorption media that maximizes moisture capture efficiency while minimizing salt migration. The system employs a continuous liquid desiccant circulation design where lithium chloride solution is distributed over specialized heat and mass exchangers, allowing simultaneous dehumidification and cooling. LG Chem's innovation includes a regeneration system that operates at temperatures below 80°C, enabling integration with waste heat sources or solar thermal systems. Their control algorithm dynamically adjusts solution concentration and flow rates based on real-time humidity measurements and predictive modeling, achieving energy savings of up to 45% compared to conventional cooling-based dehumidification. Recent advancements include the development of anti-corrosive materials specifically designed to withstand the highly hygroscopic nature of lithium chloride, extending system lifespan and reducing maintenance requirements.

Strengths: Highly efficient moisture removal even at low humidity levels where conventional systems struggle. Significant energy savings through integration with low-grade heat sources. Weaknesses: Requires careful system design to prevent lithium chloride carryover into supply air. Higher initial capital cost compared to conventional dehumidification systems.

Boveda, Inc.

Technical Solution: Boveda has developed a patented two-way humidity control technology using lithium chloride as the primary humidity regulating agent. Their solution consists of a semi-permeable membrane containing a saturated solution of lithium chloride and other proprietary salts that create a specific water activity level corresponding to a precise relative humidity. The technology works on the principle of vapor pressure equilibrium, where the solution releases or absorbs moisture to maintain a predetermined humidity level in an enclosed space. Boveda's innovation lies in their precise formulation that enables the creation of products with specific relative humidity points (ranging from 32% to 84% RH) for different applications. Their manufacturing process ensures uniform distribution of lithium chloride within a specialized membrane that prevents leakage while allowing water vapor transmission. The company has recently enhanced their technology with improved membrane materials that extend the active life of their products by up to 40% compared to earlier versions, while maintaining humidity control accuracy within ±1% of the target RH level.

Strengths: Provides passive, maintenance-free humidity control without requiring power or monitoring. Extremely precise humidity regulation at specific setpoints. Weaknesses: Limited capacity means eventual replacement is necessary once moisture absorption capacity is reached. Not suitable for very large spaces without using multiple units.

Key Technical Innovations in Lithium Chloride Applications

Moisture-measuring apparatus compensated for water vapeur pressure

PatentInactiveEP0154999A3

Innovation

- A moisture measuring device with an external controller maintains the water vapor pressure equilibrium of the hygroscopic moisture-sensing layer, separating measuring and heating currents, and using a thin film technology with a small LiCl layer on a ceramic plate, allowing for faster and more accurate humidity readings.

Humidity control system

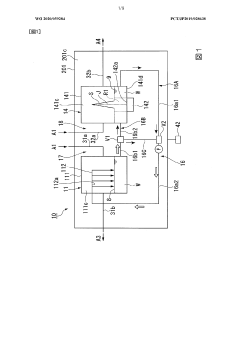

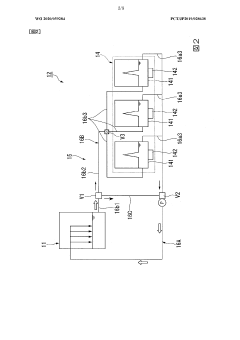

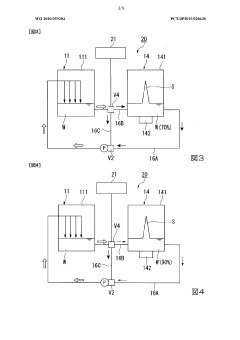

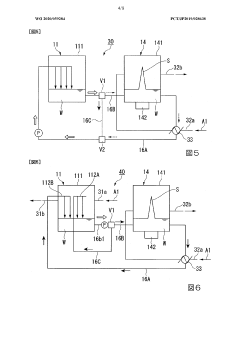

PatentWO2020059284A1

Innovation

- A humidity control system that circulates liquid hygroscopic material between a moisture absorption unit and an atomization regeneration unit, using ultrasonic waves to form a liquid column and generate atomized droplets without external heat, with a circulation mechanism that controls flow rates and temperatures to enhance atomization efficiency.

Energy Efficiency Considerations in LiCl Dehumidification

Energy efficiency represents a critical dimension in the evaluation and implementation of lithium chloride (LiCl) dehumidification systems. The hygroscopic properties of LiCl make it an excellent desiccant, but the energy requirements for regeneration and system operation significantly impact overall efficiency and operational costs. Understanding these energy considerations is essential for optimizing humidity control solutions.

Traditional LiCl dehumidification systems typically consume energy in three primary areas: solution pumping, air movement, and desiccant regeneration. The regeneration process, which removes absorbed moisture from the LiCl solution to restore its dehumidification capacity, represents the most energy-intensive component, often accounting for 60-70% of total system energy consumption. This process traditionally requires temperatures between 80-90°C, typically generated through electric heating or natural gas combustion.

Recent technological advancements have focused on reducing this energy burden through several innovative approaches. Heat recovery systems that capture and reuse thermal energy from the regeneration process have demonstrated energy savings of 25-35% in commercial applications. Additionally, the integration of low-grade heat sources, such as solar thermal collectors or industrial waste heat, has emerged as a promising strategy for reducing primary energy consumption, with pilot projects showing potential energy cost reductions of 40-50% compared to conventional systems.

The configuration of LiCl dehumidification systems also significantly impacts energy efficiency. Liquid-to-air systems, where the LiCl solution directly contacts the process air, generally demonstrate higher thermodynamic efficiency than solid desiccant wheels impregnated with LiCl. However, this advantage must be balanced against the energy required for solution pumping and distribution. Advanced spray nozzle designs and optimized solution distribution patterns have shown potential to reduce pumping energy requirements by 15-20%.

Control strategies represent another crucial aspect of energy optimization. Demand-controlled dehumidification, which modulates system operation based on real-time humidity requirements rather than fixed setpoints, has demonstrated energy savings of 20-30% in variable occupancy environments. Furthermore, predictive control algorithms that anticipate humidity loads based on weather forecasts and building usage patterns can further enhance system efficiency by optimizing regeneration cycles and solution concentration levels.

The economic implications of these energy efficiency measures are substantial. Life-cycle cost analyses indicate that while high-efficiency LiCl systems may carry 15-25% higher initial capital costs, the reduced energy consumption typically results in payback periods of 2-4 years in high-humidity environments. This economic advantage becomes even more pronounced in regions with high energy costs or where demand charges apply to peak electricity usage.

Traditional LiCl dehumidification systems typically consume energy in three primary areas: solution pumping, air movement, and desiccant regeneration. The regeneration process, which removes absorbed moisture from the LiCl solution to restore its dehumidification capacity, represents the most energy-intensive component, often accounting for 60-70% of total system energy consumption. This process traditionally requires temperatures between 80-90°C, typically generated through electric heating or natural gas combustion.

Recent technological advancements have focused on reducing this energy burden through several innovative approaches. Heat recovery systems that capture and reuse thermal energy from the regeneration process have demonstrated energy savings of 25-35% in commercial applications. Additionally, the integration of low-grade heat sources, such as solar thermal collectors or industrial waste heat, has emerged as a promising strategy for reducing primary energy consumption, with pilot projects showing potential energy cost reductions of 40-50% compared to conventional systems.

The configuration of LiCl dehumidification systems also significantly impacts energy efficiency. Liquid-to-air systems, where the LiCl solution directly contacts the process air, generally demonstrate higher thermodynamic efficiency than solid desiccant wheels impregnated with LiCl. However, this advantage must be balanced against the energy required for solution pumping and distribution. Advanced spray nozzle designs and optimized solution distribution patterns have shown potential to reduce pumping energy requirements by 15-20%.

Control strategies represent another crucial aspect of energy optimization. Demand-controlled dehumidification, which modulates system operation based on real-time humidity requirements rather than fixed setpoints, has demonstrated energy savings of 20-30% in variable occupancy environments. Furthermore, predictive control algorithms that anticipate humidity loads based on weather forecasts and building usage patterns can further enhance system efficiency by optimizing regeneration cycles and solution concentration levels.

The economic implications of these energy efficiency measures are substantial. Life-cycle cost analyses indicate that while high-efficiency LiCl systems may carry 15-25% higher initial capital costs, the reduced energy consumption typically results in payback periods of 2-4 years in high-humidity environments. This economic advantage becomes even more pronounced in regions with high energy costs or where demand charges apply to peak electricity usage.

Environmental Impact and Safety Regulations for LiCl Systems

The environmental impact of lithium chloride (LiCl) humidity control systems requires careful consideration as these systems become more widely adopted. LiCl solutions can potentially contaminate water sources if improperly disposed of, leading to increased salinity levels that may harm aquatic ecosystems. The high solubility of LiCl makes it particularly concerning as it can rapidly disperse in water bodies and is difficult to remove once dissolved. Additionally, the mining and processing of lithium compounds contribute to environmental degradation through land disturbance, water consumption, and energy use.

Regulatory frameworks governing LiCl systems vary globally but generally focus on three key areas: handling procedures, disposal requirements, and workplace safety standards. In the United States, the Environmental Protection Agency (EPA) regulates LiCl under the Toxic Substances Control Act, requiring proper labeling, storage, and disposal protocols. The European Union's REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) imposes stricter documentation requirements for chemical usage, including comprehensive safety data sheets for LiCl solutions.

Workplace safety regulations mandate specific handling procedures for LiCl, as concentrated solutions can cause skin irritation, respiratory issues, and eye damage. OSHA in the US and similar agencies worldwide require employers to provide appropriate personal protective equipment, adequate ventilation, and emergency response protocols when working with LiCl systems. Regular training for personnel handling these systems is also mandated in most jurisdictions.

Emerging regulations increasingly focus on the lifecycle management of LiCl systems, promoting circular economy principles. This includes requirements for manufacturers to develop take-back programs for spent LiCl solutions and desiccants, as well as incentives for developing more environmentally friendly alternatives. Some jurisdictions have implemented specific concentration limits for LiCl in wastewater discharges, typically ranging from 100-500 mg/L depending on the receiving environment's sensitivity.

Companies implementing LiCl humidity control systems must conduct regular environmental compliance audits to ensure adherence to evolving regulations. This includes monitoring potential leakage points, maintaining detailed records of LiCl usage and disposal, and developing emergency response plans for accidental releases. Forward-thinking organizations are also investing in closed-loop systems that minimize LiCl waste generation and maximize resource recovery, anticipating stricter future regulations.

Regulatory frameworks governing LiCl systems vary globally but generally focus on three key areas: handling procedures, disposal requirements, and workplace safety standards. In the United States, the Environmental Protection Agency (EPA) regulates LiCl under the Toxic Substances Control Act, requiring proper labeling, storage, and disposal protocols. The European Union's REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) imposes stricter documentation requirements for chemical usage, including comprehensive safety data sheets for LiCl solutions.

Workplace safety regulations mandate specific handling procedures for LiCl, as concentrated solutions can cause skin irritation, respiratory issues, and eye damage. OSHA in the US and similar agencies worldwide require employers to provide appropriate personal protective equipment, adequate ventilation, and emergency response protocols when working with LiCl systems. Regular training for personnel handling these systems is also mandated in most jurisdictions.

Emerging regulations increasingly focus on the lifecycle management of LiCl systems, promoting circular economy principles. This includes requirements for manufacturers to develop take-back programs for spent LiCl solutions and desiccants, as well as incentives for developing more environmentally friendly alternatives. Some jurisdictions have implemented specific concentration limits for LiCl in wastewater discharges, typically ranging from 100-500 mg/L depending on the receiving environment's sensitivity.

Companies implementing LiCl humidity control systems must conduct regular environmental compliance audits to ensure adherence to evolving regulations. This includes monitoring potential leakage points, maintaining detailed records of LiCl usage and disposal, and developing emergency response plans for accidental releases. Forward-thinking organizations are also investing in closed-loop systems that minimize LiCl waste generation and maximize resource recovery, anticipating stricter future regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!