How to Measure Lithium Chloride Solution Density

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiCl Density Measurement Background & Objectives

Lithium chloride (LiCl) solution density measurement has evolved significantly over the past decades, driven by the growing importance of lithium compounds in various industrial applications. The accurate determination of LiCl solution density is crucial for quality control in battery manufacturing, pharmaceutical processing, and air conditioning systems that utilize lithium bromide-based absorption refrigeration. Historically, density measurements relied on rudimentary methods such as hydrometers, but technological advancements have introduced more precise and automated techniques.

The evolution of LiCl density measurement technology reflects broader trends in analytical instrumentation, moving from manual to digital methods, from offline to inline monitoring, and from single-point measurements to continuous process control. This progression has been accelerated by the exponential growth of the lithium-ion battery market, which has created unprecedented demand for precise concentration control in lithium salt solutions during various manufacturing stages.

Our technical objective is to comprehensively evaluate current methodologies for measuring lithium chloride solution density across different concentration ranges and temperature conditions. This assessment aims to identify the most accurate, reliable, and cost-effective techniques suitable for industrial implementation, particularly in battery manufacturing environments where precision directly impacts product quality and performance.

The specific goals include establishing measurement accuracy benchmarks of ±0.001 g/cm³ or better, identifying methods capable of real-time monitoring in production environments, evaluating temperature compensation mechanisms for measurements between 10-80°C, and determining approaches suitable for integration with existing industrial control systems. Additionally, we seek to understand how measurement techniques perform across the full concentration spectrum of LiCl solutions (0-45% by weight).

Recent technological developments in density measurement, including vibrating tube densitometers, ultrasonic analyzers, and optical refractometry, offer promising alternatives to traditional methods. These technologies provide enhanced precision and the potential for continuous monitoring, which are increasingly important as manufacturing processes become more automated and quality standards more stringent.

The findings from this technical research will guide investment decisions in measurement infrastructure, inform quality control protocol development, and potentially identify opportunities for novel measurement approaches that could provide competitive advantages in production efficiency and product consistency. Understanding the strengths and limitations of various density measurement techniques is fundamental to optimizing lithium compound processing across multiple industries.

The evolution of LiCl density measurement technology reflects broader trends in analytical instrumentation, moving from manual to digital methods, from offline to inline monitoring, and from single-point measurements to continuous process control. This progression has been accelerated by the exponential growth of the lithium-ion battery market, which has created unprecedented demand for precise concentration control in lithium salt solutions during various manufacturing stages.

Our technical objective is to comprehensively evaluate current methodologies for measuring lithium chloride solution density across different concentration ranges and temperature conditions. This assessment aims to identify the most accurate, reliable, and cost-effective techniques suitable for industrial implementation, particularly in battery manufacturing environments where precision directly impacts product quality and performance.

The specific goals include establishing measurement accuracy benchmarks of ±0.001 g/cm³ or better, identifying methods capable of real-time monitoring in production environments, evaluating temperature compensation mechanisms for measurements between 10-80°C, and determining approaches suitable for integration with existing industrial control systems. Additionally, we seek to understand how measurement techniques perform across the full concentration spectrum of LiCl solutions (0-45% by weight).

Recent technological developments in density measurement, including vibrating tube densitometers, ultrasonic analyzers, and optical refractometry, offer promising alternatives to traditional methods. These technologies provide enhanced precision and the potential for continuous monitoring, which are increasingly important as manufacturing processes become more automated and quality standards more stringent.

The findings from this technical research will guide investment decisions in measurement infrastructure, inform quality control protocol development, and potentially identify opportunities for novel measurement approaches that could provide competitive advantages in production efficiency and product consistency. Understanding the strengths and limitations of various density measurement techniques is fundamental to optimizing lithium compound processing across multiple industries.

Market Applications & Demand Analysis

The lithium chloride solution density measurement market is experiencing significant growth driven by the expanding lithium battery industry. As electric vehicles and renewable energy storage solutions gain prominence globally, the demand for precise lithium compound measurements has increased dramatically. The global lithium-ion battery market, valued at approximately $44.2 billion in 2021, is projected to reach $193.13 billion by 2028, representing a compound annual growth rate of 23.3%. This exponential growth directly impacts the demand for accurate lithium chloride solution density measurement technologies.

Battery manufacturing represents the primary application sector, where precise density measurements are critical for quality control and performance optimization. Manufacturers require highly accurate density measurements to ensure consistent battery production, as even minor variations can significantly impact battery efficiency and lifespan. This segment alone accounts for nearly 65% of the total market demand for lithium chloride density measurement solutions.

The energy storage sector presents another substantial market opportunity. Grid-scale energy storage systems utilizing lithium-based technologies require precise solution density measurements during production and maintenance phases. This sector is growing at approximately 32% annually, creating increased demand for advanced measurement technologies.

Research and development facilities constitute a smaller but technically demanding market segment. These institutions require ultra-precise density measurement capabilities for developing next-generation lithium technologies. Though representing only about 8% of the current market volume, this segment drives innovation in measurement methodologies.

Geographically, Asia-Pacific dominates the market with approximately 70% share, led by China, Japan, and South Korea. North America follows with roughly 18% market share, while Europe accounts for about 10%. The remaining regions collectively represent less than 2% of the global market.

Market analysis indicates a shift toward automated, continuous monitoring systems rather than manual or batch testing approaches. End-users increasingly demand integrated solutions that provide real-time density measurements with digital data logging capabilities. This trend is particularly evident in high-volume manufacturing environments where production efficiency is paramount.

Price sensitivity varies significantly across market segments. While high-volume manufacturers prioritize cost-effectiveness and reliability, research institutions willingly invest in premium solutions offering superior accuracy. This market stratification has led to the development of tiered product offerings from measurement technology providers, catering to different precision requirements and budget constraints.

Battery manufacturing represents the primary application sector, where precise density measurements are critical for quality control and performance optimization. Manufacturers require highly accurate density measurements to ensure consistent battery production, as even minor variations can significantly impact battery efficiency and lifespan. This segment alone accounts for nearly 65% of the total market demand for lithium chloride density measurement solutions.

The energy storage sector presents another substantial market opportunity. Grid-scale energy storage systems utilizing lithium-based technologies require precise solution density measurements during production and maintenance phases. This sector is growing at approximately 32% annually, creating increased demand for advanced measurement technologies.

Research and development facilities constitute a smaller but technically demanding market segment. These institutions require ultra-precise density measurement capabilities for developing next-generation lithium technologies. Though representing only about 8% of the current market volume, this segment drives innovation in measurement methodologies.

Geographically, Asia-Pacific dominates the market with approximately 70% share, led by China, Japan, and South Korea. North America follows with roughly 18% market share, while Europe accounts for about 10%. The remaining regions collectively represent less than 2% of the global market.

Market analysis indicates a shift toward automated, continuous monitoring systems rather than manual or batch testing approaches. End-users increasingly demand integrated solutions that provide real-time density measurements with digital data logging capabilities. This trend is particularly evident in high-volume manufacturing environments where production efficiency is paramount.

Price sensitivity varies significantly across market segments. While high-volume manufacturers prioritize cost-effectiveness and reliability, research institutions willingly invest in premium solutions offering superior accuracy. This market stratification has led to the development of tiered product offerings from measurement technology providers, catering to different precision requirements and budget constraints.

Current Measurement Technologies & Limitations

The measurement of lithium chloride solution density presents unique challenges due to the solution's corrosive nature and the precision required for industrial applications. Currently, several technologies are employed for this purpose, each with distinct advantages and limitations.

Hydrometers remain one of the most traditional methods for measuring lithium chloride solution density. These devices operate on Archimedes' principle, providing direct density readings. While hydrometers offer simplicity and low cost, they suffer from several drawbacks including limited accuracy (typically ±0.001 g/cm³), temperature sensitivity requiring manual corrections, and potential contamination issues when repeatedly inserted into different solutions.

Digital density meters, particularly vibrating tube densitometers, represent a significant advancement in measurement technology. These instruments determine density by analyzing the resonant frequency of a sample-filled tube. They offer exceptional accuracy (±0.0001 g/cm³) and require minimal sample volumes. However, their high cost (ranging from $5,000 to $20,000), vulnerability to air bubbles, and potential for corrosion damage when measuring concentrated lithium chloride solutions limit widespread adoption.

Coriolis flow meters have emerged as an inline measurement solution, calculating density based on fluid oscillation characteristics. These devices enable real-time, continuous monitoring without sample extraction, making them valuable for process control applications. Nevertheless, they require significant initial investment, complex calibration procedures, and may experience drift when exposed to temperature fluctuations or vibrations.

Ultrasonic density analyzers represent a newer technology utilizing sound wave propagation through solutions to determine density. Their non-invasive nature and ability to operate without direct contact with corrosive lithium chloride solutions offer distinct advantages. However, these systems require precise calibration for specific concentration ranges and can be affected by suspended particles or gas bubbles.

Refractometers, which measure refractive index to infer density, provide another alternative approach. While offering rapid measurements and requiring minimal sample volumes, they necessitate careful correlation between refractive index and density through extensive calibration. Their accuracy diminishes at higher concentrations, limiting applicability for concentrated lithium chloride solutions.

A significant limitation across all current technologies is temperature dependence. Lithium chloride solutions exhibit substantial density variations with temperature changes, necessitating precise temperature control or compensation algorithms. Additionally, most measurement technologies require regular recalibration due to sensor drift, particularly when exposed to corrosive environments, adding operational complexity and maintenance requirements.

Hydrometers remain one of the most traditional methods for measuring lithium chloride solution density. These devices operate on Archimedes' principle, providing direct density readings. While hydrometers offer simplicity and low cost, they suffer from several drawbacks including limited accuracy (typically ±0.001 g/cm³), temperature sensitivity requiring manual corrections, and potential contamination issues when repeatedly inserted into different solutions.

Digital density meters, particularly vibrating tube densitometers, represent a significant advancement in measurement technology. These instruments determine density by analyzing the resonant frequency of a sample-filled tube. They offer exceptional accuracy (±0.0001 g/cm³) and require minimal sample volumes. However, their high cost (ranging from $5,000 to $20,000), vulnerability to air bubbles, and potential for corrosion damage when measuring concentrated lithium chloride solutions limit widespread adoption.

Coriolis flow meters have emerged as an inline measurement solution, calculating density based on fluid oscillation characteristics. These devices enable real-time, continuous monitoring without sample extraction, making them valuable for process control applications. Nevertheless, they require significant initial investment, complex calibration procedures, and may experience drift when exposed to temperature fluctuations or vibrations.

Ultrasonic density analyzers represent a newer technology utilizing sound wave propagation through solutions to determine density. Their non-invasive nature and ability to operate without direct contact with corrosive lithium chloride solutions offer distinct advantages. However, these systems require precise calibration for specific concentration ranges and can be affected by suspended particles or gas bubbles.

Refractometers, which measure refractive index to infer density, provide another alternative approach. While offering rapid measurements and requiring minimal sample volumes, they necessitate careful correlation between refractive index and density through extensive calibration. Their accuracy diminishes at higher concentrations, limiting applicability for concentrated lithium chloride solutions.

A significant limitation across all current technologies is temperature dependence. Lithium chloride solutions exhibit substantial density variations with temperature changes, necessitating precise temperature control or compensation algorithms. Additionally, most measurement technologies require regular recalibration due to sensor drift, particularly when exposed to corrosive environments, adding operational complexity and maintenance requirements.

Established LiCl Density Measurement Methods

01 Lithium chloride solution density measurement methods

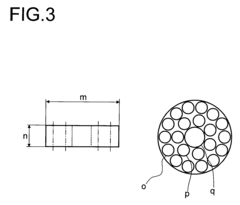

Various methods are employed to measure the density of lithium chloride solutions, which is critical for quality control and process optimization. These methods include the use of densitometers, hydrometric techniques, and advanced analytical instruments that can provide precise measurements of solution density at different concentrations and temperatures. Accurate density measurements are essential for applications requiring specific solution properties.- Density measurement methods for lithium chloride solutions: Various methods are employed to measure the density of lithium chloride solutions, including hydrometer measurements, pycnometer techniques, and digital density meters. These methods provide accurate density values at different concentrations and temperatures, which is crucial for industrial applications and quality control processes. The density of lithium chloride solutions increases with concentration and decreases with temperature, following specific mathematical relationships.

- Concentration-density relationships in lithium chloride solutions: The density of lithium chloride solutions exhibits a direct relationship with concentration. As the concentration of lithium chloride increases, the solution density increases in a predictable manner. This relationship is often expressed through mathematical equations or tables that correlate specific gravity or density values with concentration percentages. These correlations are essential for process control in industrial applications where precise concentration control is required.

- Temperature effects on lithium chloride solution density: Temperature significantly affects the density of lithium chloride solutions. As temperature increases, the density of the solution decreases following specific patterns. This temperature-density relationship is important in applications where lithium chloride solutions are used across varying temperature conditions. Correction factors and temperature compensation methods are often employed to standardize density measurements to reference temperatures for consistency in industrial processes.

- Industrial applications utilizing lithium chloride solution density properties: The density properties of lithium chloride solutions are leveraged in various industrial applications including dehumidification systems, heat pumps, air conditioning units, and battery technologies. In these applications, the specific density characteristics of lithium chloride solutions at different concentrations enable efficient heat transfer, moisture absorption, or electrochemical performance. Understanding and controlling solution density is critical for optimizing system performance and energy efficiency.

- Preparation and standardization of lithium chloride solutions with specific densities: Preparing lithium chloride solutions with precise densities involves careful measurement and mixing procedures. Standardization techniques ensure that solutions meet specific density requirements for research, analytical, or industrial applications. This includes methods for adjusting concentration to achieve target densities, purification processes to remove impurities that might affect density measurements, and quality control procedures to verify the accuracy of prepared solutions. Proper storage conditions are also important to maintain solution density over time.

02 Relationship between lithium chloride concentration and solution density

The density of lithium chloride solutions exhibits a direct relationship with concentration. As the concentration of lithium chloride increases, the solution density increases in a predictable manner. This relationship is often represented through density tables or mathematical equations that allow for the determination of concentration based on measured density values. Understanding this relationship is crucial for preparing solutions with specific properties for industrial applications.Expand Specific Solutions03 Temperature effects on lithium chloride solution density

Temperature significantly affects the density of lithium chloride solutions, with density generally decreasing as temperature increases. This temperature dependence must be accounted for in applications requiring precise concentration control. Correction factors and temperature-compensated density measurements are often employed to ensure accurate determination of solution properties across varying thermal conditions.Expand Specific Solutions04 Applications utilizing lithium chloride solution density properties

The specific density properties of lithium chloride solutions make them valuable in various applications including absorption refrigeration systems, dehumidification processes, and battery technologies. The high density and hygroscopic nature of these solutions enable efficient moisture absorption and heat transfer. In industrial settings, the density characteristics are leveraged for separation processes, extraction techniques, and as density reference standards.Expand Specific Solutions05 Equipment and systems for controlling lithium chloride solution density

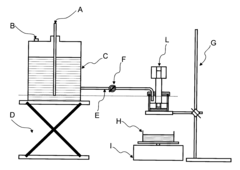

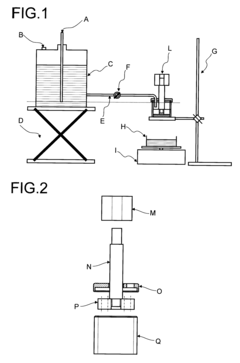

Specialized equipment and control systems have been developed to monitor and maintain specific densities of lithium chloride solutions in industrial processes. These systems incorporate density sensors, automated dosing mechanisms, and feedback control loops to ensure consistent solution properties. Real-time monitoring capabilities allow for immediate adjustments to maintain optimal density levels, which is particularly important in continuous processing operations where solution properties directly impact product quality or process efficiency.Expand Specific Solutions

Key Industry Players & Equipment Manufacturers

The lithium chloride solution density measurement market is in a growth phase, driven by increasing demand in lithium battery production and chemical processing industries. The global market size is expanding rapidly due to the lithium-ion battery boom, particularly with BYD and Hefei Guoxuan High-Tech Power Energy leading battery manufacturing innovations. Technologically, the field shows moderate maturity with established players like BASF, Solvay, and ExxonMobil Chemical Patents offering conventional density measurement solutions, while companies such as PHC Holdings and Central South University are advancing precision measurement technologies. Emerging players like Mingzheng Pengda are introducing environmental-friendly measurement approaches, indicating ongoing innovation in this space as the lithium market continues to evolve with stricter quality control requirements.

BYD Co., Ltd.

Technical Solution: BYD has developed an integrated density measurement system for lithium chloride solutions specifically tailored for battery material production. Their approach combines digital density meters with automated sampling systems that maintain sample integrity throughout the measurement process. BYD's technology employs temperature-controlled measurement cells (±0.02°C) with automatic bubble detection to eliminate measurement errors common in viscous lithium solutions. For production environments, they've implemented in-line refractometric density monitoring calibrated specifically for lithium chloride concentration ranges used in battery electrolyte preparation, achieving measurement speeds of under 30 seconds with accuracy of ±0.001 g/cm³. Their system incorporates machine learning algorithms that correlate multiple physical parameters (refractive index, conductivity, and density) to determine precise LiCl concentrations even in complex solution matrices containing multiple electrolyte components. BYD has also developed portable density measurement devices for quality control in remote facilities, utilizing tuning fork resonators with temperature compensation.

Strengths: Seamless integration with battery production processes; rapid measurement capabilities suitable for high-throughput environments; multi-parameter correlation improves accuracy in complex solutions. Weaknesses: Some methods optimized specifically for battery applications may have limited applicability in other industries; requires regular recalibration when solution compositions change; portable solutions sacrifice some precision for convenience.

Hefei Guoxuan High-Tech Power Energy Co., Ltd.

Technical Solution: Hefei Guoxuan has pioneered a comprehensive density measurement protocol for lithium chloride solutions used in their advanced battery manufacturing processes. Their approach centers on high-precision electronic density meters with oscillating tube technology, achieving measurement uncertainty of ±0.0002 g/cm³ across concentration ranges from 0.5-10 mol/L. For production environments, they've implemented ultrasonic density analyzers that provide non-invasive, real-time monitoring of LiCl solution density in process pipes without interrupting production flow. Their methodology includes specialized sample preparation techniques that prevent lithium salt crystallization during measurement, a common source of error in concentrated solutions. Guoxuan has developed proprietary calibration standards specifically for lithium-containing solutions that account for the unique viscosity and surface tension properties of these electrolytes. Their system incorporates automated temperature correction algorithms based on extensive empirical data collected across their manufacturing facilities, ensuring consistent measurements despite ambient temperature fluctuations.

Strengths: Highly optimized for battery manufacturing environments; non-invasive monitoring capabilities minimize process disruption; specialized calibration for lithium-specific applications improves accuracy. Weaknesses: Some techniques require significant initial investment; specialized calibration standards may not be readily available; highest precision methods require controlled laboratory conditions.

Critical Technologies & Scientific Principles

Glass structure, method, and electrical conductivity effect

PatentPendingIN202211024054A

Innovation

- A glass structure and method are developed using the system xLi2O-(30-x)MO-20Bi2O3-50B2O3 [M = Zn (series I), Cd (series II)] with varying mol% of Li2O, where colloidal silver paint is used as an electrode material, and the glass is prepared using the normal melt-quench technique, allowing for conductivity measurements and analysis of structural properties.

Water Swellable Material

PatentInactiveUS20080161499A1

Innovation

- A core-shell structured water-swellable material with an elastomeric polymer shell that creates internal pressure higher than external pressure, maintaining stability and absorbency while allowing for high absorbent capacity and permeability.

Calibration & Quality Control Protocols

Establishing robust calibration and quality control protocols is essential for accurate and reliable measurement of lithium chloride solution density. These protocols should begin with the selection of appropriate reference standards that closely match the expected density range of lithium chloride solutions. Primary standards such as NIST-traceable density reference materials should be utilized to calibrate measuring instruments, with secondary standards derived from these primary references for routine calibration checks.

A comprehensive calibration schedule must be implemented based on the criticality of measurements and instrument specifications. For high-precision density meters, daily verification using certified reference solutions is recommended, while full recalibration should be performed weekly or monthly depending on usage intensity. Temperature control during calibration is particularly crucial, as lithium chloride solution density varies significantly with temperature changes. Calibration should be conducted at precisely controlled temperatures, typically at 20°C, 25°C, and other temperatures relevant to the application environment.

Quality control measures should include the implementation of statistical process control (SPC) charts to monitor measurement drift and variability over time. Control limits should be established at ±0.0005 g/cm³ or tighter for critical applications. Regular blind sample testing, where operators measure samples of known density without prior knowledge of the expected values, helps identify systematic errors or operator bias in the measurement process.

Documentation requirements form another critical component of these protocols. All calibration activities must be thoroughly documented, including calibration dates, reference standards used, environmental conditions, and technician identification. Electronic laboratory information management systems (LIMS) can streamline this documentation process while ensuring data integrity and traceability.

Proficiency testing through participation in interlaboratory comparison programs provides external validation of measurement capabilities. These programs allow laboratories to compare their lithium chloride solution density measurements against those from other facilities, helping identify systematic biases or methodological issues that might otherwise go undetected through internal quality control procedures alone.

Uncertainty analysis should be performed to quantify all potential error sources in the density measurement process. This includes contributions from calibration uncertainty, temperature effects, instrument resolution, sample handling, and operator variability. The expanded measurement uncertainty should be calculated and reported alongside all density measurements, typically using a coverage factor of k=2 to provide approximately 95% confidence level.

AI-powered anomaly detection systems can be integrated into quality control workflows to identify unusual patterns in calibration data or measurement results that might indicate instrument malfunction or procedural errors before they impact production processes or research outcomes.

A comprehensive calibration schedule must be implemented based on the criticality of measurements and instrument specifications. For high-precision density meters, daily verification using certified reference solutions is recommended, while full recalibration should be performed weekly or monthly depending on usage intensity. Temperature control during calibration is particularly crucial, as lithium chloride solution density varies significantly with temperature changes. Calibration should be conducted at precisely controlled temperatures, typically at 20°C, 25°C, and other temperatures relevant to the application environment.

Quality control measures should include the implementation of statistical process control (SPC) charts to monitor measurement drift and variability over time. Control limits should be established at ±0.0005 g/cm³ or tighter for critical applications. Regular blind sample testing, where operators measure samples of known density without prior knowledge of the expected values, helps identify systematic errors or operator bias in the measurement process.

Documentation requirements form another critical component of these protocols. All calibration activities must be thoroughly documented, including calibration dates, reference standards used, environmental conditions, and technician identification. Electronic laboratory information management systems (LIMS) can streamline this documentation process while ensuring data integrity and traceability.

Proficiency testing through participation in interlaboratory comparison programs provides external validation of measurement capabilities. These programs allow laboratories to compare their lithium chloride solution density measurements against those from other facilities, helping identify systematic biases or methodological issues that might otherwise go undetected through internal quality control procedures alone.

Uncertainty analysis should be performed to quantify all potential error sources in the density measurement process. This includes contributions from calibration uncertainty, temperature effects, instrument resolution, sample handling, and operator variability. The expanded measurement uncertainty should be calculated and reported alongside all density measurements, typically using a coverage factor of k=2 to provide approximately 95% confidence level.

AI-powered anomaly detection systems can be integrated into quality control workflows to identify unusual patterns in calibration data or measurement results that might indicate instrument malfunction or procedural errors before they impact production processes or research outcomes.

Environmental & Safety Considerations

The handling of lithium chloride solutions requires careful consideration of environmental and safety aspects due to its chemical properties. Lithium chloride is highly soluble in water and can persist in the environment, potentially affecting aquatic ecosystems if discharged without proper treatment. When measuring lithium chloride solution density, researchers and operators must implement appropriate containment measures to prevent spills and leaks that could contaminate soil and water sources.

Personal protective equipment (PPE) is essential when working with lithium chloride solutions. This includes chemical-resistant gloves, safety goggles, lab coats, and in some cases, respiratory protection depending on the concentration and volume being handled. The hygroscopic nature of lithium chloride can cause skin irritation and dryness upon contact, while eye exposure may result in serious irritation or damage.

Proper ventilation systems must be in place when measuring lithium chloride solution density, especially when working with higher concentrations. This helps minimize inhalation risks associated with potential aerosol formation during measurement procedures. Temperature control is also critical, as exothermic reactions can occur when lithium chloride dissolves in water, potentially creating hazardous conditions if not properly managed.

Waste management protocols for lithium chloride solutions should align with local regulations and environmental protection standards. Neutralization or dilution may be required before disposal, and in many jurisdictions, lithium compounds are subject to special waste handling procedures due to their increasing value in battery technologies and potential environmental impact.

Emergency response procedures should be established for accidental exposures or spills. This includes readily available eyewash stations, safety showers, and spill containment kits. Staff should be trained in proper response techniques specific to lithium chloride, including appropriate neutralizing agents and containment strategies.

Long-term environmental considerations include monitoring potential accumulation of lithium in soil and groundwater near facilities that regularly work with these solutions. While lithium is naturally occurring, anthropogenic increases in concentration can disrupt ecological balances. Sustainable practices in density measurement should therefore emphasize minimal waste generation, recycling where possible, and closed-loop systems that prevent environmental release.

Risk assessment protocols should be implemented before establishing any new lithium chloride density measurement procedures, taking into account both acute and chronic exposure scenarios as well as potential environmental impacts throughout the solution's lifecycle.

Personal protective equipment (PPE) is essential when working with lithium chloride solutions. This includes chemical-resistant gloves, safety goggles, lab coats, and in some cases, respiratory protection depending on the concentration and volume being handled. The hygroscopic nature of lithium chloride can cause skin irritation and dryness upon contact, while eye exposure may result in serious irritation or damage.

Proper ventilation systems must be in place when measuring lithium chloride solution density, especially when working with higher concentrations. This helps minimize inhalation risks associated with potential aerosol formation during measurement procedures. Temperature control is also critical, as exothermic reactions can occur when lithium chloride dissolves in water, potentially creating hazardous conditions if not properly managed.

Waste management protocols for lithium chloride solutions should align with local regulations and environmental protection standards. Neutralization or dilution may be required before disposal, and in many jurisdictions, lithium compounds are subject to special waste handling procedures due to their increasing value in battery technologies and potential environmental impact.

Emergency response procedures should be established for accidental exposures or spills. This includes readily available eyewash stations, safety showers, and spill containment kits. Staff should be trained in proper response techniques specific to lithium chloride, including appropriate neutralizing agents and containment strategies.

Long-term environmental considerations include monitoring potential accumulation of lithium in soil and groundwater near facilities that regularly work with these solutions. While lithium is naturally occurring, anthropogenic increases in concentration can disrupt ecological balances. Sustainable practices in density measurement should therefore emphasize minimal waste generation, recycling where possible, and closed-loop systems that prevent environmental release.

Risk assessment protocols should be implemented before establishing any new lithium chloride density measurement procedures, taking into account both acute and chronic exposure scenarios as well as potential environmental impacts throughout the solution's lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!