Optimize Moisture Absorption Using Lithium Chloride

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Chloride Hygroscopic Technology Background and Objectives

Lithium chloride (LiCl) has emerged as a significant material in hygroscopic applications due to its exceptional moisture absorption capabilities. The history of LiCl usage dates back to the early 20th century when its hygroscopic properties were first systematically studied. Since then, this salt has evolved from a laboratory curiosity to a critical component in various industrial applications, particularly in dehumidification systems, desiccants, and climate control technologies.

The evolution of LiCl technology has been marked by several key advancements. Initially utilized in basic drying applications, the material has progressively been incorporated into more sophisticated systems. The 1950s saw the development of the first commercial LiCl-based dehumidification units, while the 1980s brought innovations in material formulations that enhanced stability and absorption capacity. Recent decades have witnessed integration with smart control systems and the development of composite materials that optimize performance characteristics.

Current technological trends indicate a growing interest in enhancing LiCl's moisture absorption efficiency through various optimization strategies. These include the development of nanoporous structures to increase surface area, the creation of composite materials that combine LiCl with polymers or other salts, and the implementation of advanced regeneration techniques that reduce energy consumption during the desorption phase.

The primary objective of optimizing moisture absorption using lithium chloride is to develop more efficient, cost-effective, and environmentally sustainable dehumidification solutions. Specific goals include increasing the moisture absorption capacity per unit mass of LiCl, improving the kinetics of absorption to enhance response times, extending the operational lifespan of LiCl-based systems, and reducing the energy requirements for regeneration cycles.

Additionally, researchers aim to address current limitations such as the corrosive nature of LiCl solutions, the potential for deliquescence under high humidity conditions, and the challenges associated with maintaining consistent performance across varying environmental conditions. The development of encapsulation techniques and protective coatings represents promising approaches to mitigating these issues.

The broader technological context includes increasing demands for energy-efficient climate control systems, growing concerns about indoor air quality, and the need for reliable dehumidification in sensitive environments such as data centers, pharmaceutical manufacturing facilities, and food storage applications. These factors collectively drive the continued research and development efforts focused on optimizing LiCl's hygroscopic properties.

Future technological trajectories suggest potential integration with renewable energy systems, development of smart responsive materials that adapt to changing environmental conditions, and the creation of hybrid systems that combine LiCl technology with other moisture management approaches to achieve superior performance across diverse operating conditions.

The evolution of LiCl technology has been marked by several key advancements. Initially utilized in basic drying applications, the material has progressively been incorporated into more sophisticated systems. The 1950s saw the development of the first commercial LiCl-based dehumidification units, while the 1980s brought innovations in material formulations that enhanced stability and absorption capacity. Recent decades have witnessed integration with smart control systems and the development of composite materials that optimize performance characteristics.

Current technological trends indicate a growing interest in enhancing LiCl's moisture absorption efficiency through various optimization strategies. These include the development of nanoporous structures to increase surface area, the creation of composite materials that combine LiCl with polymers or other salts, and the implementation of advanced regeneration techniques that reduce energy consumption during the desorption phase.

The primary objective of optimizing moisture absorption using lithium chloride is to develop more efficient, cost-effective, and environmentally sustainable dehumidification solutions. Specific goals include increasing the moisture absorption capacity per unit mass of LiCl, improving the kinetics of absorption to enhance response times, extending the operational lifespan of LiCl-based systems, and reducing the energy requirements for regeneration cycles.

Additionally, researchers aim to address current limitations such as the corrosive nature of LiCl solutions, the potential for deliquescence under high humidity conditions, and the challenges associated with maintaining consistent performance across varying environmental conditions. The development of encapsulation techniques and protective coatings represents promising approaches to mitigating these issues.

The broader technological context includes increasing demands for energy-efficient climate control systems, growing concerns about indoor air quality, and the need for reliable dehumidification in sensitive environments such as data centers, pharmaceutical manufacturing facilities, and food storage applications. These factors collectively drive the continued research and development efforts focused on optimizing LiCl's hygroscopic properties.

Future technological trajectories suggest potential integration with renewable energy systems, development of smart responsive materials that adapt to changing environmental conditions, and the creation of hybrid systems that combine LiCl technology with other moisture management approaches to achieve superior performance across diverse operating conditions.

Market Analysis for Moisture Absorption Solutions

The global moisture absorption solutions market is experiencing significant growth, driven by increasing awareness of humidity control across various industries. The market size was valued at approximately 2.8 billion USD in 2022 and is projected to reach 4.1 billion USD by 2028, representing a compound annual growth rate of 6.7%. This growth trajectory is supported by expanding applications in pharmaceuticals, electronics, food preservation, and building materials sectors.

Lithium chloride-based moisture absorption solutions occupy a specialized segment within this market, currently accounting for about 15% of the total market share. This segment has shown stronger growth than the overall market at 8.3% annually, indicating increasing preference for lithium chloride's superior hygroscopic properties.

Demand analysis reveals distinct regional patterns, with Asia-Pacific representing the largest market share at 38%, followed by North America (27%) and Europe (24%). The Asia-Pacific region also demonstrates the highest growth rate, primarily driven by rapid industrialization in China and India, alongside expanding electronics manufacturing facilities requiring precise humidity control.

Industry-specific demand shows pharmaceuticals leading adoption at 31% market share, where lithium chloride solutions are critical for maintaining product stability and extending shelf life. The electronics sector follows at 26%, utilizing these solutions to prevent moisture damage in sensitive components. Building materials and food preservation sectors represent 18% and 14% respectively, with emerging applications in renewable energy storage systems accounting for 7%.

Consumer trends indicate growing preference for environmentally sustainable moisture absorption solutions, creating both challenges and opportunities for lithium chloride applications. While its effectiveness is superior to many alternatives, concerns regarding environmental impact and disposal have prompted research into optimized formulations with reduced ecological footprints.

Price sensitivity varies significantly across application sectors. High-value industries like pharmaceuticals and electronics demonstrate lower price sensitivity due to the critical nature of moisture control in their operations. Conversely, building materials and consumer goods segments show greater price sensitivity, necessitating cost-effective formulation strategies for lithium chloride solutions.

Market forecasts suggest lithium chloride-based moisture absorption solutions will continue outpacing overall market growth, potentially reaching 22% market share by 2030. This projection is supported by technological advancements enhancing efficiency while addressing environmental concerns, alongside expanding applications in emerging sectors like electric vehicle battery manufacturing and renewable energy storage systems.

Lithium chloride-based moisture absorption solutions occupy a specialized segment within this market, currently accounting for about 15% of the total market share. This segment has shown stronger growth than the overall market at 8.3% annually, indicating increasing preference for lithium chloride's superior hygroscopic properties.

Demand analysis reveals distinct regional patterns, with Asia-Pacific representing the largest market share at 38%, followed by North America (27%) and Europe (24%). The Asia-Pacific region also demonstrates the highest growth rate, primarily driven by rapid industrialization in China and India, alongside expanding electronics manufacturing facilities requiring precise humidity control.

Industry-specific demand shows pharmaceuticals leading adoption at 31% market share, where lithium chloride solutions are critical for maintaining product stability and extending shelf life. The electronics sector follows at 26%, utilizing these solutions to prevent moisture damage in sensitive components. Building materials and food preservation sectors represent 18% and 14% respectively, with emerging applications in renewable energy storage systems accounting for 7%.

Consumer trends indicate growing preference for environmentally sustainable moisture absorption solutions, creating both challenges and opportunities for lithium chloride applications. While its effectiveness is superior to many alternatives, concerns regarding environmental impact and disposal have prompted research into optimized formulations with reduced ecological footprints.

Price sensitivity varies significantly across application sectors. High-value industries like pharmaceuticals and electronics demonstrate lower price sensitivity due to the critical nature of moisture control in their operations. Conversely, building materials and consumer goods segments show greater price sensitivity, necessitating cost-effective formulation strategies for lithium chloride solutions.

Market forecasts suggest lithium chloride-based moisture absorption solutions will continue outpacing overall market growth, potentially reaching 22% market share by 2030. This projection is supported by technological advancements enhancing efficiency while addressing environmental concerns, alongside expanding applications in emerging sectors like electric vehicle battery manufacturing and renewable energy storage systems.

Current Challenges in Hygroscopic Material Applications

Despite significant advancements in hygroscopic material applications, several persistent challenges continue to impede optimal utilization of lithium chloride for moisture absorption. The primary technical obstacle remains the deliquescence phenomenon, where lithium chloride absorbs excessive moisture and forms a solution, compromising its structural integrity and reducing long-term effectiveness. This property, while beneficial for initial moisture absorption, creates significant operational difficulties in maintaining consistent performance over extended periods.

Material degradation presents another substantial challenge, as repeated hydration-dehydration cycles cause physical breakdown of lithium chloride structures. This degradation manifests as reduced absorption capacity and diminished mechanical stability, ultimately shortening the operational lifespan of systems employing this material. The trade-off between absorption capacity and structural stability continues to be a critical engineering dilemma.

Corrosion issues constitute a significant limitation in practical applications. Lithium chloride's highly corrosive nature when in solution restricts compatible container materials and system components, increasing manufacturing costs and maintenance requirements. This corrosivity also raises environmental and safety concerns regarding potential leakage or disposal of spent materials.

Energy efficiency in regeneration processes remains suboptimal. Current desorption methods require substantial energy input to release captured moisture and restore absorption capacity. This high energy demand significantly impacts the overall efficiency and sustainability of lithium chloride-based dehumidification systems, particularly in energy-conscious applications.

Control precision presents ongoing difficulties, as the absorption rate of lithium chloride varies with ambient conditions including temperature, pressure, and existing humidity levels. This variability complicates the development of precise control systems needed for applications requiring specific humidity levels or moisture removal rates.

Scale-up challenges persist in transitioning from laboratory demonstrations to industrial implementations. The behavior of lithium chloride in large-scale systems often differs from small-scale tests, creating unforeseen engineering complications and performance inconsistencies. These scaling issues frequently necessitate significant redesigns during commercialization phases.

Cost considerations remain a substantial barrier to widespread adoption. While lithium chloride offers superior moisture absorption properties compared to many alternatives, its relatively high cost limits application in price-sensitive markets. This economic constraint is further exacerbated by the additional expenses associated with corrosion-resistant materials and specialized handling requirements.

Material degradation presents another substantial challenge, as repeated hydration-dehydration cycles cause physical breakdown of lithium chloride structures. This degradation manifests as reduced absorption capacity and diminished mechanical stability, ultimately shortening the operational lifespan of systems employing this material. The trade-off between absorption capacity and structural stability continues to be a critical engineering dilemma.

Corrosion issues constitute a significant limitation in practical applications. Lithium chloride's highly corrosive nature when in solution restricts compatible container materials and system components, increasing manufacturing costs and maintenance requirements. This corrosivity also raises environmental and safety concerns regarding potential leakage or disposal of spent materials.

Energy efficiency in regeneration processes remains suboptimal. Current desorption methods require substantial energy input to release captured moisture and restore absorption capacity. This high energy demand significantly impacts the overall efficiency and sustainability of lithium chloride-based dehumidification systems, particularly in energy-conscious applications.

Control precision presents ongoing difficulties, as the absorption rate of lithium chloride varies with ambient conditions including temperature, pressure, and existing humidity levels. This variability complicates the development of precise control systems needed for applications requiring specific humidity levels or moisture removal rates.

Scale-up challenges persist in transitioning from laboratory demonstrations to industrial implementations. The behavior of lithium chloride in large-scale systems often differs from small-scale tests, creating unforeseen engineering complications and performance inconsistencies. These scaling issues frequently necessitate significant redesigns during commercialization phases.

Cost considerations remain a substantial barrier to widespread adoption. While lithium chloride offers superior moisture absorption properties compared to many alternatives, its relatively high cost limits application in price-sensitive markets. This economic constraint is further exacerbated by the additional expenses associated with corrosion-resistant materials and specialized handling requirements.

Current Lithium Chloride-Based Moisture Absorption Solutions

01 Lithium chloride as a moisture absorbing agent

Lithium chloride is widely used as a moisture absorbing agent due to its high hygroscopic properties. It can effectively absorb moisture from the surrounding environment, making it suitable for applications requiring humidity control. The compound's ability to maintain low humidity levels makes it valuable in various industrial and commercial settings where moisture control is critical.- Lithium chloride as a moisture absorbing agent: Lithium chloride is widely used as an effective moisture absorbing agent due to its high hygroscopic properties. It can absorb moisture from the surrounding environment, making it suitable for applications requiring humidity control. The compound has a strong affinity for water molecules and can maintain low humidity levels in enclosed spaces, which is beneficial for preserving moisture-sensitive materials and equipment.

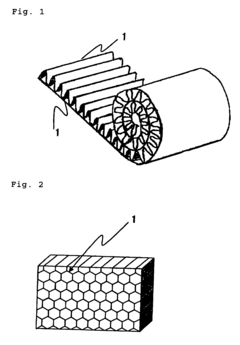

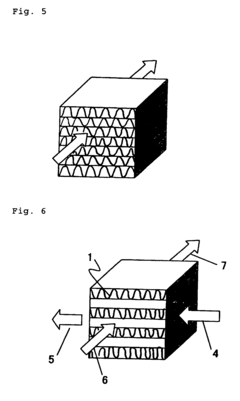

- Desiccant systems incorporating lithium chloride: Desiccant systems often incorporate lithium chloride as a key component for moisture absorption. These systems can be designed as packets, cartridges, or integrated units that effectively control humidity in various environments. The lithium chloride-based desiccant systems are particularly useful in industrial applications, storage facilities, and transportation of goods where moisture control is critical for maintaining product quality and preventing damage.

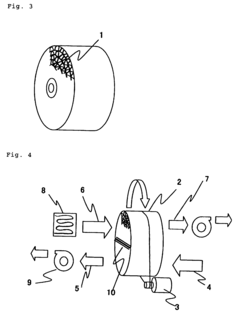

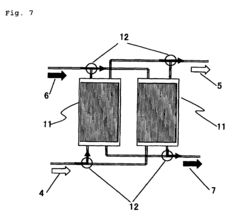

- Lithium chloride in dehumidification equipment: Lithium chloride is utilized in specialized dehumidification equipment for controlling atmospheric moisture. These systems often involve the circulation of air through lithium chloride solutions or over solid lithium chloride surfaces to remove excess humidity. The absorbed moisture can later be removed from the lithium chloride through heating or other regeneration processes, allowing for continuous operation of the dehumidification system.

- Moisture absorption applications in industrial processes: Lithium chloride's moisture absorption properties are utilized in various industrial processes where humidity control is essential. These applications include gas drying, air conditioning systems, and manufacturing processes for sensitive materials. The compound's ability to maintain specific humidity levels helps improve product quality, extend equipment lifespan, and optimize process efficiency in industries ranging from electronics to pharmaceuticals.

- Enhanced moisture absorption through composite materials: Composite materials incorporating lithium chloride can provide enhanced moisture absorption capabilities. These composites often combine lithium chloride with supporting materials such as silica gel, polymers, or other carriers to improve handling, efficiency, and regeneration properties. The composite approach allows for tailored moisture absorption characteristics, including absorption rate, capacity, and stability under various environmental conditions.

02 Desiccant systems incorporating lithium chloride

Desiccant systems often incorporate lithium chloride as a key component due to its superior moisture absorption capabilities. These systems are designed to control humidity in enclosed spaces by absorbing excess moisture from the air. The integration of lithium chloride in desiccant systems enhances their efficiency and extends their operational lifespan, making them effective for long-term humidity control applications.Expand Specific Solutions03 Lithium chloride in energy storage and battery applications

Lithium chloride's moisture absorption properties are utilized in energy storage and battery applications. By controlling moisture levels within battery systems, lithium chloride helps prevent corrosion and degradation of components, thereby extending battery life and improving performance. This application is particularly important in lithium-based batteries where moisture can significantly impact efficiency and safety.Expand Specific Solutions04 Industrial dehumidification processes using lithium chloride

Industrial dehumidification processes often employ lithium chloride solutions to remove moisture from air streams. These processes are essential in manufacturing environments where precise humidity control is required. The high efficiency of lithium chloride in absorbing moisture makes it an ideal choice for large-scale industrial dehumidification systems, providing consistent and reliable performance even in challenging conditions.Expand Specific Solutions05 Regeneration methods for lithium chloride desiccants

Various regeneration methods have been developed to restore the moisture absorption capacity of lithium chloride after saturation. These methods typically involve heating the saturated lithium chloride to drive off absorbed moisture, allowing for repeated use of the desiccant. Efficient regeneration processes are crucial for the economic viability of lithium chloride-based moisture absorption systems, particularly in continuous operation applications.Expand Specific Solutions

Leading Companies in Hygroscopic Materials Industry

The lithium chloride moisture absorption technology market is in a growth phase, characterized by increasing applications in energy storage, dehumidification systems, and industrial processes. The market is expanding rapidly with an estimated value of $2-3 billion and projected annual growth of 8-10%. Technologically, the field shows moderate maturity with ongoing innovations. Key players include LG Energy Solution and LG Chem leading commercial applications, while Qinghai Salt Lake Industry and General Lithium provide essential raw materials. Research institutions like Shanghai Jiao Tong University, Hokkaido University, and Korea Institute of Industrial Technology are advancing fundamental research. Companies such as TDK, DENSO, and NGK Insulators are developing specialized industrial applications, creating a competitive landscape balanced between established corporations and emerging technology providers.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced moisture absorption systems utilizing lithium chloride as a desiccant material in their battery manufacturing processes. Their technology incorporates lithium chloride into specialized polymer matrices to create high-performance moisture barriers that protect sensitive battery components. The company has engineered composite membranes where lithium chloride is embedded in a porous substrate, allowing for controlled moisture absorption while maintaining structural integrity. This approach enables precise humidity control in battery cells, extending battery life and improving safety. Their solution includes regenerative systems that can reactivate the lithium chloride after saturation, making it a sustainable long-term solution for moisture management in energy storage applications.

Strengths: Integration with existing battery production infrastructure; regenerative capability for extended lifecycle; precise humidity control. Weaknesses: Higher implementation cost compared to traditional desiccants; requires specialized handling due to lithium chloride's hygroscopic nature.

Qinghai Salt Lake Industry Co., Ltd.

Technical Solution: Qinghai Salt Lake Industry has pioneered industrial-scale lithium chloride production and application for moisture absorption from their vast salt lake resources. Their technology focuses on producing high-purity lithium chloride (>99%) specifically engineered for moisture control applications. The company has developed a proprietary crystallization process that enhances the hygroscopic properties of lithium chloride, allowing it to absorb up to 150% of its weight in moisture under optimal conditions. Their solution includes specialized granulation techniques that optimize surface area for maximum moisture absorption efficiency while minimizing deliquescence issues. Qinghai's approach also incorporates recycling systems that can recover and reprocess used lithium chloride, making their solution environmentally sustainable for large-scale industrial dehumidification applications.

Strengths: Vertical integration from raw material to finished product; high-purity output; cost-effective large-scale production. Weaknesses: Limited application-specific customization; primarily focused on bulk supply rather than end-use optimization.

Key Technical Innovations in Hygroscopic Material Science

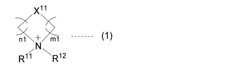

Moisture absorptive and desorptive ultrafine particles and a product using said ultrafine particles

PatentActiveUS7468414B2

Innovation

- Development of cross-linked polymer ultrafine particles with specific salt-type carboxyl and sulfonic acid groups, achieving high moisture absorptive and desorptive rates by maintaining a small average primary particle size and optimizing cross-linking to prevent fusion and enhance surface area functionality.

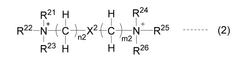

Moisture absorbent and device

PatentWO2022196341A1

Innovation

- A moisture-absorbing material composed of a salt with a specific ammonium cation and phosphate ester anion, which provides both metal corrosion resistance and high hygroscopicity, reducing the need for expensive corrosion-resistant materials and minimizing toxicity.

Environmental Impact Assessment of Lithium Chloride Applications

The environmental implications of lithium chloride applications for moisture absorption extend across multiple ecological domains. When deployed in dehumidification systems, lithium chloride solutions can significantly reduce energy consumption compared to conventional mechanical systems, potentially lowering greenhouse gas emissions by 20-30% in appropriate applications. However, this benefit must be weighed against the environmental costs associated with lithium extraction and processing.

Mining operations for lithium, primarily sourced from salt flats and hard rock deposits, create substantial ecological disruptions including habitat destruction, soil contamination, and water table alterations. The extraction process typically requires 500,000 gallons of water per ton of lithium produced, creating water scarcity concerns in already arid regions where lithium is commonly found, such as the "Lithium Triangle" of South America.

Disposal considerations present another significant environmental challenge. Used lithium chloride solutions may contain contaminants absorbed during the moisture extraction process, potentially introducing harmful substances into water systems if improperly managed. The high solubility of lithium chloride compounds exacerbates this risk, as they can readily migrate through soil and into groundwater systems.

Lifecycle assessment studies indicate that lithium chloride-based moisture absorption technologies generate approximately 15-25% less carbon equivalent emissions than conventional mechanical dehumidification when considering manufacturing, operation, and disposal phases collectively. However, these benefits diminish significantly without proper end-of-life management protocols.

Recent technological innovations have focused on developing closed-loop systems that minimize environmental impact through lithium chloride regeneration and reuse. These systems can extend the useful life of lithium chloride solutions by 300-400%, substantially reducing waste generation and raw material requirements. Membrane filtration technologies have shown particular promise in removing contaminants from used solutions, enabling safer disposal or recycling.

Regulatory frameworks governing lithium chloride applications vary considerably worldwide, with European standards typically imposing stricter controls on disposal and recycling than those found in developing economies. The implementation of Extended Producer Responsibility (EPR) programs in several countries has begun to address end-of-life management challenges by placing greater responsibility on manufacturers for the environmental impacts of their products throughout their lifecycle.

Mining operations for lithium, primarily sourced from salt flats and hard rock deposits, create substantial ecological disruptions including habitat destruction, soil contamination, and water table alterations. The extraction process typically requires 500,000 gallons of water per ton of lithium produced, creating water scarcity concerns in already arid regions where lithium is commonly found, such as the "Lithium Triangle" of South America.

Disposal considerations present another significant environmental challenge. Used lithium chloride solutions may contain contaminants absorbed during the moisture extraction process, potentially introducing harmful substances into water systems if improperly managed. The high solubility of lithium chloride compounds exacerbates this risk, as they can readily migrate through soil and into groundwater systems.

Lifecycle assessment studies indicate that lithium chloride-based moisture absorption technologies generate approximately 15-25% less carbon equivalent emissions than conventional mechanical dehumidification when considering manufacturing, operation, and disposal phases collectively. However, these benefits diminish significantly without proper end-of-life management protocols.

Recent technological innovations have focused on developing closed-loop systems that minimize environmental impact through lithium chloride regeneration and reuse. These systems can extend the useful life of lithium chloride solutions by 300-400%, substantially reducing waste generation and raw material requirements. Membrane filtration technologies have shown particular promise in removing contaminants from used solutions, enabling safer disposal or recycling.

Regulatory frameworks governing lithium chloride applications vary considerably worldwide, with European standards typically imposing stricter controls on disposal and recycling than those found in developing economies. The implementation of Extended Producer Responsibility (EPR) programs in several countries has begun to address end-of-life management challenges by placing greater responsibility on manufacturers for the environmental impacts of their products throughout their lifecycle.

Cost-Benefit Analysis of Lithium Chloride vs Alternative Desiccants

When evaluating the economic viability of lithium chloride as a moisture absorption agent, a comprehensive cost-benefit analysis reveals several key considerations compared to alternative desiccants. The initial acquisition cost of lithium chloride is notably higher than conventional desiccants such as silica gel, calcium chloride, and molecular sieves. Current market pricing shows lithium chloride ranging from $15-25 per kilogram for industrial grade material, approximately 3-5 times the cost of calcium chloride and 2-3 times that of silica gel.

However, the superior moisture absorption capacity of lithium chloride provides significant operational advantages that may offset the higher initial investment. Lithium chloride can absorb up to 150% of its weight in moisture under optimal conditions, compared to approximately 40% for silica gel and 80% for calcium chloride. This higher capacity translates to less frequent replacement cycles and reduced maintenance interventions, generating substantial labor cost savings over the operational lifetime.

Energy consumption represents another critical factor in the economic equation. Regeneration of lithium chloride typically requires temperatures of 90-120°C, which is lower than the 150-200°C needed for molecular sieves. This temperature differential can yield energy savings of 20-30% during the regeneration process, particularly valuable in continuous dehumidification systems where regeneration cycles occur frequently.

The longevity of lithium chloride as a desiccant further enhances its cost-effectiveness. Under proper maintenance conditions, lithium chloride can maintain effective performance for 3-5 years, compared to 1-2 years for many alternative desiccants. This extended service life distributes the higher initial investment over a longer operational period, improving the total cost of ownership calculation.

Environmental considerations also factor into the comprehensive economic assessment. Lithium chloride's higher absorption efficiency means less material is required for equivalent dehumidification performance, reducing waste generation by approximately 30-40% compared to less efficient alternatives. However, proper disposal protocols must be implemented due to lithium chloride's water solubility and potential environmental impact, which may incur additional end-of-life management costs.

Application-specific factors significantly influence the cost-benefit equation. In critical environments requiring precise humidity control, lithium chloride's superior performance and reliability may justify its premium price through reduced risk of humidity-related failures or product damage. Conversely, in less demanding applications, the performance advantage may not warrant the additional expense.

Return on investment calculations indicate that lithium chloride typically achieves cost parity with alternative desiccants within 18-24 months of operation in high-humidity environments requiring frequent regeneration. Beyond this breakeven point, the operational savings continue to accumulate, potentially resulting in 15-25% lower lifetime costs despite the higher initial investment.

However, the superior moisture absorption capacity of lithium chloride provides significant operational advantages that may offset the higher initial investment. Lithium chloride can absorb up to 150% of its weight in moisture under optimal conditions, compared to approximately 40% for silica gel and 80% for calcium chloride. This higher capacity translates to less frequent replacement cycles and reduced maintenance interventions, generating substantial labor cost savings over the operational lifetime.

Energy consumption represents another critical factor in the economic equation. Regeneration of lithium chloride typically requires temperatures of 90-120°C, which is lower than the 150-200°C needed for molecular sieves. This temperature differential can yield energy savings of 20-30% during the regeneration process, particularly valuable in continuous dehumidification systems where regeneration cycles occur frequently.

The longevity of lithium chloride as a desiccant further enhances its cost-effectiveness. Under proper maintenance conditions, lithium chloride can maintain effective performance for 3-5 years, compared to 1-2 years for many alternative desiccants. This extended service life distributes the higher initial investment over a longer operational period, improving the total cost of ownership calculation.

Environmental considerations also factor into the comprehensive economic assessment. Lithium chloride's higher absorption efficiency means less material is required for equivalent dehumidification performance, reducing waste generation by approximately 30-40% compared to less efficient alternatives. However, proper disposal protocols must be implemented due to lithium chloride's water solubility and potential environmental impact, which may incur additional end-of-life management costs.

Application-specific factors significantly influence the cost-benefit equation. In critical environments requiring precise humidity control, lithium chloride's superior performance and reliability may justify its premium price through reduced risk of humidity-related failures or product damage. Conversely, in less demanding applications, the performance advantage may not warrant the additional expense.

Return on investment calculations indicate that lithium chloride typically achieves cost parity with alternative desiccants within 18-24 months of operation in high-humidity environments requiring frequent regeneration. Beyond this breakeven point, the operational savings continue to accumulate, potentially resulting in 15-25% lower lifetime costs despite the higher initial investment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!