How to Enhance Lithium Chloride Desiccant Formulations

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Chloride Desiccant Technology Background and Objectives

Lithium chloride (LiCl) has emerged as a pivotal material in desiccant technology since the early 20th century, with significant advancements occurring post-1950s when industrial dehumidification systems became more widespread. The hygroscopic properties of LiCl make it exceptionally effective at moisture absorption, capable of reducing relative humidity to levels below 15% under optimal conditions, which is substantially lower than what conventional silica gel or calcium chloride desiccants can achieve.

The evolution of LiCl desiccant technology has been marked by several key developments. Initially used in simple solid form, the technology progressed to impregnated matrices in the 1960s, followed by liquid desiccant systems in the 1970s and 1980s. Recent advancements have focused on composite formulations that enhance stability, absorption capacity, and regeneration efficiency while reducing corrosion issues inherent to chloride-based compounds.

Current market trends indicate a growing demand for energy-efficient dehumidification solutions across multiple sectors including HVAC systems, pharmaceutical storage, food preservation, and electronics manufacturing. This demand is driven by increasing awareness of indoor air quality, stricter regulations on energy consumption, and the expanding need for controlled environments in advanced manufacturing processes.

The primary technical objectives for enhancing LiCl desiccant formulations include increasing moisture absorption capacity per unit weight, improving regeneration efficiency at lower temperatures, extending operational lifespan, reducing corrosivity to metal components, and developing cost-effective production methods for advanced formulations. Additionally, there is significant interest in creating environmentally sustainable versions that maintain performance while reducing environmental impact.

Research indicates that modified LiCl formulations incorporating nanomaterials or polymer matrices can potentially increase absorption capacity by 30-40% compared to conventional formulations. Similarly, composite systems utilizing LiCl with other hygroscopic materials show promise in addressing the deliquescence issues that have historically limited certain applications.

The trajectory of LiCl desiccant technology is moving toward smart, responsive systems that can adapt to varying environmental conditions, potentially integrating with IoT platforms for optimized performance. Concurrently, there is growing interest in bio-based carrier materials that can reduce the environmental footprint while maintaining or enhancing performance characteristics.

As global humidity control requirements become more stringent and energy efficiency more critical, enhanced LiCl formulations represent a significant opportunity for technological advancement in dehumidification systems, with potential applications extending beyond traditional uses into emerging fields such as renewable energy storage and advanced materials preservation.

The evolution of LiCl desiccant technology has been marked by several key developments. Initially used in simple solid form, the technology progressed to impregnated matrices in the 1960s, followed by liquid desiccant systems in the 1970s and 1980s. Recent advancements have focused on composite formulations that enhance stability, absorption capacity, and regeneration efficiency while reducing corrosion issues inherent to chloride-based compounds.

Current market trends indicate a growing demand for energy-efficient dehumidification solutions across multiple sectors including HVAC systems, pharmaceutical storage, food preservation, and electronics manufacturing. This demand is driven by increasing awareness of indoor air quality, stricter regulations on energy consumption, and the expanding need for controlled environments in advanced manufacturing processes.

The primary technical objectives for enhancing LiCl desiccant formulations include increasing moisture absorption capacity per unit weight, improving regeneration efficiency at lower temperatures, extending operational lifespan, reducing corrosivity to metal components, and developing cost-effective production methods for advanced formulations. Additionally, there is significant interest in creating environmentally sustainable versions that maintain performance while reducing environmental impact.

Research indicates that modified LiCl formulations incorporating nanomaterials or polymer matrices can potentially increase absorption capacity by 30-40% compared to conventional formulations. Similarly, composite systems utilizing LiCl with other hygroscopic materials show promise in addressing the deliquescence issues that have historically limited certain applications.

The trajectory of LiCl desiccant technology is moving toward smart, responsive systems that can adapt to varying environmental conditions, potentially integrating with IoT platforms for optimized performance. Concurrently, there is growing interest in bio-based carrier materials that can reduce the environmental footprint while maintaining or enhancing performance characteristics.

As global humidity control requirements become more stringent and energy efficiency more critical, enhanced LiCl formulations represent a significant opportunity for technological advancement in dehumidification systems, with potential applications extending beyond traditional uses into emerging fields such as renewable energy storage and advanced materials preservation.

Market Analysis for Advanced Desiccant Solutions

The global desiccant market is experiencing significant growth, with the advanced desiccant segment showing particularly strong momentum. Current market valuations place the overall desiccant market at approximately 2.1 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 5.7% through 2030. Within this broader market, lithium chloride-based desiccants represent a specialized but rapidly expanding niche, currently valued at around 310 million USD.

Key market drivers for enhanced lithium chloride desiccant formulations include the growing demand for moisture control in pharmaceutical manufacturing, electronics production, and industrial gas processing. The pharmaceutical sector alone accounts for nearly 28% of advanced desiccant consumption, driven by stringent regulatory requirements for product stability and shelf life. Electronics manufacturing represents another 23% of market demand, with requirements for increasingly efficient moisture control in smaller form factors.

Regional analysis reveals Asia-Pacific as the dominant market for advanced desiccants, accounting for approximately 41% of global consumption. This is primarily attributed to the region's robust electronics manufacturing sector and expanding pharmaceutical production capabilities. North America follows at 27% market share, with Europe at 22%. Emerging markets in Latin America and Africa are showing accelerated adoption rates, albeit from a smaller base.

Customer segmentation indicates three primary buyer categories: original equipment manufacturers (OEMs) integrating desiccant systems into their products, industrial processors requiring bulk desiccant materials, and specialized service providers focused on environmental control solutions. The OEM segment represents the largest growth opportunity, with a projected CAGR of 7.2% through 2030.

Pricing trends for lithium chloride desiccants have shown volatility in recent years, influenced by fluctuations in raw material costs and supply chain disruptions. Premium formulations with enhanced absorption capacity command price premiums of 30-45% over standard offerings, indicating strong market willingness to pay for performance improvements.

Distribution channels are evolving, with direct-to-manufacturer sales representing 62% of transactions, while specialized industrial suppliers account for 31%. E-commerce platforms are emerging as a significant channel for replacement products and smaller volume purchases, growing at twice the rate of traditional distribution methods.

Market barriers include raw material cost fluctuations, regulatory compliance requirements for certain applications, and the technical expertise required for optimal implementation. These factors have contributed to market consolidation, with the top five suppliers now controlling approximately 57% of global advanced desiccant sales.

Key market drivers for enhanced lithium chloride desiccant formulations include the growing demand for moisture control in pharmaceutical manufacturing, electronics production, and industrial gas processing. The pharmaceutical sector alone accounts for nearly 28% of advanced desiccant consumption, driven by stringent regulatory requirements for product stability and shelf life. Electronics manufacturing represents another 23% of market demand, with requirements for increasingly efficient moisture control in smaller form factors.

Regional analysis reveals Asia-Pacific as the dominant market for advanced desiccants, accounting for approximately 41% of global consumption. This is primarily attributed to the region's robust electronics manufacturing sector and expanding pharmaceutical production capabilities. North America follows at 27% market share, with Europe at 22%. Emerging markets in Latin America and Africa are showing accelerated adoption rates, albeit from a smaller base.

Customer segmentation indicates three primary buyer categories: original equipment manufacturers (OEMs) integrating desiccant systems into their products, industrial processors requiring bulk desiccant materials, and specialized service providers focused on environmental control solutions. The OEM segment represents the largest growth opportunity, with a projected CAGR of 7.2% through 2030.

Pricing trends for lithium chloride desiccants have shown volatility in recent years, influenced by fluctuations in raw material costs and supply chain disruptions. Premium formulations with enhanced absorption capacity command price premiums of 30-45% over standard offerings, indicating strong market willingness to pay for performance improvements.

Distribution channels are evolving, with direct-to-manufacturer sales representing 62% of transactions, while specialized industrial suppliers account for 31%. E-commerce platforms are emerging as a significant channel for replacement products and smaller volume purchases, growing at twice the rate of traditional distribution methods.

Market barriers include raw material cost fluctuations, regulatory compliance requirements for certain applications, and the technical expertise required for optimal implementation. These factors have contributed to market consolidation, with the top five suppliers now controlling approximately 57% of global advanced desiccant sales.

Current Limitations and Challenges in LiCl Desiccant Formulations

Despite the widespread use of lithium chloride (LiCl) as a desiccant material, several significant limitations and challenges persist in current formulations that hinder optimal performance. The hygroscopic nature of LiCl, while beneficial for moisture absorption, leads to a problematic phenomenon known as deliquescence when relative humidity exceeds approximately 11%. This transition from solid to liquid state causes operational difficulties in practical applications, including leakage issues, contamination of surrounding components, and reduced mechanical stability of desiccant structures.

The corrosive properties of LiCl present another major challenge, particularly when used in proximity to metal components. This corrosivity accelerates the degradation of equipment and infrastructure, necessitating more frequent maintenance and replacement cycles, thereby increasing operational costs. The corrosion risk is especially pronounced in applications where the desiccant may come into direct contact with sensitive electronic components or structural elements.

Performance degradation over repeated absorption-desorption cycles represents a significant limitation in current LiCl formulations. This cycling fatigue manifests as reduced moisture absorption capacity and efficiency over time, shortening the effective service life of the desiccant system. The regeneration process itself is energy-intensive, requiring substantial thermal input to drive off absorbed moisture, which negatively impacts the overall energy efficiency of systems employing LiCl desiccants.

Environmental and health concerns also pose challenges to widespread LiCl adoption. The potential for lithium leaching into the environment raises ecological concerns, while handling risks during manufacturing, installation, and disposal present occupational health considerations. These factors have prompted increasing regulatory scrutiny in various jurisdictions, potentially limiting future applications.

Current formulation techniques face difficulties in achieving optimal dispersion of LiCl within carrier materials. Uneven distribution leads to inconsistent performance characteristics and localized areas of excessive deliquescence. Additionally, the thermal conductivity properties of many LiCl formulations are suboptimal, limiting heat transfer efficiency during regeneration cycles and contributing to energy inefficiency.

Cost factors remain a significant barrier, particularly for large-scale applications. The market volatility of lithium compounds, driven by competing demands from the battery industry, has created price instability that complicates long-term economic planning for desiccant applications. Furthermore, the specialized manufacturing processes required for high-performance LiCl formulations add to production costs.

Integration challenges with existing HVAC and dehumidification systems represent another limitation, as many current systems are not optimized to accommodate the specific operational parameters of LiCl-based desiccants, requiring significant redesign or adaptation efforts.

The corrosive properties of LiCl present another major challenge, particularly when used in proximity to metal components. This corrosivity accelerates the degradation of equipment and infrastructure, necessitating more frequent maintenance and replacement cycles, thereby increasing operational costs. The corrosion risk is especially pronounced in applications where the desiccant may come into direct contact with sensitive electronic components or structural elements.

Performance degradation over repeated absorption-desorption cycles represents a significant limitation in current LiCl formulations. This cycling fatigue manifests as reduced moisture absorption capacity and efficiency over time, shortening the effective service life of the desiccant system. The regeneration process itself is energy-intensive, requiring substantial thermal input to drive off absorbed moisture, which negatively impacts the overall energy efficiency of systems employing LiCl desiccants.

Environmental and health concerns also pose challenges to widespread LiCl adoption. The potential for lithium leaching into the environment raises ecological concerns, while handling risks during manufacturing, installation, and disposal present occupational health considerations. These factors have prompted increasing regulatory scrutiny in various jurisdictions, potentially limiting future applications.

Current formulation techniques face difficulties in achieving optimal dispersion of LiCl within carrier materials. Uneven distribution leads to inconsistent performance characteristics and localized areas of excessive deliquescence. Additionally, the thermal conductivity properties of many LiCl formulations are suboptimal, limiting heat transfer efficiency during regeneration cycles and contributing to energy inefficiency.

Cost factors remain a significant barrier, particularly for large-scale applications. The market volatility of lithium compounds, driven by competing demands from the battery industry, has created price instability that complicates long-term economic planning for desiccant applications. Furthermore, the specialized manufacturing processes required for high-performance LiCl formulations add to production costs.

Integration challenges with existing HVAC and dehumidification systems represent another limitation, as many current systems are not optimized to accommodate the specific operational parameters of LiCl-based desiccants, requiring significant redesign or adaptation efforts.

Contemporary LiCl Formulation Enhancement Approaches

01 Composite desiccant formulations with lithium chloride

Composite desiccant formulations incorporate lithium chloride with other materials to enhance moisture absorption capacity and efficiency. These formulations typically combine lithium chloride with carrier materials such as silica gel, activated alumina, or molecular sieves to create synergistic effects. The composite structure provides improved surface area for moisture adsorption while maintaining the hygroscopic properties of lithium chloride, resulting in enhanced desiccant performance across varying humidity conditions.- Lithium chloride desiccant composition improvements: Enhanced lithium chloride desiccant formulations can be achieved through specific composition modifications. These improvements include optimizing the concentration of lithium chloride, incorporating stabilizing agents, and using specific carriers or substrates. Such enhancements lead to increased moisture absorption capacity, improved stability, and extended service life of the desiccant. The improved formulations show better performance in various humidity conditions and temperature ranges.

- Carrier materials and substrate integration: The effectiveness of lithium chloride as a desiccant can be enhanced by incorporating it into appropriate carrier materials or substrates. Various materials such as silica gel, activated alumina, zeolites, and porous polymers can serve as carriers for lithium chloride. These carriers provide increased surface area for moisture absorption, improve handling characteristics, and can prevent deliquescence issues. The selection of carrier material significantly impacts the overall performance and application range of the desiccant formulation.

- Stabilization techniques for lithium chloride desiccants: Various stabilization techniques can be employed to enhance the performance and longevity of lithium chloride desiccants. These include the addition of anti-caking agents, crystallization modifiers, and hygroscopic stabilizers. Other approaches involve encapsulation methods, polymer coating, and the incorporation of specific additives that prevent deliquescence while maintaining moisture absorption capacity. These stabilization techniques help overcome common issues such as clumping, reduced efficiency over time, and physical degradation of the desiccant material.

- Manufacturing processes for enhanced desiccant formulations: Specialized manufacturing processes can significantly improve lithium chloride desiccant formulations. These processes include controlled crystallization techniques, spray drying, granulation methods, and precise mixing procedures. Advanced manufacturing approaches such as sol-gel processing, microencapsulation, and controlled deposition on substrates can create desiccants with optimized particle size, porosity, and surface characteristics. These manufacturing innovations result in desiccants with superior moisture absorption rates, capacity, and regeneration capabilities.

- Application-specific formulation enhancements: Lithium chloride desiccant formulations can be specifically enhanced for particular applications. For refrigeration and air conditioning systems, formulations may include additives that improve heat transfer and resistance to temperature fluctuations. For pharmaceutical and electronics packaging, specialized formulations may incorporate indicators or controlled release mechanisms. Other application-specific enhancements include combinations with antimicrobial agents, integration with specific filter materials, or modifications for extreme environmental conditions. These tailored formulations provide optimal performance in their intended use cases.

02 Stabilized lithium chloride desiccant systems

Stabilized lithium chloride desiccant systems incorporate additives or processing techniques to prevent deliquescence and maintain structural integrity during moisture absorption. These formulations may include binders, anti-caking agents, or encapsulation technologies that allow lithium chloride to absorb moisture while preventing it from dissolving completely. The stabilization techniques help extend the useful life of the desiccant, improve handling characteristics, and maintain performance efficiency over multiple adsorption-desorption cycles.Expand Specific Solutions03 Regeneration methods for lithium chloride desiccants

Advanced regeneration methods for lithium chloride desiccants focus on efficient moisture removal and restoration of absorption capacity. These techniques include optimized heating profiles, vacuum regeneration, microwave drying, or combination approaches that minimize energy consumption while maximizing moisture removal. The regeneration processes are designed to prevent degradation of the lithium chloride structure, maintain chemical stability, and ensure consistent performance over multiple regeneration cycles, thereby extending the operational lifespan of the desiccant system.Expand Specific Solutions04 Lithium chloride desiccant with enhanced thermal properties

Formulations that enhance the thermal properties of lithium chloride desiccants focus on improving heat transfer, thermal stability, and energy efficiency during both adsorption and regeneration phases. These enhancements may include incorporation of thermally conductive materials, phase change materials, or specialized heat exchange structures. The improved thermal properties allow for more efficient moisture removal, reduced regeneration temperatures, and better overall system performance in applications such as dehumidification systems, air conditioning, and industrial drying processes.Expand Specific Solutions05 Environmentally optimized lithium chloride formulations

Environmentally optimized lithium chloride formulations focus on reducing environmental impact while maintaining or improving desiccant performance. These formulations may incorporate biodegradable carriers, reduce the total lithium chloride content through enhanced efficiency, or include recovery systems to prevent environmental release. Additionally, these formulations may be designed for compatibility with closed-loop systems, minimizing waste generation and resource consumption while providing effective moisture control in various applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Desiccant Industry

The lithium chloride desiccant formulation market is in a growth phase, driven by increasing demand for efficient dehumidification solutions across industrial and commercial sectors. The global desiccant market is projected to expand significantly, with lithium chloride formulations gaining prominence due to their superior moisture absorption capabilities. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include Albemarle Corp., a major lithium compound producer, and Origin Materials, focusing on sustainable chemical development. Academic institutions like Central South University and Zhejiang Sci-Tech University contribute significant research. Industrial giants Samsung SDI, Toyota Industries, and Sumitomo Chemical are leveraging their manufacturing expertise to develop enhanced formulations, while specialized companies like Lilac Solutions and Forager Station are pioneering novel extraction and application technologies.

Sumitomo Chemical Co., Ltd.

Technical Solution: Sumitomo Chemical has developed advanced lithium chloride desiccant formulations utilizing their expertise in polymer chemistry and materials science. Their approach centers on creating LiCl-polymer composites through a proprietary emulsion polymerization process that encapsulates lithium chloride within hydrophilic polymer networks. This technology prevents the common issue of deliquescence (turning into liquid when absorbing moisture) while maintaining rapid moisture absorption kinetics. Sumitomo's research has demonstrated that their formulations can absorb up to 3 times their weight in moisture under standard conditions (25°C, 80% RH), approximately 40% more than conventional LiCl desiccants. The company has also developed specialized surface treatments that enhance the regeneration capabilities of their desiccants, allowing for effective reuse after thermal regeneration at temperatures as low as 80°C, compared to the 120°C typically required for standard LiCl regeneration. Their formulations incorporate pH buffers that neutralize the acidic byproducts formed during moisture absorption, significantly reducing corrosion risks to metal components.

Strengths: Superior moisture absorption capacity; excellent regeneration characteristics at lower temperatures; reduced corrosion potential through pH buffering; maintained effectiveness through multiple regeneration cycles. Weaknesses: Higher production costs than basic LiCl formulations; more complex manufacturing process requiring specialized equipment; potential for polymer degradation in extremely high humidity environments.

Molten Salt Solutions, LLC

Technical Solution: Molten Salt Solutions has developed innovative lithium chloride desiccant formulations specifically designed for high-temperature applications. Their proprietary technology involves creating eutectic mixtures of lithium chloride with other hygroscopic salts (primarily calcium and magnesium chlorides) that demonstrate synergistic moisture absorption properties. The company's research has shown that these multi-salt formulations maintain desiccant functionality at temperatures up to 200°C, significantly outperforming traditional LiCl desiccants that degrade above 120°C. Their process includes a specialized thermal treatment that creates a microporous structure within the salt matrix, increasing surface area for moisture adsorption by approximately 65% compared to conventional formulations. Molten Salt Solutions has also incorporated proprietary stabilizing agents that reduce the corrosive nature of LiCl while maintaining its exceptional hygroscopic properties, making their formulations suitable for use with sensitive equipment and materials.

Strengths: Exceptional high-temperature performance; reduced corrosivity while maintaining hygroscopic properties; synergistic effects from multi-salt formulation increasing overall efficiency. Weaknesses: More complex manufacturing process requiring precise control of salt ratios; potentially higher cost due to specialized formulation; may require specific handling procedures due to unique chemical properties.

Key Patents and Research in Lithium Chloride Desiccant Technology

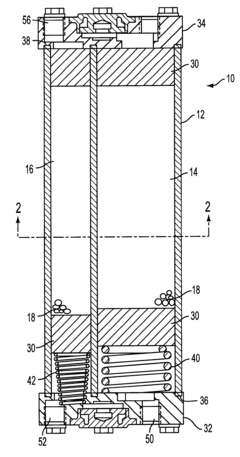

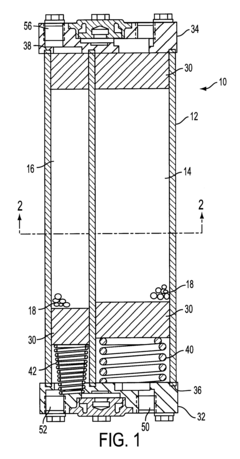

Lithium chloride desiccant for trailer air dryer and pressure swing dehydration

PatentInactiveUS6358300B1

Innovation

- The use of semi-rigid porous substrates impregnated with lithium chloride as a desiccant in air dryers, which effectively removes moisture from compressed air and withstands oil, with a method involving a saturated lithium chloride solution applied to the substrates, heated to drive off excess solvent, creating a high-capacity desiccant that remains effective for longer.

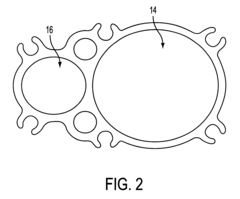

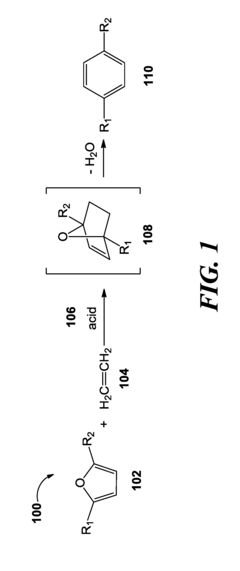

Methods of producing para-xylene and terephthalic acid

PatentActiveUS20160362357A1

Innovation

- The use of Lewis acids to convert 2,5-dimethylfuran (DMF) into para-xylene, with specific reaction conditions and catalysts, reduces the formation of byproducts, thereby increasing the yield of para-xylene, which can then be oxidized to produce terephthalic acid, utilizing ethylene in the presence of acids and desiccants to enhance the reaction efficiency.

Environmental Impact and Sustainability Considerations

The environmental impact of lithium chloride desiccant formulations represents a critical consideration in their development and application. Traditional desiccant systems often involve significant energy consumption during regeneration processes, contributing to carbon emissions and resource depletion. Lithium chloride, while effective as a desiccant, presents specific environmental challenges throughout its lifecycle that must be addressed through innovative formulation approaches.

Water consumption associated with lithium extraction remains a primary concern, particularly in regions where lithium mining occurs in water-stressed environments. Enhanced formulations that extend the service life of lithium chloride desiccants can significantly reduce the frequency of replacement and consequently minimize the demand for raw materials. Additionally, optimizing regeneration temperatures through advanced formulation techniques can substantially decrease the energy requirements for desiccant reactivation.

Chemical stability improvements in lithium chloride formulations offer dual environmental benefits by reducing both leaching potential and the frequency of system maintenance. The incorporation of stabilizing compounds that prevent lithium chloride degradation without introducing additional environmental hazards represents a promising direction for sustainable formulation development. Furthermore, exploring biodegradable carrier materials compatible with lithium chloride can address end-of-life disposal concerns.

Circular economy principles should guide the development of next-generation lithium chloride desiccants. Formulations designed with recoverability in mind enable the extraction and reuse of lithium compounds after the desiccant's useful life, creating closed-loop systems that minimize waste. Research into recovery processes that are economically viable at commercial scales will be essential for implementing these circular approaches effectively.

The carbon footprint of desiccant systems extends beyond their direct operation to include manufacturing processes and transportation impacts. Life cycle assessment methodologies reveal that enhanced formulations offering higher efficiency and longevity can deliver significant environmental benefits despite potentially higher initial resource investments. Quantifying these trade-offs through comprehensive environmental impact assessments provides valuable guidance for formulation optimization.

Regulatory frameworks increasingly emphasize environmental performance, with restrictions on hazardous substances and emissions becoming more stringent globally. Future-proof lithium chloride formulations must anticipate these regulatory trends by eliminating potentially problematic additives and minimizing environmental risks. Collaboration between industry stakeholders, regulatory bodies, and research institutions will be essential to establish sustainability standards specific to desiccant technologies.

Water consumption associated with lithium extraction remains a primary concern, particularly in regions where lithium mining occurs in water-stressed environments. Enhanced formulations that extend the service life of lithium chloride desiccants can significantly reduce the frequency of replacement and consequently minimize the demand for raw materials. Additionally, optimizing regeneration temperatures through advanced formulation techniques can substantially decrease the energy requirements for desiccant reactivation.

Chemical stability improvements in lithium chloride formulations offer dual environmental benefits by reducing both leaching potential and the frequency of system maintenance. The incorporation of stabilizing compounds that prevent lithium chloride degradation without introducing additional environmental hazards represents a promising direction for sustainable formulation development. Furthermore, exploring biodegradable carrier materials compatible with lithium chloride can address end-of-life disposal concerns.

Circular economy principles should guide the development of next-generation lithium chloride desiccants. Formulations designed with recoverability in mind enable the extraction and reuse of lithium compounds after the desiccant's useful life, creating closed-loop systems that minimize waste. Research into recovery processes that are economically viable at commercial scales will be essential for implementing these circular approaches effectively.

The carbon footprint of desiccant systems extends beyond their direct operation to include manufacturing processes and transportation impacts. Life cycle assessment methodologies reveal that enhanced formulations offering higher efficiency and longevity can deliver significant environmental benefits despite potentially higher initial resource investments. Quantifying these trade-offs through comprehensive environmental impact assessments provides valuable guidance for formulation optimization.

Regulatory frameworks increasingly emphasize environmental performance, with restrictions on hazardous substances and emissions becoming more stringent globally. Future-proof lithium chloride formulations must anticipate these regulatory trends by eliminating potentially problematic additives and minimizing environmental risks. Collaboration between industry stakeholders, regulatory bodies, and research institutions will be essential to establish sustainability standards specific to desiccant technologies.

Performance Metrics and Testing Methodologies

Evaluating the performance of lithium chloride desiccant formulations requires comprehensive testing methodologies and well-defined metrics to ensure consistent quality and effectiveness. The industry has established several standardized approaches to measure key performance indicators that determine the commercial viability and technical efficacy of these formulations.

The primary performance metrics for lithium chloride desiccants include moisture absorption capacity, absorption rate, regeneration efficiency, and cycle stability. Moisture absorption capacity, typically measured in grams of water per gram of desiccant, indicates the maximum amount of moisture the formulation can absorb before reaching equilibrium. This metric directly correlates with the operational efficiency and determines the required quantity of desiccant for specific applications.

Absorption rate measurements quantify how quickly the desiccant can remove moisture from the surrounding environment, which is crucial for applications requiring rapid humidity control. Standard testing involves exposing the desiccant to controlled humidity environments (typically 80% RH) and measuring weight gain over time intervals. The resulting absorption curves provide valuable insights into performance under various conditions.

Regeneration efficiency testing evaluates how completely and efficiently the desiccant can be dried for reuse. This involves measuring energy consumption during regeneration cycles and determining the percentage of original absorption capacity retained after multiple regeneration processes. Industry standards typically require maintaining at least 90% of original capacity after 1000 regeneration cycles for high-performance applications.

Thermal stability testing exposes desiccant formulations to temperature extremes (typically -40°C to 200°C) to evaluate performance consistency across operational temperature ranges. This is particularly important for applications in extreme environments where temperature fluctuations could compromise desiccant effectiveness.

Chemical stability testing assesses the desiccant's resistance to degradation when exposed to common contaminants, acids, bases, and oxidizing agents. Accelerated aging tests simulate long-term exposure to determine the expected service life of the formulation under various environmental conditions.

Advanced testing methodologies now incorporate real-time monitoring systems that track performance metrics during actual operation. These include infrared spectroscopy for moisture content analysis, differential scanning calorimetry for thermodynamic property assessment, and automated cycling equipment that simulates years of operation within compressed timeframes.

Standardization of these testing protocols is essential for meaningful comparison between different formulations. Organizations such as ASTM International and ISO have developed specific standards (e.g., ASTM E104, ISO 12571) that provide guidelines for consistent testing and reporting of desiccant performance data, ensuring reliability and reproducibility across different laboratories and manufacturers.

The primary performance metrics for lithium chloride desiccants include moisture absorption capacity, absorption rate, regeneration efficiency, and cycle stability. Moisture absorption capacity, typically measured in grams of water per gram of desiccant, indicates the maximum amount of moisture the formulation can absorb before reaching equilibrium. This metric directly correlates with the operational efficiency and determines the required quantity of desiccant for specific applications.

Absorption rate measurements quantify how quickly the desiccant can remove moisture from the surrounding environment, which is crucial for applications requiring rapid humidity control. Standard testing involves exposing the desiccant to controlled humidity environments (typically 80% RH) and measuring weight gain over time intervals. The resulting absorption curves provide valuable insights into performance under various conditions.

Regeneration efficiency testing evaluates how completely and efficiently the desiccant can be dried for reuse. This involves measuring energy consumption during regeneration cycles and determining the percentage of original absorption capacity retained after multiple regeneration processes. Industry standards typically require maintaining at least 90% of original capacity after 1000 regeneration cycles for high-performance applications.

Thermal stability testing exposes desiccant formulations to temperature extremes (typically -40°C to 200°C) to evaluate performance consistency across operational temperature ranges. This is particularly important for applications in extreme environments where temperature fluctuations could compromise desiccant effectiveness.

Chemical stability testing assesses the desiccant's resistance to degradation when exposed to common contaminants, acids, bases, and oxidizing agents. Accelerated aging tests simulate long-term exposure to determine the expected service life of the formulation under various environmental conditions.

Advanced testing methodologies now incorporate real-time monitoring systems that track performance metrics during actual operation. These include infrared spectroscopy for moisture content analysis, differential scanning calorimetry for thermodynamic property assessment, and automated cycling equipment that simulates years of operation within compressed timeframes.

Standardization of these testing protocols is essential for meaningful comparison between different formulations. Organizations such as ASTM International and ISO have developed specific standards (e.g., ASTM E104, ISO 12571) that provide guidelines for consistent testing and reporting of desiccant performance data, ensuring reliability and reproducibility across different laboratories and manufacturers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!