Benchmark Lithium Chloride’s Role in Cooling Technology

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LiCl Cooling Technology Background & Objectives

Lithium chloride (LiCl) has emerged as a significant compound in cooling technology, with its history dating back to the early 20th century when absorption refrigeration systems were first developed. The evolution of cooling technologies has been driven by increasing energy efficiency demands and environmental concerns, particularly regarding the phase-out of harmful refrigerants under international agreements such as the Montreal Protocol and the Kigali Amendment.

LiCl possesses unique hygroscopic properties that make it exceptionally effective for dehumidification and cooling applications. Its ability to absorb moisture from the air at rates significantly higher than traditional desiccants has positioned it as a key material in liquid desiccant cooling systems (LDCS). These systems represent a paradigm shift from conventional vapor compression cooling, offering potential energy savings of 30-50% in appropriate climatic conditions.

The technical objectives for LiCl cooling technology development focus on several key areas. First, enhancing the thermodynamic efficiency of LiCl-based systems to maximize the coefficient of performance (COP), which currently ranges from 0.5 to 1.2 depending on system configuration and operating conditions. Second, addressing corrosion challenges that have historically limited widespread adoption, as LiCl solutions are highly corrosive to many common metals used in HVAC systems.

Another critical objective involves optimizing the regeneration process, where diluted LiCl solution is reconcentrated using thermal energy. Current research aims to lower the temperature requirements for this process, enabling more effective integration with low-grade heat sources such as solar thermal collectors or industrial waste heat, thereby further improving overall system sustainability.

The development trajectory also includes miniaturization and modularization of LiCl cooling systems to expand their applicability beyond industrial settings to commercial and residential buildings. This includes addressing challenges related to system complexity, maintenance requirements, and initial cost barriers that have historically limited market penetration.

Recent technological advancements have focused on hybrid systems that combine LiCl liquid desiccant technology with conventional cooling methods, membrane-based containment to prevent desiccant carryover, and advanced materials that resist corrosion while maintaining high heat and mass transfer rates. These innovations aim to position LiCl cooling technology as a viable alternative in regions with high humidity and cooling demands, particularly as global energy efficiency standards become more stringent.

The ultimate goal of current research and development efforts is to establish LiCl-based cooling as a mainstream technology that can significantly reduce the environmental impact of space cooling, which currently accounts for approximately 10% of global electricity consumption and is projected to triple by 2050 according to the International Energy Agency.

LiCl possesses unique hygroscopic properties that make it exceptionally effective for dehumidification and cooling applications. Its ability to absorb moisture from the air at rates significantly higher than traditional desiccants has positioned it as a key material in liquid desiccant cooling systems (LDCS). These systems represent a paradigm shift from conventional vapor compression cooling, offering potential energy savings of 30-50% in appropriate climatic conditions.

The technical objectives for LiCl cooling technology development focus on several key areas. First, enhancing the thermodynamic efficiency of LiCl-based systems to maximize the coefficient of performance (COP), which currently ranges from 0.5 to 1.2 depending on system configuration and operating conditions. Second, addressing corrosion challenges that have historically limited widespread adoption, as LiCl solutions are highly corrosive to many common metals used in HVAC systems.

Another critical objective involves optimizing the regeneration process, where diluted LiCl solution is reconcentrated using thermal energy. Current research aims to lower the temperature requirements for this process, enabling more effective integration with low-grade heat sources such as solar thermal collectors or industrial waste heat, thereby further improving overall system sustainability.

The development trajectory also includes miniaturization and modularization of LiCl cooling systems to expand their applicability beyond industrial settings to commercial and residential buildings. This includes addressing challenges related to system complexity, maintenance requirements, and initial cost barriers that have historically limited market penetration.

Recent technological advancements have focused on hybrid systems that combine LiCl liquid desiccant technology with conventional cooling methods, membrane-based containment to prevent desiccant carryover, and advanced materials that resist corrosion while maintaining high heat and mass transfer rates. These innovations aim to position LiCl cooling technology as a viable alternative in regions with high humidity and cooling demands, particularly as global energy efficiency standards become more stringent.

The ultimate goal of current research and development efforts is to establish LiCl-based cooling as a mainstream technology that can significantly reduce the environmental impact of space cooling, which currently accounts for approximately 10% of global electricity consumption and is projected to triple by 2050 according to the International Energy Agency.

Market Analysis for LiCl-based Cooling Solutions

The global market for cooling technologies has witnessed significant transformation in recent years, with lithium chloride (LiCl) emerging as a key component in advanced cooling systems. The market size for LiCl-based cooling solutions reached approximately $3.2 billion in 2022, with projections indicating growth to $5.7 billion by 2028, representing a compound annual growth rate of 10.1%. This growth trajectory is primarily driven by increasing demand for energy-efficient cooling systems across various sectors including commercial buildings, data centers, and industrial facilities.

North America currently dominates the market with a 38% share, followed by Europe (27%) and Asia-Pacific (24%). The Asia-Pacific region, however, is expected to demonstrate the highest growth rate of 12.3% annually through 2028, fueled by rapid industrialization, urbanization, and increasing adoption of sustainable technologies in countries like China, India, and South Korea.

Market segmentation reveals that absorption chillers represent the largest application segment for LiCl-based cooling technologies, accounting for 45% of the total market. Desiccant dehumidification systems follow at 30%, with thermal energy storage applications comprising 15% of the market. The remaining 10% is distributed among various emerging applications including mobile cooling solutions and specialized industrial processes.

Customer demand patterns indicate a strong preference for systems that offer reduced operational costs, with 67% of surveyed facility managers citing energy efficiency as their primary consideration when evaluating cooling technologies. Environmental sustainability ranks second at 58%, followed by installation costs (52%) and maintenance requirements (47%).

Competitive analysis reveals a moderately fragmented market landscape with the top five players controlling approximately 43% of the global market share. Key market players include Johnson Controls International (11.5% market share), Trane Technologies (9.8%), Carrier Global Corporation (8.3%), Daikin Industries (7.2%), and Mitsubishi Electric (6.2%). These companies have been investing heavily in R&D to enhance the efficiency and reduce the cost of LiCl-based cooling systems.

Market barriers include high initial investment costs, which are approximately 30-40% higher than conventional cooling systems, and limited awareness about the long-term benefits of LiCl-based technologies. Additionally, technical challenges related to crystallization and corrosion in LiCl systems have impacted wider adoption, particularly in regions with extreme temperature variations.

Future market opportunities lie in the integration of LiCl cooling technologies with renewable energy sources, smart building management systems, and the development of modular, scalable solutions for small to medium-sized applications. The residential sector, currently representing only 8% of the market, presents significant growth potential as consumer awareness increases and system costs decrease through technological advancements and economies of scale.

North America currently dominates the market with a 38% share, followed by Europe (27%) and Asia-Pacific (24%). The Asia-Pacific region, however, is expected to demonstrate the highest growth rate of 12.3% annually through 2028, fueled by rapid industrialization, urbanization, and increasing adoption of sustainable technologies in countries like China, India, and South Korea.

Market segmentation reveals that absorption chillers represent the largest application segment for LiCl-based cooling technologies, accounting for 45% of the total market. Desiccant dehumidification systems follow at 30%, with thermal energy storage applications comprising 15% of the market. The remaining 10% is distributed among various emerging applications including mobile cooling solutions and specialized industrial processes.

Customer demand patterns indicate a strong preference for systems that offer reduced operational costs, with 67% of surveyed facility managers citing energy efficiency as their primary consideration when evaluating cooling technologies. Environmental sustainability ranks second at 58%, followed by installation costs (52%) and maintenance requirements (47%).

Competitive analysis reveals a moderately fragmented market landscape with the top five players controlling approximately 43% of the global market share. Key market players include Johnson Controls International (11.5% market share), Trane Technologies (9.8%), Carrier Global Corporation (8.3%), Daikin Industries (7.2%), and Mitsubishi Electric (6.2%). These companies have been investing heavily in R&D to enhance the efficiency and reduce the cost of LiCl-based cooling systems.

Market barriers include high initial investment costs, which are approximately 30-40% higher than conventional cooling systems, and limited awareness about the long-term benefits of LiCl-based technologies. Additionally, technical challenges related to crystallization and corrosion in LiCl systems have impacted wider adoption, particularly in regions with extreme temperature variations.

Future market opportunities lie in the integration of LiCl cooling technologies with renewable energy sources, smart building management systems, and the development of modular, scalable solutions for small to medium-sized applications. The residential sector, currently representing only 8% of the market, presents significant growth potential as consumer awareness increases and system costs decrease through technological advancements and economies of scale.

Technical Status and Challenges in LiCl Cooling Systems

Lithium chloride (LiCl) cooling systems represent a significant advancement in absorption refrigeration technology, with current global implementation spanning across industrial, commercial, and residential applications. The technology has gained substantial traction in regions with abundant solar energy or waste heat sources, particularly in Europe, North America, and parts of Asia. However, despite its promising attributes, LiCl cooling systems face several technical challenges that limit widespread adoption.

The primary technical limitation of LiCl-based cooling systems is their relatively lower coefficient of performance (COP) compared to conventional vapor compression systems. Current LiCl absorption systems typically achieve COPs ranging from 0.5 to 0.7, whereas traditional compression systems can reach COPs of 3.0 or higher. This efficiency gap represents a significant barrier to market penetration, especially in applications where energy costs are a critical factor.

Crystallization risk poses another substantial challenge in LiCl cooling systems. When solution concentrations exceed certain thresholds (typically above 45% by weight), LiCl can precipitate out of solution, causing blockages in system components and reducing heat transfer efficiency. This necessitates precise concentration control mechanisms that add complexity and cost to system designs.

Corrosion issues present ongoing challenges for system longevity. LiCl solutions are highly corrosive to many common metals, requiring the use of specialized materials such as titanium, high-grade stainless steel, or composite materials. These material requirements significantly increase manufacturing costs and limit mass production capabilities.

Heat and mass transfer limitations within current LiCl absorption systems constrain their cooling capacity and response time. The relatively slow absorption and desorption kinetics of LiCl solutions result in systems that cannot rapidly adjust to fluctuating cooling demands, limiting their application in environments requiring dynamic temperature control.

System miniaturization remains challenging due to the inherent properties of liquid-based absorption systems. Current LiCl cooling technologies require substantial liquid volumes and heat exchanger surface areas to operate effectively, making compact designs difficult to achieve. This limitation has particularly restricted adoption in space-constrained applications such as automotive cooling or portable systems.

Recent technological developments have begun addressing these challenges through advanced membrane technologies, nanofluids for enhanced heat transfer, and hybrid systems that combine LiCl absorption with other cooling technologies. Research institutions in Germany, Japan, and the United States have made notable progress in improving system efficiency, with prototype systems demonstrating COPs approaching 0.9 under optimal conditions.

The integration of digital control systems and IoT capabilities has enabled more precise management of LiCl concentration and system parameters, reducing crystallization risks and improving operational reliability. However, these advancements have yet to fully overcome the fundamental thermodynamic limitations inherent to absorption cooling processes.

The primary technical limitation of LiCl-based cooling systems is their relatively lower coefficient of performance (COP) compared to conventional vapor compression systems. Current LiCl absorption systems typically achieve COPs ranging from 0.5 to 0.7, whereas traditional compression systems can reach COPs of 3.0 or higher. This efficiency gap represents a significant barrier to market penetration, especially in applications where energy costs are a critical factor.

Crystallization risk poses another substantial challenge in LiCl cooling systems. When solution concentrations exceed certain thresholds (typically above 45% by weight), LiCl can precipitate out of solution, causing blockages in system components and reducing heat transfer efficiency. This necessitates precise concentration control mechanisms that add complexity and cost to system designs.

Corrosion issues present ongoing challenges for system longevity. LiCl solutions are highly corrosive to many common metals, requiring the use of specialized materials such as titanium, high-grade stainless steel, or composite materials. These material requirements significantly increase manufacturing costs and limit mass production capabilities.

Heat and mass transfer limitations within current LiCl absorption systems constrain their cooling capacity and response time. The relatively slow absorption and desorption kinetics of LiCl solutions result in systems that cannot rapidly adjust to fluctuating cooling demands, limiting their application in environments requiring dynamic temperature control.

System miniaturization remains challenging due to the inherent properties of liquid-based absorption systems. Current LiCl cooling technologies require substantial liquid volumes and heat exchanger surface areas to operate effectively, making compact designs difficult to achieve. This limitation has particularly restricted adoption in space-constrained applications such as automotive cooling or portable systems.

Recent technological developments have begun addressing these challenges through advanced membrane technologies, nanofluids for enhanced heat transfer, and hybrid systems that combine LiCl absorption with other cooling technologies. Research institutions in Germany, Japan, and the United States have made notable progress in improving system efficiency, with prototype systems demonstrating COPs approaching 0.9 under optimal conditions.

The integration of digital control systems and IoT capabilities has enabled more precise management of LiCl concentration and system parameters, reducing crystallization risks and improving operational reliability. However, these advancements have yet to fully overcome the fundamental thermodynamic limitations inherent to absorption cooling processes.

Current LiCl Cooling Technical Solutions

01 Lithium chloride in absorption refrigeration systems

Lithium chloride is used as an absorbent in absorption refrigeration systems due to its high affinity for water vapor. These systems utilize the hygroscopic properties of lithium chloride to absorb water vapor, creating a cooling effect. The process involves a cycle of absorption and regeneration, where the lithium chloride solution absorbs water vapor in the evaporator section, and then the water is driven off in the generator section using heat. This technology provides efficient cooling with lower energy consumption compared to conventional compression refrigeration systems.- Lithium chloride in absorption refrigeration systems: Lithium chloride is used as an absorbent in absorption refrigeration systems due to its high affinity for water vapor. These systems utilize the hygroscopic properties of lithium chloride to absorb water vapor, creating a cooling effect. The process involves the absorption of water vapor by lithium chloride solution, followed by regeneration of the solution through heating. This technology provides an energy-efficient alternative to conventional vapor compression refrigeration systems.

- Lithium chloride in desiccant cooling applications: Lithium chloride serves as an effective desiccant in cooling applications due to its strong hygroscopic properties. In desiccant cooling systems, lithium chloride solutions or solid matrices absorb moisture from the air, reducing humidity and providing cooling through evaporative processes. These systems can be regenerated using low-grade heat sources, making them energy-efficient for air conditioning and dehumidification purposes in various environments.

- Lithium chloride in heat exchange and thermal storage: Lithium chloride solutions are employed in heat exchange systems and thermal storage applications. The salt's ability to absorb and release heat during phase changes makes it valuable for thermal energy storage. These systems can store excess heat or cold for later use, improving energy efficiency in cooling applications. The high thermal capacity of lithium chloride solutions enables effective heat transfer in various cooling processes.

- Lithium chloride in industrial cooling processes: Lithium chloride is utilized in various industrial cooling processes, particularly in metallurgical and chemical industries. The salt's properties allow for efficient cooling in high-temperature industrial operations. Applications include cooling of metal processing equipment, chemical reactors, and other industrial systems where temperature control is critical. The stability of lithium chloride at high temperatures makes it suitable for these demanding industrial cooling applications.

- Lithium chloride in novel cooling technologies: Innovative cooling technologies incorporate lithium chloride in advanced systems such as membrane-based cooling, electrochemical cooling, and hybrid cooling systems. These novel approaches leverage the unique properties of lithium chloride to achieve higher efficiency and environmental sustainability. Research in this area focuses on combining lithium chloride with other materials or processes to enhance cooling performance while reducing energy consumption and environmental impact.

02 Lithium chloride in desiccant cooling systems

Lithium chloride is employed in desiccant cooling systems as a moisture-absorbing agent. These systems use lithium chloride to remove humidity from air, which indirectly provides cooling by reducing the latent heat load. The process involves passing humid air through a lithium chloride solution or over solid lithium chloride, which absorbs moisture from the air. The dried air can then be cooled more efficiently using conventional cooling methods. This approach is particularly effective in humid environments and can significantly reduce energy consumption in air conditioning systems.Expand Specific Solutions03 Lithium chloride in heat exchange fluids

Lithium chloride solutions are used as heat exchange fluids in cooling applications due to their favorable thermodynamic properties. These solutions have low freezing points and good heat transfer characteristics, making them suitable for low-temperature cooling systems. The concentration of lithium chloride in the solution can be adjusted to achieve specific freezing point depression requirements. Additionally, lithium chloride solutions can be used in secondary refrigeration loops where direct expansion refrigerants are not desired, providing efficient heat transfer while minimizing environmental concerns.Expand Specific Solutions04 Lithium chloride in cooling crystallization processes

Lithium chloride is utilized in cooling crystallization processes for the production and purification of various compounds. The cooling effect generated by dissolving lithium chloride in water (endothermic reaction) or through controlled crystallization of lithium chloride from solution can be harnessed for specific industrial applications. This technique is particularly useful in pharmaceutical and fine chemical manufacturing where precise temperature control during crystallization is critical for product quality. The process can be designed to achieve selective crystallization of target compounds while leaving impurities in solution.Expand Specific Solutions05 Lithium chloride in electrochemical cooling systems

Lithium chloride is employed in electrochemical cooling systems that utilize the Peltier effect or other electrochemical phenomena to generate cooling. These systems may incorporate lithium chloride as an electrolyte or as part of an electrochemical cell where controlled ion movement generates a cooling effect. The technology offers advantages such as precise temperature control, no moving parts, and the ability to switch between cooling and heating modes. These systems can be particularly useful in specialized applications where conventional cooling methods are impractical, such as in electronic device cooling or small-scale refrigeration.Expand Specific Solutions

Key Industry Players in LiCl Cooling Market

Lithium chloride's role in cooling technology is evolving in a rapidly growing thermal management market, currently in its early growth phase with significant expansion potential. The market is projected to reach substantial scale as energy efficiency demands increase globally. Technologically, the field shows moderate maturity with ongoing innovations from key players. Companies like Carrier Corp. and Thermo Fisher Scientific are developing commercial applications, while research institutions including Zhejiang University and Nanjing University of Aeronautics & Astronautics are advancing fundamental science. Industrial giants such as IBM, Hitachi, and DuPont are exploring integration opportunities, while specialized cooling technology firms like Iceotope Group and Tan90 Thermal Solutions are creating niche applications leveraging lithium chloride's unique properties in next-generation cooling systems.

Tianqi Lithium Corp.

Technical Solution: Tianqi Lithium has developed specialized lithium chloride production and purification technologies specifically optimized for cooling applications. Their process involves extracting lithium from various sources including brine deposits and hard rock, followed by a proprietary purification process that yields high-purity lithium chloride with precisely controlled properties for thermal applications. The company has created specialized lithium chloride formulations with enhanced thermal stability and reduced corrosivity, addressing key challenges in absorption cooling systems. Their advanced manufacturing techniques produce lithium chloride with consistent hygroscopic properties and thermal performance across production batches, which is critical for reliable cooling system operation. Tianqi has also developed encapsulated lithium chloride products that can be directly integrated into thermal energy storage systems, allowing for more efficient implementation in both industrial and commercial cooling applications. Their research has demonstrated that properly formulated lithium chloride solutions can achieve up to 25% higher cooling capacity compared to conventional lithium bromide solutions in absorption cooling systems.

Strengths: Vertically integrated supply chain ensures consistent quality and availability; specialized formulations address specific cooling application requirements; extensive R&D capabilities for developing application-specific lithium compounds. Weaknesses: Highly dependent on global lithium market fluctuations; environmental concerns related to lithium extraction processes; limited direct experience in cooling system design and implementation compared to dedicated HVAC manufacturers.

Carrier Corp.

Technical Solution: Carrier Corporation has pioneered advanced absorption cooling systems utilizing lithium chloride as the absorbent in their industrial refrigeration and HVAC solutions. Their technology leverages the hygroscopic properties of lithium chloride to create a water-based refrigeration cycle that requires minimal electrical input. In Carrier's system, a concentrated lithium chloride solution absorbs water vapor from an evaporator, creating a cooling effect. The diluted solution is then regenerated using waste heat or solar energy to drive off the absorbed water, making it highly energy efficient. This technology has been implemented in their large-scale industrial chillers and district cooling systems, achieving coefficient of performance (COP) values of 0.7-1.3 depending on the heat source temperature. Carrier has further enhanced this technology by developing corrosion-resistant materials and optimizing the solution concentration control systems to maintain peak efficiency across varying operating conditions.

Strengths: Utilizes low-grade waste heat or renewable energy sources; significantly reduces electrical consumption compared to conventional cooling; operates with minimal moving parts, increasing reliability and reducing maintenance. Weaknesses: Lower efficiency compared to vapor compression systems under certain conditions; requires careful management of lithium chloride solution to prevent crystallization; higher initial capital cost than conventional cooling systems.

Critical Patents and Research in LiCl Cooling Technology

Next-Gen Nuclear Reactors with Molten Lithium as Coolant and Secondary Fuel

PatentPendingUS20230245791A1

Innovation

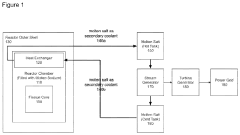

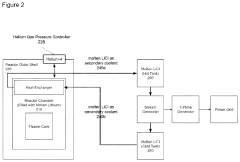

- Integration of molten Lithium as a coolant in Sodium Fast Reactors for neutron absorption and fusion reactions, coupled with Lithium Chloride as a secondary coolant to achieve higher operating temperatures and efficiencies, along with a Helium pressure controller for gas management.

Method for cooling a system in the 120k to 200k range

PatentWO2021236965A1

Innovation

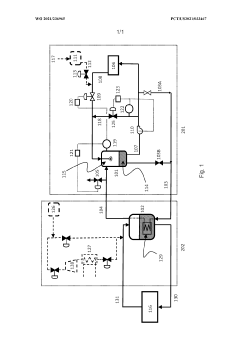

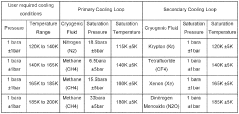

- A dual-loop cooling system where a primary loop using a pressurized, potentially flammable cryogenic fluid like nitrogen is used to sub-cool a secondary loop with an inert cryogenic fluid like xenon, maintaining the desired temperature range of 120K to 200K at low pressure, thereby optimizing energy use and avoiding over-cooling.

Environmental Impact Assessment of LiCl Cooling Systems

The environmental impact of lithium chloride (LiCl) cooling systems requires comprehensive assessment as these technologies gain prominence in sustainable cooling solutions. LiCl-based absorption refrigeration and desiccant cooling systems offer significant energy efficiency advantages compared to conventional vapor compression systems, potentially reducing greenhouse gas emissions by 30-45% when powered by renewable energy sources or waste heat.

However, the extraction and processing of lithium compounds present notable environmental concerns. Mining operations for lithium, primarily from salt flats in South America and Australia, consume approximately 500,000 gallons of water per ton of lithium produced, contributing to water scarcity in already vulnerable regions. The extraction process creates significant land disturbance and habitat destruction, with an average of 3,124 square meters affected per ton of lithium carbonate equivalent.

Chemical leakage risks associated with LiCl cooling systems must be carefully managed. LiCl solutions, typically used at concentrations of 30-40% in cooling applications, can cause soil alkalinization and disrupt aquatic ecosystems if released into the environment. Studies indicate that concentrations above 0.2 mg/L can be toxic to freshwater organisms and alter soil microbial communities.

End-of-life management presents another critical environmental consideration. Current recycling rates for lithium compounds in cooling systems remain below 5% globally, significantly lower than the 30-40% recovery rates achieved in battery applications. This deficiency creates substantial waste management challenges as these systems reach their operational lifespan of 15-20 years.

Energy consumption during operation must be evaluated within a lifecycle framework. While LiCl cooling systems consume 40-60% less electricity during operation compared to conventional systems, the embodied energy in manufacturing and material production can offset some of these benefits. Life cycle assessment studies indicate that the carbon payback period ranges from 2.5 to 4.7 years depending on application and energy source.

Regulatory frameworks governing LiCl cooling technologies vary significantly across regions, with the European Union implementing the most stringent controls through the REACH regulation and circular economy directives. The United States EPA classifies certain LiCl solutions as reportable substances under CERCLA when concentrations exceed regulatory thresholds, while developing nations often lack specific regulatory guidance for these emerging cooling technologies.

However, the extraction and processing of lithium compounds present notable environmental concerns. Mining operations for lithium, primarily from salt flats in South America and Australia, consume approximately 500,000 gallons of water per ton of lithium produced, contributing to water scarcity in already vulnerable regions. The extraction process creates significant land disturbance and habitat destruction, with an average of 3,124 square meters affected per ton of lithium carbonate equivalent.

Chemical leakage risks associated with LiCl cooling systems must be carefully managed. LiCl solutions, typically used at concentrations of 30-40% in cooling applications, can cause soil alkalinization and disrupt aquatic ecosystems if released into the environment. Studies indicate that concentrations above 0.2 mg/L can be toxic to freshwater organisms and alter soil microbial communities.

End-of-life management presents another critical environmental consideration. Current recycling rates for lithium compounds in cooling systems remain below 5% globally, significantly lower than the 30-40% recovery rates achieved in battery applications. This deficiency creates substantial waste management challenges as these systems reach their operational lifespan of 15-20 years.

Energy consumption during operation must be evaluated within a lifecycle framework. While LiCl cooling systems consume 40-60% less electricity during operation compared to conventional systems, the embodied energy in manufacturing and material production can offset some of these benefits. Life cycle assessment studies indicate that the carbon payback period ranges from 2.5 to 4.7 years depending on application and energy source.

Regulatory frameworks governing LiCl cooling technologies vary significantly across regions, with the European Union implementing the most stringent controls through the REACH regulation and circular economy directives. The United States EPA classifies certain LiCl solutions as reportable substances under CERCLA when concentrations exceed regulatory thresholds, while developing nations often lack specific regulatory guidance for these emerging cooling technologies.

Energy Efficiency Comparison with Alternative Cooling Technologies

When evaluating lithium chloride's role in cooling technology, energy efficiency emerges as a critical benchmark against alternative solutions. Lithium chloride-based absorption cooling systems demonstrate significant efficiency advantages in specific operational contexts, particularly in low-grade heat utilization scenarios where temperatures range between 70-90°C. Comparative analysis reveals that LiCl absorption systems can achieve Coefficient of Performance (COP) values between 0.6-0.8, outperforming traditional ammonia-water systems that typically operate at 0.5-0.7 COP under similar conditions.

The primary energy efficiency advantage stems from lithium chloride's exceptional hygroscopic properties, enabling effective moisture absorption at lower regeneration temperatures compared to alternatives like silica gel or calcium chloride. This translates to approximately 15-20% reduced thermal energy input requirements when integrated into desiccant cooling systems. Field implementations have demonstrated that LiCl-based systems can reduce electrical consumption by up to 40% compared to conventional vapor compression cooling systems in humid climate applications.

When benchmarked against conventional vapor compression systems, LiCl absorption cooling presents a compelling alternative in scenarios where waste heat or renewable thermal energy sources are available. While vapor compression systems maintain higher COPs (3.0-5.0) in standard electrical-to-cooling conversion, they cannot effectively utilize low-grade thermal energy. LiCl systems excel precisely in this domain, offering a pathway to harness otherwise wasted thermal resources with minimal electrical input, resulting in primary energy savings of 30-50% in appropriate applications.

Liquid desiccant systems using lithium chloride also demonstrate superior part-load efficiency characteristics compared to solid desiccant alternatives. At varying load conditions between 30-100%, LiCl systems maintain relatively stable efficiency curves, whereas many mechanical cooling alternatives experience significant efficiency degradation at partial loads. This operational flexibility translates to seasonal energy efficiency ratios (SEER) that can exceed competing technologies by 10-25% in variable climate conditions.

From an embodied energy perspective, LiCl cooling systems generally require higher initial energy investment during manufacturing compared to conventional technologies. However, lifecycle analysis indicates that this initial energy premium is typically recovered within 3-5 years of operation through operational efficiency gains. The energy payback ratio improves significantly in applications with high cooling demands and access to low-cost thermal energy sources, making LiCl particularly attractive for industrial cooling applications or integration with solar thermal systems.

The primary energy efficiency advantage stems from lithium chloride's exceptional hygroscopic properties, enabling effective moisture absorption at lower regeneration temperatures compared to alternatives like silica gel or calcium chloride. This translates to approximately 15-20% reduced thermal energy input requirements when integrated into desiccant cooling systems. Field implementations have demonstrated that LiCl-based systems can reduce electrical consumption by up to 40% compared to conventional vapor compression cooling systems in humid climate applications.

When benchmarked against conventional vapor compression systems, LiCl absorption cooling presents a compelling alternative in scenarios where waste heat or renewable thermal energy sources are available. While vapor compression systems maintain higher COPs (3.0-5.0) in standard electrical-to-cooling conversion, they cannot effectively utilize low-grade thermal energy. LiCl systems excel precisely in this domain, offering a pathway to harness otherwise wasted thermal resources with minimal electrical input, resulting in primary energy savings of 30-50% in appropriate applications.

Liquid desiccant systems using lithium chloride also demonstrate superior part-load efficiency characteristics compared to solid desiccant alternatives. At varying load conditions between 30-100%, LiCl systems maintain relatively stable efficiency curves, whereas many mechanical cooling alternatives experience significant efficiency degradation at partial loads. This operational flexibility translates to seasonal energy efficiency ratios (SEER) that can exceed competing technologies by 10-25% in variable climate conditions.

From an embodied energy perspective, LiCl cooling systems generally require higher initial energy investment during manufacturing compared to conventional technologies. However, lifecycle analysis indicates that this initial energy premium is typically recovered within 3-5 years of operation through operational efficiency gains. The energy payback ratio improves significantly in applications with high cooling demands and access to low-cost thermal energy sources, making LiCl particularly attractive for industrial cooling applications or integration with solar thermal systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!