LM7 engine fuel management and its effect on power output

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Engine Overview

The LM7 engine, also known as the Vortec 5300, is a V8 engine produced by General Motors as part of its Gen III small-block engine family. Introduced in 1999, the LM7 quickly became a popular choice for GM's full-size trucks and SUVs due to its balance of power, efficiency, and reliability. This 5.3-liter engine features an aluminum block with cast-in-place iron cylinder liners, aluminum heads, and a compression ratio of 9.5:1.

One of the key innovations in the LM7 engine is its advanced fuel management system. This system utilizes sequential fuel injection, which precisely controls the timing and amount of fuel delivered to each cylinder. The engine control module (ECM) constantly monitors various sensors to optimize fuel delivery based on driving conditions, load, and environmental factors. This level of control allows for improved fuel efficiency and reduced emissions without sacrificing performance.

The LM7's fuel management system incorporates several components that work in harmony to achieve optimal engine performance. These include high-pressure fuel injectors, a returnless fuel system, and an electronic throttle control. The returnless fuel system eliminates the need for a fuel return line, reducing heat transfer to the fuel and improving overall system efficiency. The electronic throttle control, often referred to as "drive-by-wire," replaces the traditional mechanical linkage between the accelerator pedal and throttle body with an electronic system, allowing for more precise control of engine power output.

Power output is a critical aspect of the LM7 engine's performance, and the fuel management system plays a crucial role in this regard. In its stock configuration, the LM7 typically produces between 285 and 295 horsepower, depending on the specific application and model year. This power output is achieved through careful calibration of the fuel injection system, ignition timing, and air intake management.

The relationship between fuel management and power output in the LM7 engine is complex and multifaceted. By precisely controlling the air-fuel mixture, the engine can operate at its most efficient point, maximizing power while minimizing fuel consumption. The ECM's ability to adjust fuel delivery in real-time allows the engine to respond quickly to changes in driver input and load conditions, ensuring optimal performance across a wide range of operating conditions.

Furthermore, the LM7's fuel management system incorporates features such as deceleration fuel cut-off and idle speed control, which contribute to both fuel efficiency and overall drivability. These features demonstrate the sophisticated nature of the engine's fuel management strategy and its impact on not just power output, but also on the vehicle's overall performance characteristics.

One of the key innovations in the LM7 engine is its advanced fuel management system. This system utilizes sequential fuel injection, which precisely controls the timing and amount of fuel delivered to each cylinder. The engine control module (ECM) constantly monitors various sensors to optimize fuel delivery based on driving conditions, load, and environmental factors. This level of control allows for improved fuel efficiency and reduced emissions without sacrificing performance.

The LM7's fuel management system incorporates several components that work in harmony to achieve optimal engine performance. These include high-pressure fuel injectors, a returnless fuel system, and an electronic throttle control. The returnless fuel system eliminates the need for a fuel return line, reducing heat transfer to the fuel and improving overall system efficiency. The electronic throttle control, often referred to as "drive-by-wire," replaces the traditional mechanical linkage between the accelerator pedal and throttle body with an electronic system, allowing for more precise control of engine power output.

Power output is a critical aspect of the LM7 engine's performance, and the fuel management system plays a crucial role in this regard. In its stock configuration, the LM7 typically produces between 285 and 295 horsepower, depending on the specific application and model year. This power output is achieved through careful calibration of the fuel injection system, ignition timing, and air intake management.

The relationship between fuel management and power output in the LM7 engine is complex and multifaceted. By precisely controlling the air-fuel mixture, the engine can operate at its most efficient point, maximizing power while minimizing fuel consumption. The ECM's ability to adjust fuel delivery in real-time allows the engine to respond quickly to changes in driver input and load conditions, ensuring optimal performance across a wide range of operating conditions.

Furthermore, the LM7's fuel management system incorporates features such as deceleration fuel cut-off and idle speed control, which contribute to both fuel efficiency and overall drivability. These features demonstrate the sophisticated nature of the engine's fuel management strategy and its impact on not just power output, but also on the vehicle's overall performance characteristics.

Market Demand Analysis

The market demand for advanced fuel management systems in LM7 engines has been steadily increasing, driven by the automotive industry's pursuit of improved power output and fuel efficiency. As emissions regulations become more stringent worldwide, manufacturers are seeking innovative solutions to optimize engine performance while meeting environmental standards. This has created a significant opportunity for fuel management technologies that can enhance the LM7 engine's power output without compromising fuel economy.

In the performance vehicle segment, there is a growing demand for aftermarket fuel management systems that can unlock the full potential of LM7 engines. Enthusiasts and tuners are constantly looking for ways to increase horsepower and torque, creating a niche market for specialized fuel management solutions. This demand is particularly strong in regions with a robust car modification culture, such as North America and parts of Europe.

The commercial vehicle sector also shows interest in advanced fuel management for LM7 engines, as fleet operators seek to reduce fuel costs and improve overall efficiency. With fuel prices remaining a significant operational expense, any technology that can optimize fuel consumption while maintaining or improving power output is highly valued in this market segment.

Environmental concerns and government policies are further driving the demand for sophisticated fuel management systems. As countries implement stricter emissions standards, there is a growing need for technologies that can help LM7 engines meet these requirements without sacrificing performance. This has led to increased investment in research and development of fuel management solutions that can provide a balance between power output and environmental compliance.

The automotive aftermarket industry has recognized the potential in LM7 engine fuel management, with numerous companies developing performance-enhancing products. These range from simple plug-and-play modules to complex, fully programmable engine management systems. The market for these products is expected to grow as more vehicle owners seek to customize and improve their LM7-equipped vehicles.

In the racing and high-performance sectors, the demand for cutting-edge fuel management systems for LM7 engines is particularly strong. Professional racing teams and serious enthusiasts are willing to invest in advanced technologies that can provide even marginal gains in power output, creating a premium market segment for specialized fuel management solutions.

As the automotive industry continues to evolve towards electrification, there is also a growing interest in hybrid technologies that can integrate advanced fuel management systems with electric powertrains. This presents new opportunities for innovative fuel management solutions that can optimize the performance of LM7 engines in hybrid configurations, potentially extending the market relevance of these engines in the face of increasing electrification.

In the performance vehicle segment, there is a growing demand for aftermarket fuel management systems that can unlock the full potential of LM7 engines. Enthusiasts and tuners are constantly looking for ways to increase horsepower and torque, creating a niche market for specialized fuel management solutions. This demand is particularly strong in regions with a robust car modification culture, such as North America and parts of Europe.

The commercial vehicle sector also shows interest in advanced fuel management for LM7 engines, as fleet operators seek to reduce fuel costs and improve overall efficiency. With fuel prices remaining a significant operational expense, any technology that can optimize fuel consumption while maintaining or improving power output is highly valued in this market segment.

Environmental concerns and government policies are further driving the demand for sophisticated fuel management systems. As countries implement stricter emissions standards, there is a growing need for technologies that can help LM7 engines meet these requirements without sacrificing performance. This has led to increased investment in research and development of fuel management solutions that can provide a balance between power output and environmental compliance.

The automotive aftermarket industry has recognized the potential in LM7 engine fuel management, with numerous companies developing performance-enhancing products. These range from simple plug-and-play modules to complex, fully programmable engine management systems. The market for these products is expected to grow as more vehicle owners seek to customize and improve their LM7-equipped vehicles.

In the racing and high-performance sectors, the demand for cutting-edge fuel management systems for LM7 engines is particularly strong. Professional racing teams and serious enthusiasts are willing to invest in advanced technologies that can provide even marginal gains in power output, creating a premium market segment for specialized fuel management solutions.

As the automotive industry continues to evolve towards electrification, there is also a growing interest in hybrid technologies that can integrate advanced fuel management systems with electric powertrains. This presents new opportunities for innovative fuel management solutions that can optimize the performance of LM7 engines in hybrid configurations, potentially extending the market relevance of these engines in the face of increasing electrification.

Fuel Management Challenges

The LM7 engine, a popular V8 powerplant used in various General Motors vehicles, faces several fuel management challenges that directly impact its power output. One of the primary issues is achieving optimal fuel atomization across a wide range of operating conditions. The engine's design, while robust, struggles to maintain consistent fuel droplet size and distribution, particularly at high RPMs or under heavy load.

Another significant challenge is the precise control of fuel injection timing and duration. The LM7's electronic fuel injection system must adapt to rapidly changing engine conditions, including temperature fluctuations, varying air density, and different fuel qualities. Inaccuracies in fuel delivery can lead to power loss, increased emissions, and potential engine damage.

The management of air-fuel ratios presents a complex balancing act. Lean mixtures can improve fuel efficiency but may reduce power output and increase the risk of engine knock. Conversely, rich mixtures can boost power but at the cost of increased fuel consumption and emissions. Finding the optimal balance across different driving scenarios remains a persistent challenge for LM7 fuel management systems.

Fuel pressure regulation is another critical aspect that affects power output. Maintaining consistent fuel pressure is essential for proper injector operation and fuel atomization. However, the LM7 engine can experience pressure fluctuations due to various factors, including fuel pump wear, clogged filters, or inadequate fuel line sizing. These issues can lead to inconsistent fuel delivery and compromised engine performance.

The integration of advanced technologies, such as direct injection or variable valve timing, into the LM7 platform presents both opportunities and challenges. While these technologies can potentially enhance fuel management and power output, they also introduce additional complexity and potential points of failure in the fuel system.

Environmental factors and regulatory requirements add another layer of complexity to fuel management. The LM7 engine must meet increasingly stringent emissions standards while maintaining performance. This often requires compromises in fuel management strategies, potentially limiting maximum power output in favor of cleaner exhaust emissions.

Lastly, the long-term reliability and durability of fuel system components pose ongoing challenges. Fuel injectors, sensors, and control modules must maintain accuracy and efficiency over extended periods, often in harsh operating environments. Degradation of these components can lead to gradual power loss and increased fuel consumption, necessitating careful monitoring and maintenance strategies.

Another significant challenge is the precise control of fuel injection timing and duration. The LM7's electronic fuel injection system must adapt to rapidly changing engine conditions, including temperature fluctuations, varying air density, and different fuel qualities. Inaccuracies in fuel delivery can lead to power loss, increased emissions, and potential engine damage.

The management of air-fuel ratios presents a complex balancing act. Lean mixtures can improve fuel efficiency but may reduce power output and increase the risk of engine knock. Conversely, rich mixtures can boost power but at the cost of increased fuel consumption and emissions. Finding the optimal balance across different driving scenarios remains a persistent challenge for LM7 fuel management systems.

Fuel pressure regulation is another critical aspect that affects power output. Maintaining consistent fuel pressure is essential for proper injector operation and fuel atomization. However, the LM7 engine can experience pressure fluctuations due to various factors, including fuel pump wear, clogged filters, or inadequate fuel line sizing. These issues can lead to inconsistent fuel delivery and compromised engine performance.

The integration of advanced technologies, such as direct injection or variable valve timing, into the LM7 platform presents both opportunities and challenges. While these technologies can potentially enhance fuel management and power output, they also introduce additional complexity and potential points of failure in the fuel system.

Environmental factors and regulatory requirements add another layer of complexity to fuel management. The LM7 engine must meet increasingly stringent emissions standards while maintaining performance. This often requires compromises in fuel management strategies, potentially limiting maximum power output in favor of cleaner exhaust emissions.

Lastly, the long-term reliability and durability of fuel system components pose ongoing challenges. Fuel injectors, sensors, and control modules must maintain accuracy and efficiency over extended periods, often in harsh operating environments. Degradation of these components can lead to gradual power loss and increased fuel consumption, necessitating careful monitoring and maintenance strategies.

Current Fuel Solutions

01 Fuel management system optimization

The LM7 engine's fuel management system can be optimized to improve power output. This involves fine-tuning the fuel injection timing, adjusting air-fuel ratios, and implementing advanced control algorithms to maximize combustion efficiency and engine performance.- Fuel management system optimization: The LM7 engine's fuel management system can be optimized to improve power output. This involves fine-tuning the fuel injection timing, adjusting air-fuel ratios, and implementing advanced control algorithms to ensure optimal combustion efficiency. These optimizations can lead to increased power output while maintaining fuel economy.

- Electronic control unit (ECU) enhancements: Enhancing the ECU capabilities of the LM7 engine can significantly improve fuel management and power output. This may include upgrading the ECU software, implementing more sophisticated mapping techniques, and integrating real-time sensor data for more precise control over engine parameters.

- Sensor technology improvements: Incorporating advanced sensor technologies in the LM7 engine's fuel management system can lead to more accurate monitoring of engine conditions. This includes using high-precision oxygen sensors, mass airflow sensors, and temperature sensors to provide real-time data for optimizing fuel delivery and ignition timing, resulting in improved power output.

- Turbocharging and supercharging integration: Integrating turbocharging or supercharging systems with the LM7 engine's fuel management system can significantly boost power output. This involves modifying the fuel delivery system to accommodate the increased air intake, adjusting boost pressure control, and optimizing fuel injection parameters to match the forced induction system.

- Variable valve timing implementation: Implementing variable valve timing in conjunction with the LM7 engine's fuel management system can enhance power output across different RPM ranges. This technology allows for dynamic adjustment of valve timing, improving volumetric efficiency and optimizing fuel consumption based on engine load and speed.

02 Electronic control unit (ECU) enhancements

Enhancing the ECU capabilities of the LM7 engine can lead to improved power output. This includes upgrading the ECU software, implementing more sophisticated mapping techniques, and integrating real-time sensor data for more precise fuel management and engine control.Expand Specific Solutions03 Fuel injection system improvements

Upgrading the fuel injection system of the LM7 engine can result in increased power output. This may involve using higher-pressure fuel injectors, implementing direct injection technology, or optimizing injector spray patterns for more efficient fuel atomization and combustion.Expand Specific Solutions04 Turbocharging and forced induction

Incorporating turbocharging or other forced induction methods can significantly boost the LM7 engine's power output. This involves optimizing the fuel management system to work in conjunction with the increased air intake, adjusting fuel delivery to match the higher air pressure, and fine-tuning the engine's overall performance.Expand Specific Solutions05 Sensor technology and data integration

Implementing advanced sensor technology and integrating real-time data can enhance the LM7 engine's fuel management system and power output. This includes using more accurate oxygen sensors, mass airflow sensors, and temperature sensors to provide precise feedback for optimal fuel delivery and engine performance.Expand Specific Solutions

Key Industry Players

The LM7 engine fuel management and its impact on power output represents a mature technology within the automotive industry, currently in a phase of incremental improvements. The market for this technology is substantial, driven by the global demand for efficient and powerful engines. Major players like Toyota, Honda, GM, and Hyundai are actively involved in refining fuel management systems to optimize power output. The technology's maturity is evident in the widespread adoption across various vehicle segments, with companies like Bosch and Denso providing advanced fuel injection systems. Continuous research and development efforts by these companies focus on enhancing fuel efficiency and power delivery, indicating a competitive landscape where marginal gains can lead to significant market advantages.

Toyota Motor Corp.

Technical Solution: Toyota's approach to LM7 engine fuel management centers around their D-4S (Direct injection 4-stroke gasoline engine Superior version) technology. This system combines both direct and port fuel injection, allowing for optimal fuel delivery across all engine speeds and loads. At low RPMs, the port injection system provides better fuel atomization and smoother operation, while at higher RPMs, the direct injection takes over for improved power and efficiency[11]. Toyota has also implemented an advanced air-fuel ratio control system that uses wide-range oxygen sensors to maintain the ideal mixture under various driving conditions. The company's fuel management system is integrated with their hybrid drive technology, allowing for seamless transitions between electric and gasoline power, further optimizing fuel consumption and power output[12]. Additionally, Toyota has developed a unique heat management system that rapidly warms the engine to its optimal operating temperature, reducing fuel consumption during cold starts[13].

Strengths: Dual injection system provides flexibility across all engine speeds, excellent integration with hybrid technology, and advanced thermal management. Weaknesses: Increased system complexity may lead to higher production and maintenance costs.

GM Global Technology Operations LLC

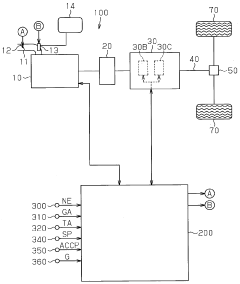

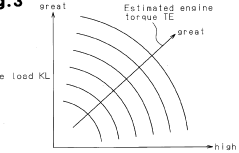

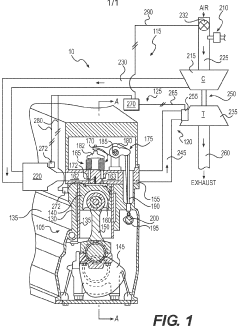

Technical Solution: GM's LM7 engine fuel management system employs advanced electronic control units (ECUs) and sophisticated algorithms to optimize fuel injection timing and quantity. The system utilizes multiple sensors to monitor engine parameters such as throttle position, air intake, and exhaust gas composition. This data is processed in real-time to adjust fuel delivery for maximum efficiency and power output. GM has implemented a direct injection system in newer LM7 variants, which allows for more precise fuel control and improved atomization[1]. The company has also integrated variable valve timing technology, enabling dynamic adjustment of valve operation to enhance power across different RPM ranges[3].

Strengths: Precise fuel control, improved fuel efficiency, and enhanced power output across a wide RPM range. Weaknesses: Complexity of the system may lead to higher maintenance costs and potential reliability issues in the long term.

Innovative Fuel Technologies

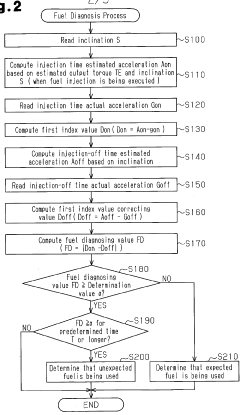

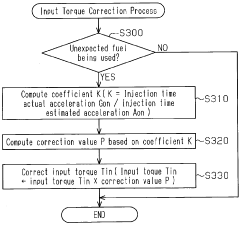

Engine fuel diagnosis device and control apparatus for automatic transmission having the device

PatentWO2010013722A1

Innovation

- An engine fuel diagnosis device that includes an inclination detection section, a first estimating section, and a diagnosing section to detect the usage state of unexpected fuels by computing the deviation between estimated and actual vehicle accelerations, allowing for correction of input torque calculations and hydraulic pressure adjustments.

Engine control system having emissions-based adjustment

PatentWO2010062460A1

Innovation

- An engine control system that includes sensors to measure combustion pressure within the cylinders, a controller to determine NOx production based on these measurements, and adjusts the air/fuel ratio to regulate NOx emissions, using in-cylinder sensors to provide accurate and reliable data for NOx estimation and control.

Emissions Regulations Impact

Emissions regulations have significantly impacted the development and performance of the LM7 engine's fuel management system, consequently affecting its power output. These regulations, primarily aimed at reducing harmful emissions and improving air quality, have necessitated substantial changes in engine design and operation.

The introduction of stricter emissions standards, such as Euro 6 in Europe and Tier 3 in the United States, has forced manufacturers to implement more sophisticated fuel management systems. These systems must balance the conflicting demands of power output and emissions control, often leading to compromises in engine performance.

One of the primary ways emissions regulations have influenced the LM7 engine is through the implementation of more precise fuel injection systems. These systems allow for better control over the air-fuel mixture, resulting in more complete combustion and reduced emissions. However, this can sometimes come at the cost of reduced power output, as the engine may run leaner mixtures to meet emissions targets.

The use of exhaust gas recirculation (EGR) systems, mandated by emissions regulations, has also impacted the LM7 engine's fuel management and power output. EGR systems reduce nitrogen oxide emissions by recirculating a portion of the exhaust gas back into the combustion chamber. While effective at reducing emissions, this can lead to a slight decrease in engine efficiency and power output.

Catalytic converters, another key component required by emissions regulations, create back pressure in the exhaust system. This back pressure can negatively affect engine performance, particularly at high RPMs, potentially reducing the LM7 engine's maximum power output.

The need to meet emissions standards has also led to the adoption of more advanced engine control units (ECUs) in the LM7 engine. These ECUs continuously monitor and adjust various engine parameters to optimize performance while staying within emissions limits. While this technology allows for more efficient operation, it can sometimes prioritize emissions control over maximum power output.

Furthermore, emissions regulations have influenced the development of fuel formulations. The requirement for cleaner-burning fuels has led to changes in fuel composition, which can affect the LM7 engine's performance and power output. For instance, the increased use of ethanol in gasoline can impact fuel economy and potentially alter the engine's power characteristics.

In conclusion, while emissions regulations have undoubtedly led to cleaner and more efficient LM7 engines, they have also presented challenges in maintaining high power outputs. The ongoing challenge for engineers is to continue improving fuel management systems that can meet increasingly stringent emissions standards while still delivering the performance expected from the LM7 engine.

The introduction of stricter emissions standards, such as Euro 6 in Europe and Tier 3 in the United States, has forced manufacturers to implement more sophisticated fuel management systems. These systems must balance the conflicting demands of power output and emissions control, often leading to compromises in engine performance.

One of the primary ways emissions regulations have influenced the LM7 engine is through the implementation of more precise fuel injection systems. These systems allow for better control over the air-fuel mixture, resulting in more complete combustion and reduced emissions. However, this can sometimes come at the cost of reduced power output, as the engine may run leaner mixtures to meet emissions targets.

The use of exhaust gas recirculation (EGR) systems, mandated by emissions regulations, has also impacted the LM7 engine's fuel management and power output. EGR systems reduce nitrogen oxide emissions by recirculating a portion of the exhaust gas back into the combustion chamber. While effective at reducing emissions, this can lead to a slight decrease in engine efficiency and power output.

Catalytic converters, another key component required by emissions regulations, create back pressure in the exhaust system. This back pressure can negatively affect engine performance, particularly at high RPMs, potentially reducing the LM7 engine's maximum power output.

The need to meet emissions standards has also led to the adoption of more advanced engine control units (ECUs) in the LM7 engine. These ECUs continuously monitor and adjust various engine parameters to optimize performance while staying within emissions limits. While this technology allows for more efficient operation, it can sometimes prioritize emissions control over maximum power output.

Furthermore, emissions regulations have influenced the development of fuel formulations. The requirement for cleaner-burning fuels has led to changes in fuel composition, which can affect the LM7 engine's performance and power output. For instance, the increased use of ethanol in gasoline can impact fuel economy and potentially alter the engine's power characteristics.

In conclusion, while emissions regulations have undoubtedly led to cleaner and more efficient LM7 engines, they have also presented challenges in maintaining high power outputs. The ongoing challenge for engineers is to continue improving fuel management systems that can meet increasingly stringent emissions standards while still delivering the performance expected from the LM7 engine.

Performance Tuning Trends

Performance tuning trends in LM7 engine fuel management have evolved significantly over the years, driven by the constant pursuit of increased power output and efficiency. One of the primary focuses has been on optimizing the fuel injection system to achieve more precise control over fuel delivery. Advanced electronic fuel injection systems have replaced older carburetor setups, allowing for real-time adjustments based on various engine parameters.

The trend towards higher compression ratios has necessitated improvements in fuel management to prevent detonation and maximize power. This has led to the development of sophisticated knock sensors and adaptive timing control systems. These technologies work in tandem with fuel management systems to optimize ignition timing and fuel delivery under varying operating conditions.

Another significant trend is the integration of forced induction systems, such as turbochargers and superchargers, with fuel management. This combination requires careful calibration of fuel maps to ensure proper air-fuel ratios across a wide range of boost pressures. Tuners have developed strategies to enrich fuel mixtures under high boost conditions to prevent engine damage while maintaining optimal power output.

The adoption of direct fuel injection technology has been a game-changer in LM7 engine performance tuning. This system allows for more precise fuel atomization and timing, resulting in improved combustion efficiency and power output. Tuners have focused on optimizing injection timing and duration to extract maximum performance while maintaining reliability.

Variable valve timing systems have also become increasingly prevalent, working in conjunction with fuel management to optimize engine breathing and fuel efficiency. This technology allows for dynamic adjustment of valve timing based on engine speed and load, requiring sophisticated fuel management strategies to maintain optimal air-fuel ratios across the entire operating range.

The trend towards ethanol-based fuels, particularly E85, has introduced new challenges and opportunities in fuel management tuning. These high-octane fuels allow for more aggressive timing and boost levels but require significant adjustments to fuel delivery due to their different stoichiometric ratios compared to gasoline.

Lastly, the rise of aftermarket engine management systems has revolutionized performance tuning. These programmable systems offer unprecedented control over fuel and ignition parameters, allowing tuners to fine-tune engine performance to a degree not possible with stock ECUs. This trend has led to the development of sophisticated tuning software and data logging tools, enabling more precise and data-driven approaches to optimizing LM7 engine performance.

The trend towards higher compression ratios has necessitated improvements in fuel management to prevent detonation and maximize power. This has led to the development of sophisticated knock sensors and adaptive timing control systems. These technologies work in tandem with fuel management systems to optimize ignition timing and fuel delivery under varying operating conditions.

Another significant trend is the integration of forced induction systems, such as turbochargers and superchargers, with fuel management. This combination requires careful calibration of fuel maps to ensure proper air-fuel ratios across a wide range of boost pressures. Tuners have developed strategies to enrich fuel mixtures under high boost conditions to prevent engine damage while maintaining optimal power output.

The adoption of direct fuel injection technology has been a game-changer in LM7 engine performance tuning. This system allows for more precise fuel atomization and timing, resulting in improved combustion efficiency and power output. Tuners have focused on optimizing injection timing and duration to extract maximum performance while maintaining reliability.

Variable valve timing systems have also become increasingly prevalent, working in conjunction with fuel management to optimize engine breathing and fuel efficiency. This technology allows for dynamic adjustment of valve timing based on engine speed and load, requiring sophisticated fuel management strategies to maintain optimal air-fuel ratios across the entire operating range.

The trend towards ethanol-based fuels, particularly E85, has introduced new challenges and opportunities in fuel management tuning. These high-octane fuels allow for more aggressive timing and boost levels but require significant adjustments to fuel delivery due to their different stoichiometric ratios compared to gasoline.

Lastly, the rise of aftermarket engine management systems has revolutionized performance tuning. These programmable systems offer unprecedented control over fuel and ignition parameters, allowing tuners to fine-tune engine performance to a degree not possible with stock ECUs. This trend has led to the development of sophisticated tuning software and data logging tools, enabling more precise and data-driven approaches to optimizing LM7 engine performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!