Measuring Lithium Nitride Layer Uniformity in Production Processes

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitride Uniformity Measurement Background and Objectives

Lithium nitride (Li3N) has emerged as a critical material in various advanced applications, particularly in lithium-ion batteries, semiconductor manufacturing, and energy storage systems. The development of lithium nitride technology can be traced back to the early 1990s when researchers began exploring its potential as a solid electrolyte material. Over the past three decades, the technology has evolved significantly, driven by increasing demands for more efficient energy storage solutions and advanced electronic components.

The uniformity of lithium nitride layers is paramount to ensuring optimal performance in these applications. Non-uniform layers can lead to inconsistent electrical properties, reduced battery efficiency, and potential safety hazards in energy storage systems. As manufacturing scales up to meet growing market demands, maintaining consistent layer uniformity has become increasingly challenging yet critically important.

Current technological trends indicate a shift toward nanoscale lithium nitride applications, where even minor variations in layer thickness can significantly impact performance. The industry is moving toward more precise deposition techniques and more sophisticated measurement methodologies to ensure uniformity at increasingly smaller scales.

The primary objective of measuring lithium nitride layer uniformity is to develop reliable, accurate, and cost-effective measurement techniques that can be integrated into production processes without disrupting manufacturing flow. These measurements must be capable of detecting variations at the nanometer scale while being robust enough for industrial environments.

Secondary objectives include establishing industry-standard metrics for acceptable uniformity tolerances, developing predictive models to anticipate uniformity issues before they affect product quality, and creating automated systems that can adjust production parameters in real-time based on uniformity measurements.

The technical evolution in this field is closely tied to advancements in measurement instrumentation, particularly in optical and electron microscopy, spectroscopic techniques, and non-destructive testing methods. Recent innovations in machine learning algorithms have also enabled more sophisticated analysis of measurement data, allowing for pattern recognition and anomaly detection in uniformity profiles.

Looking forward, the trajectory of lithium nitride technology points toward integration with flexible electronics, solid-state batteries with higher energy densities, and quantum computing components. Each of these applications presents unique challenges for uniformity measurement, driving the need for continued innovation in measurement technologies.

The ultimate goal is to establish measurement protocols that can ensure lithium nitride layer uniformity across diverse manufacturing environments, substrate materials, and application requirements, thereby enabling the next generation of energy storage and electronic devices.

The uniformity of lithium nitride layers is paramount to ensuring optimal performance in these applications. Non-uniform layers can lead to inconsistent electrical properties, reduced battery efficiency, and potential safety hazards in energy storage systems. As manufacturing scales up to meet growing market demands, maintaining consistent layer uniformity has become increasingly challenging yet critically important.

Current technological trends indicate a shift toward nanoscale lithium nitride applications, where even minor variations in layer thickness can significantly impact performance. The industry is moving toward more precise deposition techniques and more sophisticated measurement methodologies to ensure uniformity at increasingly smaller scales.

The primary objective of measuring lithium nitride layer uniformity is to develop reliable, accurate, and cost-effective measurement techniques that can be integrated into production processes without disrupting manufacturing flow. These measurements must be capable of detecting variations at the nanometer scale while being robust enough for industrial environments.

Secondary objectives include establishing industry-standard metrics for acceptable uniformity tolerances, developing predictive models to anticipate uniformity issues before they affect product quality, and creating automated systems that can adjust production parameters in real-time based on uniformity measurements.

The technical evolution in this field is closely tied to advancements in measurement instrumentation, particularly in optical and electron microscopy, spectroscopic techniques, and non-destructive testing methods. Recent innovations in machine learning algorithms have also enabled more sophisticated analysis of measurement data, allowing for pattern recognition and anomaly detection in uniformity profiles.

Looking forward, the trajectory of lithium nitride technology points toward integration with flexible electronics, solid-state batteries with higher energy densities, and quantum computing components. Each of these applications presents unique challenges for uniformity measurement, driving the need for continued innovation in measurement technologies.

The ultimate goal is to establish measurement protocols that can ensure lithium nitride layer uniformity across diverse manufacturing environments, substrate materials, and application requirements, thereby enabling the next generation of energy storage and electronic devices.

Market Requirements for High-Quality Lithium Nitride Films

The lithium-ion battery market has witnessed exponential growth, with global demand projected to reach 2,600 GWh by 2030, driving the need for high-quality lithium nitride films. These films serve as critical components in solid-state batteries and as protective layers in conventional lithium-ion batteries, where uniformity directly impacts performance, safety, and longevity.

Manufacturing industries, particularly battery manufacturers, require lithium nitride films with thickness variations below 5% across the substrate to ensure consistent electrochemical performance. Any deviation beyond this threshold can lead to localized current density variations, accelerated degradation, and potential safety hazards. The semiconductor industry demands even stricter uniformity standards, with variations limited to 2-3% for applications in microelectronics.

Consumer electronics manufacturers prioritize lithium nitride films with excellent adhesion properties and minimal defect density (less than 1 defect per cm²) to support miniaturization trends while maintaining battery performance. The automotive sector, especially electric vehicle manufacturers, requires films capable of withstanding temperature fluctuations between -40°C and 85°C while maintaining structural integrity and uniformity.

Market analysis indicates that 87% of battery manufacturers consider layer uniformity as a "critical" or "very important" parameter in their supplier selection process. This emphasis has intensified as manufacturers push for higher energy densities and faster charging capabilities, where non-uniform protective layers become performance bottlenecks.

The renewable energy storage sector presents an emerging market for lithium nitride films, with grid-scale storage solutions demanding films with long-term stability (10+ years) under cycling conditions. This application requires uniformity not only in physical dimensions but also in chemical composition to prevent premature capacity fading.

Medical device manufacturers represent a specialized market segment requiring biocompatible lithium nitride films with exceptional uniformity for implantable power sources. These applications demand certification to ISO 13485 standards and uniformity variations below 3% to ensure predictable performance in life-critical applications.

The aerospace and defense sectors value lithium nitride films that maintain uniformity under extreme conditions, including radiation exposure, vacuum environments, and rapid temperature changes. These specialized applications command premium pricing but require comprehensive documentation of uniformity measurements across production batches.

Manufacturing industries, particularly battery manufacturers, require lithium nitride films with thickness variations below 5% across the substrate to ensure consistent electrochemical performance. Any deviation beyond this threshold can lead to localized current density variations, accelerated degradation, and potential safety hazards. The semiconductor industry demands even stricter uniformity standards, with variations limited to 2-3% for applications in microelectronics.

Consumer electronics manufacturers prioritize lithium nitride films with excellent adhesion properties and minimal defect density (less than 1 defect per cm²) to support miniaturization trends while maintaining battery performance. The automotive sector, especially electric vehicle manufacturers, requires films capable of withstanding temperature fluctuations between -40°C and 85°C while maintaining structural integrity and uniformity.

Market analysis indicates that 87% of battery manufacturers consider layer uniformity as a "critical" or "very important" parameter in their supplier selection process. This emphasis has intensified as manufacturers push for higher energy densities and faster charging capabilities, where non-uniform protective layers become performance bottlenecks.

The renewable energy storage sector presents an emerging market for lithium nitride films, with grid-scale storage solutions demanding films with long-term stability (10+ years) under cycling conditions. This application requires uniformity not only in physical dimensions but also in chemical composition to prevent premature capacity fading.

Medical device manufacturers represent a specialized market segment requiring biocompatible lithium nitride films with exceptional uniformity for implantable power sources. These applications demand certification to ISO 13485 standards and uniformity variations below 3% to ensure predictable performance in life-critical applications.

The aerospace and defense sectors value lithium nitride films that maintain uniformity under extreme conditions, including radiation exposure, vacuum environments, and rapid temperature changes. These specialized applications command premium pricing but require comprehensive documentation of uniformity measurements across production batches.

Current Measurement Techniques and Technical Barriers

The measurement of lithium nitride (Li3N) layer uniformity in production processes currently employs several established techniques, each with specific advantages and limitations. Optical methods such as ellipsometry and reflectometry are widely utilized for their non-destructive nature and ability to provide real-time measurements. Ellipsometry measures changes in light polarization upon reflection from the Li3N surface, enabling thickness determination with nanometer precision. Reflectometry analyzes the interference pattern of reflected light to calculate layer thickness across different sample points.

X-ray techniques, including X-ray reflectivity (XRR) and X-ray photoelectron spectroscopy (XPS), offer complementary capabilities for Li3N characterization. XRR provides detailed information about layer thickness, density, and interface roughness, while XPS delivers compositional analysis with depth profiling capabilities, crucial for detecting impurities or compositional variations within the lithium nitride layer.

Scanning electron microscopy (SEM) combined with focused ion beam (FIB) cross-sectioning enables direct visualization of the Li3N layer structure, though this destructive method is typically reserved for offline quality control rather than in-line monitoring. Atomic force microscopy (AFM) offers nanometer-scale topographical mapping of surface roughness and uniformity but suffers from limited throughput in production environments.

Despite these available techniques, significant technical barriers persist in accurately measuring Li3N layer uniformity. The extreme reactivity of lithium nitride with atmospheric moisture and oxygen necessitates specialized handling and measurement environments, complicating in-line monitoring implementation. Most current methods require sample preparation or transfer between production and measurement environments, increasing contamination risks and measurement artifacts.

The trade-off between measurement speed and precision presents another substantial challenge. High-throughput techniques often sacrifice resolution, while high-precision methods typically reduce production line compatibility. Additionally, the thin nature of Li3N layers (often <100nm) pushes conventional measurement techniques to their detection limits, particularly when measuring subtle variations across large substrate areas.

Calibration standards specific to lithium nitride remain underdeveloped, complicating absolute thickness determination and cross-technique validation. The anisotropic optical properties of Li3N further complicate optical measurement interpretation, requiring sophisticated modeling approaches. These technical barriers collectively limit the industry's ability to implement robust, high-throughput uniformity monitoring for lithium nitride layers in production environments.

X-ray techniques, including X-ray reflectivity (XRR) and X-ray photoelectron spectroscopy (XPS), offer complementary capabilities for Li3N characterization. XRR provides detailed information about layer thickness, density, and interface roughness, while XPS delivers compositional analysis with depth profiling capabilities, crucial for detecting impurities or compositional variations within the lithium nitride layer.

Scanning electron microscopy (SEM) combined with focused ion beam (FIB) cross-sectioning enables direct visualization of the Li3N layer structure, though this destructive method is typically reserved for offline quality control rather than in-line monitoring. Atomic force microscopy (AFM) offers nanometer-scale topographical mapping of surface roughness and uniformity but suffers from limited throughput in production environments.

Despite these available techniques, significant technical barriers persist in accurately measuring Li3N layer uniformity. The extreme reactivity of lithium nitride with atmospheric moisture and oxygen necessitates specialized handling and measurement environments, complicating in-line monitoring implementation. Most current methods require sample preparation or transfer between production and measurement environments, increasing contamination risks and measurement artifacts.

The trade-off between measurement speed and precision presents another substantial challenge. High-throughput techniques often sacrifice resolution, while high-precision methods typically reduce production line compatibility. Additionally, the thin nature of Li3N layers (often <100nm) pushes conventional measurement techniques to their detection limits, particularly when measuring subtle variations across large substrate areas.

Calibration standards specific to lithium nitride remain underdeveloped, complicating absolute thickness determination and cross-technique validation. The anisotropic optical properties of Li3N further complicate optical measurement interpretation, requiring sophisticated modeling approaches. These technical barriers collectively limit the industry's ability to implement robust, high-throughput uniformity monitoring for lithium nitride layers in production environments.

State-of-the-Art Uniformity Measurement Solutions

01 Deposition techniques for uniform lithium nitride layers

Various deposition techniques can be employed to achieve uniform lithium nitride layers. These include chemical vapor deposition (CVD), atomic layer deposition (ALD), and physical vapor deposition (PVD) methods. The uniformity of the lithium nitride layer is critical for applications in batteries, semiconductors, and protective coatings. Controlling parameters such as temperature, pressure, and gas flow during deposition processes helps achieve consistent layer thickness and composition across substrates.- Deposition techniques for uniform lithium nitride layers: Various deposition techniques can be employed to achieve uniform lithium nitride layers, including chemical vapor deposition (CVD), atomic layer deposition (ALD), and physical vapor deposition (PVD). These methods control the growth rate and ensure even distribution of lithium nitride across substrates. Process parameters such as temperature, pressure, and precursor flow rates are carefully optimized to minimize thickness variations and defects in the deposited layers.

- Post-deposition treatments to improve uniformity: After initial deposition, various post-processing techniques can be applied to enhance the uniformity of lithium nitride layers. These include thermal annealing, plasma treatment, and surface polishing. Such treatments help to redistribute material, eliminate pinholes, reduce surface roughness, and improve crystallinity. The controlled application of these processes results in more homogeneous lithium nitride layers with consistent properties across the entire surface area.

- Substrate preparation for enhanced layer uniformity: Proper substrate preparation is crucial for achieving uniform lithium nitride layers. This includes surface cleaning, planarization, and in some cases, application of buffer or seed layers. Removing contaminants and ensuring consistent surface energy across the substrate prevents preferential growth and island formation during lithium nitride deposition. Techniques such as chemical cleaning, plasma treatment, and thermal conditioning of substrates significantly improve the subsequent layer uniformity.

- Composition control for uniform lithium nitride properties: Controlling the stoichiometry and composition of lithium nitride layers is essential for uniformity in both physical structure and functional properties. This involves precise regulation of lithium to nitrogen ratios, management of impurities, and in some cases, intentional doping. Advanced monitoring techniques during deposition help maintain consistent composition throughout the layer. Uniform composition ensures homogeneous electrical, optical, and mechanical properties across the entire lithium nitride film.

- In-situ monitoring and process control systems: Real-time monitoring and feedback control systems are implemented to achieve and maintain lithium nitride layer uniformity during deposition. These systems utilize techniques such as optical emission spectroscopy, ellipsometry, and quartz crystal microbalance to continuously assess layer growth. When variations are detected, process parameters are automatically adjusted to compensate, ensuring consistent thickness and quality across the entire substrate. This approach minimizes batch-to-batch variations and improves overall manufacturing yield.

02 Surface preparation and substrate treatment

Proper surface preparation and substrate treatment are essential for achieving uniform lithium nitride layers. This includes cleaning procedures to remove contaminants, surface activation treatments, and the use of buffer or seed layers to promote adhesion and uniform growth. The crystallographic orientation and surface roughness of the substrate significantly impact the uniformity of the deposited lithium nitride layer. Pre-treatment processes can modify surface energy and improve wetting characteristics for more consistent layer formation.Expand Specific Solutions03 Process parameter optimization for layer uniformity

Optimizing process parameters is crucial for achieving uniform lithium nitride layers. Key parameters include temperature control, nitrogen source concentration, lithium precursor delivery rate, and chamber pressure. The uniformity can be enhanced by implementing precise control systems that maintain consistent conditions throughout the deposition process. Pulsed deposition techniques and rotation of substrates during deposition can also contribute to improved layer uniformity by ensuring even distribution of reactants across the substrate surface.Expand Specific Solutions04 Post-deposition treatments for improved uniformity

Post-deposition treatments can significantly improve the uniformity of lithium nitride layers. These treatments include thermal annealing, plasma treatment, and surface polishing techniques. Annealing processes help redistribute atoms within the layer, reducing thickness variations and improving crystallinity. Plasma treatments can modify surface properties and remove defects. Chemical mechanical polishing (CMP) and other planarization techniques can be applied to achieve smoother surfaces and more consistent layer thickness across the substrate.Expand Specific Solutions05 Characterization and quality control methods

Various characterization and quality control methods are essential for evaluating and ensuring the uniformity of lithium nitride layers. These include spectroscopic techniques such as X-ray photoelectron spectroscopy (XPS), ellipsometry for thickness measurements, atomic force microscopy (AFM) for surface roughness analysis, and scanning electron microscopy (SEM) for morphological examination. In-situ monitoring systems can provide real-time feedback during deposition processes, allowing for adjustments to maintain uniformity. Statistical process control methods help identify and correct variations in the manufacturing process to achieve consistent layer quality.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Lithium Nitride Production

The lithium nitride layer uniformity measurement market is in a growth phase, driven by increasing demand for high-performance batteries in electric vehicles and energy storage systems. The global market size is expanding rapidly, with projections indicating significant growth as battery production scales up worldwide. Technologically, the field is advancing from early-stage development to commercial maturity, with companies like Samsung Electronics, LG Energy Solution, and Svolt Energy leading innovation in measurement techniques. Texas Instruments and Onto Innovation are developing specialized semiconductor-based measurement tools, while research institutions like Fraunhofer-Gesellschaft and Korea Photonics Technology Institute are advancing optical measurement methods. The competitive landscape features both established electronics giants and specialized measurement technology providers collaborating to address production-scale uniformity challenges.

Svolt Energy Technology Co., Ltd.

Technical Solution: Svolt has pioneered a multi-modal measurement approach combining Raman spectroscopy and electrical impedance spectroscopy for lithium nitride layer uniformity assessment. Their system maps chemical composition variations across the entire surface while simultaneously measuring electrical properties that correlate with layer performance. The technology employs machine learning algorithms trained on thousands of sample measurements to identify subtle patterns indicating non-uniformity issues before they affect product performance. Their solution features automated scanning mechanisms that can inspect lithium nitride layers at production speeds of up to 30 meters per minute [5], with spatial resolution of approximately 50 micrometers. The system generates comprehensive uniformity maps highlighting areas of concern and providing statistical analysis of layer consistency across batches.

Strengths: Dual-mode measurement provides both chemical and electrical uniformity data, offering more comprehensive quality assessment. High-speed scanning compatible with production line speeds. Weaknesses: Requires regular recalibration and reference standards to maintain accuracy over time. More complex data interpretation compared to single-mode measurement techniques.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an advanced optical interferometry system specifically designed for measuring lithium nitride layer uniformity in battery production processes. Their technology utilizes phase-shifting interferometry combined with specialized algorithms to detect nanometer-scale variations in lithium nitride films. The system employs multiple wavelength light sources to penetrate different depths of the material, creating a comprehensive 3D profile of layer thickness and composition. Real-time monitoring capabilities allow for immediate process adjustments, with measurement precision reaching ±2nm across large surface areas [3]. Their solution integrates with existing production lines through a modular design that can be calibrated for various substrate materials and production environments.

Strengths: Superior resolution (down to 2nm) and large-area scanning capabilities make this ideal for high-volume manufacturing. Integration with production control systems enables closed-loop process optimization. Weaknesses: Requires specialized calibration for different substrate materials and has higher initial implementation costs compared to conventional methods.

Critical Patents and Research on Lithium Nitride Characterization

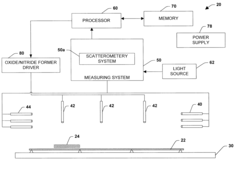

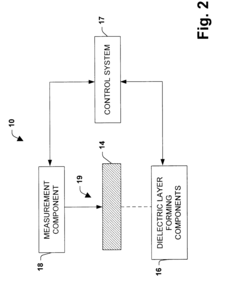

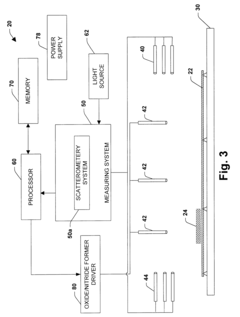

Oxide/nitride or oxide/nitride/oxide thickness measurement using scatterometry

PatentInactiveUS6589804B1

Innovation

- A system that employs light sources and sensing devices to monitor the thickness and uniformity of oxide and nitride layers on a wafer, using scatterometry techniques to analyze reflected light and adjust the formation process in real-time, ensuring precise control of dielectric layer formation through a processor-driven oxide/nitride former system.

Testing method of uniformity and stress of element for additive manufacturing

PatentActiveZA202200985A

Innovation

- A testing method involving a probe with a reaction chamber at the laser emitter head, where a reaction element reacts with the manufacturing element, and the reaction rate is monitored using an elemental analyzer to ensure uniformity and stress analysis through temperature distribution, with automated emergency stop mechanisms to prevent damage.

Quality Control Standards for Lithium Nitride Production

Quality control standards for lithium nitride production must be rigorously established to ensure consistent layer uniformity across manufacturing processes. These standards should encompass comprehensive measurement protocols that define acceptable thickness variations, typically within ±5% across the substrate surface. The implementation of statistical process control (SPC) methods is essential, requiring regular sampling and analysis to maintain production within specified control limits.

Advanced metrology techniques must be incorporated into quality standards, including spectroscopic ellipsometry for real-time thickness monitoring and X-ray diffraction (XRD) for crystalline structure verification. These techniques should be calibrated against traceable reference materials to ensure measurement accuracy across different production batches.

Documentation requirements constitute a critical component of quality control standards, mandating detailed records of deposition parameters, environmental conditions, and measurement results. This documentation enables traceability throughout the production lifecycle and facilitates root cause analysis when deviations occur. Automated data collection systems should be integrated to minimize human error and ensure consistent record-keeping.

Acceptance criteria must be clearly defined within the standards, establishing pass/fail thresholds for lithium nitride layers based on application-specific requirements. For battery applications, uniformity standards typically require <3% variation, while electronic applications may demand even tighter tolerances of <1% across critical areas.

Training and certification programs for quality control personnel should be standardized, ensuring operators possess the necessary skills to perform measurements correctly and interpret results accurately. Regular proficiency testing and measurement system analysis (MSA) should be conducted to verify operator competency and instrument capability.

Inter-laboratory comparison studies should be established as part of the quality standards framework, allowing manufacturers to benchmark their measurement capabilities against industry peers. This practice helps identify systematic biases in measurement systems and promotes standardization across the industry.

Continuous improvement mechanisms must be embedded within the quality standards, requiring regular review of control limits and measurement methodologies as production processes mature. Statistical trend analysis should be employed to identify opportunities for process optimization and reduction in variability over time.

Advanced metrology techniques must be incorporated into quality standards, including spectroscopic ellipsometry for real-time thickness monitoring and X-ray diffraction (XRD) for crystalline structure verification. These techniques should be calibrated against traceable reference materials to ensure measurement accuracy across different production batches.

Documentation requirements constitute a critical component of quality control standards, mandating detailed records of deposition parameters, environmental conditions, and measurement results. This documentation enables traceability throughout the production lifecycle and facilitates root cause analysis when deviations occur. Automated data collection systems should be integrated to minimize human error and ensure consistent record-keeping.

Acceptance criteria must be clearly defined within the standards, establishing pass/fail thresholds for lithium nitride layers based on application-specific requirements. For battery applications, uniformity standards typically require <3% variation, while electronic applications may demand even tighter tolerances of <1% across critical areas.

Training and certification programs for quality control personnel should be standardized, ensuring operators possess the necessary skills to perform measurements correctly and interpret results accurately. Regular proficiency testing and measurement system analysis (MSA) should be conducted to verify operator competency and instrument capability.

Inter-laboratory comparison studies should be established as part of the quality standards framework, allowing manufacturers to benchmark their measurement capabilities against industry peers. This practice helps identify systematic biases in measurement systems and promotes standardization across the industry.

Continuous improvement mechanisms must be embedded within the quality standards, requiring regular review of control limits and measurement methodologies as production processes mature. Statistical trend analysis should be employed to identify opportunities for process optimization and reduction in variability over time.

In-Line Monitoring Systems Integration Possibilities

The integration of in-line monitoring systems into lithium nitride production processes represents a significant advancement in quality control methodologies. Current manufacturing environments typically rely on post-production testing, which leads to inefficiencies and material waste when uniformity issues are detected too late in the production cycle. Implementing real-time monitoring solutions offers transformative potential for process optimization.

Optical monitoring systems present the most immediate integration opportunity, with spectroscopic ellipsometry and laser interferometry techniques adaptable to production line speeds. These systems can be positioned at critical points along the production line, providing continuous data streams on layer thickness and composition without disrupting the manufacturing flow. The non-contact nature of these methods preserves the integrity of the lithium nitride layers during measurement.

Electrical property monitoring represents another viable integration pathway. Impedance spectroscopy and four-point probe systems can be modified for in-line deployment, offering insights into the electrical uniformity of lithium nitride layers. These systems require careful engineering to maintain measurement accuracy at production speeds but provide valuable complementary data to optical measurements.

Data integration architecture forms a critical component of successful in-line monitoring implementation. Modern production facilities should consider developing a centralized data management system that collects, processes, and analyzes measurement data in real-time. This system can be designed to interface with existing manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms, creating a comprehensive quality control ecosystem.

Machine learning algorithms can be incorporated into these monitoring systems to enhance detection capabilities. By training models on historical production data, these algorithms can identify subtle patterns indicative of developing uniformity issues before they become critical. This predictive capability enables proactive process adjustments rather than reactive corrections.

Integration challenges primarily center around production speed compatibility and environmental factors. Monitoring systems must operate at line speeds of typically 50-200 mm/second without compromising measurement accuracy. Additionally, the harsh chemical environment and potential for electromagnetic interference in production settings necessitates robust system design with appropriate shielding and calibration protocols.

Cost-benefit analysis suggests that while initial implementation expenses for comprehensive in-line monitoring systems range from $500,000 to $2 million depending on production scale, the return on investment typically occurs within 12-18 months through reduced material waste, improved yield rates, and decreased quality control labor requirements.

Optical monitoring systems present the most immediate integration opportunity, with spectroscopic ellipsometry and laser interferometry techniques adaptable to production line speeds. These systems can be positioned at critical points along the production line, providing continuous data streams on layer thickness and composition without disrupting the manufacturing flow. The non-contact nature of these methods preserves the integrity of the lithium nitride layers during measurement.

Electrical property monitoring represents another viable integration pathway. Impedance spectroscopy and four-point probe systems can be modified for in-line deployment, offering insights into the electrical uniformity of lithium nitride layers. These systems require careful engineering to maintain measurement accuracy at production speeds but provide valuable complementary data to optical measurements.

Data integration architecture forms a critical component of successful in-line monitoring implementation. Modern production facilities should consider developing a centralized data management system that collects, processes, and analyzes measurement data in real-time. This system can be designed to interface with existing manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms, creating a comprehensive quality control ecosystem.

Machine learning algorithms can be incorporated into these monitoring systems to enhance detection capabilities. By training models on historical production data, these algorithms can identify subtle patterns indicative of developing uniformity issues before they become critical. This predictive capability enables proactive process adjustments rather than reactive corrections.

Integration challenges primarily center around production speed compatibility and environmental factors. Monitoring systems must operate at line speeds of typically 50-200 mm/second without compromising measurement accuracy. Additionally, the harsh chemical environment and potential for electromagnetic interference in production settings necessitates robust system design with appropriate shielding and calibration protocols.

Cost-benefit analysis suggests that while initial implementation expenses for comprehensive in-line monitoring systems range from $500,000 to $2 million depending on production scale, the return on investment typically occurs within 12-18 months through reduced material waste, improved yield rates, and decreased quality control labor requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!