PETG in Low-Temperature Environments: Material Performance Analysis

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG Low-Temp Background

Polyethylene terephthalate glycol (PETG) has emerged as a versatile thermoplastic polymer with a wide range of applications across various industries. Its unique properties, including high impact strength, clarity, and chemical resistance, have made it a popular choice for packaging, medical devices, and 3D printing. However, the performance of PETG in low-temperature environments has become a subject of increasing interest and concern.

The study of PETG's behavior in cold conditions is crucial for expanding its potential applications and ensuring its reliability in diverse environmental settings. Low-temperature environments can significantly affect the mechanical and physical properties of polymers, potentially leading to brittleness, reduced impact resistance, and dimensional instability. Understanding these effects on PETG is essential for engineers, designers, and manufacturers who seek to utilize this material in products exposed to cold climates or refrigerated conditions.

Recent advancements in polymer science have focused on enhancing the low-temperature performance of thermoplastics, including PETG. Researchers have been exploring various strategies, such as the incorporation of additives, modification of molecular structure, and development of composite materials, to improve the material's cold weather resistance. These efforts aim to extend PETG's usability in applications ranging from outdoor signage and automotive components to cold chain packaging and aerospace parts.

The growing demand for materials that can withstand extreme temperatures has driven the need for comprehensive analysis of PETG's performance in low-temperature environments. This includes investigating its glass transition temperature, impact strength, tensile properties, and dimensional stability under cold conditions. Such studies are critical for predicting the material's behavior and ensuring its suitability for specific applications in challenging thermal environments.

Furthermore, the analysis of PETG's low-temperature performance is closely tied to sustainability concerns. As industries strive to reduce their environmental impact, understanding the durability and longevity of materials in various conditions becomes paramount. By optimizing PETG's cold weather performance, manufacturers can potentially extend product lifespans, reduce material waste, and improve overall sustainability in applications where low-temperature resistance is crucial.

In light of these considerations, a thorough examination of PETG's behavior in low-temperature environments is not only scientifically intriguing but also commercially significant. This analysis will provide valuable insights for material scientists, product developers, and end-users, enabling them to make informed decisions about the use of PETG in cold-weather applications and guiding future research and development efforts in this field.

The study of PETG's behavior in cold conditions is crucial for expanding its potential applications and ensuring its reliability in diverse environmental settings. Low-temperature environments can significantly affect the mechanical and physical properties of polymers, potentially leading to brittleness, reduced impact resistance, and dimensional instability. Understanding these effects on PETG is essential for engineers, designers, and manufacturers who seek to utilize this material in products exposed to cold climates or refrigerated conditions.

Recent advancements in polymer science have focused on enhancing the low-temperature performance of thermoplastics, including PETG. Researchers have been exploring various strategies, such as the incorporation of additives, modification of molecular structure, and development of composite materials, to improve the material's cold weather resistance. These efforts aim to extend PETG's usability in applications ranging from outdoor signage and automotive components to cold chain packaging and aerospace parts.

The growing demand for materials that can withstand extreme temperatures has driven the need for comprehensive analysis of PETG's performance in low-temperature environments. This includes investigating its glass transition temperature, impact strength, tensile properties, and dimensional stability under cold conditions. Such studies are critical for predicting the material's behavior and ensuring its suitability for specific applications in challenging thermal environments.

Furthermore, the analysis of PETG's low-temperature performance is closely tied to sustainability concerns. As industries strive to reduce their environmental impact, understanding the durability and longevity of materials in various conditions becomes paramount. By optimizing PETG's cold weather performance, manufacturers can potentially extend product lifespans, reduce material waste, and improve overall sustainability in applications where low-temperature resistance is crucial.

In light of these considerations, a thorough examination of PETG's behavior in low-temperature environments is not only scientifically intriguing but also commercially significant. This analysis will provide valuable insights for material scientists, product developers, and end-users, enabling them to make informed decisions about the use of PETG in cold-weather applications and guiding future research and development efforts in this field.

Market Demand Analysis

The market demand for PETG (Polyethylene Terephthalate Glycol) in low-temperature environments has been steadily increasing across various industries. This growth is primarily driven by the material's unique properties that make it suitable for applications where traditional plastics may fail or underperform in cold conditions.

In the packaging industry, there is a significant demand for PETG in cold chain logistics and refrigerated storage solutions. The material's excellent impact resistance and clarity at low temperatures make it ideal for food and pharmaceutical packaging that requires refrigeration or freezing. The global cold chain market, which heavily relies on such materials, is projected to grow substantially in the coming years, further boosting the demand for PETG.

The automotive sector represents another key market for PETG in low-temperature environments. As electric vehicles gain popularity, there is an increasing need for materials that can withstand extreme temperature fluctuations, particularly in battery components and cooling systems. PETG's thermal stability and chemical resistance make it a preferred choice for these applications, driving demand in the automotive industry.

In the construction and building materials sector, PETG is gaining traction for its performance in cold climates. Its ability to maintain flexibility and strength in sub-zero temperatures makes it suitable for outdoor signage, roofing materials, and insulation components. The growing focus on energy-efficient buildings in colder regions is expected to fuel the demand for PETG-based products in this sector.

The medical and healthcare industry also contributes significantly to the market demand for PETG in low-temperature applications. The material's compatibility with sterilization processes and its ability to maintain integrity in cold storage make it valuable for medical device components, laboratory equipment, and cryogenic storage containers. As the healthcare sector continues to expand globally, the demand for PETG in these applications is anticipated to rise.

Additionally, the aerospace and defense industries are exploring PETG for its performance in extreme cold environments. Its use in aircraft components, satellite parts, and military equipment operating in arctic conditions is driving research and development efforts, potentially opening new market opportunities.

The outdoor recreation and sports equipment market also shows promising growth potential for PETG in low-temperature applications. From ski goggles to camping gear, manufacturers are leveraging PETG's durability and impact resistance in cold weather to develop high-performance products.

As sustainability becomes increasingly important across industries, the recyclability of PETG adds to its market appeal. This factor is likely to drive further adoption in environmentally conscious markets, particularly as regulations around plastic use and recycling become more stringent.

In the packaging industry, there is a significant demand for PETG in cold chain logistics and refrigerated storage solutions. The material's excellent impact resistance and clarity at low temperatures make it ideal for food and pharmaceutical packaging that requires refrigeration or freezing. The global cold chain market, which heavily relies on such materials, is projected to grow substantially in the coming years, further boosting the demand for PETG.

The automotive sector represents another key market for PETG in low-temperature environments. As electric vehicles gain popularity, there is an increasing need for materials that can withstand extreme temperature fluctuations, particularly in battery components and cooling systems. PETG's thermal stability and chemical resistance make it a preferred choice for these applications, driving demand in the automotive industry.

In the construction and building materials sector, PETG is gaining traction for its performance in cold climates. Its ability to maintain flexibility and strength in sub-zero temperatures makes it suitable for outdoor signage, roofing materials, and insulation components. The growing focus on energy-efficient buildings in colder regions is expected to fuel the demand for PETG-based products in this sector.

The medical and healthcare industry also contributes significantly to the market demand for PETG in low-temperature applications. The material's compatibility with sterilization processes and its ability to maintain integrity in cold storage make it valuable for medical device components, laboratory equipment, and cryogenic storage containers. As the healthcare sector continues to expand globally, the demand for PETG in these applications is anticipated to rise.

Additionally, the aerospace and defense industries are exploring PETG for its performance in extreme cold environments. Its use in aircraft components, satellite parts, and military equipment operating in arctic conditions is driving research and development efforts, potentially opening new market opportunities.

The outdoor recreation and sports equipment market also shows promising growth potential for PETG in low-temperature applications. From ski goggles to camping gear, manufacturers are leveraging PETG's durability and impact resistance in cold weather to develop high-performance products.

As sustainability becomes increasingly important across industries, the recyclability of PETG adds to its market appeal. This factor is likely to drive further adoption in environmentally conscious markets, particularly as regulations around plastic use and recycling become more stringent.

Current Challenges

PETG (Polyethylene Terephthalate Glycol-modified) has gained significant attention in various industries due to its unique properties. However, its performance in low-temperature environments presents several challenges that require careful consideration and analysis.

One of the primary challenges faced by PETG in low-temperature conditions is its tendency to become brittle. As temperatures drop, the polymer chains in PETG become less flexible, leading to a reduction in impact strength and overall toughness. This brittleness can result in cracking or shattering when subjected to sudden impacts or stress, limiting its applicability in certain cold-weather applications.

Another significant challenge is the potential for dimensional instability. PETG, like many polymers, experiences thermal contraction when exposed to low temperatures. This contraction can lead to warping, shrinkage, or distortion of PETG components, potentially compromising their structural integrity and functionality. Maintaining precise dimensions and shapes in cold environments becomes a critical concern for engineers and designers working with PETG.

The glass transition temperature (Tg) of PETG also plays a crucial role in its low-temperature performance. While PETG generally has a lower Tg compared to some other thermoplastics, it still experiences a significant change in mechanical properties as it approaches and passes through its Tg. This transition can lead to alterations in stiffness, strength, and overall material behavior, which must be carefully accounted for in design and application considerations.

Moisture absorption is another challenge that becomes more pronounced in low-temperature environments. PETG, although less hygroscopic than some other polymers, can still absorb moisture from the surrounding environment. In cold conditions, this absorbed moisture can freeze, potentially causing internal stress and microcracking within the material. The freeze-thaw cycles that may occur in fluctuating temperature environments can exacerbate this issue, leading to accelerated degradation of the material over time.

The thermal conductivity of PETG also presents challenges in low-temperature applications. PETG, like most polymers, has relatively low thermal conductivity. In cold environments, this property can lead to thermal gradients within the material, potentially causing uneven stress distribution and localized areas of brittleness. Managing these thermal gradients becomes crucial for maintaining the overall integrity and performance of PETG components in cold conditions.

Lastly, the processing and fabrication of PETG for low-temperature applications pose additional challenges. The material's behavior during molding, extrusion, or other forming processes can be significantly affected by the intended operating temperature. Achieving optimal crystallinity, molecular orientation, and residual stress levels that will perform well in cold environments requires careful control of processing parameters and potentially specialized techniques.

One of the primary challenges faced by PETG in low-temperature conditions is its tendency to become brittle. As temperatures drop, the polymer chains in PETG become less flexible, leading to a reduction in impact strength and overall toughness. This brittleness can result in cracking or shattering when subjected to sudden impacts or stress, limiting its applicability in certain cold-weather applications.

Another significant challenge is the potential for dimensional instability. PETG, like many polymers, experiences thermal contraction when exposed to low temperatures. This contraction can lead to warping, shrinkage, or distortion of PETG components, potentially compromising their structural integrity and functionality. Maintaining precise dimensions and shapes in cold environments becomes a critical concern for engineers and designers working with PETG.

The glass transition temperature (Tg) of PETG also plays a crucial role in its low-temperature performance. While PETG generally has a lower Tg compared to some other thermoplastics, it still experiences a significant change in mechanical properties as it approaches and passes through its Tg. This transition can lead to alterations in stiffness, strength, and overall material behavior, which must be carefully accounted for in design and application considerations.

Moisture absorption is another challenge that becomes more pronounced in low-temperature environments. PETG, although less hygroscopic than some other polymers, can still absorb moisture from the surrounding environment. In cold conditions, this absorbed moisture can freeze, potentially causing internal stress and microcracking within the material. The freeze-thaw cycles that may occur in fluctuating temperature environments can exacerbate this issue, leading to accelerated degradation of the material over time.

The thermal conductivity of PETG also presents challenges in low-temperature applications. PETG, like most polymers, has relatively low thermal conductivity. In cold environments, this property can lead to thermal gradients within the material, potentially causing uneven stress distribution and localized areas of brittleness. Managing these thermal gradients becomes crucial for maintaining the overall integrity and performance of PETG components in cold conditions.

Lastly, the processing and fabrication of PETG for low-temperature applications pose additional challenges. The material's behavior during molding, extrusion, or other forming processes can be significantly affected by the intended operating temperature. Achieving optimal crystallinity, molecular orientation, and residual stress levels that will perform well in cold environments requires careful control of processing parameters and potentially specialized techniques.

Existing Solutions

01 Mechanical properties of PETG

PETG exhibits excellent mechanical properties, including high impact strength, good flexibility, and durability. It offers a balance of toughness and rigidity, making it suitable for various applications requiring both strength and impact resistance.- Mechanical properties of PETG: PETG exhibits excellent mechanical properties, including high impact strength, good flexibility, and durability. It offers a balance of toughness and rigidity, making it suitable for various applications requiring both strength and impact resistance.

- Thermal characteristics of PETG: PETG demonstrates good thermal stability and heat resistance. It maintains its properties over a wide temperature range and has a relatively low glass transition temperature, allowing for easier processing and thermoforming compared to other thermoplastics.

- Chemical resistance of PETG: PETG offers good resistance to various chemicals, including acids, bases, and many solvents. This characteristic makes it suitable for applications in chemical storage, laboratory equipment, and packaging for aggressive substances.

- Optical properties of PETG: PETG possesses excellent optical clarity and transparency, with high light transmission rates. It also exhibits good color stability and resistance to yellowing, making it ideal for applications requiring visual appeal and long-term clarity.

- Processing and fabrication of PETG: PETG is known for its ease of processing and fabrication. It can be easily thermoformed, injection molded, extruded, and blow molded. The material also demonstrates good printability and can be bonded using various adhesives or welding techniques.

02 Thermal characteristics of PETG

PETG demonstrates good thermal stability and heat resistance. It maintains its properties over a wide temperature range and has a relatively low glass transition temperature, allowing for easier processing and thermoforming compared to other thermoplastics.Expand Specific Solutions03 Chemical resistance of PETG

PETG shows resistance to various chemicals, including acids, bases, and many solvents. This chemical resistance makes it suitable for applications in packaging, medical devices, and laboratory equipment where exposure to different substances is common.Expand Specific Solutions04 Optical properties of PETG

PETG offers excellent optical clarity and transparency, with high light transmission rates. It maintains its clarity even after thermoforming or other processing methods, making it ideal for applications requiring visual appeal or clear visibility.Expand Specific Solutions05 Processing and fabrication of PETG

PETG is known for its ease of processing and fabrication. It can be easily thermoformed, injection molded, or extruded. The material also exhibits good printability and can be bonded or welded using various techniques, allowing for versatile manufacturing options.Expand Specific Solutions

Key Industry Players

The PETG low-temperature performance analysis market is in a growth phase, driven by increasing demand for durable materials in cold environments. The global market size for specialty polymers like PETG is projected to reach billions of dollars by 2025. Technologically, PETG is relatively mature but still evolving, with companies like LG Chem, Eastman, and SK Chemicals leading innovation. Emerging players such as Zhejiang Hailide and Super-Dragon Engineering Plastic are also contributing to advancements. The competitive landscape is characterized by a mix of established chemical giants and specialized materials firms, with ongoing R&D focused on enhancing PETG's low-temperature properties for diverse applications.

LG Chem Ltd.

Technical Solution: LG Chem has developed a specialized PETG formulation for low-temperature environments, incorporating advanced polymer blending techniques and additives to enhance cold resistance. Their proprietary technology involves the addition of impact modifiers and crystallization inhibitors, which maintain the material's ductility and prevent brittleness at sub-zero temperatures[1]. The company has also implemented a unique thermal stabilization process that ensures consistent performance across a wide temperature range, from -40°C to +60°C[2]. LG Chem's PETG exhibits improved dimensional stability and reduced shrinkage in cold conditions, making it suitable for outdoor applications and cold storage solutions[3].

Strengths: Superior cold resistance, maintained ductility at low temperatures, and wide temperature range applicability. Weaknesses: Potentially higher production costs due to specialized additives and processing techniques.

Solvay Specialty Polymers USA LLC

Technical Solution: Solvay has engineered a high-performance PETG variant specifically designed for low-temperature environments. Their approach involves the incorporation of nano-scale reinforcements and proprietary copolymer blends to enhance the material's low-temperature impact strength and flexibility[4]. Solvay's PETG formulation utilizes a unique cross-linking technology that maintains molecular mobility at low temperatures, preventing embrittlement and cracking[5]. The company has also developed a surface treatment process that reduces ice adhesion, making the material ideal for applications in freezing conditions[6]. Extensive testing has shown that Solvay's PETG retains over 80% of its room temperature mechanical properties at -30°C[7].

Strengths: Excellent low-temperature impact resistance, reduced ice adhesion, and retention of mechanical properties in cold environments. Weaknesses: Potentially higher material costs and limited availability due to specialized formulation.

Core PETG Innovations

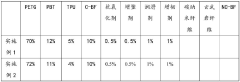

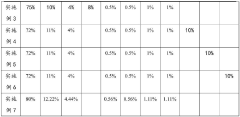

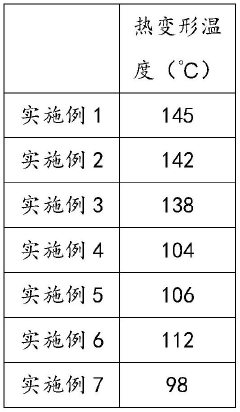

High-temperature-resistant PETG plastic and processing technology thereof

PatentInactiveCN115232448A

Innovation

- Modified epoxy resin and PETG resin are combined, and raw materials such as chlorinated polyethylene, talc, silica, stearate and paraffin are added, and processed through a twin-screw extruder to prepare high-temperature PETG plastic. Ensure that the material does not hydrolyze or deform at 210-220°C.

High-temperature-resistant and chemical-resistant PETG material

PatentActiveCN115505246A

Innovation

- By mixing PETG with PBT and a basalt fiber composite with carbon nanofibers grafted on the surface, and adding TPU to form a ternary phase mixture, the heat resistance and mechanical properties of the material are improved, the heat deformation temperature is significantly increased, and the cost is reduced. .

Regulatory Considerations

When considering PETG in low-temperature environments, regulatory considerations play a crucial role in ensuring compliance and safety. Various regulatory bodies have established guidelines and standards for the use of materials in specific applications, particularly those involving food contact, medical devices, and consumer products.

The U.S. Food and Drug Administration (FDA) has specific regulations for materials used in food packaging and medical devices. For PETG used in these applications, manufacturers must ensure compliance with FDA regulations, including 21 CFR 177.1315 for food contact substances. This regulation outlines the acceptable use conditions and limitations for PETG in food-related applications, especially when exposed to low temperatures during storage or transportation.

In the European Union, the European Food Safety Authority (EFSA) and the European Medicines Agency (EMA) provide regulatory frameworks for materials used in food contact and medical applications. The EU Regulation No. 10/2011 on plastic materials and articles intended to come into contact with food is particularly relevant for PETG applications in low-temperature environments, such as refrigerated or frozen food packaging.

For medical device applications, PETG must meet the requirements set forth by regulatory bodies such as the FDA's Center for Devices and Radiological Health (CDRH) in the United States and the Medical Device Regulation (MDR) in the European Union. These regulations often require extensive testing and documentation to demonstrate the material's safety and performance under various conditions, including low temperatures.

Environmental regulations also come into play when considering PETG usage. The material's recyclability and environmental impact must be assessed in accordance with local and international environmental standards. In some regions, there may be specific regulations governing the use of plastics in certain applications, which could affect the adoption of PETG in low-temperature environments.

Occupational safety regulations, such as those established by the Occupational Safety and Health Administration (OSHA) in the United States, may also apply to the handling and processing of PETG, especially in industrial settings where the material is exposed to low temperatures. These regulations ensure worker safety and proper handling procedures are in place.

As technology and environmental concerns evolve, regulatory bodies continually update their guidelines. Manufacturers and researchers working with PETG in low-temperature environments must stay informed about these changes and adapt their practices accordingly. This may involve ongoing material testing, documentation updates, and potential reformulation to meet new regulatory requirements.

The U.S. Food and Drug Administration (FDA) has specific regulations for materials used in food packaging and medical devices. For PETG used in these applications, manufacturers must ensure compliance with FDA regulations, including 21 CFR 177.1315 for food contact substances. This regulation outlines the acceptable use conditions and limitations for PETG in food-related applications, especially when exposed to low temperatures during storage or transportation.

In the European Union, the European Food Safety Authority (EFSA) and the European Medicines Agency (EMA) provide regulatory frameworks for materials used in food contact and medical applications. The EU Regulation No. 10/2011 on plastic materials and articles intended to come into contact with food is particularly relevant for PETG applications in low-temperature environments, such as refrigerated or frozen food packaging.

For medical device applications, PETG must meet the requirements set forth by regulatory bodies such as the FDA's Center for Devices and Radiological Health (CDRH) in the United States and the Medical Device Regulation (MDR) in the European Union. These regulations often require extensive testing and documentation to demonstrate the material's safety and performance under various conditions, including low temperatures.

Environmental regulations also come into play when considering PETG usage. The material's recyclability and environmental impact must be assessed in accordance with local and international environmental standards. In some regions, there may be specific regulations governing the use of plastics in certain applications, which could affect the adoption of PETG in low-temperature environments.

Occupational safety regulations, such as those established by the Occupational Safety and Health Administration (OSHA) in the United States, may also apply to the handling and processing of PETG, especially in industrial settings where the material is exposed to low temperatures. These regulations ensure worker safety and proper handling procedures are in place.

As technology and environmental concerns evolve, regulatory bodies continually update their guidelines. Manufacturers and researchers working with PETG in low-temperature environments must stay informed about these changes and adapt their practices accordingly. This may involve ongoing material testing, documentation updates, and potential reformulation to meet new regulatory requirements.

Environmental Impact

The environmental impact of PETG (Polyethylene Terephthalate Glycol-modified) in low-temperature environments is a crucial aspect to consider when evaluating its performance and suitability for various applications. PETG, known for its durability and versatility, exhibits unique characteristics that influence its interaction with the environment under cold conditions.

In low-temperature settings, PETG demonstrates enhanced resistance to degradation compared to many other polymers. This property contributes to a reduced rate of microplastic formation, which is a significant environmental concern associated with plastic materials. The slower breakdown of PETG in cold environments can potentially lead to less pollution in ecosystems such as arctic regions or cold water bodies.

However, the persistence of PETG in low-temperature environments also raises concerns about its long-term accumulation in these ecosystems. While it may not degrade as quickly, the material can still contribute to plastic pollution over extended periods. This is particularly relevant in polar regions, where the cold temperatures can further slow down any natural degradation processes.

The production and disposal of PETG also have environmental implications. The manufacturing process of PETG requires less energy compared to some other plastics, potentially reducing its carbon footprint. However, the recycling of PETG in low-temperature environments presents challenges. The material's altered properties in cold conditions may affect the efficiency of recycling processes, potentially leading to increased waste if not properly managed.

When considering the use of PETG in low-temperature applications, it's essential to evaluate its impact on wildlife. The material's durability in cold environments means it could pose risks to animals if improperly disposed of or if it enters natural habitats. This is particularly concerning in marine environments, where PETG products could persist for extended periods.

On a positive note, the use of PETG in low-temperature environments can contribute to energy efficiency in certain applications. Its insulating properties and resistance to cold can lead to reduced energy consumption in refrigeration and cold storage systems, indirectly contributing to lower greenhouse gas emissions.

The environmental impact of PETG in low-temperature environments also extends to its potential for replacing more harmful materials. In some cold-weather applications, PETG can serve as an alternative to materials with higher environmental impacts, potentially leading to overall ecological benefits when considering the entire lifecycle of products.

In low-temperature settings, PETG demonstrates enhanced resistance to degradation compared to many other polymers. This property contributes to a reduced rate of microplastic formation, which is a significant environmental concern associated with plastic materials. The slower breakdown of PETG in cold environments can potentially lead to less pollution in ecosystems such as arctic regions or cold water bodies.

However, the persistence of PETG in low-temperature environments also raises concerns about its long-term accumulation in these ecosystems. While it may not degrade as quickly, the material can still contribute to plastic pollution over extended periods. This is particularly relevant in polar regions, where the cold temperatures can further slow down any natural degradation processes.

The production and disposal of PETG also have environmental implications. The manufacturing process of PETG requires less energy compared to some other plastics, potentially reducing its carbon footprint. However, the recycling of PETG in low-temperature environments presents challenges. The material's altered properties in cold conditions may affect the efficiency of recycling processes, potentially leading to increased waste if not properly managed.

When considering the use of PETG in low-temperature applications, it's essential to evaluate its impact on wildlife. The material's durability in cold environments means it could pose risks to animals if improperly disposed of or if it enters natural habitats. This is particularly concerning in marine environments, where PETG products could persist for extended periods.

On a positive note, the use of PETG in low-temperature environments can contribute to energy efficiency in certain applications. Its insulating properties and resistance to cold can lead to reduced energy consumption in refrigeration and cold storage systems, indirectly contributing to lower greenhouse gas emissions.

The environmental impact of PETG in low-temperature environments also extends to its potential for replacing more harmful materials. In some cold-weather applications, PETG can serve as an alternative to materials with higher environmental impacts, potentially leading to overall ecological benefits when considering the entire lifecycle of products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!