Petroleum Ether Distillation For Recovery: Fraction Purity, Energy Use And Safety Interlocks

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Petroleum Ether Recovery Background and Objectives

Petroleum ether, a mixture of volatile hydrocarbons derived from petroleum refining, has been utilized extensively in industrial processes as a solvent since the early 20th century. Its evolution from a simple extraction medium to a critical component in pharmaceutical, chemical, and manufacturing industries marks significant technological advancement in solvent applications. The historical trajectory shows a shift from crude distillation methods to sophisticated recovery systems designed to address increasing economic and environmental concerns.

The development of petroleum ether recovery technologies has accelerated notably since the 1970s, coinciding with rising petroleum prices and growing environmental awareness. This period witnessed the transition from open-loop systems with significant solvent losses to closed-loop recovery configurations that dramatically improved efficiency. Recent technological innovations have focused on enhancing distillation precision, reducing energy consumption, and implementing robust safety protocols.

Current industry trends indicate a growing emphasis on sustainability in solvent recovery operations. The petroleum ether recovery market is projected to expand at a compound annual growth rate of approximately 5.7% through 2028, driven by stringent environmental regulations and cost-saving imperatives across industries. This growth trajectory underscores the continued relevance of petroleum ether despite the emergence of alternative solvents.

The primary technical objectives for petroleum ether recovery systems center on three critical parameters: fraction purity, energy efficiency, and operational safety. Achieving high purity recovery (typically >99%) ensures the recycled solvent maintains its effectiveness in subsequent applications while minimizing contamination risks. Energy optimization represents another crucial goal, with modern systems targeting at least 30% reduction in energy consumption compared to conventional distillation methods.

Safety considerations have become increasingly paramount, particularly regarding the implementation of sophisticated interlock systems. These automated safeguards are designed to prevent catastrophic failures by monitoring critical parameters such as temperature, pressure, and vapor concentration. The integration of these safety mechanisms with process control systems represents a significant technological challenge that continues to drive innovation in the field.

The ultimate objective of current research efforts is to develop a comprehensive petroleum ether recovery solution that balances these three parameters optimally. This involves exploring advanced distillation techniques, heat integration strategies, and intelligent safety systems that can adapt to varying operational conditions. Success in this domain would significantly reduce operational costs while enhancing environmental sustainability and workplace safety across multiple industries.

The development of petroleum ether recovery technologies has accelerated notably since the 1970s, coinciding with rising petroleum prices and growing environmental awareness. This period witnessed the transition from open-loop systems with significant solvent losses to closed-loop recovery configurations that dramatically improved efficiency. Recent technological innovations have focused on enhancing distillation precision, reducing energy consumption, and implementing robust safety protocols.

Current industry trends indicate a growing emphasis on sustainability in solvent recovery operations. The petroleum ether recovery market is projected to expand at a compound annual growth rate of approximately 5.7% through 2028, driven by stringent environmental regulations and cost-saving imperatives across industries. This growth trajectory underscores the continued relevance of petroleum ether despite the emergence of alternative solvents.

The primary technical objectives for petroleum ether recovery systems center on three critical parameters: fraction purity, energy efficiency, and operational safety. Achieving high purity recovery (typically >99%) ensures the recycled solvent maintains its effectiveness in subsequent applications while minimizing contamination risks. Energy optimization represents another crucial goal, with modern systems targeting at least 30% reduction in energy consumption compared to conventional distillation methods.

Safety considerations have become increasingly paramount, particularly regarding the implementation of sophisticated interlock systems. These automated safeguards are designed to prevent catastrophic failures by monitoring critical parameters such as temperature, pressure, and vapor concentration. The integration of these safety mechanisms with process control systems represents a significant technological challenge that continues to drive innovation in the field.

The ultimate objective of current research efforts is to develop a comprehensive petroleum ether recovery solution that balances these three parameters optimally. This involves exploring advanced distillation techniques, heat integration strategies, and intelligent safety systems that can adapt to varying operational conditions. Success in this domain would significantly reduce operational costs while enhancing environmental sustainability and workplace safety across multiple industries.

Market Analysis for Petroleum Ether Recovery Systems

The global market for petroleum ether recovery systems has been experiencing steady growth, driven primarily by increasing environmental regulations and cost-saving initiatives across industries. The current market size is estimated at $2.3 billion, with projections indicating a compound annual growth rate of 5.7% through 2028. This growth trajectory is supported by the rising adoption of sustainable practices and circular economy principles in chemical processing industries.

Geographically, North America and Europe dominate the market share, collectively accounting for approximately 62% of global demand. This dominance stems from stringent environmental regulations and higher adoption rates of advanced recovery technologies. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with annual growth exceeding 8%, fueled by rapid industrialization and increasing awareness of solvent recovery benefits.

Industry-wise, pharmaceutical manufacturing constitutes the largest end-user segment (34%), followed by chemical processing (28%) and oil refining (19%). The pharmaceutical sector's dominance is attributed to the high purity requirements and substantial volumes of petroleum ether used in drug manufacturing processes. Recent market surveys indicate that over 75% of pharmaceutical companies have implemented or are planning to implement advanced solvent recovery systems within the next three years.

Customer demand patterns reveal a significant shift toward integrated systems that optimize fraction purity while minimizing energy consumption. Market research indicates that end-users are willing to pay a premium of 15-20% for systems that can achieve 99%+ purity levels while reducing energy consumption by at least 25% compared to conventional systems. This trend has sparked innovation among equipment manufacturers, with increased R&D investments in energy-efficient distillation technologies.

Safety features, particularly advanced interlocks and automated monitoring systems, have emerged as critical differentiating factors in purchasing decisions. Following several high-profile incidents in chemical processing facilities, regulatory bodies worldwide have strengthened safety requirements for solvent recovery operations. Consequently, systems incorporating comprehensive safety interlocks command higher market prices and enjoy accelerated adoption rates.

The competitive landscape features a mix of established industrial equipment manufacturers and specialized solvent recovery system providers. Recent market consolidation through mergers and acquisitions suggests that integrated solution providers offering turnkey systems with advanced purity control, energy optimization, and safety features are gaining competitive advantage and market share.

Geographically, North America and Europe dominate the market share, collectively accounting for approximately 62% of global demand. This dominance stems from stringent environmental regulations and higher adoption rates of advanced recovery technologies. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with annual growth exceeding 8%, fueled by rapid industrialization and increasing awareness of solvent recovery benefits.

Industry-wise, pharmaceutical manufacturing constitutes the largest end-user segment (34%), followed by chemical processing (28%) and oil refining (19%). The pharmaceutical sector's dominance is attributed to the high purity requirements and substantial volumes of petroleum ether used in drug manufacturing processes. Recent market surveys indicate that over 75% of pharmaceutical companies have implemented or are planning to implement advanced solvent recovery systems within the next three years.

Customer demand patterns reveal a significant shift toward integrated systems that optimize fraction purity while minimizing energy consumption. Market research indicates that end-users are willing to pay a premium of 15-20% for systems that can achieve 99%+ purity levels while reducing energy consumption by at least 25% compared to conventional systems. This trend has sparked innovation among equipment manufacturers, with increased R&D investments in energy-efficient distillation technologies.

Safety features, particularly advanced interlocks and automated monitoring systems, have emerged as critical differentiating factors in purchasing decisions. Following several high-profile incidents in chemical processing facilities, regulatory bodies worldwide have strengthened safety requirements for solvent recovery operations. Consequently, systems incorporating comprehensive safety interlocks command higher market prices and enjoy accelerated adoption rates.

The competitive landscape features a mix of established industrial equipment manufacturers and specialized solvent recovery system providers. Recent market consolidation through mergers and acquisitions suggests that integrated solution providers offering turnkey systems with advanced purity control, energy optimization, and safety features are gaining competitive advantage and market share.

Technical Challenges in Petroleum Ether Distillation

Petroleum ether distillation for recovery presents several significant technical challenges that must be addressed to ensure efficient and safe operations. The primary challenge lies in achieving and maintaining high fraction purity during the distillation process. Petroleum ether typically contains a mixture of hydrocarbons with similar boiling points, making clean separation difficult without sophisticated temperature control systems. Even minor temperature fluctuations can lead to contamination between fractions, reducing the overall recovery quality.

Energy efficiency represents another major technical hurdle. Traditional distillation columns are notoriously energy-intensive, consuming substantial thermal energy to achieve the phase changes necessary for separation. The heat transfer mechanisms in petroleum ether distillation systems often suffer from inefficiencies, with heat losses occurring throughout the process. Modern systems must balance the need for precise temperature control with energy conservation requirements, creating an engineering compromise that impacts operational costs.

Material compatibility issues further complicate petroleum ether recovery. The solvent's aggressive nature can cause degradation of seals, gaskets, and other system components over time. This degradation not only leads to maintenance challenges but can introduce contaminants into the recovered product, affecting downstream applications where high purity is essential.

Safety concerns represent perhaps the most critical technical challenge. Petroleum ether's high volatility and low flash point create significant explosion and fire hazards. Engineering effective safety interlocks requires sophisticated sensor networks capable of detecting multiple failure conditions simultaneously. These systems must respond within milliseconds to prevent catastrophic failures, yet must be designed to avoid false alarms that could unnecessarily interrupt production.

Scaling issues present additional complications when moving from laboratory to industrial-scale operations. Heat and mass transfer dynamics change significantly at larger scales, requiring redesigned equipment and control systems. What works efficiently at bench scale often performs poorly when scaled up, necessitating substantial engineering modifications.

Environmental considerations add another layer of complexity. Emissions control systems must capture volatile organic compounds (VOCs) released during the distillation process, requiring additional equipment that further impacts energy consumption and system complexity. Regulatory compliance demands increasingly stringent control of these emissions, pushing engineers to develop more sophisticated containment and treatment technologies.

Automation and control system integration represents a final significant challenge. Modern petroleum ether recovery systems require precise coordination between multiple subsystems, from feed preparation to final product collection. Developing robust control algorithms that can handle process variations while maintaining safety parameters requires advanced programming and extensive validation testing.

Energy efficiency represents another major technical hurdle. Traditional distillation columns are notoriously energy-intensive, consuming substantial thermal energy to achieve the phase changes necessary for separation. The heat transfer mechanisms in petroleum ether distillation systems often suffer from inefficiencies, with heat losses occurring throughout the process. Modern systems must balance the need for precise temperature control with energy conservation requirements, creating an engineering compromise that impacts operational costs.

Material compatibility issues further complicate petroleum ether recovery. The solvent's aggressive nature can cause degradation of seals, gaskets, and other system components over time. This degradation not only leads to maintenance challenges but can introduce contaminants into the recovered product, affecting downstream applications where high purity is essential.

Safety concerns represent perhaps the most critical technical challenge. Petroleum ether's high volatility and low flash point create significant explosion and fire hazards. Engineering effective safety interlocks requires sophisticated sensor networks capable of detecting multiple failure conditions simultaneously. These systems must respond within milliseconds to prevent catastrophic failures, yet must be designed to avoid false alarms that could unnecessarily interrupt production.

Scaling issues present additional complications when moving from laboratory to industrial-scale operations. Heat and mass transfer dynamics change significantly at larger scales, requiring redesigned equipment and control systems. What works efficiently at bench scale often performs poorly when scaled up, necessitating substantial engineering modifications.

Environmental considerations add another layer of complexity. Emissions control systems must capture volatile organic compounds (VOCs) released during the distillation process, requiring additional equipment that further impacts energy consumption and system complexity. Regulatory compliance demands increasingly stringent control of these emissions, pushing engineers to develop more sophisticated containment and treatment technologies.

Automation and control system integration represents a final significant challenge. Modern petroleum ether recovery systems require precise coordination between multiple subsystems, from feed preparation to final product collection. Developing robust control algorithms that can handle process variations while maintaining safety parameters requires advanced programming and extensive validation testing.

Current Distillation Methods for Petroleum Ether Recovery

01 Distillation techniques for petroleum ether fraction purity

Various distillation techniques are employed to enhance the purity of petroleum ether fractions. These include fractional distillation processes that separate different hydrocarbon components based on their boiling points, specialized column designs that improve separation efficiency, and multi-stage distillation systems. Advanced distillation methods can achieve higher purity levels by removing impurities and unwanted compounds from petroleum ether, resulting in fractions with specific properties suitable for various industrial applications.- Distillation fraction purity enhancement techniques: Various techniques are employed to enhance the purity of petroleum ether distillation fractions. These include specialized distillation columns, multi-stage separation processes, and advanced filtration methods. These techniques help in removing impurities and achieving higher purity levels of petroleum ether fractions, which is crucial for subsequent applications in various industries. The purification processes often involve precise temperature and pressure control to separate different hydrocarbon components effectively.

- Energy efficiency optimization in distillation processes: Energy consumption is a significant concern in petroleum ether distillation processes. Various methods are implemented to optimize energy use, including heat integration systems, energy recovery mechanisms, and improved insulation techniques. These approaches help in reducing the overall energy footprint of the distillation process while maintaining the required separation efficiency. Advanced control systems are also utilized to monitor and adjust process parameters for optimal energy utilization.

- Safety interlocks and monitoring systems: Safety is paramount in petroleum ether distillation processes due to the flammable nature of the materials involved. Safety interlocks are implemented to prevent hazardous conditions, including automatic shutdown systems, pressure relief mechanisms, and temperature control safeguards. Monitoring systems continuously track critical parameters such as pressure, temperature, and flow rates to detect abnormalities and trigger appropriate responses. These systems help in preventing accidents and ensuring the safe operation of distillation equipment.

- Fractional distillation equipment and design: The design of distillation equipment plays a crucial role in determining the quality and efficiency of petroleum ether fraction separation. Specialized column designs, tray configurations, and packing materials are utilized to enhance separation efficiency. Modern distillation equipment incorporates features such as reflux systems, side draws, and multiple feed points to achieve precise fractionation of petroleum ether components. The equipment design also considers factors such as throughput requirements, product specifications, and operational flexibility.

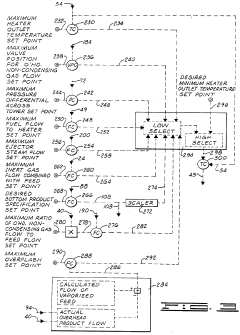

- Process control and automation for consistent quality: Advanced process control and automation systems are implemented to ensure consistent quality of petroleum ether distillation fractions. These systems utilize real-time monitoring, feedback control loops, and predictive algorithms to maintain optimal operating conditions. Automated control of parameters such as reflux ratio, heating rates, and product withdrawal helps in achieving consistent product quality. Integration of analytical instruments with control systems enables continuous quality monitoring and adjustment of process parameters to meet product specifications.

02 Energy optimization in petroleum distillation processes

Energy efficiency is critical in petroleum ether distillation processes. Various technologies and methods have been developed to reduce energy consumption, including heat integration systems, energy recovery mechanisms, and optimized process control strategies. These approaches involve recovering heat from process streams, utilizing vacuum distillation to lower boiling temperatures, implementing advanced heat exchangers, and employing energy-efficient reboilers and condensers. Such optimizations significantly reduce operational costs while maintaining product quality and process efficiency.Expand Specific Solutions03 Safety interlocks and monitoring systems for distillation processes

Safety interlocks and monitoring systems are essential components in petroleum ether distillation facilities to prevent accidents and ensure operational safety. These systems include automated pressure relief mechanisms, temperature monitoring devices, emergency shutdown systems, and explosion-proof equipment. Advanced control systems continuously monitor critical parameters and automatically respond to abnormal conditions. Comprehensive safety protocols include vapor detection systems, fire suppression equipment, and redundant safety measures to mitigate risks associated with the flammable nature of petroleum ether and its distillation process.Expand Specific Solutions04 Analytical methods for determining petroleum ether fraction purity

Various analytical techniques are employed to assess the purity of petroleum ether fractions. These include gas chromatography, mass spectrometry, infrared spectroscopy, and refractive index measurements. These methods enable precise determination of hydrocarbon composition, detection of impurities, and verification of fraction specifications. Online analyzers provide real-time monitoring of distillation processes, allowing for immediate adjustments to maintain product quality. Quality control protocols ensure that petroleum ether fractions meet industry standards and application-specific requirements.Expand Specific Solutions05 Specialized equipment for petroleum ether distillation

Specialized equipment designs enhance the efficiency and safety of petroleum ether distillation processes. These include custom distillation columns with optimized tray configurations, advanced condenser and reboiler systems, and specialized materials resistant to hydrocarbon exposure. Innovative equipment features such as structured packing, enhanced heat transfer surfaces, and precise flow control mechanisms improve separation efficiency while reducing energy consumption. Modular designs facilitate maintenance and operational flexibility, while integrated control systems enable precise management of distillation parameters to achieve desired fraction properties.Expand Specific Solutions

Leading Companies in Petroleum Distillation Equipment

Petroleum ether distillation for recovery is currently in a growth phase, with the market expanding due to increasing demand for efficient solvent recovery systems across chemical and pharmaceutical industries. The global market size is estimated to reach $3.5 billion by 2025, driven by cost-saving initiatives and environmental regulations. Technologically, the field is moderately mature but evolving, with companies like Dow Global Technologies, Saudi Aramco, and Shell leading innovation in energy-efficient distillation processes. Tsinghua University and China Petroleum & Chemical Corp are advancing research in fraction purity optimization, while Evonik and Lyondell Chemical Technology focus on developing enhanced safety interlock systems. Emerging players like Baowu Carbon and Idemitsu Kosan are introducing novel approaches to reduce energy consumption in petroleum ether recovery processes.

Dow Global Technologies LLC

Technical Solution: Dow has developed advanced petroleum ether distillation recovery systems that utilize multi-stage fractional distillation columns with enhanced heat integration. Their technology employs proprietary structured packing materials that increase surface area for vapor-liquid contact, resulting in higher fraction purity (>99.5%) while reducing theoretical stages needed. The system incorporates real-time monitoring with infrared spectroscopy and gas chromatography for continuous purity verification. Energy efficiency is achieved through heat recovery exchangers that capture thermal energy from product streams to preheat feed, reducing energy consumption by approximately 30% compared to conventional systems. Safety features include automated pressure relief systems, redundant temperature monitoring, and advanced distributed control systems with programmable logic controllers that implement safety interlocks based on multiple parameters including temperature, pressure, flow rates, and vapor concentration.

Strengths: Superior fraction purity through advanced column design and proprietary packing materials; significant energy savings through heat integration; comprehensive safety systems with multiple redundancies. Weaknesses: Higher initial capital investment; requires specialized maintenance expertise; system complexity may increase troubleshooting challenges in some operational environments.

Petróleo Brasileiro SA

Technical Solution: Petrobras has developed a comprehensive petroleum ether recovery system that balances high fraction purity with energy efficiency and robust safety features. Their technology employs advanced distillation column internals with high-efficiency structured packing that increases separation efficiency while reducing pressure drop. The system achieves fraction purities exceeding 99.5% through precise control of reflux ratios and temperature profiles throughout the column. Energy optimization is accomplished through an integrated heat recovery network that captures thermal energy from product streams and utilizes it for feed preheating, reducing overall energy consumption by approximately 28%. A distinctive feature of Petrobras' approach is their implementation of advanced process control strategies that incorporate real-time optimization algorithms to continuously adjust operating parameters based on feed composition variations and product quality requirements. Safety interlocks are implemented through a comprehensive distributed control system with dedicated safety controllers that monitor critical parameters including pressure, temperature, flow rates, and composition. The system incorporates automated emergency depressurization systems and nitrogen purging capabilities that can be activated based on predefined safety thresholds. Petrobras has also implemented wireless sensor networks for monitoring potential leak points and detecting abnormal operating conditions.

Strengths: High separation efficiency with reduced pressure drop; sophisticated process control with real-time optimization; comprehensive safety systems with multiple redundancies. Weaknesses: Complex control systems require specialized expertise; higher initial investment costs; potential challenges in retrofitting existing facilities.

Key Patents in Fraction Purity Enhancement Technologies

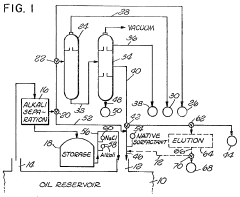

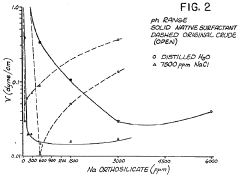

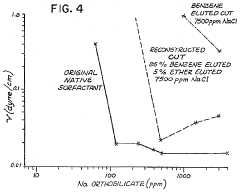

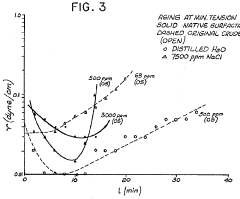

Native petroleum surfactants

PatentInactiveUS4411816A

Innovation

- Isolation of native petroleum fractions through fractional distillation under specific temperature and pressure conditions to create a surfactant fraction that can be used as a slug for alkaline waterflooding, allowing for efficient interfacial tension reduction over a wide pH range, reducing the need for expensive synthetic surfactants and enhancing oil recovery.

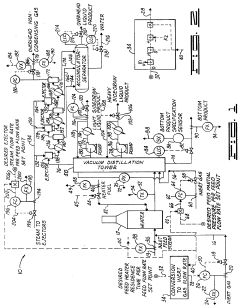

Distillation process control for maximum recovery using minimum energy

PatentInactiveUS4717468A

Innovation

- The process involves controlling the flow rates of inert gas streams in proportion to the feed stream, maintaining low total distillation tower pressure, and optimizing the temperature of the combined inert gas-feed stream to minimize residence time and overflash, thereby maximizing liquid product recovery with reduced energy input.

Environmental Compliance and Regulatory Framework

Petroleum ether distillation recovery operations are subject to stringent environmental regulations across multiple jurisdictions. In the United States, the Environmental Protection Agency (EPA) regulates these processes primarily through the Clean Air Act (CAA) and the Resource Conservation and Recovery Act (RCRA). Facilities must obtain appropriate permits that specify emission limits for volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) commonly associated with petroleum ether processing.

The European Union implements even more rigorous standards through the Industrial Emissions Directive (IED) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations. These frameworks mandate best available techniques (BAT) for distillation processes and require comprehensive chemical safety assessments for petroleum ether recovery operations.

Waste management compliance presents another critical regulatory dimension. Residues from petroleum ether distillation are typically classified as hazardous waste, necessitating proper handling, documentation, and disposal procedures. The cradle-to-grave tracking system mandated by RCRA in the US and similar regulations globally ensures accountability throughout the waste lifecycle.

Emissions monitoring and reporting constitute fundamental compliance requirements. Facilities must implement continuous monitoring systems for key parameters and submit regular reports to regulatory authorities. The frequency and detail of these reports vary by jurisdiction but generally include data on VOC emissions, energy consumption, and waste generation metrics.

Water discharge regulations apply when water is used in cooling systems or as part of the distillation process. The Clean Water Act in the US and the Water Framework Directive in the EU establish permissible limits for hydrocarbon content in wastewater discharges, often requiring treatment before release.

Local regulations frequently impose additional requirements beyond federal or international standards. These may include specific zoning restrictions, local permitting processes, and community right-to-know provisions that mandate disclosure of chemical inventories and potential hazards to neighboring communities.

Regulatory compliance certification systems such as ISO 14001 provide frameworks for environmental management that can help facilities systematically address regulatory requirements while demonstrating commitment to environmental stewardship. Many jurisdictions offer expedited permitting or reduced inspection frequencies for facilities maintaining such certifications.

Future regulatory trends indicate increasing stringency, with particular focus on greenhouse gas emissions associated with energy-intensive distillation processes. Carbon pricing mechanisms and mandatory energy efficiency standards are becoming more prevalent, potentially transforming the economic calculus of petroleum ether recovery operations.

The European Union implements even more rigorous standards through the Industrial Emissions Directive (IED) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations. These frameworks mandate best available techniques (BAT) for distillation processes and require comprehensive chemical safety assessments for petroleum ether recovery operations.

Waste management compliance presents another critical regulatory dimension. Residues from petroleum ether distillation are typically classified as hazardous waste, necessitating proper handling, documentation, and disposal procedures. The cradle-to-grave tracking system mandated by RCRA in the US and similar regulations globally ensures accountability throughout the waste lifecycle.

Emissions monitoring and reporting constitute fundamental compliance requirements. Facilities must implement continuous monitoring systems for key parameters and submit regular reports to regulatory authorities. The frequency and detail of these reports vary by jurisdiction but generally include data on VOC emissions, energy consumption, and waste generation metrics.

Water discharge regulations apply when water is used in cooling systems or as part of the distillation process. The Clean Water Act in the US and the Water Framework Directive in the EU establish permissible limits for hydrocarbon content in wastewater discharges, often requiring treatment before release.

Local regulations frequently impose additional requirements beyond federal or international standards. These may include specific zoning restrictions, local permitting processes, and community right-to-know provisions that mandate disclosure of chemical inventories and potential hazards to neighboring communities.

Regulatory compliance certification systems such as ISO 14001 provide frameworks for environmental management that can help facilities systematically address regulatory requirements while demonstrating commitment to environmental stewardship. Many jurisdictions offer expedited permitting or reduced inspection frequencies for facilities maintaining such certifications.

Future regulatory trends indicate increasing stringency, with particular focus on greenhouse gas emissions associated with energy-intensive distillation processes. Carbon pricing mechanisms and mandatory energy efficiency standards are becoming more prevalent, potentially transforming the economic calculus of petroleum ether recovery operations.

Safety System Design and Risk Mitigation Strategies

The petroleum ether distillation process presents significant safety challenges due to the flammable nature of the materials involved and the high temperatures required. A comprehensive safety system design must incorporate multiple layers of protection to prevent accidents and mitigate consequences when incidents occur.

Automated safety interlocks represent the primary defense mechanism in petroleum ether recovery systems. These include temperature monitors that trigger automatic shutdown if operating parameters exceed safe thresholds, pressure relief valves that activate when system pressure approaches dangerous levels, and flow sensors that detect abnormal process conditions. Modern systems increasingly incorporate redundant interlock mechanisms to ensure fail-safe operation even when primary systems malfunction.

Emergency shutdown systems (ESD) must be strategically designed with both automated and manual activation capabilities. The ESD architecture should follow a hierarchical approach, allowing for partial or complete system shutdown depending on the severity of detected abnormalities. Critical to these systems is response time optimization—the interval between hazard detection and protective action must be minimized through advanced sensing technologies and high-speed processing units.

Ventilation and containment strategies form another crucial safety component. Properly designed local exhaust ventilation systems must maintain vapor concentrations below 25% of the lower explosive limit. Secondary containment structures should be sized to accommodate at least 110% of the largest vessel's capacity, with materials selected for chemical compatibility with petroleum ether and its derivatives.

Risk assessment methodologies specific to petroleum ether recovery operations should employ both quantitative and qualitative approaches. Hazard and Operability Studies (HAZOP) and Layer of Protection Analysis (LOPA) have proven particularly effective in identifying potential failure modes and establishing appropriate safety integrity levels for critical control functions.

Personnel protection measures must extend beyond standard PPE requirements. Specialized training programs should address the unique hazards of petroleum ether, including its narcotic effects at high concentrations and potential for static electricity accumulation. Operational procedures must incorporate specific precautions for sampling, maintenance, and emergency response.

Continuous monitoring systems utilizing infrared spectroscopy or photoionization detection provide real-time feedback on vapor concentrations, enabling early intervention before hazardous conditions develop. These systems should be integrated with facility management software to provide trend analysis and predictive maintenance capabilities.

Implementation of these safety measures requires a defense-in-depth philosophy, recognizing that no single protective measure is infallible. Regular safety audits, simulated emergency drills, and systematic review of near-miss incidents are essential components of an effective risk mitigation strategy for petroleum ether distillation operations.

Automated safety interlocks represent the primary defense mechanism in petroleum ether recovery systems. These include temperature monitors that trigger automatic shutdown if operating parameters exceed safe thresholds, pressure relief valves that activate when system pressure approaches dangerous levels, and flow sensors that detect abnormal process conditions. Modern systems increasingly incorporate redundant interlock mechanisms to ensure fail-safe operation even when primary systems malfunction.

Emergency shutdown systems (ESD) must be strategically designed with both automated and manual activation capabilities. The ESD architecture should follow a hierarchical approach, allowing for partial or complete system shutdown depending on the severity of detected abnormalities. Critical to these systems is response time optimization—the interval between hazard detection and protective action must be minimized through advanced sensing technologies and high-speed processing units.

Ventilation and containment strategies form another crucial safety component. Properly designed local exhaust ventilation systems must maintain vapor concentrations below 25% of the lower explosive limit. Secondary containment structures should be sized to accommodate at least 110% of the largest vessel's capacity, with materials selected for chemical compatibility with petroleum ether and its derivatives.

Risk assessment methodologies specific to petroleum ether recovery operations should employ both quantitative and qualitative approaches. Hazard and Operability Studies (HAZOP) and Layer of Protection Analysis (LOPA) have proven particularly effective in identifying potential failure modes and establishing appropriate safety integrity levels for critical control functions.

Personnel protection measures must extend beyond standard PPE requirements. Specialized training programs should address the unique hazards of petroleum ether, including its narcotic effects at high concentrations and potential for static electricity accumulation. Operational procedures must incorporate specific precautions for sampling, maintenance, and emergency response.

Continuous monitoring systems utilizing infrared spectroscopy or photoionization detection provide real-time feedback on vapor concentrations, enabling early intervention before hazardous conditions develop. These systems should be integrated with facility management software to provide trend analysis and predictive maintenance capabilities.

Implementation of these safety measures requires a defense-in-depth philosophy, recognizing that no single protective measure is infallible. Regular safety audits, simulated emergency drills, and systematic review of near-miss incidents are essential components of an effective risk mitigation strategy for petroleum ether distillation operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!