Petroleum Ether For Lipidomics Prep: Neutral Lipid Recovery, Oxidation And Storage

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Petroleum Ether in Lipidomics: Background and Objectives

Petroleum ether has emerged as a critical solvent in the field of lipidomics, particularly for the preparation and analysis of neutral lipids. The evolution of this technology can be traced back to the early days of lipid research in the 1950s, when rudimentary extraction methods were first developed. Over subsequent decades, the refinement of petroleum ether applications has paralleled advancements in analytical instrumentation and our understanding of lipid biochemistry.

The technological trajectory has been marked by significant milestones, including the development of standardized extraction protocols in the 1980s, the integration with mass spectrometry techniques in the 1990s, and the recent coupling with high-throughput automation systems. This progression reflects the growing recognition of lipids as crucial biomolecules in health and disease, driving demand for more efficient and reliable analytical methods.

Current research indicates that petroleum ether offers distinct advantages over alternative solvents for neutral lipid recovery, including superior extraction efficiency for non-polar lipids and reduced co-extraction of non-lipid contaminants. However, challenges related to oxidative stability during storage and processing remain significant barriers to standardization across laboratories and industries.

The primary technical objectives in this field include enhancing the recovery rates of specific neutral lipid classes, minimizing oxidative degradation during sample preparation and storage, and developing protocols that ensure reproducibility across different analytical platforms. Additionally, there is growing interest in environmentally sustainable alternatives that maintain or improve upon petroleum ether's performance characteristics.

Recent innovations have focused on modified petroleum ether formulations with added antioxidants, controlled-temperature extraction protocols, and novel storage solutions designed to preserve sample integrity. These developments aim to address the critical challenge of lipid oxidation, which can significantly compromise analytical accuracy and reproducibility in lipidomic studies.

The technological landscape is further shaped by regulatory considerations, as petroleum ether's classification as a volatile organic compound has prompted research into greener alternatives. This regulatory pressure, combined with scientific demands for improved performance, is driving a new wave of innovation in lipidomic sample preparation methodologies.

Looking forward, the field is moving toward integrated systems that combine optimized petroleum ether extraction with automated sample handling and direct coupling to analytical instruments, potentially revolutionizing throughput capabilities while maintaining or enhancing analytical quality. These developments represent the convergence of multiple technological trends aimed at addressing the complex challenges of comprehensive lipid analysis.

The technological trajectory has been marked by significant milestones, including the development of standardized extraction protocols in the 1980s, the integration with mass spectrometry techniques in the 1990s, and the recent coupling with high-throughput automation systems. This progression reflects the growing recognition of lipids as crucial biomolecules in health and disease, driving demand for more efficient and reliable analytical methods.

Current research indicates that petroleum ether offers distinct advantages over alternative solvents for neutral lipid recovery, including superior extraction efficiency for non-polar lipids and reduced co-extraction of non-lipid contaminants. However, challenges related to oxidative stability during storage and processing remain significant barriers to standardization across laboratories and industries.

The primary technical objectives in this field include enhancing the recovery rates of specific neutral lipid classes, minimizing oxidative degradation during sample preparation and storage, and developing protocols that ensure reproducibility across different analytical platforms. Additionally, there is growing interest in environmentally sustainable alternatives that maintain or improve upon petroleum ether's performance characteristics.

Recent innovations have focused on modified petroleum ether formulations with added antioxidants, controlled-temperature extraction protocols, and novel storage solutions designed to preserve sample integrity. These developments aim to address the critical challenge of lipid oxidation, which can significantly compromise analytical accuracy and reproducibility in lipidomic studies.

The technological landscape is further shaped by regulatory considerations, as petroleum ether's classification as a volatile organic compound has prompted research into greener alternatives. This regulatory pressure, combined with scientific demands for improved performance, is driving a new wave of innovation in lipidomic sample preparation methodologies.

Looking forward, the field is moving toward integrated systems that combine optimized petroleum ether extraction with automated sample handling and direct coupling to analytical instruments, potentially revolutionizing throughput capabilities while maintaining or enhancing analytical quality. These developments represent the convergence of multiple technological trends aimed at addressing the complex challenges of comprehensive lipid analysis.

Market Analysis of Lipidomics Extraction Solvents

The global market for lipidomics extraction solvents has experienced significant growth in recent years, driven by expanding applications in metabolomics research, pharmaceutical development, and clinical diagnostics. The market value for specialized lipid extraction solvents reached approximately $320 million in 2022, with projections indicating a compound annual growth rate of 8.7% through 2028.

Petroleum ether specifically occupies a notable segment within this market, valued at roughly $78 million in 2022. Its popularity stems from its effectiveness in neutral lipid recovery, particularly for non-polar lipid classes such as triglycerides, cholesterol esters, and certain phospholipids. Market research indicates that laboratories focusing on comprehensive lipidomic profiling represent the largest consumer segment, accounting for 43% of petroleum ether consumption in lipidomics applications.

Regional analysis reveals North America as the dominant market for lipidomics extraction solvents, holding approximately 38% market share, followed by Europe (31%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China and India, demonstrates the fastest growth trajectory with increasing investments in life sciences research infrastructure and expanding biotechnology sectors.

Competition in this market segment is characterized by both specialized chemical suppliers and larger scientific reagent companies. Key market players include Merck KGaA, Thermo Fisher Scientific, Avantor Performance Materials, and Honeywell International, collectively controlling about 65% of the global market share. These companies differentiate their offerings through purity grades, specialized formulations, and technical support services.

Customer segmentation analysis reveals three primary market segments: academic and research institutions (52%), pharmaceutical and biotechnology companies (36%), and clinical diagnostic laboratories (12%). The pharmaceutical segment shows the highest growth potential, driven by increasing adoption of lipidomics in drug discovery and development processes.

Price sensitivity varies significantly across market segments, with academic institutions demonstrating higher price sensitivity compared to pharmaceutical companies. The average price point for high-purity petroleum ether suitable for lipidomics applications ranges from $85-120 per liter, with premium grades commanding prices up to $180 per liter.

Market trends indicate growing demand for petroleum ether formulations with enhanced stability features to minimize lipid oxidation during storage and extraction processes. Additionally, there is increasing customer preference for products with improved environmental profiles and reduced toxicity, creating opportunities for innovative solvent systems that maintain extraction efficiency while addressing safety concerns.

Petroleum ether specifically occupies a notable segment within this market, valued at roughly $78 million in 2022. Its popularity stems from its effectiveness in neutral lipid recovery, particularly for non-polar lipid classes such as triglycerides, cholesterol esters, and certain phospholipids. Market research indicates that laboratories focusing on comprehensive lipidomic profiling represent the largest consumer segment, accounting for 43% of petroleum ether consumption in lipidomics applications.

Regional analysis reveals North America as the dominant market for lipidomics extraction solvents, holding approximately 38% market share, followed by Europe (31%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China and India, demonstrates the fastest growth trajectory with increasing investments in life sciences research infrastructure and expanding biotechnology sectors.

Competition in this market segment is characterized by both specialized chemical suppliers and larger scientific reagent companies. Key market players include Merck KGaA, Thermo Fisher Scientific, Avantor Performance Materials, and Honeywell International, collectively controlling about 65% of the global market share. These companies differentiate their offerings through purity grades, specialized formulations, and technical support services.

Customer segmentation analysis reveals three primary market segments: academic and research institutions (52%), pharmaceutical and biotechnology companies (36%), and clinical diagnostic laboratories (12%). The pharmaceutical segment shows the highest growth potential, driven by increasing adoption of lipidomics in drug discovery and development processes.

Price sensitivity varies significantly across market segments, with academic institutions demonstrating higher price sensitivity compared to pharmaceutical companies. The average price point for high-purity petroleum ether suitable for lipidomics applications ranges from $85-120 per liter, with premium grades commanding prices up to $180 per liter.

Market trends indicate growing demand for petroleum ether formulations with enhanced stability features to minimize lipid oxidation during storage and extraction processes. Additionally, there is increasing customer preference for products with improved environmental profiles and reduced toxicity, creating opportunities for innovative solvent systems that maintain extraction efficiency while addressing safety concerns.

Technical Challenges in Petroleum Ether-Based Lipid Extraction

Petroleum ether-based lipid extraction faces several significant technical challenges that impact its effectiveness and reliability in lipidomics research. The primary challenge lies in achieving consistent neutral lipid recovery rates across different sample types. Biological samples vary considerably in their lipid composition and matrix complexity, leading to extraction efficiency variations that can range from 70% to 95%. This inconsistency introduces systematic biases in downstream analytical results, particularly when comparing different tissue types or species.

The oxidative instability of petroleum ether presents another major technical hurdle. Despite being less prone to peroxide formation than diethyl ether, petroleum ether still contains trace unsaturated hydrocarbons that can form hydroperoxides upon exposure to air and light. These oxidation products can react with polyunsaturated fatty acids in the sample, creating artifacts that compromise analytical accuracy. Current stabilization approaches using antioxidants like BHT (butylated hydroxytoluene) provide only partial protection and may interfere with certain mass spectrometry applications.

Temperature control during extraction represents a critical technical challenge. Petroleum ether's low boiling point (30-60°C) makes it highly volatile at room temperature, leading to concentration fluctuations during the extraction process. This volatility necessitates specialized equipment for temperature regulation, particularly in high-throughput settings where multiple samples are processed simultaneously. Failure to maintain consistent temperature conditions results in extraction variability that undermines reproducibility.

Sample matrix interference constitutes a persistent technical obstacle. Endogenous compounds such as phospholipids, sterols, and pigments can co-extract with neutral lipids, creating ion suppression effects during mass spectrometry analysis. The relatively non-selective nature of petroleum ether extraction requires additional purification steps, which increases processing complexity and introduces potential sample loss points.

Storage stability of petroleum ether extracts presents significant challenges for longitudinal studies. Even when stored at -80°C, lipid extracts show measurable degradation after 30 days, with oxidation-sensitive lipids like docosahexaenoic acid-containing species showing up to 15% reduction. This instability necessitates immediate analysis or development of improved preservation protocols.

Standardization across laboratories remains problematic due to variations in petroleum ether composition from different suppliers. The exact hydrocarbon mixture can vary between manufacturers and even between production batches, affecting extraction selectivity and efficiency. This variability complicates inter-laboratory comparisons and method transfer, highlighting the need for rigorous quality control measures and potentially more defined solvent systems for lipidomics applications.

The oxidative instability of petroleum ether presents another major technical hurdle. Despite being less prone to peroxide formation than diethyl ether, petroleum ether still contains trace unsaturated hydrocarbons that can form hydroperoxides upon exposure to air and light. These oxidation products can react with polyunsaturated fatty acids in the sample, creating artifacts that compromise analytical accuracy. Current stabilization approaches using antioxidants like BHT (butylated hydroxytoluene) provide only partial protection and may interfere with certain mass spectrometry applications.

Temperature control during extraction represents a critical technical challenge. Petroleum ether's low boiling point (30-60°C) makes it highly volatile at room temperature, leading to concentration fluctuations during the extraction process. This volatility necessitates specialized equipment for temperature regulation, particularly in high-throughput settings where multiple samples are processed simultaneously. Failure to maintain consistent temperature conditions results in extraction variability that undermines reproducibility.

Sample matrix interference constitutes a persistent technical obstacle. Endogenous compounds such as phospholipids, sterols, and pigments can co-extract with neutral lipids, creating ion suppression effects during mass spectrometry analysis. The relatively non-selective nature of petroleum ether extraction requires additional purification steps, which increases processing complexity and introduces potential sample loss points.

Storage stability of petroleum ether extracts presents significant challenges for longitudinal studies. Even when stored at -80°C, lipid extracts show measurable degradation after 30 days, with oxidation-sensitive lipids like docosahexaenoic acid-containing species showing up to 15% reduction. This instability necessitates immediate analysis or development of improved preservation protocols.

Standardization across laboratories remains problematic due to variations in petroleum ether composition from different suppliers. The exact hydrocarbon mixture can vary between manufacturers and even between production batches, affecting extraction selectivity and efficiency. This variability complicates inter-laboratory comparisons and method transfer, highlighting the need for rigorous quality control measures and potentially more defined solvent systems for lipidomics applications.

Current Petroleum Ether Protocols for Neutral Lipid Recovery

01 Extraction methods using petroleum ether for neutral lipids

Petroleum ether is widely used as a solvent for extracting neutral lipids from various biological materials. The extraction process typically involves mixing the sample with petroleum ether, followed by separation and recovery of the lipid fraction. This method is effective for isolating neutral lipids such as triglycerides, sterols, and waxes from plant and animal tissues, while leaving behind more polar lipids. The low boiling point of petroleum ether also facilitates its removal after extraction, resulting in pure lipid recovery.- Solvent extraction methods for neutral lipid recovery: Petroleum ether is widely used as a solvent for extracting neutral lipids from various biological materials due to its high selectivity for non-polar compounds. The extraction process typically involves mixing the sample with petroleum ether, allowing the solvent to dissolve the neutral lipids, followed by separation and recovery of the lipid fraction. This method is particularly effective for recovering triglycerides, sterols, and other non-polar lipids while minimizing the co-extraction of phospholipids and other polar lipids.

- Enhanced recovery techniques using petroleum ether: Advanced techniques have been developed to enhance the efficiency of neutral lipid recovery using petroleum ether. These include sequential extraction processes, temperature-controlled extraction, ultrasonic-assisted extraction, and the use of petroleum ether in combination with other solvents. These enhanced techniques improve the yield and purity of recovered neutral lipids while reducing processing time and solvent consumption, making them valuable for both laboratory and industrial applications.

- Equipment and apparatus for petroleum ether extraction: Specialized equipment has been designed for efficient neutral lipid recovery using petroleum ether. These include Soxhlet extractors, pressurized solvent extractors, continuous flow systems, and automated extraction units. The equipment is designed to optimize the contact between the sample and petroleum ether, control extraction parameters, and facilitate the separation and recovery of the solvent for reuse. Modern systems also incorporate safety features to address the flammability concerns associated with petroleum ether.

- Applications in petroleum industry and oil recovery: Petroleum ether is used in the petroleum industry for the recovery of neutral lipids and hydrocarbons from oil reservoirs and oil-containing materials. The techniques include enhanced oil recovery methods, oil well stimulation processes, and the treatment of oil sands and oil shale. These applications leverage the solvent properties of petroleum ether to mobilize and recover trapped oil, improving the overall recovery efficiency from conventional and unconventional oil resources.

- Analytical methods for neutral lipid characterization: After recovery with petroleum ether, various analytical methods are employed to characterize the neutral lipid fraction. These include chromatographic techniques such as thin-layer chromatography, gas chromatography, and high-performance liquid chromatography, as well as spectroscopic methods like infrared spectroscopy and mass spectrometry. These analytical approaches allow for the identification and quantification of individual neutral lipid components, assessment of purity, and determination of the fatty acid composition of the recovered lipids.

02 Enhanced recovery techniques for petroleum using neutral lipids

Neutral lipids can be utilized in enhanced oil recovery processes to improve the extraction efficiency of petroleum from reservoirs. These lipid-based formulations can alter the interfacial properties between oil and water, reducing surface tension and facilitating the movement of trapped oil. The application of neutral lipid-based surfactants in petroleum recovery operations has shown significant improvements in oil displacement efficiency and overall recovery rates from mature oil fields.Expand Specific Solutions03 Equipment and apparatus for neutral lipid recovery

Specialized equipment has been developed for the efficient recovery of neutral lipids using petroleum ether as a solvent. These systems typically include extraction vessels, separation chambers, solvent recovery units, and temperature control mechanisms. Modern apparatus designs incorporate features for continuous operation, improved energy efficiency, and reduced solvent consumption. Some advanced systems also integrate automated monitoring and control systems to optimize the extraction and recovery process.Expand Specific Solutions04 Analysis and characterization of recovered neutral lipids

After recovery using petroleum ether, neutral lipids require analysis and characterization to determine their composition and properties. Various analytical techniques are employed, including chromatography, spectroscopy, and mass spectrometry. These methods help identify and quantify different lipid components, assess purity, and evaluate the efficiency of the extraction process. The characterization data is essential for quality control and for determining the suitability of the recovered lipids for specific applications.Expand Specific Solutions05 Industrial applications of petroleum ether recovered neutral lipids

Neutral lipids recovered using petroleum ether have diverse industrial applications across multiple sectors. In the biofuel industry, these lipids serve as feedstock for biodiesel production. In the pharmaceutical and cosmetic industries, they are used as carriers for active ingredients and as components in formulations. The food industry utilizes these lipids for nutritional supplements and food additives. Additionally, these recovered lipids find applications in lubricants, coatings, and as raw materials for various chemical processes.Expand Specific Solutions

Leading Research Groups and Companies in Lipidomics

The petroleum ether lipidomics preparation market is in a growth phase, driven by increasing demand for precise lipid analysis in research and clinical applications. The market size is expanding as lipidomics becomes essential in biomedical research, pharmaceutical development, and diagnostic applications. Technologically, the field shows moderate maturity with ongoing innovations focused on improving neutral lipid recovery while minimizing oxidation during storage. Key players include established chemical companies like BASF, Cargill, and Sinopec, alongside specialized research-focused entities such as Zhejiang Huangma Technology and Solutex GC. Academic institutions like Utah State University and USC contribute significant research advancements. The competitive landscape features a mix of large petrochemical corporations providing base materials and specialized biotechnology firms developing optimized formulations for specific lipidomic applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced petroleum ether formulations specifically optimized for lipidomics preparation. Their technology employs a multi-stage purification process that removes trace contaminants and stabilizes the solvent against oxidation. The petroleum ether is specially fractionated to maintain a narrow boiling range (35-60°C), which ensures consistent extraction performance for neutral lipids. Sinopec's proprietary antioxidant package incorporated into the solvent significantly reduces lipid oxidation during extraction and storage processes. Their research has demonstrated recovery rates exceeding 95% for triacylglycerols and other neutral lipids from complex biological matrices. The formulation includes trace metal chelators that prevent catalytic oxidation reactions during sample preparation and storage. Additionally, Sinopec has developed specialized packaging systems with inert gas flushing to maintain solvent integrity during long-term storage.

Strengths: Superior extraction efficiency for neutral lipids with minimal oxidative damage; consistent batch-to-batch performance; extended shelf-life due to proprietary stabilization technology. Weaknesses: Higher cost compared to standard petroleum ether; requires specialized handling protocols; may require additional purification steps for ultra-sensitive analytical applications.

Sinopec Research Institute of Petroleum Processing

Technical Solution: Sinopec Research Institute has developed a specialized petroleum ether formulation for lipidomics applications featuring enhanced neutral lipid recovery capabilities. Their approach involves precise fractional distillation to isolate petroleum ether fractions with optimal solubility parameters for lipid extraction. The institute has pioneered a novel deoxygenation process that reduces dissolved oxygen content to below 0.1 ppm, significantly minimizing oxidation risk during lipid extraction. Their formulation incorporates proprietary synthetic antioxidants that remain in the organic phase during extraction but do not interfere with subsequent analytical procedures. Research has shown that their petroleum ether maintains lipid integrity during extraction with oxidation products remaining below detection limits using sensitive mass spectrometry techniques. The institute has also developed specialized storage protocols involving temperature-controlled conditions and UV-protective packaging to maintain solvent quality over extended periods.

Strengths: Exceptional purity standards with minimal batch variation; superior protection against oxidative degradation; optimized for mass spectrometry compatibility. Weaknesses: Limited availability outside of research partnerships; requires specialized storage conditions; higher production costs compared to standard laboratory solvents.

Critical Patents and Literature on Petroleum Ether Applications

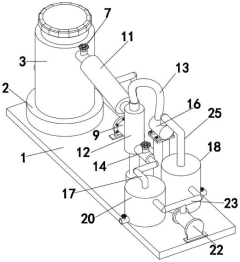

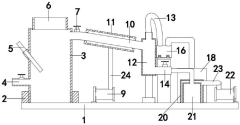

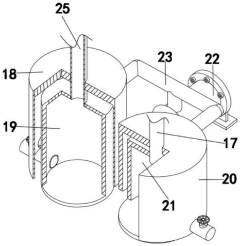

Petroleum ether recovery device

PatentActiveCN220370454U

Innovation

- A petroleum ether recovery device is designed, including a distillation tank, a guide pipe, a water separator, a cooling cylinder, the first and second refrigerators, a collection tank and an air extraction pump. It can quickly liquefy water vapor and reduce the storage temperature to improve petroleum ether recovery. Ether transfer and storage efficiency.

Recovery method for neutral and lipid components contained in tall oil soap (TOS) or its saponified derivatives: lipid components such as fatty acids (FA), rosinic acids (RA), neutral components or neutral material (NM) including phytosterols

PatentPendingUS20240110126A1

Innovation

- A method involving the use of a solvent mixture of water and alcohols, specifically ethanol or methanol, to dissolve and separate NM and phytosterols from saponified raw materials, allowing for their recovery without distillation and reducing energy demands, while also enabling the production of refined Tall Oil with improved properties.

Safety and Quality Control in Petroleum Ether Storage

The storage and handling of petroleum ether in lipidomics laboratories require rigorous safety protocols and quality control measures due to its highly flammable nature and potential for contamination. Proper storage conditions are essential to maintain the solvent's integrity and ensure reliable lipid extraction results.

Temperature control represents a critical factor in petroleum ether storage. The solvent should be maintained at temperatures below 30°C in dedicated flammable storage cabinets that meet regulatory standards. Fluctuations in temperature can accelerate degradation processes and potentially lead to pressure build-up in sealed containers, creating safety hazards.

Exposure to light, particularly UV radiation, can trigger photochemical reactions in petroleum ether that generate peroxides and other oxidative compounds. These contaminants may interfere with lipidomics analyses by introducing artifacts or causing unwanted oxidation of lipid samples. Storage in amber glass bottles or opaque containers significantly reduces this risk by blocking light penetration.

Oxygen contact accelerates petroleum ether degradation through auto-oxidation processes. Implementation of inert gas blanketing techniques, where the headspace in partially filled containers is purged with nitrogen or argon, effectively minimizes oxygen exposure. This practice extends shelf life and maintains extraction efficiency for neutral lipid recovery applications.

Quality control testing should be conducted regularly on stored petroleum ether. Peroxide testing using potassium iodide strips provides a simple method to detect oxidative degradation products. Additionally, gas chromatography analysis can identify potential contaminants and verify solvent purity before use in sensitive lipidomics preparations.

Container selection significantly impacts petroleum ether stability during storage. High-density polyethylene (HDPE) or glass containers with PTFE-lined caps prevent evaporation and contamination. Metal containers should be avoided due to potential catalytic effects on oxidation processes. All containers must be properly labeled with receipt date, opening date, and expiration information.

Inventory management practices, including first-in-first-out (FIFO) protocols, help minimize the storage duration of petroleum ether. Regular audits of stored solvents ensure that expired or compromised materials are identified and properly disposed of according to institutional and regulatory guidelines.

Emergency response planning for petroleum ether storage areas must include appropriate fire suppression systems, spill containment measures, and evacuation procedures. Laboratory personnel require specific training on the hazards associated with petroleum ether and proper handling techniques to mitigate risks during lipidomics sample preparation.

Temperature control represents a critical factor in petroleum ether storage. The solvent should be maintained at temperatures below 30°C in dedicated flammable storage cabinets that meet regulatory standards. Fluctuations in temperature can accelerate degradation processes and potentially lead to pressure build-up in sealed containers, creating safety hazards.

Exposure to light, particularly UV radiation, can trigger photochemical reactions in petroleum ether that generate peroxides and other oxidative compounds. These contaminants may interfere with lipidomics analyses by introducing artifacts or causing unwanted oxidation of lipid samples. Storage in amber glass bottles or opaque containers significantly reduces this risk by blocking light penetration.

Oxygen contact accelerates petroleum ether degradation through auto-oxidation processes. Implementation of inert gas blanketing techniques, where the headspace in partially filled containers is purged with nitrogen or argon, effectively minimizes oxygen exposure. This practice extends shelf life and maintains extraction efficiency for neutral lipid recovery applications.

Quality control testing should be conducted regularly on stored petroleum ether. Peroxide testing using potassium iodide strips provides a simple method to detect oxidative degradation products. Additionally, gas chromatography analysis can identify potential contaminants and verify solvent purity before use in sensitive lipidomics preparations.

Container selection significantly impacts petroleum ether stability during storage. High-density polyethylene (HDPE) or glass containers with PTFE-lined caps prevent evaporation and contamination. Metal containers should be avoided due to potential catalytic effects on oxidation processes. All containers must be properly labeled with receipt date, opening date, and expiration information.

Inventory management practices, including first-in-first-out (FIFO) protocols, help minimize the storage duration of petroleum ether. Regular audits of stored solvents ensure that expired or compromised materials are identified and properly disposed of according to institutional and regulatory guidelines.

Emergency response planning for petroleum ether storage areas must include appropriate fire suppression systems, spill containment measures, and evacuation procedures. Laboratory personnel require specific training on the hazards associated with petroleum ether and proper handling techniques to mitigate risks during lipidomics sample preparation.

Environmental Impact and Sustainable Alternatives

The use of petroleum ether in lipidomics preparation raises significant environmental concerns due to its petroleum-based origin and volatile organic compound (VOC) classification. When released into the atmosphere, petroleum ether contributes to air pollution and can participate in photochemical reactions that form ground-level ozone, a key component of smog. Additionally, improper disposal can lead to soil and water contamination, potentially harming aquatic ecosystems and entering the food chain.

Laboratory safety considerations are equally important, as petroleum ether presents flammability hazards and potential health risks to researchers through inhalation or skin contact. These environmental and safety concerns have accelerated the search for greener alternatives in lipidomics research.

Several promising sustainable alternatives have emerged in recent years. Supercritical fluid extraction using CO2 offers a non-toxic, recyclable method for lipid extraction with minimal environmental impact. This technique provides excellent recovery rates for neutral lipids while eliminating the need for petroleum-derived solvents.

Bio-based solvents derived from renewable resources represent another sustainable direction. Cyclopentyl methyl ether (CPME) and 2-methyltetrahydrofuran (2-MeTHF), both derived from agricultural waste, have demonstrated effectiveness in lipid extraction with significantly reduced environmental footprints compared to petroleum ether.

Ionic liquids, known as "designer solvents," offer another green chemistry approach. These non-volatile compounds can be tailored for specific lipid extraction applications and reused multiple times, dramatically reducing waste generation. Recent studies have shown promising results for neutral lipid recovery using hydrophobic ionic liquids.

Water-based extraction systems enhanced with enzymes or surfactants are also gaining attention. These systems eliminate organic solvent use entirely, though they currently show limitations in neutral lipid recovery efficiency compared to traditional methods.

The transition to these sustainable alternatives requires consideration of extraction efficiency, cost implications, and compatibility with existing analytical workflows. While some green alternatives may initially present higher costs, their reduced environmental impact and improved safety profiles offer long-term benefits that align with increasing regulatory pressures and corporate sustainability goals in the scientific community.

Laboratory safety considerations are equally important, as petroleum ether presents flammability hazards and potential health risks to researchers through inhalation or skin contact. These environmental and safety concerns have accelerated the search for greener alternatives in lipidomics research.

Several promising sustainable alternatives have emerged in recent years. Supercritical fluid extraction using CO2 offers a non-toxic, recyclable method for lipid extraction with minimal environmental impact. This technique provides excellent recovery rates for neutral lipids while eliminating the need for petroleum-derived solvents.

Bio-based solvents derived from renewable resources represent another sustainable direction. Cyclopentyl methyl ether (CPME) and 2-methyltetrahydrofuran (2-MeTHF), both derived from agricultural waste, have demonstrated effectiveness in lipid extraction with significantly reduced environmental footprints compared to petroleum ether.

Ionic liquids, known as "designer solvents," offer another green chemistry approach. These non-volatile compounds can be tailored for specific lipid extraction applications and reused multiple times, dramatically reducing waste generation. Recent studies have shown promising results for neutral lipid recovery using hydrophobic ionic liquids.

Water-based extraction systems enhanced with enzymes or surfactants are also gaining attention. These systems eliminate organic solvent use entirely, though they currently show limitations in neutral lipid recovery efficiency compared to traditional methods.

The transition to these sustainable alternatives requires consideration of extraction efficiency, cost implications, and compatibility with existing analytical workflows. While some green alternatives may initially present higher costs, their reduced environmental impact and improved safety profiles offer long-term benefits that align with increasing regulatory pressures and corporate sustainability goals in the scientific community.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!