Polyvinyl Acetate for Foam Production: Current Research Directions

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVA Foam Evolution

The evolution of Polyvinyl Acetate (PVA) foam production has been marked by significant advancements in materials science and manufacturing processes. Initially developed in the mid-20th century, PVA foam has undergone continuous refinement to meet the growing demands of various industries.

In its early stages, PVA foam production was limited by the challenges of achieving consistent cell structure and density. Researchers focused on improving the foaming process, experimenting with different chemical formulations and physical conditions. The 1970s saw a breakthrough with the introduction of cross-linking agents, which enhanced the foam's stability and mechanical properties.

The 1980s and 1990s witnessed a shift towards environmentally friendly production methods. Water-based PVA foam systems gained popularity, reducing the reliance on harmful solvents. This period also saw the development of biodegradable PVA foams, aligning with growing environmental concerns.

The turn of the millennium brought about a revolution in PVA foam technology with the advent of nanotechnology. Researchers began incorporating nanoparticles into PVA foam matrices, significantly improving their mechanical strength, thermal insulation, and fire-retardant properties. This innovation opened up new applications in aerospace and automotive industries.

Recent years have seen a focus on smart and responsive PVA foams. Scientists have been exploring ways to create foams that can change their properties in response to external stimuli such as temperature, pH, or electrical fields. This research direction holds promise for applications in drug delivery systems and adaptive insulation materials.

The latest frontier in PVA foam evolution is the integration of 3D printing technology. Researchers are developing methods to 3D print PVA foams with precise control over pore size and distribution, enabling customized foam structures for specific applications. This approach has shown potential in tissue engineering and personalized medical devices.

Throughout its evolution, PVA foam production has consistently aimed at improving key performance metrics such as density, compressive strength, thermal conductivity, and biodegradability. The journey from basic foaming techniques to advanced, multifunctional materials reflects the dynamic nature of materials science and the ever-expanding possibilities in foam technology.

In its early stages, PVA foam production was limited by the challenges of achieving consistent cell structure and density. Researchers focused on improving the foaming process, experimenting with different chemical formulations and physical conditions. The 1970s saw a breakthrough with the introduction of cross-linking agents, which enhanced the foam's stability and mechanical properties.

The 1980s and 1990s witnessed a shift towards environmentally friendly production methods. Water-based PVA foam systems gained popularity, reducing the reliance on harmful solvents. This period also saw the development of biodegradable PVA foams, aligning with growing environmental concerns.

The turn of the millennium brought about a revolution in PVA foam technology with the advent of nanotechnology. Researchers began incorporating nanoparticles into PVA foam matrices, significantly improving their mechanical strength, thermal insulation, and fire-retardant properties. This innovation opened up new applications in aerospace and automotive industries.

Recent years have seen a focus on smart and responsive PVA foams. Scientists have been exploring ways to create foams that can change their properties in response to external stimuli such as temperature, pH, or electrical fields. This research direction holds promise for applications in drug delivery systems and adaptive insulation materials.

The latest frontier in PVA foam evolution is the integration of 3D printing technology. Researchers are developing methods to 3D print PVA foams with precise control over pore size and distribution, enabling customized foam structures for specific applications. This approach has shown potential in tissue engineering and personalized medical devices.

Throughout its evolution, PVA foam production has consistently aimed at improving key performance metrics such as density, compressive strength, thermal conductivity, and biodegradability. The journey from basic foaming techniques to advanced, multifunctional materials reflects the dynamic nature of materials science and the ever-expanding possibilities in foam technology.

Market Demand Analysis

The market demand for polyvinyl acetate (PVA) in foam production has been steadily increasing due to its versatile properties and wide range of applications. The global PVA market is experiencing significant growth, driven by the rising demand for eco-friendly and sustainable materials in various industries. In the foam production sector, PVA is gaining traction as a key ingredient due to its excellent adhesive properties, water solubility, and ability to form stable emulsions.

The construction industry is a major consumer of PVA-based foams, particularly in insulation and sealant applications. The growing emphasis on energy-efficient buildings and stringent building codes has led to increased adoption of PVA foams for thermal and acoustic insulation. Additionally, the automotive sector is showing a rising interest in PVA foams for lightweight components and interior applications, aligning with the industry's shift towards fuel efficiency and sustainability.

In the packaging industry, PVA foams are gaining popularity as an alternative to traditional petroleum-based materials. The biodegradable nature of PVA aligns with the increasing consumer demand for environmentally friendly packaging solutions. This trend is expected to drive further growth in the PVA foam market, especially in food packaging and protective packaging applications.

The healthcare and personal care sectors are also contributing to the market demand for PVA foams. The material's biocompatibility and non-toxic nature make it suitable for wound dressings, drug delivery systems, and cosmetic applications. The ongoing research in these areas is likely to open up new avenues for PVA foam applications, further boosting market growth.

Geographically, Asia-Pacific is emerging as a key market for PVA foam production, driven by rapid industrialization, urbanization, and increasing disposable incomes. North America and Europe continue to be significant markets, with a focus on innovative applications and sustainable solutions. The market is also witnessing a trend towards customized PVA foam solutions, catering to specific industry requirements and performance criteria.

However, the market faces challenges such as fluctuating raw material prices and competition from alternative materials. Despite these challenges, the overall market outlook remains positive, with technological advancements and ongoing research expected to enhance the properties and applications of PVA foams, thereby expanding market opportunities.

In conclusion, the market demand for PVA in foam production is robust and diverse, spanning multiple industries and applications. The material's eco-friendly profile, versatility, and potential for innovation are key factors driving its adoption and market growth. As research continues to unlock new possibilities, the PVA foam market is poised for sustained expansion in the coming years.

The construction industry is a major consumer of PVA-based foams, particularly in insulation and sealant applications. The growing emphasis on energy-efficient buildings and stringent building codes has led to increased adoption of PVA foams for thermal and acoustic insulation. Additionally, the automotive sector is showing a rising interest in PVA foams for lightweight components and interior applications, aligning with the industry's shift towards fuel efficiency and sustainability.

In the packaging industry, PVA foams are gaining popularity as an alternative to traditional petroleum-based materials. The biodegradable nature of PVA aligns with the increasing consumer demand for environmentally friendly packaging solutions. This trend is expected to drive further growth in the PVA foam market, especially in food packaging and protective packaging applications.

The healthcare and personal care sectors are also contributing to the market demand for PVA foams. The material's biocompatibility and non-toxic nature make it suitable for wound dressings, drug delivery systems, and cosmetic applications. The ongoing research in these areas is likely to open up new avenues for PVA foam applications, further boosting market growth.

Geographically, Asia-Pacific is emerging as a key market for PVA foam production, driven by rapid industrialization, urbanization, and increasing disposable incomes. North America and Europe continue to be significant markets, with a focus on innovative applications and sustainable solutions. The market is also witnessing a trend towards customized PVA foam solutions, catering to specific industry requirements and performance criteria.

However, the market faces challenges such as fluctuating raw material prices and competition from alternative materials. Despite these challenges, the overall market outlook remains positive, with technological advancements and ongoing research expected to enhance the properties and applications of PVA foams, thereby expanding market opportunities.

In conclusion, the market demand for PVA in foam production is robust and diverse, spanning multiple industries and applications. The material's eco-friendly profile, versatility, and potential for innovation are key factors driving its adoption and market growth. As research continues to unlock new possibilities, the PVA foam market is poised for sustained expansion in the coming years.

PVA Foam Challenges

Polyvinyl acetate (PVA) foam production faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is achieving consistent and uniform foam structure. The foaming process of PVA is highly sensitive to various factors, including temperature, pressure, and the concentration of foaming agents. This sensitivity often leads to inconsistencies in pore size distribution and overall foam density, which can negatively impact the final product's mechanical properties and functionality.

Another major challenge lies in controlling the foam's stability during the production process. PVA foams tend to collapse or coalesce before they can be properly set, resulting in a loss of desired porosity and structure. This instability is particularly problematic when attempting to produce low-density foams with high porosity, which are often required for applications such as thermal insulation or acoustic absorption.

The environmental impact of PVA foam production also presents a significant challenge. Traditional foaming methods often involve the use of volatile organic compounds (VOCs) or other environmentally harmful blowing agents. Finding eco-friendly alternatives that can effectively create the desired foam structure without compromising performance or increasing production costs remains a key area of concern for researchers and manufacturers alike.

Durability and long-term stability of PVA foams pose another set of challenges. PVA is inherently hydrophilic, making it susceptible to moisture absorption and subsequent degradation. This characteristic limits its application in environments where water resistance is crucial. Developing effective methods to enhance the water resistance of PVA foams without sacrificing their beneficial properties is an ongoing challenge in the field.

Scalability and cost-effectiveness in production represent additional hurdles. While PVA foams show promise in various applications, transitioning from laboratory-scale production to industrial-scale manufacturing while maintaining quality and consistency is complex. The cost of raw materials, energy consumption during production, and the need for specialized equipment can make large-scale PVA foam production economically challenging.

Lastly, achieving specific functional properties tailored to different applications remains a significant challenge. For instance, creating PVA foams with enhanced thermal insulation, improved fire resistance, or specific mechanical strengths often requires the incorporation of additives or modifications to the base PVA material. Balancing these enhancements while maintaining the foam's core characteristics and processability is a delicate task that continues to challenge researchers and engineers in the field.

Another major challenge lies in controlling the foam's stability during the production process. PVA foams tend to collapse or coalesce before they can be properly set, resulting in a loss of desired porosity and structure. This instability is particularly problematic when attempting to produce low-density foams with high porosity, which are often required for applications such as thermal insulation or acoustic absorption.

The environmental impact of PVA foam production also presents a significant challenge. Traditional foaming methods often involve the use of volatile organic compounds (VOCs) or other environmentally harmful blowing agents. Finding eco-friendly alternatives that can effectively create the desired foam structure without compromising performance or increasing production costs remains a key area of concern for researchers and manufacturers alike.

Durability and long-term stability of PVA foams pose another set of challenges. PVA is inherently hydrophilic, making it susceptible to moisture absorption and subsequent degradation. This characteristic limits its application in environments where water resistance is crucial. Developing effective methods to enhance the water resistance of PVA foams without sacrificing their beneficial properties is an ongoing challenge in the field.

Scalability and cost-effectiveness in production represent additional hurdles. While PVA foams show promise in various applications, transitioning from laboratory-scale production to industrial-scale manufacturing while maintaining quality and consistency is complex. The cost of raw materials, energy consumption during production, and the need for specialized equipment can make large-scale PVA foam production economically challenging.

Lastly, achieving specific functional properties tailored to different applications remains a significant challenge. For instance, creating PVA foams with enhanced thermal insulation, improved fire resistance, or specific mechanical strengths often requires the incorporation of additives or modifications to the base PVA material. Balancing these enhancements while maintaining the foam's core characteristics and processability is a delicate task that continues to challenge researchers and engineers in the field.

Current PVA Solutions

01 Composition and preparation of polyvinyl acetate foam

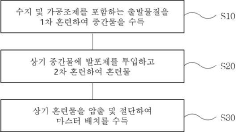

Polyvinyl acetate foam is prepared by combining polyvinyl acetate with foaming agents and other additives. The composition may include plasticizers, stabilizers, and cross-linking agents to enhance the foam's properties. The foam can be produced through various methods such as mechanical frothing, chemical blowing, or physical blowing processes.- Composition and preparation of polyvinyl acetate foam: Polyvinyl acetate foam is prepared by combining polyvinyl acetate with foaming agents and other additives. The composition may include plasticizers, stabilizers, and cross-linking agents to enhance the foam's properties. The foam can be produced through various methods such as mechanical frothing, chemical blowing, or physical blowing processes.

- Applications of polyvinyl acetate foam: Polyvinyl acetate foam finds applications in various industries due to its versatile properties. It is used in packaging, construction, automotive, and consumer goods. The foam can be employed as insulation material, cushioning, sound absorption, and in the production of lightweight composite materials.

- Modifications and improvements to polyvinyl acetate foam: Researchers have developed methods to modify and improve the properties of polyvinyl acetate foam. These include incorporating nanoparticles, blending with other polymers, and surface treatments. Such modifications can enhance the foam's mechanical strength, thermal stability, fire resistance, and water resistance.

- Environmentally friendly polyvinyl acetate foam: Efforts have been made to develop more environmentally friendly versions of polyvinyl acetate foam. This includes the use of bio-based raw materials, biodegradable additives, and recyclable formulations. These innovations aim to reduce the environmental impact of foam production and disposal.

- Polyvinyl acetate foam in adhesive applications: Polyvinyl acetate foam has found use in various adhesive applications. The foam can be formulated to create pressure-sensitive adhesives, hot-melt adhesives, and specialty bonding agents. These foamed adhesives offer advantages such as improved gap-filling properties, reduced weight, and enhanced flexibility compared to traditional adhesives.

02 Applications of polyvinyl acetate foam

Polyvinyl acetate foam finds applications in various industries due to its versatile properties. It is used in packaging, insulation, cushioning, and as a sound-absorbing material. The foam can be molded into different shapes and sizes, making it suitable for diverse products such as furniture, automotive parts, and construction materials.Expand Specific Solutions03 Modifications and improvements to polyvinyl acetate foam

Researchers have developed various modifications to enhance the properties of polyvinyl acetate foam. These improvements include incorporating nanoparticles, blending with other polymers, and using novel cross-linking agents. Such modifications can result in improved mechanical strength, thermal stability, and flame retardancy of the foam.Expand Specific Solutions04 Environmental considerations and biodegradable alternatives

With increasing environmental concerns, efforts have been made to develop more eco-friendly versions of polyvinyl acetate foam. This includes the use of bio-based raw materials, incorporation of biodegradable additives, and development of recycling processes for polyvinyl acetate foam waste. Some researchers have also explored alternatives that maintain similar properties while being more environmentally friendly.Expand Specific Solutions05 Specialized formulations for specific applications

Tailored formulations of polyvinyl acetate foam have been developed for specific applications. These may include flame-retardant foams for construction, water-resistant foams for outdoor use, or high-density foams for load-bearing applications. The formulations often involve careful selection of additives and processing conditions to achieve the desired properties for each application.Expand Specific Solutions

Key Industry Players

The polyvinyl acetate foam production market is in a growth phase, driven by increasing demand in various industries such as construction, automotive, and packaging. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Celanese International Corp., BASF Corp., and Eastman Chemical Co. leading innovation. These firms are investing in research and development to improve foam properties, production efficiency, and sustainability. Academic institutions such as Sichuan University and Tianjin University are also contributing to technological advancements through collaborative research efforts. The competitive landscape is characterized by a mix of established chemical giants and specialized manufacturers, with companies like Kuraray Co., Ltd. and Sekisui Chemical Co., Ltd. focusing on niche applications and high-performance products.

Celanese International Corp.

Technical Solution: Celanese has been advancing PVAc foam technology through the development of specialized grades tailored for specific applications. Their current research direction includes the creation of ultra-low density PVAc foams for thermal insulation applications, achieving improved R-values compared to traditional materials[13]. Celanese is also investigating the use of reactive extrusion techniques to produce PVAc foams with enhanced cell structure control and mechanical properties[14]. Furthermore, they are exploring the incorporation of functional additives into PVAc foams to impart properties such as antimicrobial activity or phase change capabilities, expanding the potential applications of these materials[15].

Strengths: Extensive experience in acetyl chemistry, strong focus on application-specific solutions, and global manufacturing capabilities. Weaknesses: Potential challenges in balancing performance enhancements with cost-effectiveness in competitive markets.

BASF Corp.

Technical Solution: BASF has developed innovative polyvinyl acetate (PVAc) formulations for foam production, focusing on enhancing the material's performance and sustainability. Their research direction includes the incorporation of bio-based monomers to increase the renewable content of PVAc foams[1]. They have also explored the use of supercritical CO2 as a blowing agent, which allows for the production of PVAc foams with improved cell structure and reduced environmental impact[2]. BASF's latest PVAc foam technology incorporates nanoparticles to enhance mechanical properties and flame retardancy, addressing key challenges in foam applications[3].

Strengths: Strong R&D capabilities, focus on sustainability, and ability to integrate advanced technologies. Weaknesses: Potential higher production costs due to specialized formulations and processes.

PVA Foam Innovations

POLYVINYL ACETATE latex

PatentInactiveBR102015030874A2

Innovation

- Polymerizing vinyl acetate under emulsion polymerization conditions with a chain transfer agent such as hypophosphite salts or X-R2SH, where R1 is a C1-C4 alkyl group and X is sulfonate, hydroxyl, sulfate, phosphate, phosphonate, or carboxylic acid, to produce vinyl acetate homopolymers or copolymers with reduced viscosities.

Manufacturing method of a foam using an eco-friendly blowing agent

PatentPendingKR1020240060096A

Innovation

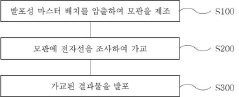

- A method involving the production of a foamable masterbatch containing ethylene vinyl acetate (EVA), a hydrazide-based foaming agent, and processing aids like fatty acid esters, amides, and polysiloxanes, which is extruded, crosslinked with electron beams, and then foamed to achieve uniformity and improved flowability.

Environmental Impact

The environmental impact of polyvinyl acetate (PVA) foam production has become a significant concern in recent years, prompting researchers and manufacturers to explore more sustainable alternatives and production methods. PVA foam, while versatile and widely used, poses several environmental challenges throughout its lifecycle.

One of the primary environmental concerns is the use of petrochemical-based raw materials in PVA production. The reliance on non-renewable resources contributes to the depletion of fossil fuels and increases the carbon footprint of the manufacturing process. Additionally, the production of PVA often involves the use of volatile organic compounds (VOCs) and other potentially harmful chemicals, which can lead to air and water pollution if not properly managed.

The foam production process itself can be energy-intensive, further contributing to greenhouse gas emissions. The curing and drying stages, in particular, often require significant amounts of heat, which is typically generated through the combustion of fossil fuels. This energy consumption not only impacts the environment but also increases production costs.

Waste management is another critical environmental issue associated with PVA foam production. The foam's durability, while beneficial for many applications, becomes problematic at the end of its lifecycle. PVA foam is not biodegradable and can persist in the environment for extended periods. Improper disposal can lead to the accumulation of foam waste in landfills or, worse, in natural ecosystems.

Recent research has focused on addressing these environmental concerns through various approaches. One promising direction is the development of bio-based alternatives to traditional PVA. These materials, derived from renewable resources such as plant-based polymers, aim to reduce the reliance on petrochemicals and decrease the overall carbon footprint of foam production.

Another area of research is the improvement of production processes to minimize energy consumption and emissions. This includes the exploration of low-temperature curing methods, the use of renewable energy sources in manufacturing, and the implementation of closed-loop systems to reduce waste and recycle materials.

Efforts are also being made to enhance the recyclability and biodegradability of PVA foam products. Researchers are investigating ways to modify the foam's chemical structure to facilitate easier breakdown and reprocessing at the end of its life cycle. Some studies have explored the incorporation of biodegradable additives or the development of composite materials that maintain the desirable properties of PVA foam while improving its environmental profile.

The environmental impact of PVA foam production extends beyond manufacturing and disposal. The use phase of foam products can also have significant implications, particularly in applications where the foam may come into contact with the environment. For instance, in marine applications, there is a risk of foam degradation and microplastic release, which can harm aquatic ecosystems.

One of the primary environmental concerns is the use of petrochemical-based raw materials in PVA production. The reliance on non-renewable resources contributes to the depletion of fossil fuels and increases the carbon footprint of the manufacturing process. Additionally, the production of PVA often involves the use of volatile organic compounds (VOCs) and other potentially harmful chemicals, which can lead to air and water pollution if not properly managed.

The foam production process itself can be energy-intensive, further contributing to greenhouse gas emissions. The curing and drying stages, in particular, often require significant amounts of heat, which is typically generated through the combustion of fossil fuels. This energy consumption not only impacts the environment but also increases production costs.

Waste management is another critical environmental issue associated with PVA foam production. The foam's durability, while beneficial for many applications, becomes problematic at the end of its lifecycle. PVA foam is not biodegradable and can persist in the environment for extended periods. Improper disposal can lead to the accumulation of foam waste in landfills or, worse, in natural ecosystems.

Recent research has focused on addressing these environmental concerns through various approaches. One promising direction is the development of bio-based alternatives to traditional PVA. These materials, derived from renewable resources such as plant-based polymers, aim to reduce the reliance on petrochemicals and decrease the overall carbon footprint of foam production.

Another area of research is the improvement of production processes to minimize energy consumption and emissions. This includes the exploration of low-temperature curing methods, the use of renewable energy sources in manufacturing, and the implementation of closed-loop systems to reduce waste and recycle materials.

Efforts are also being made to enhance the recyclability and biodegradability of PVA foam products. Researchers are investigating ways to modify the foam's chemical structure to facilitate easier breakdown and reprocessing at the end of its life cycle. Some studies have explored the incorporation of biodegradable additives or the development of composite materials that maintain the desirable properties of PVA foam while improving its environmental profile.

The environmental impact of PVA foam production extends beyond manufacturing and disposal. The use phase of foam products can also have significant implications, particularly in applications where the foam may come into contact with the environment. For instance, in marine applications, there is a risk of foam degradation and microplastic release, which can harm aquatic ecosystems.

Regulatory Landscape

The regulatory landscape surrounding polyvinyl acetate (PVA) for foam production is complex and evolving, reflecting growing concerns about environmental impact and consumer safety. Regulatory bodies worldwide have implemented various measures to ensure the responsible use of PVA in foam manufacturing processes.

In the United States, the Environmental Protection Agency (EPA) regulates PVA under the Toxic Substances Control Act (TSCA). The agency has established guidelines for the production, handling, and disposal of PVA-based materials. Manufacturers are required to report any new uses of PVA and provide safety data to demonstrate compliance with environmental standards.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects PVA usage in foam production. Under REACH, companies must register PVA and provide detailed information on its properties, potential risks, and safe handling procedures. The European Chemicals Agency (ECHA) oversees this process and may impose restrictions on PVA use if significant environmental or health concerns are identified.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Ministry of Ecology and Environment has set standards for PVA emissions and waste management in foam production facilities. Japan's Chemical Substances Control Law requires manufacturers to assess the environmental and health impacts of PVA before its use in consumer products.

Globally, the United Nations Environment Programme (UNEP) has been advocating for sustainable foam production practices. While not directly regulating PVA, UNEP's initiatives influence national policies and industry standards, promoting the adoption of environmentally friendly alternatives and improved waste management strategies.

Recent regulatory trends indicate a shift towards stricter controls on volatile organic compound (VOC) emissions associated with PVA-based foams. Many jurisdictions are implementing more stringent air quality standards, which may impact the formulation and production processes of PVA foams.

The food packaging industry faces particularly rigorous regulations when using PVA in foam products. The U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) have established specific migration limits for PVA components in food-contact materials, ensuring consumer safety.

As sustainability becomes a greater focus, regulators are increasingly encouraging the development of bio-based alternatives to traditional PVA foams. Incentives for research into renewable sources and biodegradable formulations are being introduced in various countries, potentially reshaping the regulatory landscape for foam production in the coming years.

In the United States, the Environmental Protection Agency (EPA) regulates PVA under the Toxic Substances Control Act (TSCA). The agency has established guidelines for the production, handling, and disposal of PVA-based materials. Manufacturers are required to report any new uses of PVA and provide safety data to demonstrate compliance with environmental standards.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects PVA usage in foam production. Under REACH, companies must register PVA and provide detailed information on its properties, potential risks, and safe handling procedures. The European Chemicals Agency (ECHA) oversees this process and may impose restrictions on PVA use if significant environmental or health concerns are identified.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Ministry of Ecology and Environment has set standards for PVA emissions and waste management in foam production facilities. Japan's Chemical Substances Control Law requires manufacturers to assess the environmental and health impacts of PVA before its use in consumer products.

Globally, the United Nations Environment Programme (UNEP) has been advocating for sustainable foam production practices. While not directly regulating PVA, UNEP's initiatives influence national policies and industry standards, promoting the adoption of environmentally friendly alternatives and improved waste management strategies.

Recent regulatory trends indicate a shift towards stricter controls on volatile organic compound (VOC) emissions associated with PVA-based foams. Many jurisdictions are implementing more stringent air quality standards, which may impact the formulation and production processes of PVA foams.

The food packaging industry faces particularly rigorous regulations when using PVA in foam products. The U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) have established specific migration limits for PVA components in food-contact materials, ensuring consumer safety.

As sustainability becomes a greater focus, regulators are increasingly encouraging the development of bio-based alternatives to traditional PVA foams. Incentives for research into renewable sources and biodegradable formulations are being introduced in various countries, potentially reshaping the regulatory landscape for foam production in the coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!