Redefining Chemical Catalysis with Fluoroantimonic Acid

JUN 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluoroantimonic Acid Catalysis Background and Objectives

Fluoroantimonic acid, a superacid composed of a mixture of hydrogen fluoride (HF) and antimony pentafluoride (SbF5), has emerged as a groundbreaking catalyst in chemical synthesis. This powerful compound has revolutionized the field of catalysis, offering unprecedented reactivity and selectivity in various chemical transformations.

The development of fluoroantimonic acid catalysis can be traced back to the early 1960s when George A. Olah and his colleagues first synthesized and characterized this superacid. Their pioneering work laid the foundation for understanding the unique properties and potential applications of fluoroantimonic acid in organic chemistry.

Over the past decades, the field of superacid catalysis has experienced significant growth, with fluoroantimonic acid at the forefront of this technological advancement. Its exceptional acidity, surpassing that of conventional mineral acids by several orders of magnitude, has opened up new possibilities in chemical synthesis and industrial processes.

The primary objective of exploring fluoroantimonic acid catalysis is to harness its extraordinary catalytic properties to enable previously challenging or impossible chemical transformations. Researchers aim to develop novel synthetic methodologies, improve reaction efficiencies, and expand the scope of accessible chemical structures.

One of the key goals in this field is to understand the fundamental mechanisms underlying fluoroantimonic acid-catalyzed reactions. By elucidating these mechanisms, scientists can design more efficient and selective catalytic systems, leading to the development of new chemical processes with reduced environmental impact and improved atom economy.

Another important objective is to explore the potential of fluoroantimonic acid catalysis in industrial applications. The ability to catalyze reactions under milder conditions and with higher selectivity could lead to more sustainable and cost-effective manufacturing processes across various sectors, including pharmaceuticals, petrochemicals, and materials science.

As the field of catalysis continues to evolve, researchers are also focusing on developing novel superacid systems inspired by fluoroantimonic acid. These efforts aim to create catalysts with tailored properties, addressing specific challenges in chemical synthesis and expanding the toolbox of available catalytic methodologies.

The ongoing research in fluoroantimonic acid catalysis is driven by the need for more efficient and sustainable chemical processes. By redefining the boundaries of chemical catalysis, this superacid holds the potential to revolutionize various aspects of synthetic chemistry and industrial production, paving the way for innovative solutions to complex chemical challenges.

The development of fluoroantimonic acid catalysis can be traced back to the early 1960s when George A. Olah and his colleagues first synthesized and characterized this superacid. Their pioneering work laid the foundation for understanding the unique properties and potential applications of fluoroantimonic acid in organic chemistry.

Over the past decades, the field of superacid catalysis has experienced significant growth, with fluoroantimonic acid at the forefront of this technological advancement. Its exceptional acidity, surpassing that of conventional mineral acids by several orders of magnitude, has opened up new possibilities in chemical synthesis and industrial processes.

The primary objective of exploring fluoroantimonic acid catalysis is to harness its extraordinary catalytic properties to enable previously challenging or impossible chemical transformations. Researchers aim to develop novel synthetic methodologies, improve reaction efficiencies, and expand the scope of accessible chemical structures.

One of the key goals in this field is to understand the fundamental mechanisms underlying fluoroantimonic acid-catalyzed reactions. By elucidating these mechanisms, scientists can design more efficient and selective catalytic systems, leading to the development of new chemical processes with reduced environmental impact and improved atom economy.

Another important objective is to explore the potential of fluoroantimonic acid catalysis in industrial applications. The ability to catalyze reactions under milder conditions and with higher selectivity could lead to more sustainable and cost-effective manufacturing processes across various sectors, including pharmaceuticals, petrochemicals, and materials science.

As the field of catalysis continues to evolve, researchers are also focusing on developing novel superacid systems inspired by fluoroantimonic acid. These efforts aim to create catalysts with tailored properties, addressing specific challenges in chemical synthesis and expanding the toolbox of available catalytic methodologies.

The ongoing research in fluoroantimonic acid catalysis is driven by the need for more efficient and sustainable chemical processes. By redefining the boundaries of chemical catalysis, this superacid holds the potential to revolutionize various aspects of synthetic chemistry and industrial production, paving the way for innovative solutions to complex chemical challenges.

Industrial Demand for Advanced Catalytic Processes

The industrial demand for advanced catalytic processes has been steadily increasing, driven by the need for more efficient, sustainable, and cost-effective chemical production methods. Fluoroantimonic acid, as a superacid with exceptional catalytic properties, has garnered significant attention in various industrial sectors. Its potential to redefine chemical catalysis has sparked interest among manufacturers seeking to optimize their processes and reduce environmental impact.

In the petrochemical industry, there is a growing demand for catalysts that can enhance the efficiency of hydrocarbon cracking and isomerization reactions. Fluoroantimonic acid's ability to catalyze these reactions at lower temperatures and pressures than conventional catalysts makes it an attractive option for refineries looking to reduce energy consumption and operational costs. The automotive sector has also shown interest in this superacid for its potential applications in fuel cell technology and the production of high-performance lubricants.

The pharmaceutical industry is another major driver of demand for advanced catalytic processes. As drug development becomes increasingly complex, there is a pressing need for catalysts that can facilitate the synthesis of complex organic molecules with high selectivity and yield. Fluoroantimonic acid's exceptional acidity and catalytic activity make it a promising candidate for streamlining pharmaceutical manufacturing processes, potentially reducing production costs and time-to-market for new drugs.

In the polymer industry, the demand for catalysts that can enable the production of specialty plastics and high-performance materials is on the rise. Fluoroantimonic acid's ability to catalyze polymerization reactions under milder conditions could lead to the development of novel materials with enhanced properties, opening up new opportunities in sectors such as aerospace, electronics, and advanced manufacturing.

The fine chemicals industry is also exploring the potential of fluoroantimonic acid in the production of specialty chemicals and intermediates. Its strong Lewis acidity makes it particularly useful for catalyzing reactions that are challenging with conventional catalysts, such as Friedel-Crafts alkylations and acylations. This could lead to more efficient production routes for a wide range of valuable chemical products.

However, the adoption of fluoroantimonic acid in industrial processes faces several challenges. Its extreme corrosiveness and sensitivity to moisture require specialized handling and equipment, which can increase implementation costs. Additionally, safety concerns and environmental regulations surrounding the use of such a potent acid need to be addressed. Despite these challenges, the potential benefits of fluoroantimonic acid in terms of process efficiency and product quality continue to drive research and development efforts in various industries.

In the petrochemical industry, there is a growing demand for catalysts that can enhance the efficiency of hydrocarbon cracking and isomerization reactions. Fluoroantimonic acid's ability to catalyze these reactions at lower temperatures and pressures than conventional catalysts makes it an attractive option for refineries looking to reduce energy consumption and operational costs. The automotive sector has also shown interest in this superacid for its potential applications in fuel cell technology and the production of high-performance lubricants.

The pharmaceutical industry is another major driver of demand for advanced catalytic processes. As drug development becomes increasingly complex, there is a pressing need for catalysts that can facilitate the synthesis of complex organic molecules with high selectivity and yield. Fluoroantimonic acid's exceptional acidity and catalytic activity make it a promising candidate for streamlining pharmaceutical manufacturing processes, potentially reducing production costs and time-to-market for new drugs.

In the polymer industry, the demand for catalysts that can enable the production of specialty plastics and high-performance materials is on the rise. Fluoroantimonic acid's ability to catalyze polymerization reactions under milder conditions could lead to the development of novel materials with enhanced properties, opening up new opportunities in sectors such as aerospace, electronics, and advanced manufacturing.

The fine chemicals industry is also exploring the potential of fluoroantimonic acid in the production of specialty chemicals and intermediates. Its strong Lewis acidity makes it particularly useful for catalyzing reactions that are challenging with conventional catalysts, such as Friedel-Crafts alkylations and acylations. This could lead to more efficient production routes for a wide range of valuable chemical products.

However, the adoption of fluoroantimonic acid in industrial processes faces several challenges. Its extreme corrosiveness and sensitivity to moisture require specialized handling and equipment, which can increase implementation costs. Additionally, safety concerns and environmental regulations surrounding the use of such a potent acid need to be addressed. Despite these challenges, the potential benefits of fluoroantimonic acid in terms of process efficiency and product quality continue to drive research and development efforts in various industries.

Current State and Challenges in Superacid Catalysis

Superacid catalysis has emerged as a powerful tool in chemical synthesis, with fluoroantimonic acid (HSbF6) at the forefront of this field. The current state of superacid catalysis is characterized by significant advancements in both theoretical understanding and practical applications. Researchers have made substantial progress in elucidating the mechanisms of superacid-catalyzed reactions, leading to improved control and selectivity in various chemical transformations.

One of the primary challenges in superacid catalysis is the extreme reactivity of these substances, which can lead to undesired side reactions and product degradation. Scientists are actively working on developing more stable and selective superacid catalysts that can maintain their activity under milder conditions. This includes the exploration of supported superacids and the design of novel catalyst structures that can better direct the course of reactions.

Another significant challenge lies in the scalability of superacid-catalyzed processes. While fluoroantimonic acid and other superacids have shown remarkable efficiency in laboratory-scale reactions, translating these successes to industrial-scale applications remains problematic. Issues such as corrosion of equipment, safety concerns, and difficulties in product isolation and purification continue to hinder widespread adoption in large-scale manufacturing.

The environmental impact of superacids is also a pressing concern. Many superacids, including fluoroantimonic acid, are highly toxic and corrosive, posing significant risks to both human health and the environment. Researchers are investigating greener alternatives and developing methods to minimize the use and release of these hazardous substances. This includes the exploration of recyclable superacid catalysts and the development of more environmentally benign reaction conditions.

In terms of technological advancements, there has been significant progress in the characterization and analysis of superacid-catalyzed reactions. Advanced spectroscopic techniques, such as in situ NMR and synchrotron-based X-ray methods, have provided unprecedented insights into the behavior of superacids and their interactions with substrates. These tools are enabling researchers to fine-tune catalyst designs and optimize reaction conditions with greater precision.

The field of computational chemistry has also made substantial contributions to superacid catalysis. Quantum mechanical calculations and molecular dynamics simulations are now routinely used to predict and interpret the behavior of superacids in complex chemical systems. These computational approaches are accelerating the discovery of new catalysts and reaction pathways, complementing experimental efforts in the field.

One of the primary challenges in superacid catalysis is the extreme reactivity of these substances, which can lead to undesired side reactions and product degradation. Scientists are actively working on developing more stable and selective superacid catalysts that can maintain their activity under milder conditions. This includes the exploration of supported superacids and the design of novel catalyst structures that can better direct the course of reactions.

Another significant challenge lies in the scalability of superacid-catalyzed processes. While fluoroantimonic acid and other superacids have shown remarkable efficiency in laboratory-scale reactions, translating these successes to industrial-scale applications remains problematic. Issues such as corrosion of equipment, safety concerns, and difficulties in product isolation and purification continue to hinder widespread adoption in large-scale manufacturing.

The environmental impact of superacids is also a pressing concern. Many superacids, including fluoroantimonic acid, are highly toxic and corrosive, posing significant risks to both human health and the environment. Researchers are investigating greener alternatives and developing methods to minimize the use and release of these hazardous substances. This includes the exploration of recyclable superacid catalysts and the development of more environmentally benign reaction conditions.

In terms of technological advancements, there has been significant progress in the characterization and analysis of superacid-catalyzed reactions. Advanced spectroscopic techniques, such as in situ NMR and synchrotron-based X-ray methods, have provided unprecedented insights into the behavior of superacids and their interactions with substrates. These tools are enabling researchers to fine-tune catalyst designs and optimize reaction conditions with greater precision.

The field of computational chemistry has also made substantial contributions to superacid catalysis. Quantum mechanical calculations and molecular dynamics simulations are now routinely used to predict and interpret the behavior of superacids in complex chemical systems. These computational approaches are accelerating the discovery of new catalysts and reaction pathways, complementing experimental efforts in the field.

Existing Applications of Fluoroantimonic Acid

01 Use of fluoroantimonic acid as a catalyst in chemical reactions

Fluoroantimonic acid is employed as a powerful catalyst in various chemical reactions due to its extremely high acidity. It can catalyze reactions such as isomerization, alkylation, and polymerization, offering high efficiency and selectivity in organic synthesis processes.- Fluoroantimonic acid as a catalyst in chemical reactions: Fluoroantimonic acid is utilized as a powerful catalyst in various chemical reactions due to its extremely high acidity. It can catalyze reactions such as isomerization, alkylation, and polymerization of hydrocarbons. The acid's strong protonating ability enables it to activate substrates that are typically unreactive with other catalysts.

- Applications in petroleum refining and petrochemical industry: Fluoroantimonic acid finds significant applications in the petroleum refining and petrochemical industries. It is used in processes such as hydrocracking, isomerization of light naphtha, and production of high-octane gasoline components. The acid's catalytic properties help improve the efficiency and yield of these industrial processes.

- Synthesis and preparation methods of fluoroantimonic acid: Various methods for synthesizing and preparing fluoroantimonic acid have been developed. These include the reaction of hydrogen fluoride with antimony pentafluoride, as well as other novel approaches to produce the acid with high purity and stability. The preparation methods aim to optimize the acid's catalytic performance and handling safety.

- Use in organic synthesis and fine chemical production: Fluoroantimonic acid serves as a catalyst in organic synthesis reactions and the production of fine chemicals. It facilitates the formation of carbon-carbon bonds, rearrangements, and other transformations that are challenging with conventional catalysts. The acid's unique properties enable the synthesis of complex organic molecules and pharmaceutical intermediates.

- Safety considerations and handling techniques: Due to its extreme acidity and reactivity, special safety considerations and handling techniques are required when working with fluoroantimonic acid. This includes the use of specialized containment materials, personal protective equipment, and proper disposal methods. Research focuses on developing safer formulations and handling protocols to mitigate risks associated with its use in industrial and laboratory settings.

02 Application in hydrocarbon processing

Fluoroantimonic acid catalysis is utilized in hydrocarbon processing industries, particularly in petroleum refining. It can facilitate cracking, isomerization, and alkylation of hydrocarbons, leading to improved fuel quality and increased production of high-value petrochemicals.Expand Specific Solutions03 Synthesis of novel materials

The strong catalytic properties of fluoroantimonic acid are exploited in the synthesis of novel materials, including advanced polymers, nanostructures, and functional materials. Its ability to promote certain reactions under mild conditions makes it valuable in materials science research and development.Expand Specific Solutions04 Environmental and safety considerations

Due to the highly corrosive and reactive nature of fluoroantimonic acid, special handling procedures and safety measures are required. Research focuses on developing safer alternatives or containment methods to mitigate environmental and health risks associated with its use in chemical catalysis.Expand Specific Solutions05 Innovations in catalyst systems and reaction conditions

Ongoing research aims to optimize fluoroantimonic acid catalysis through innovations in catalyst systems and reaction conditions. This includes developing supported catalysts, exploring synergistic effects with other catalysts, and fine-tuning reaction parameters to enhance efficiency and selectivity.Expand Specific Solutions

Key Players in Superacid Catalysis Research

The field of chemical catalysis using fluoroantimonic acid is in a nascent stage of development, with significant potential for growth. The market size is currently limited but expected to expand as research progresses. Technologically, it's still in the early phases of maturity, with ongoing research and development efforts. Companies like DuPont de Nemours, Inc., BASF SE, and 3M Innovative Properties Co. are at the forefront of this technology, leveraging their expertise in chemical engineering and materials science. Academic institutions such as Yale University and Zhejiang University are also contributing to advancements in this area. The competitive landscape is characterized by a mix of established chemical companies and research institutions, each striving to unlock the full potential of fluoroantimonic acid in catalysis applications.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a novel approach to utilizing fluoroantimonic acid in chemical catalysis. Their method involves encapsulating the superacid within specially designed polymer matrices, allowing for controlled release and enhanced stability. This innovative technique enables the use of fluoroantimonic acid in a wider range of chemical reactions, including those in the production of high-performance polymers and advanced materials. DuPont's research has also focused on optimizing reaction conditions to maximize catalytic efficiency while minimizing potential environmental impacts.

Strengths: Enhanced stability and control of the superacid, broader application range, and improved safety. Weaknesses: High production costs and potential environmental concerns if not properly managed.

BASF Corp.

Technical Solution: BASF has pioneered a groundbreaking approach to harnessing the power of fluoroantimonic acid in chemical catalysis. Their technology involves creating a highly stable, nano-structured support system for the superacid, which allows for precise control over catalytic reactions. This innovation enables the use of fluoroantimonic acid in continuous flow processes, significantly improving efficiency and reducing waste in large-scale chemical manufacturing. BASF's research has also led to the development of novel ligand systems that can modulate the acidity and selectivity of fluoroantimonic acid-based catalysts, opening up new possibilities in fine chemical synthesis and petrochemical processing.

Strengths: Improved efficiency in large-scale processes, enhanced selectivity, and reduced waste. Weaknesses: High initial investment costs and potential safety concerns in handling.

Core Innovations in Fluoroantimonic Acid Catalysis

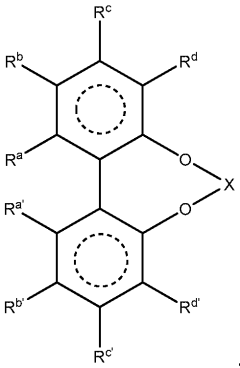

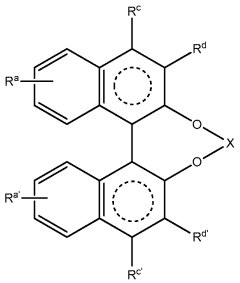

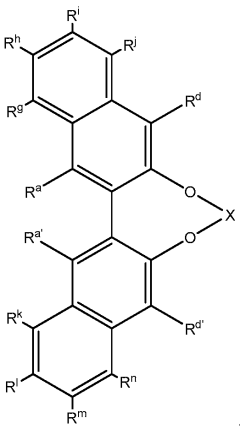

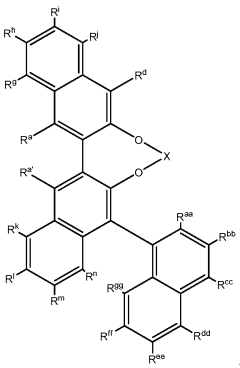

Asymmetric electrophilic fluorination using an anionic chiral phase-transfer catalyst

PatentWO2013096971A1

Innovation

- Development of chiral anionic phase-transfer catalysts that facilitate enantioselective electrophilic addition reactions by forming soluble ion pairs with insoluble cationic electrophilic reagents, enabling efficient and enantiocontrolled C-F bond formation through electrophilic addition reactions.

Method for the production of [18f] fluoride-marked aromatic l-amino acids

PatentInactiveEP1663915A1

Innovation

- A process involving nucleophilic substitution of a negatively charged [18F]fluoride ion with a suitable L-enantiomeric compound, followed by cleavage of protective groups, allowing for direct labeling and production of [18F]fluoro-L-phenylalanine derivatives in few steps, eliminating the need for enantiomer separation and achieving high stereochemical purity.

Safety and Handling Protocols for Superacids

The handling of superacids, particularly fluoroantimonic acid, requires stringent safety protocols due to their extreme corrosiveness and reactivity. Personal protective equipment (PPE) is paramount, including chemical-resistant suits, gloves, and full-face respirators with appropriate filters. All handling must occur in a fume hood with proper ventilation to prevent exposure to toxic fumes.

Storage of superacids necessitates specialized containers made of materials resistant to their corrosive nature, such as fluoropolymers like PTFE or PFA. These containers must be sealed tightly and stored in a cool, dry area away from incompatible substances. Regular inspections of storage areas and containers are crucial to detect any signs of degradation or leakage.

Transportation of superacids requires adherence to strict regulations. They must be packaged in UN-approved containers with appropriate labeling and documentation. Vehicles transporting these materials should be equipped with spill containment kits and staffed by trained personnel familiar with emergency response procedures.

In the event of a spill, immediate action is critical. The affected area must be evacuated, and only trained personnel wearing appropriate PPE should attempt cleanup. Neutralization agents, such as sodium bicarbonate or calcium carbonate, should be readily available to mitigate the acid's effects. Proper disposal of contaminated materials must follow local and national hazardous waste regulations.

Training is a cornerstone of safe superacid handling. All personnel working with these substances must undergo comprehensive safety training, including proper handling techniques, emergency procedures, and first aid measures. Regular refresher courses and safety drills should be conducted to maintain preparedness.

Environmental considerations are also crucial. Waste management protocols must be in place to prevent environmental contamination. This includes proper neutralization and disposal of acid waste, as well as monitoring of air and water quality in the vicinity of handling and storage areas.

Lastly, a robust emergency response plan is essential. This plan should outline procedures for various scenarios, including spills, fires, and personnel exposure. It should detail evacuation routes, emergency contact information, and coordination with local emergency services. Regular review and updating of this plan ensure its effectiveness in the face of evolving risks and regulations.

Storage of superacids necessitates specialized containers made of materials resistant to their corrosive nature, such as fluoropolymers like PTFE or PFA. These containers must be sealed tightly and stored in a cool, dry area away from incompatible substances. Regular inspections of storage areas and containers are crucial to detect any signs of degradation or leakage.

Transportation of superacids requires adherence to strict regulations. They must be packaged in UN-approved containers with appropriate labeling and documentation. Vehicles transporting these materials should be equipped with spill containment kits and staffed by trained personnel familiar with emergency response procedures.

In the event of a spill, immediate action is critical. The affected area must be evacuated, and only trained personnel wearing appropriate PPE should attempt cleanup. Neutralization agents, such as sodium bicarbonate or calcium carbonate, should be readily available to mitigate the acid's effects. Proper disposal of contaminated materials must follow local and national hazardous waste regulations.

Training is a cornerstone of safe superacid handling. All personnel working with these substances must undergo comprehensive safety training, including proper handling techniques, emergency procedures, and first aid measures. Regular refresher courses and safety drills should be conducted to maintain preparedness.

Environmental considerations are also crucial. Waste management protocols must be in place to prevent environmental contamination. This includes proper neutralization and disposal of acid waste, as well as monitoring of air and water quality in the vicinity of handling and storage areas.

Lastly, a robust emergency response plan is essential. This plan should outline procedures for various scenarios, including spills, fires, and personnel exposure. It should detail evacuation routes, emergency contact information, and coordination with local emergency services. Regular review and updating of this plan ensure its effectiveness in the face of evolving risks and regulations.

Environmental Impact of Fluoroantimonic Acid Use

The use of fluoroantimonic acid in chemical catalysis presents significant environmental challenges due to its extreme corrosiveness and reactivity. As the strongest known superacid, fluoroantimonic acid can cause severe damage to ecosystems if released into the environment. Its highly reactive nature means it can rapidly decompose organic matter, potentially leading to widespread destruction of plant and animal life in affected areas.

One of the primary environmental concerns is the potential for fluoroantimonic acid to contaminate water sources. Even small amounts of this superacid can drastically alter the pH of water bodies, making them uninhabitable for aquatic life. The acid's ability to dissolve many materials, including glass and certain metals, poses risks of equipment failure and subsequent environmental release during handling and storage.

Air pollution is another significant issue associated with fluoroantimonic acid use. The acid can release toxic fumes, including hydrogen fluoride and antimony compounds, which can contribute to air quality degradation and pose health risks to both humans and wildlife. These emissions may also contribute to the formation of acid rain, further impacting ecosystems over a wider area.

The production and disposal of fluoroantimonic acid also raise environmental concerns. The manufacturing process involves hazardous materials and energy-intensive steps, contributing to carbon emissions and resource depletion. Proper disposal of waste products and contaminated materials from catalytic processes using this superacid requires specialized facilities and procedures to prevent environmental contamination.

To mitigate these environmental risks, strict safety protocols and containment measures are essential in facilities using fluoroantimonic acid. This includes the use of specialized materials for storage and handling, advanced air filtration systems, and comprehensive emergency response plans. Additionally, research into less environmentally harmful alternatives or methods to reduce the quantity of fluoroantimonic acid used in catalytic processes is crucial for sustainable chemical industry practices.

The long-term environmental effects of fluoroantimonic acid exposure are not fully understood, necessitating ongoing research and monitoring. Potential bioaccumulation of fluorine and antimony compounds in the food chain is a concern that requires further investigation. Environmental impact assessments and regular monitoring of areas surrounding facilities using this superacid are essential to detect and address any contamination promptly.

In conclusion, while fluoroantimonic acid offers significant benefits in chemical catalysis, its environmental impact is a major consideration that must be carefully managed. Balancing the technological advantages with environmental protection requires ongoing innovation in safety measures, process efficiency, and the development of more environmentally friendly alternatives.

One of the primary environmental concerns is the potential for fluoroantimonic acid to contaminate water sources. Even small amounts of this superacid can drastically alter the pH of water bodies, making them uninhabitable for aquatic life. The acid's ability to dissolve many materials, including glass and certain metals, poses risks of equipment failure and subsequent environmental release during handling and storage.

Air pollution is another significant issue associated with fluoroantimonic acid use. The acid can release toxic fumes, including hydrogen fluoride and antimony compounds, which can contribute to air quality degradation and pose health risks to both humans and wildlife. These emissions may also contribute to the formation of acid rain, further impacting ecosystems over a wider area.

The production and disposal of fluoroantimonic acid also raise environmental concerns. The manufacturing process involves hazardous materials and energy-intensive steps, contributing to carbon emissions and resource depletion. Proper disposal of waste products and contaminated materials from catalytic processes using this superacid requires specialized facilities and procedures to prevent environmental contamination.

To mitigate these environmental risks, strict safety protocols and containment measures are essential in facilities using fluoroantimonic acid. This includes the use of specialized materials for storage and handling, advanced air filtration systems, and comprehensive emergency response plans. Additionally, research into less environmentally harmful alternatives or methods to reduce the quantity of fluoroantimonic acid used in catalytic processes is crucial for sustainable chemical industry practices.

The long-term environmental effects of fluoroantimonic acid exposure are not fully understood, necessitating ongoing research and monitoring. Potential bioaccumulation of fluorine and antimony compounds in the food chain is a concern that requires further investigation. Environmental impact assessments and regular monitoring of areas surrounding facilities using this superacid are essential to detect and address any contamination promptly.

In conclusion, while fluoroantimonic acid offers significant benefits in chemical catalysis, its environmental impact is a major consideration that must be carefully managed. Balancing the technological advantages with environmental protection requires ongoing innovation in safety measures, process efficiency, and the development of more environmentally friendly alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!