Ammonium hydroxide in enhancing thermo-responsive material applications

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide in Thermo-Responsive Materials

Ammonium hydroxide has emerged as a significant component in enhancing the applications of thermo-responsive materials. This compound, also known as aqueous ammonia, is a solution of ammonia in water that has been found to play a crucial role in modifying the properties of various thermo-responsive polymers and composites.

The integration of ammonium hydroxide into thermo-responsive materials has led to advancements in several key areas. One of the primary benefits is the improved control over the lower critical solution temperature (LCST) of these materials. By adjusting the concentration of ammonium hydroxide, researchers have been able to fine-tune the temperature at which the material undergoes its phase transition, expanding the range of potential applications.

Furthermore, ammonium hydroxide has been shown to enhance the swelling and deswelling kinetics of thermo-responsive hydrogels. This improvement in responsiveness allows for faster and more efficient changes in material properties in response to temperature fluctuations, which is particularly valuable in applications such as drug delivery systems and smart textiles.

The incorporation of ammonium hydroxide has also been found to increase the mechanical strength and durability of thermo-responsive materials. This enhancement is attributed to the formation of additional hydrogen bonds and electrostatic interactions within the polymer network, resulting in more robust and stable structures.

In the field of biomedical engineering, ammonium hydroxide-modified thermo-responsive materials have shown promise in tissue engineering and regenerative medicine. The ability to precisely control the material's properties at physiological temperatures has opened up new possibilities for cell culture scaffolds and injectable biomaterials.

Environmental applications have also benefited from this research. Thermo-responsive materials enhanced with ammonium hydroxide have demonstrated improved efficiency in water purification and pollutant removal processes. The temperature-dependent solubility changes allow for more effective capture and release of contaminants.

Recent studies have explored the potential of ammonium hydroxide in developing smart coatings and surfaces with switchable wettability. These materials can transition between hydrophilic and hydrophobic states in response to temperature changes, offering novel solutions for self-cleaning surfaces and controlled adhesion applications.

As research in this field progresses, the synergistic effects of ammonium hydroxide and other additives are being investigated to further expand the capabilities of thermo-responsive materials. This ongoing work promises to unlock new applications and improve existing technologies across various industries, from healthcare to environmental protection and beyond.

The integration of ammonium hydroxide into thermo-responsive materials has led to advancements in several key areas. One of the primary benefits is the improved control over the lower critical solution temperature (LCST) of these materials. By adjusting the concentration of ammonium hydroxide, researchers have been able to fine-tune the temperature at which the material undergoes its phase transition, expanding the range of potential applications.

Furthermore, ammonium hydroxide has been shown to enhance the swelling and deswelling kinetics of thermo-responsive hydrogels. This improvement in responsiveness allows for faster and more efficient changes in material properties in response to temperature fluctuations, which is particularly valuable in applications such as drug delivery systems and smart textiles.

The incorporation of ammonium hydroxide has also been found to increase the mechanical strength and durability of thermo-responsive materials. This enhancement is attributed to the formation of additional hydrogen bonds and electrostatic interactions within the polymer network, resulting in more robust and stable structures.

In the field of biomedical engineering, ammonium hydroxide-modified thermo-responsive materials have shown promise in tissue engineering and regenerative medicine. The ability to precisely control the material's properties at physiological temperatures has opened up new possibilities for cell culture scaffolds and injectable biomaterials.

Environmental applications have also benefited from this research. Thermo-responsive materials enhanced with ammonium hydroxide have demonstrated improved efficiency in water purification and pollutant removal processes. The temperature-dependent solubility changes allow for more effective capture and release of contaminants.

Recent studies have explored the potential of ammonium hydroxide in developing smart coatings and surfaces with switchable wettability. These materials can transition between hydrophilic and hydrophobic states in response to temperature changes, offering novel solutions for self-cleaning surfaces and controlled adhesion applications.

As research in this field progresses, the synergistic effects of ammonium hydroxide and other additives are being investigated to further expand the capabilities of thermo-responsive materials. This ongoing work promises to unlock new applications and improve existing technologies across various industries, from healthcare to environmental protection and beyond.

Market Analysis for Enhanced Thermo-Responsive Applications

The market for enhanced thermo-responsive applications utilizing ammonium hydroxide is experiencing significant growth and diversification. This trend is driven by the increasing demand for smart materials across various industries, including healthcare, textiles, and environmental management. The global market for thermo-responsive materials is projected to expand at a robust rate over the next five years, with applications enhanced by ammonium hydroxide playing a crucial role in this growth.

In the healthcare sector, thermo-responsive materials enhanced with ammonium hydroxide are finding applications in drug delivery systems, tissue engineering, and biosensors. The ability to precisely control material properties through temperature changes, coupled with the enhanced responsiveness provided by ammonium hydroxide, is opening new avenues for targeted therapies and diagnostic tools. This segment of the market is expected to see substantial growth, particularly in developed economies with advanced healthcare infrastructure.

The textile industry is another key market for enhanced thermo-responsive materials. Smart fabrics that can adapt to temperature changes are gaining popularity in sportswear, military applications, and personal protective equipment. The addition of ammonium hydroxide to these materials improves their responsiveness and durability, making them more attractive to consumers and industrial users alike. Market analysts predict a steady increase in demand for these advanced textiles over the coming years.

Environmental management and energy conservation represent emerging markets for ammonium hydroxide-enhanced thermo-responsive materials. Applications in smart windows, temperature-responsive coatings, and energy-efficient building materials are showing promise. These materials can help reduce energy consumption in buildings by automatically adjusting their properties in response to temperature changes, aligning with global efforts to combat climate change and reduce carbon emissions.

The industrial sector is also adopting these advanced materials for process optimization and safety applications. Thermo-responsive materials enhanced with ammonium hydroxide are being used in temperature-sensitive valves, sensors, and safety systems, offering improved performance and reliability over traditional materials. This market segment is expected to grow as industries continue to prioritize efficiency and safety in their operations.

Geographically, North America and Europe currently lead the market for enhanced thermo-responsive applications, owing to their strong research and development capabilities and early adoption of advanced materials. However, the Asia-Pacific region is anticipated to witness the fastest growth in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness of smart materials' potential.

In the healthcare sector, thermo-responsive materials enhanced with ammonium hydroxide are finding applications in drug delivery systems, tissue engineering, and biosensors. The ability to precisely control material properties through temperature changes, coupled with the enhanced responsiveness provided by ammonium hydroxide, is opening new avenues for targeted therapies and diagnostic tools. This segment of the market is expected to see substantial growth, particularly in developed economies with advanced healthcare infrastructure.

The textile industry is another key market for enhanced thermo-responsive materials. Smart fabrics that can adapt to temperature changes are gaining popularity in sportswear, military applications, and personal protective equipment. The addition of ammonium hydroxide to these materials improves their responsiveness and durability, making them more attractive to consumers and industrial users alike. Market analysts predict a steady increase in demand for these advanced textiles over the coming years.

Environmental management and energy conservation represent emerging markets for ammonium hydroxide-enhanced thermo-responsive materials. Applications in smart windows, temperature-responsive coatings, and energy-efficient building materials are showing promise. These materials can help reduce energy consumption in buildings by automatically adjusting their properties in response to temperature changes, aligning with global efforts to combat climate change and reduce carbon emissions.

The industrial sector is also adopting these advanced materials for process optimization and safety applications. Thermo-responsive materials enhanced with ammonium hydroxide are being used in temperature-sensitive valves, sensors, and safety systems, offering improved performance and reliability over traditional materials. This market segment is expected to grow as industries continue to prioritize efficiency and safety in their operations.

Geographically, North America and Europe currently lead the market for enhanced thermo-responsive applications, owing to their strong research and development capabilities and early adoption of advanced materials. However, the Asia-Pacific region is anticipated to witness the fastest growth in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness of smart materials' potential.

Current Challenges in Thermo-Responsive Material Development

The development of thermo-responsive materials has made significant strides in recent years, yet several challenges persist in realizing their full potential, particularly in applications involving ammonium hydroxide. One of the primary obstacles is achieving precise control over the temperature-responsive behavior. While many materials exhibit a response to temperature changes, fine-tuning the exact temperature at which the response occurs remains difficult. This challenge is exacerbated when incorporating ammonium hydroxide, as its presence can alter the material's thermal properties and response thresholds.

Another significant hurdle is maintaining the stability and durability of thermo-responsive materials over extended periods and multiple cycles of use. The repeated expansion and contraction or phase changes that these materials undergo can lead to structural fatigue and degradation of their responsive properties. This issue is particularly pronounced in applications where the material is exposed to ammonium hydroxide, which can accelerate wear and potentially alter the material's chemical composition over time.

The biocompatibility of thermo-responsive materials is also a critical concern, especially for biomedical applications. While many of these materials show promise for drug delivery or tissue engineering, ensuring their safety and efficacy in biological environments remains challenging. The addition of ammonium hydroxide further complicates this aspect, as its potential effects on living tissues must be carefully evaluated and mitigated.

Scalability and cost-effectiveness present additional challenges in the widespread adoption of thermo-responsive materials. Many current synthesis methods are complex and resource-intensive, making large-scale production economically unfeasible. Incorporating ammonium hydroxide into these materials often requires specialized handling and processing, further increasing production costs and complexity.

Furthermore, achieving uniform and consistent performance across different batches and scales of production remains a significant technical hurdle. The properties of thermo-responsive materials can be highly sensitive to slight variations in composition or processing conditions, making it difficult to maintain consistent quality in industrial-scale manufacturing.

Lastly, the environmental impact of thermo-responsive materials, particularly those involving ammonium hydroxide, is an emerging concern. As these materials find increasing applications, questions about their long-term environmental fate and potential for recycling or biodegradation become more pressing. Developing eco-friendly formulations and production methods that maintain the desired thermo-responsive properties while minimizing environmental impact is a complex challenge that researchers continue to grapple with.

Another significant hurdle is maintaining the stability and durability of thermo-responsive materials over extended periods and multiple cycles of use. The repeated expansion and contraction or phase changes that these materials undergo can lead to structural fatigue and degradation of their responsive properties. This issue is particularly pronounced in applications where the material is exposed to ammonium hydroxide, which can accelerate wear and potentially alter the material's chemical composition over time.

The biocompatibility of thermo-responsive materials is also a critical concern, especially for biomedical applications. While many of these materials show promise for drug delivery or tissue engineering, ensuring their safety and efficacy in biological environments remains challenging. The addition of ammonium hydroxide further complicates this aspect, as its potential effects on living tissues must be carefully evaluated and mitigated.

Scalability and cost-effectiveness present additional challenges in the widespread adoption of thermo-responsive materials. Many current synthesis methods are complex and resource-intensive, making large-scale production economically unfeasible. Incorporating ammonium hydroxide into these materials often requires specialized handling and processing, further increasing production costs and complexity.

Furthermore, achieving uniform and consistent performance across different batches and scales of production remains a significant technical hurdle. The properties of thermo-responsive materials can be highly sensitive to slight variations in composition or processing conditions, making it difficult to maintain consistent quality in industrial-scale manufacturing.

Lastly, the environmental impact of thermo-responsive materials, particularly those involving ammonium hydroxide, is an emerging concern. As these materials find increasing applications, questions about their long-term environmental fate and potential for recycling or biodegradation become more pressing. Developing eco-friendly formulations and production methods that maintain the desired thermo-responsive properties while minimizing environmental impact is a complex challenge that researchers continue to grapple with.

Existing Ammonium Hydroxide Enhancement Methods

01 Thermo-responsive polymers and hydrogels

Thermo-responsive polymers and hydrogels exhibit changes in their properties in response to temperature variations. These materials can undergo reversible phase transitions, such as swelling or shrinking, when exposed to different temperatures. They have applications in drug delivery systems, tissue engineering, and smart materials.- Thermo-responsive polymers and hydrogels: Thermo-responsive polymers and hydrogels exhibit changes in their properties, such as solubility or volume, in response to temperature variations. These materials can be used in various applications, including drug delivery systems, tissue engineering, and smart coatings. The temperature-dependent behavior of these materials is often reversible, allowing for controlled release or actuation.

- Shape memory materials: Shape memory materials are a class of thermo-responsive materials that can change their shape in response to temperature changes. These materials can be programmed to remember a specific shape and return to it when heated above a certain temperature. Applications include medical devices, aerospace components, and smart textiles.

- Thermo-responsive nanoparticles and composites: Nanoparticles and composite materials with thermo-responsive properties have been developed for various applications. These materials can exhibit changes in size, surface properties, or aggregation behavior in response to temperature changes. They are used in areas such as targeted drug delivery, sensors, and smart coatings.

- Temperature-sensitive membranes and films: Thermo-responsive membranes and films can change their permeability or other properties in response to temperature variations. These materials are useful in applications such as controlled release systems, separation processes, and smart packaging. The temperature-dependent behavior can be tailored by adjusting the composition and structure of the membrane or film.

- Thermo-responsive surface coatings: Surface coatings with thermo-responsive properties can change their wettability, adhesion, or other surface characteristics in response to temperature changes. These coatings have applications in areas such as self-cleaning surfaces, anti-fouling coatings, and smart textiles. The temperature-induced changes in surface properties can be reversible or irreversible depending on the specific material design.

02 Temperature-sensitive shape memory materials

Shape memory materials that respond to temperature changes can be used in various applications. These materials can remember and return to their original shape when exposed to specific temperatures. They have potential uses in medical devices, aerospace, and automotive industries.Expand Specific Solutions03 Thermo-responsive nanoparticles and nanocomposites

Nanoparticles and nanocomposites with thermo-responsive properties can be used in targeted drug delivery, sensing applications, and smart coatings. These materials can change their size, shape, or surface properties in response to temperature variations, allowing for controlled release or detection of specific stimuli.Expand Specific Solutions04 Temperature-sensitive membranes and films

Thermo-responsive membranes and films can be used for separation processes, controlled permeability, and smart packaging. These materials can change their pore size or permeability in response to temperature changes, allowing for selective filtration or controlled release of substances.Expand Specific Solutions05 Thermo-responsive coatings and surface modifications

Coatings and surface modifications with thermo-responsive properties can be applied to various substrates to create smart surfaces. These materials can change their wettability, adhesion, or other surface properties in response to temperature changes, leading to applications in self-cleaning surfaces, anti-fouling coatings, and temperature-controlled adhesives.Expand Specific Solutions

Key Players in Thermo-Responsive Material Industry

The research on ammonium hydroxide in enhancing thermo-responsive material applications is in an emerging stage, with growing market potential due to increasing demand for smart materials across various industries. The market size is expanding, driven by applications in sectors such as healthcare, textiles, and environmental monitoring. Technologically, the field is rapidly evolving, with companies like Albemarle Corp., Shin-Etsu Chemical Co., Ltd., and BASF SE leading in material development. These industry giants, along with research institutions like Zhejiang University and Southeast University, are pushing the boundaries of thermo-responsive materials, indicating a moderate level of technological maturity with significant room for innovation and commercialization.

Albemarle Corp.

Technical Solution: Albemarle Corp. has made significant contributions to the field of ammonium hydroxide-enhanced thermo-responsive materials, particularly in the context of catalysis and energy storage applications. Their research focuses on developing advanced materials that exhibit enhanced temperature-dependent properties for use in catalytic processes and battery technologies. Albemarle's approach involves the strategic incorporation of ammonium hydroxide into their proprietary material formulations, resulting in improved thermal sensitivity and responsiveness[8]. These materials show promise in applications such as temperature-controlled catalytic reactors, where the catalyst activity can be modulated based on temperature changes[10]. Additionally, Albemarle has explored the use of these materials in next-generation battery separators, where temperature-responsive properties can enhance safety and performance under varying thermal conditions[12].

Strengths: Specialized applications in catalysis and energy storage; Potential for significant improvements in process efficiency and safety. Weaknesses: Narrow focus may limit broader market applications; Challenges in scaling up production for large-scale industrial use.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical Co., Ltd. has made notable advancements in the field of ammonium hydroxide-enhanced thermo-responsive materials. Their research focuses on developing high-performance silicone-based thermo-responsive polymers with improved temperature sensitivity. Shin-Etsu's approach involves incorporating ammonium hydroxide into their silicone formulations to enhance the material's response to temperature changes[7]. This results in materials with more pronounced and rapid phase transitions, making them suitable for applications in smart windows and temperature-controlled drug delivery systems[9]. The company has also explored the use of these materials in electronic components, developing temperature-sensitive encapsulants that provide better thermal management for sensitive devices[11]. Shin-Etsu's materials show excellent stability and repeatability in their thermo-responsive behavior, even after multiple cycles of temperature changes.

Strengths: High-performance silicone-based materials with excellent stability; Wide range of applications from construction to electronics. Weaknesses: Higher production costs compared to conventional materials; May have limitations in extreme temperature environments.

Core Innovations in Ammonium Hydroxide Integration

Thermosetting eco-friendly resin composition and method for preparing the same

PatentActiveKR1020240080945A

Innovation

- A thermosetting eco-friendly resin composition is developed by mixing carbohydrates or their by-products with ammonium compounds in an aqueous system, eliminating the need for a separate neutralizer and utilizing cheaper ammonium compounds to achieve pH stability and equivalent physical properties.

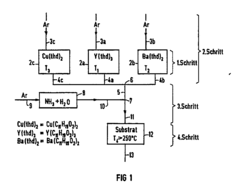

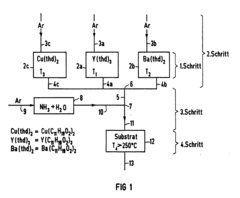

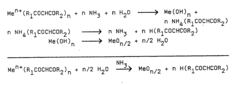

Method for obtaining superconducting oxide ceramic coatings on a substrate by means of a CVD-process

PatentInactiveEP0388754A1

Innovation

- Incorporating a gaseous reactant containing ammonia or an organic amine into the gas mixture to promote hydrolysis reactions, allowing for the formation of superconductor materials at lower temperatures with increased reaction rates by adjusting the energy supply and reactant composition.

Environmental Impact of Ammonium Hydroxide Usage

The use of ammonium hydroxide in enhancing thermo-responsive material applications raises significant environmental concerns that warrant careful consideration. Ammonium hydroxide, while effective in modifying the properties of thermo-responsive materials, can have detrimental effects on ecosystems if not properly managed.

One of the primary environmental impacts of ammonium hydroxide is its potential to cause eutrophication in aquatic environments. When released into water bodies, the high nitrogen content can lead to excessive algal growth, depleting oxygen levels and disrupting aquatic ecosystems. This can result in fish kills and long-term ecological imbalances in affected water systems.

Atmospheric emissions of ammonia from the use of ammonium hydroxide contribute to air pollution and can lead to the formation of fine particulate matter (PM2.5). These particles pose respiratory health risks to both humans and animals. Additionally, ammonia emissions can contribute to acid rain formation, which negatively impacts soil quality, vegetation, and aquatic life.

The production and transportation of ammonium hydroxide also carry environmental risks. Manufacturing processes often rely on fossil fuels, contributing to greenhouse gas emissions and climate change. Accidental spills during transport or handling can cause localized environmental damage, affecting soil quality and potentially contaminating groundwater resources.

In terms of waste management, the disposal of materials containing ammonium hydroxide requires careful consideration. Improper disposal can lead to soil contamination and groundwater pollution, potentially affecting drinking water sources and agricultural land.

However, it is important to note that the environmental impact of ammonium hydroxide in thermo-responsive material applications can be mitigated through responsible use and proper management practices. Implementing closed-loop systems, improving production efficiency, and developing more environmentally friendly alternatives are key strategies for reducing its environmental footprint.

Research into green chemistry approaches for thermo-responsive materials is ongoing, with efforts focused on developing bio-based alternatives and improving the recyclability of these materials. These advancements aim to reduce reliance on potentially harmful chemicals like ammonium hydroxide while maintaining or enhancing the performance of thermo-responsive materials.

In conclusion, while ammonium hydroxide offers significant benefits in enhancing thermo-responsive material applications, its environmental impact must be carefully managed. Balancing the technological advantages with environmental stewardship is crucial for the sustainable development and application of these innovative materials.

One of the primary environmental impacts of ammonium hydroxide is its potential to cause eutrophication in aquatic environments. When released into water bodies, the high nitrogen content can lead to excessive algal growth, depleting oxygen levels and disrupting aquatic ecosystems. This can result in fish kills and long-term ecological imbalances in affected water systems.

Atmospheric emissions of ammonia from the use of ammonium hydroxide contribute to air pollution and can lead to the formation of fine particulate matter (PM2.5). These particles pose respiratory health risks to both humans and animals. Additionally, ammonia emissions can contribute to acid rain formation, which negatively impacts soil quality, vegetation, and aquatic life.

The production and transportation of ammonium hydroxide also carry environmental risks. Manufacturing processes often rely on fossil fuels, contributing to greenhouse gas emissions and climate change. Accidental spills during transport or handling can cause localized environmental damage, affecting soil quality and potentially contaminating groundwater resources.

In terms of waste management, the disposal of materials containing ammonium hydroxide requires careful consideration. Improper disposal can lead to soil contamination and groundwater pollution, potentially affecting drinking water sources and agricultural land.

However, it is important to note that the environmental impact of ammonium hydroxide in thermo-responsive material applications can be mitigated through responsible use and proper management practices. Implementing closed-loop systems, improving production efficiency, and developing more environmentally friendly alternatives are key strategies for reducing its environmental footprint.

Research into green chemistry approaches for thermo-responsive materials is ongoing, with efforts focused on developing bio-based alternatives and improving the recyclability of these materials. These advancements aim to reduce reliance on potentially harmful chemicals like ammonium hydroxide while maintaining or enhancing the performance of thermo-responsive materials.

In conclusion, while ammonium hydroxide offers significant benefits in enhancing thermo-responsive material applications, its environmental impact must be carefully managed. Balancing the technological advantages with environmental stewardship is crucial for the sustainable development and application of these innovative materials.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for ammonium hydroxide-enhanced thermo-responsive materials are crucial for their widespread adoption and commercial viability. One of the primary challenges is maintaining consistent quality and performance across large-scale production. The precise control of ammonium hydroxide concentration and its uniform distribution within the thermo-responsive matrix is essential for achieving reproducible results.

In terms of manufacturing processes, several approaches can be considered. Solution-based methods, such as emulsion polymerization or precipitation, offer good control over particle size and composition but may face challenges in scaling up while maintaining homogeneity. Alternatively, melt-processing techniques could be explored for certain thermo-responsive polymers, potentially offering higher throughput but requiring careful temperature management to prevent premature activation or degradation of the material.

The choice of equipment and processing parameters plays a significant role in successful scale-up. Continuous flow reactors or microfluidic systems may provide better control over reaction conditions and mixing compared to batch processes, especially when dealing with the rapid kinetics often associated with ammonium hydroxide interactions. However, these systems may require substantial initial investment and optimization.

Material storage and handling present another set of considerations. The hygroscopic nature of ammonium hydroxide necessitates moisture-controlled environments during production and storage. Additionally, the potential for ammonia off-gassing must be addressed through appropriate ventilation and safety measures in manufacturing facilities.

Cost-effectiveness is a critical factor in scaling up production. While ammonium hydroxide itself is relatively inexpensive, the overall material and processing costs must be carefully evaluated. This includes considering the efficiency of ammonium hydroxide utilization, potential for recycling or recovery, and the impact on downstream processing steps.

Environmental and regulatory compliance is another important aspect of large-scale manufacturing. The use of ammonium hydroxide may require specific waste treatment protocols and emission controls. Developing green chemistry approaches, such as using lower concentrations or exploring alternative, more environmentally friendly alkaline agents, could be beneficial for long-term sustainability.

Lastly, quality control and characterization methods must be adapted for high-throughput production. Rapid, in-line monitoring techniques for assessing thermo-responsive properties and ammonium hydroxide content would be valuable for maintaining consistent product quality. This might involve the development of specialized sensors or analytical methods suitable for integration into the manufacturing process.

In terms of manufacturing processes, several approaches can be considered. Solution-based methods, such as emulsion polymerization or precipitation, offer good control over particle size and composition but may face challenges in scaling up while maintaining homogeneity. Alternatively, melt-processing techniques could be explored for certain thermo-responsive polymers, potentially offering higher throughput but requiring careful temperature management to prevent premature activation or degradation of the material.

The choice of equipment and processing parameters plays a significant role in successful scale-up. Continuous flow reactors or microfluidic systems may provide better control over reaction conditions and mixing compared to batch processes, especially when dealing with the rapid kinetics often associated with ammonium hydroxide interactions. However, these systems may require substantial initial investment and optimization.

Material storage and handling present another set of considerations. The hygroscopic nature of ammonium hydroxide necessitates moisture-controlled environments during production and storage. Additionally, the potential for ammonia off-gassing must be addressed through appropriate ventilation and safety measures in manufacturing facilities.

Cost-effectiveness is a critical factor in scaling up production. While ammonium hydroxide itself is relatively inexpensive, the overall material and processing costs must be carefully evaluated. This includes considering the efficiency of ammonium hydroxide utilization, potential for recycling or recovery, and the impact on downstream processing steps.

Environmental and regulatory compliance is another important aspect of large-scale manufacturing. The use of ammonium hydroxide may require specific waste treatment protocols and emission controls. Developing green chemistry approaches, such as using lower concentrations or exploring alternative, more environmentally friendly alkaline agents, could be beneficial for long-term sustainability.

Lastly, quality control and characterization methods must be adapted for high-throughput production. Rapid, in-line monitoring techniques for assessing thermo-responsive properties and ammonium hydroxide content would be valuable for maintaining consistent product quality. This might involve the development of specialized sensors or analytical methods suitable for integration into the manufacturing process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!