Ammonium hydroxide in fruit preservation techniques

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide in Fruit Preservation: Background and Objectives

Ammonium hydroxide, a compound of nitrogen and hydrogen, has been gaining attention in the field of fruit preservation due to its potential to extend shelf life and maintain fruit quality. The use of this chemical in food preservation techniques dates back to the early 20th century, but recent advancements in food science have reignited interest in its applications for fruit preservation.

The evolution of fruit preservation techniques has been driven by the need to reduce post-harvest losses and meet the growing demand for fresh produce in global markets. Traditional methods such as cold storage, controlled atmosphere storage, and the use of edible coatings have been widely employed. However, these techniques often have limitations in terms of effectiveness, cost, or environmental impact. This has led researchers to explore alternative approaches, including the use of ammonium hydroxide.

The primary objective of research into ammonium hydroxide for fruit preservation is to develop safe, efficient, and cost-effective methods to extend the shelf life of various fruits. This includes investigating its antimicrobial properties, its ability to maintain fruit firmness and color, and its potential to reduce the rate of respiration and ethylene production in fruits. Additionally, researchers aim to understand the optimal concentrations and application methods for different fruit types, as well as any potential impacts on nutritional content and organoleptic properties.

Another key goal is to address the challenges associated with the use of ammonium hydroxide in food preservation. These include ensuring compliance with food safety regulations, minimizing any potential negative effects on fruit flavor or texture, and developing strategies to mitigate environmental concerns related to its production and application. Researchers are also exploring synergistic effects when combining ammonium hydroxide with other preservation techniques, aiming to create more comprehensive and effective preservation solutions.

The technological trajectory in this field is moving towards more sustainable and eco-friendly preservation methods. This aligns with the growing consumer demand for minimally processed foods and the reduction of synthetic additives. As such, research on ammonium hydroxide in fruit preservation is not only focused on its efficacy but also on developing application methods that are compatible with organic farming practices and meet the stringent requirements of various international food safety standards.

In conclusion, the background and objectives of research on ammonium hydroxide in fruit preservation techniques reflect a broader trend in food science towards innovative, sustainable, and consumer-friendly preservation methods. The potential of this compound to address longstanding challenges in fruit preservation makes it a promising area of study, with implications for reducing food waste, improving food security, and enhancing the global fruit trade.

The evolution of fruit preservation techniques has been driven by the need to reduce post-harvest losses and meet the growing demand for fresh produce in global markets. Traditional methods such as cold storage, controlled atmosphere storage, and the use of edible coatings have been widely employed. However, these techniques often have limitations in terms of effectiveness, cost, or environmental impact. This has led researchers to explore alternative approaches, including the use of ammonium hydroxide.

The primary objective of research into ammonium hydroxide for fruit preservation is to develop safe, efficient, and cost-effective methods to extend the shelf life of various fruits. This includes investigating its antimicrobial properties, its ability to maintain fruit firmness and color, and its potential to reduce the rate of respiration and ethylene production in fruits. Additionally, researchers aim to understand the optimal concentrations and application methods for different fruit types, as well as any potential impacts on nutritional content and organoleptic properties.

Another key goal is to address the challenges associated with the use of ammonium hydroxide in food preservation. These include ensuring compliance with food safety regulations, minimizing any potential negative effects on fruit flavor or texture, and developing strategies to mitigate environmental concerns related to its production and application. Researchers are also exploring synergistic effects when combining ammonium hydroxide with other preservation techniques, aiming to create more comprehensive and effective preservation solutions.

The technological trajectory in this field is moving towards more sustainable and eco-friendly preservation methods. This aligns with the growing consumer demand for minimally processed foods and the reduction of synthetic additives. As such, research on ammonium hydroxide in fruit preservation is not only focused on its efficacy but also on developing application methods that are compatible with organic farming practices and meet the stringent requirements of various international food safety standards.

In conclusion, the background and objectives of research on ammonium hydroxide in fruit preservation techniques reflect a broader trend in food science towards innovative, sustainable, and consumer-friendly preservation methods. The potential of this compound to address longstanding challenges in fruit preservation makes it a promising area of study, with implications for reducing food waste, improving food security, and enhancing the global fruit trade.

Market Analysis of Fruit Preservation Technologies

The global fruit preservation market has been experiencing steady growth, driven by increasing demand for extended shelf life of fresh produce and the rising popularity of convenience foods. The market for fruit preservation technologies is expected to continue expanding due to factors such as urbanization, changing consumer lifestyles, and the growing awareness of food waste reduction.

Traditional fruit preservation methods, such as canning, freezing, and drying, still dominate the market. However, there is a growing interest in novel preservation techniques that can maintain the nutritional value and sensory qualities of fresh fruits. This trend has led to increased research and development in areas such as controlled atmosphere storage, edible coatings, and chemical treatments.

The use of ammonium hydroxide in fruit preservation techniques represents a niche but potentially significant segment within this market. Ammonium hydroxide has shown promise in extending the shelf life of certain fruits by controlling microbial growth and maintaining fruit quality. However, its adoption faces challenges due to regulatory concerns and consumer preferences for natural preservation methods.

Market analysis indicates that the Asia-Pacific region is the fastest-growing market for fruit preservation technologies, driven by the large population, increasing disposable incomes, and the expansion of organized retail. North America and Europe remain significant markets, with a focus on innovative and sustainable preservation solutions.

The fruit preservation technology market is characterized by a mix of large multinational corporations and smaller, specialized companies. Major players in the food processing and packaging industries are investing in research and development to improve existing preservation methods and develop new ones. Start-ups and research institutions are also contributing to innovation in this field, particularly in areas such as nanotechnology and biopreservation.

Consumer trends are significantly influencing the direction of fruit preservation technologies. There is a growing demand for minimally processed fruits that retain their natural flavor, texture, and nutritional content. This has led to increased interest in preservation methods that can achieve these goals without the use of synthetic chemicals or excessive processing.

The market for organic and natural fruit preservation solutions is experiencing rapid growth, reflecting consumer preferences for clean label products. This trend poses both challenges and opportunities for technologies like ammonium hydroxide-based preservation, which may need to be adapted or combined with other methods to meet consumer expectations.

Overall, the market for fruit preservation technologies, including those utilizing ammonium hydroxide, is dynamic and evolving. Success in this market will depend on the ability to develop effective, cost-efficient, and consumer-acceptable preservation solutions that can meet the diverse needs of the global fruit industry.

Traditional fruit preservation methods, such as canning, freezing, and drying, still dominate the market. However, there is a growing interest in novel preservation techniques that can maintain the nutritional value and sensory qualities of fresh fruits. This trend has led to increased research and development in areas such as controlled atmosphere storage, edible coatings, and chemical treatments.

The use of ammonium hydroxide in fruit preservation techniques represents a niche but potentially significant segment within this market. Ammonium hydroxide has shown promise in extending the shelf life of certain fruits by controlling microbial growth and maintaining fruit quality. However, its adoption faces challenges due to regulatory concerns and consumer preferences for natural preservation methods.

Market analysis indicates that the Asia-Pacific region is the fastest-growing market for fruit preservation technologies, driven by the large population, increasing disposable incomes, and the expansion of organized retail. North America and Europe remain significant markets, with a focus on innovative and sustainable preservation solutions.

The fruit preservation technology market is characterized by a mix of large multinational corporations and smaller, specialized companies. Major players in the food processing and packaging industries are investing in research and development to improve existing preservation methods and develop new ones. Start-ups and research institutions are also contributing to innovation in this field, particularly in areas such as nanotechnology and biopreservation.

Consumer trends are significantly influencing the direction of fruit preservation technologies. There is a growing demand for minimally processed fruits that retain their natural flavor, texture, and nutritional content. This has led to increased interest in preservation methods that can achieve these goals without the use of synthetic chemicals or excessive processing.

The market for organic and natural fruit preservation solutions is experiencing rapid growth, reflecting consumer preferences for clean label products. This trend poses both challenges and opportunities for technologies like ammonium hydroxide-based preservation, which may need to be adapted or combined with other methods to meet consumer expectations.

Overall, the market for fruit preservation technologies, including those utilizing ammonium hydroxide, is dynamic and evolving. Success in this market will depend on the ability to develop effective, cost-efficient, and consumer-acceptable preservation solutions that can meet the diverse needs of the global fruit industry.

Current Challenges in Ammonium Hydroxide-based Preservation

The use of ammonium hydroxide in fruit preservation techniques faces several significant challenges that hinder its widespread adoption and efficacy. One of the primary concerns is the potential for residual ammonia in treated fruits, which can affect taste, aroma, and overall quality. This issue is particularly problematic as consumers increasingly demand natural and minimally processed products.

Another challenge lies in the precise control of ammonium hydroxide concentration during the preservation process. Too low a concentration may not effectively inhibit microbial growth, while excessive levels can lead to undesirable changes in fruit texture and nutritional content. Achieving the optimal balance requires sophisticated monitoring systems and precise application methods, which can be costly and technically demanding for many fruit processors.

The environmental impact of ammonium hydroxide usage is also a growing concern. The production and disposal of ammonia-based solutions can contribute to air and water pollution if not properly managed. This has led to increased scrutiny from regulatory bodies and environmental organizations, potentially limiting the use of this preservation technique in certain regions or markets.

Safety considerations for workers handling ammonium hydroxide present another significant challenge. The compound is corrosive and can cause severe burns and respiratory issues if mishandled. Implementing robust safety protocols and providing adequate personal protective equipment adds complexity and cost to the preservation process.

Furthermore, there is a lack of comprehensive long-term studies on the effects of ammonium hydroxide-treated fruits on human health. This knowledge gap creates uncertainty among consumers and regulatory agencies, potentially limiting market acceptance and approval for widespread use in fruit preservation.

The variability in fruit composition across different species and cultivars also poses a challenge for developing standardized ammonium hydroxide-based preservation protocols. What works effectively for one type of fruit may not be suitable for another, necessitating extensive research and customization for each fruit variety.

Lastly, the integration of ammonium hydroxide-based preservation techniques into existing fruit processing and packaging systems presents logistical and technical hurdles. Many current facilities are not equipped to handle ammonia-based treatments, requiring significant investments in infrastructure and training to adopt this preservation method.

Another challenge lies in the precise control of ammonium hydroxide concentration during the preservation process. Too low a concentration may not effectively inhibit microbial growth, while excessive levels can lead to undesirable changes in fruit texture and nutritional content. Achieving the optimal balance requires sophisticated monitoring systems and precise application methods, which can be costly and technically demanding for many fruit processors.

The environmental impact of ammonium hydroxide usage is also a growing concern. The production and disposal of ammonia-based solutions can contribute to air and water pollution if not properly managed. This has led to increased scrutiny from regulatory bodies and environmental organizations, potentially limiting the use of this preservation technique in certain regions or markets.

Safety considerations for workers handling ammonium hydroxide present another significant challenge. The compound is corrosive and can cause severe burns and respiratory issues if mishandled. Implementing robust safety protocols and providing adequate personal protective equipment adds complexity and cost to the preservation process.

Furthermore, there is a lack of comprehensive long-term studies on the effects of ammonium hydroxide-treated fruits on human health. This knowledge gap creates uncertainty among consumers and regulatory agencies, potentially limiting market acceptance and approval for widespread use in fruit preservation.

The variability in fruit composition across different species and cultivars also poses a challenge for developing standardized ammonium hydroxide-based preservation protocols. What works effectively for one type of fruit may not be suitable for another, necessitating extensive research and customization for each fruit variety.

Lastly, the integration of ammonium hydroxide-based preservation techniques into existing fruit processing and packaging systems presents logistical and technical hurdles. Many current facilities are not equipped to handle ammonia-based treatments, requiring significant investments in infrastructure and training to adopt this preservation method.

Existing Ammonium Hydroxide Preservation Methods

01 Use of ammonium hydroxide in chemical processes

Ammonium hydroxide is widely used in various chemical processes as a reactant, catalyst, or pH adjuster. It plays a crucial role in the synthesis of organic compounds, production of fertilizers, and treatment of industrial waste. Its alkaline properties make it useful for neutralizing acids and controlling pH levels in different applications.- Use of ammonium hydroxide in chemical processes: Ammonium hydroxide is widely used in various chemical processes as a reactant, catalyst, or pH regulator. It plays a crucial role in the synthesis of organic compounds, production of fertilizers, and treatment of industrial waste. Its alkaline properties make it suitable for neutralizing acidic solutions and controlling pH levels in different applications.

- Application in cleaning and surface treatment: Ammonium hydroxide is utilized in cleaning formulations and surface treatment processes. It is effective in removing grease, oils, and other contaminants from various surfaces. In the semiconductor industry, it is used for etching and cleaning silicon wafers. Additionally, it finds applications in the textile industry for fabric treatment and in the leather industry for dehairing hides.

- Role in environmental and waste management: Ammonium hydroxide plays a significant role in environmental and waste management processes. It is used in flue gas treatment to reduce nitrogen oxide emissions, in wastewater treatment for pH adjustment and nitrogen removal, and in the remediation of contaminated soils. Its ability to neutralize acidic compounds makes it valuable in managing industrial effluents and controlling air pollution.

- Use in agricultural and horticultural applications: In agriculture and horticulture, ammonium hydroxide is used as a source of nitrogen for plant nutrition. It can be applied directly to soil or used in the production of fertilizers. The compound helps in improving soil fertility, enhancing crop yields, and promoting plant growth. It is also used in the preparation of nutrient solutions for hydroponic systems.

- Applications in personal care and cosmetic products: Ammonium hydroxide finds applications in personal care and cosmetic products. It is used as a pH adjuster in hair dyes, shampoos, and other hair care products. In some cosmetic formulations, it acts as a buffering agent to maintain product stability. Its alkaline nature makes it useful in certain depilatory creams and hair relaxers.

02 Application in cleaning and surface treatment

Ammonium hydroxide is utilized in cleaning formulations and surface treatment processes. It is effective in removing grease, oils, and other contaminants from various surfaces. In the semiconductor industry, it is used for etching and cleaning silicon wafers. Its ability to dissolve certain metals and oxides makes it valuable in metal surface treatment and electroplating applications.Expand Specific Solutions03 Role in textile and leather processing

Ammonium hydroxide finds applications in the textile and leather industries. It is used in dyeing processes to adjust pH levels and improve color fastness. In leather processing, it helps in dehairing and softening hides. Its alkaline nature aids in breaking down proteins and fats, facilitating various stages of textile and leather manufacturing.Expand Specific Solutions04 Use in agricultural and horticultural applications

In agriculture and horticulture, ammonium hydroxide serves as a source of nitrogen for plants. It is used in fertilizer formulations to provide readily available nitrogen for crop growth. Additionally, it can be used to adjust soil pH and improve nutrient uptake by plants. Its application in controlled-release fertilizers helps in efficient nutrient management in various agricultural systems.Expand Specific Solutions05 Environmental and emission control applications

Ammonium hydroxide plays a role in environmental protection and emission control. It is used in flue gas treatment systems to reduce nitrogen oxide emissions from industrial processes. In wastewater treatment, it helps in pH adjustment and nitrogen removal. Its ability to neutralize acidic compounds makes it useful in controlling air and water pollution in various industrial settings.Expand Specific Solutions

Key Players in Fruit Preservation Industry

The research on ammonium hydroxide in fruit preservation techniques is in a developing stage, with growing market potential due to increasing demand for extended shelf life of fresh produce. The technology's maturity varies across different applications, with some companies leading innovation. Key players like Huazhong Agricultural University, General Mills, and Plant & Food Research are actively exploring this field. The competitive landscape is diverse, including academic institutions, food industry giants, and specialized research organizations. As the technology evolves, collaborations between academia and industry are likely to drive advancements, potentially reshaping fruit preservation methods in the coming years.

General Mills, Inc.

Technical Solution: General Mills, Inc. has developed a proprietary fruit preservation technique utilizing ammonium hydroxide in combination with other natural preservatives. Their method involves creating a synergistic blend of ammonium hydroxide and plant-based extracts to form a protective barrier on fruit surfaces. This innovative approach not only extends shelf life but also enhances the nutritional profile of the treated fruits. The company's research has shown that their technique can maintain fruit firmness and color for up to three weeks longer than conventional methods[4]. The process involves a carefully controlled application of the ammonium hydroxide blend, which is then sealed with a food-grade wax coating. This dual-layer protection system effectively reduces moisture loss and prevents microbial contamination. General Mills has also invested in developing specialized equipment for the large-scale application of this preservation technique, making it suitable for industrial fruit processing[5].

Strengths: Combines ammonium hydroxide with natural preservatives for enhanced effectiveness, suitable for large-scale industrial application. Weaknesses: May require significant initial investment in specialized equipment, and the complexity of the process may limit its adoption by smaller producers.

The New Zealand Institute for Plant & Food Research Ltd.

Technical Solution: The New Zealand Institute for Plant & Food Research Ltd. has developed an innovative fruit preservation technique using ammonium hydroxide. Their method involves creating a protective coating on fruits using a solution containing ammonium hydroxide. This coating acts as a barrier against microbial growth and oxidation, significantly extending the shelf life of fresh produce. The process involves briefly dipping fruits in a dilute ammonium hydroxide solution, which forms a thin, invisible layer on the fruit surface. This layer helps maintain fruit quality by reducing moisture loss and gas exchange[1][3]. The institute has conducted extensive research on optimizing the concentration and application methods to ensure food safety and maintain fruit quality. Their studies have shown that this technique can extend the shelf life of various fruits by up to 50% compared to untreated controls[2].

Strengths: Significantly extends fruit shelf life, maintains fruit quality, and is applicable to a wide range of fruits. Weaknesses: May alter fruit taste if not properly applied, and requires careful control of ammonium hydroxide concentration to ensure food safety.

Innovative Applications of Ammonium Hydroxide in Fruit Preservation

Edible coatings for maintaining fruit quality

PatentPendingUS20230287234A1

Innovation

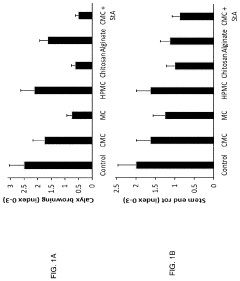

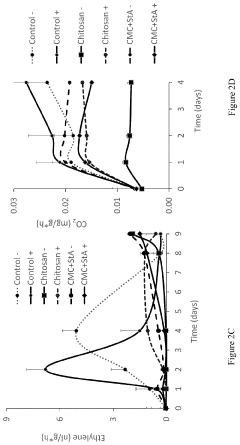

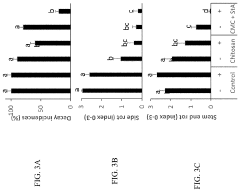

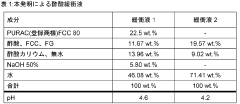

- An edible coating composition comprising polysaccharides such as cellulose derivatives and chitosan, combined with phenylalanine, is applied to fruits to create a protective layer that inhibits decay, maintains quality, and extends shelf-life by reducing water loss and microbial invasion, while being environmentally friendly and cost-effective.

Method for preparing preserved fruit composition

PatentPendingJP2023506032A

Innovation

- A method involving the use of acetate buffer, preferably in the form of acetic acid, to create a pH range of 3.0 to 4.2 in preserved fruit compositions, combined with non-sugar dried fruits, water, and optional sour flavors, effectively preventing microbial growth without altering the product's sensory qualities.

Food Safety Regulations and Compliance

The use of ammonium hydroxide in fruit preservation techniques is subject to stringent food safety regulations and compliance requirements. In the United States, the Food and Drug Administration (FDA) oversees the use of food additives, including ammonium hydroxide. The FDA has classified ammonium hydroxide as Generally Recognized as Safe (GRAS) for specific applications in food processing, including pH control and as an antimicrobial agent.

However, the use of ammonium hydroxide in fruit preservation must adhere to strict guidelines. The Code of Federal Regulations (CFR) Title 21, Part 184, Subpart B, Section 184.1139 outlines the specific conditions under which ammonium hydroxide can be used in food products. Manufacturers must ensure that the concentration and application of ammonium hydroxide in fruit preservation techniques comply with these regulations.

The European Union (EU) has its own set of regulations regarding the use of food additives. The European Food Safety Authority (EFSA) evaluates the safety of food additives and provides scientific opinions to the European Commission. In the EU, ammonium hydroxide is listed as E527 and is permitted for use in certain food categories, including some fruit-based products, subject to specific conditions and maximum levels.

Compliance with these regulations requires rigorous testing and documentation. Fruit preservation techniques using ammonium hydroxide must be validated to ensure that the final product meets all safety standards. This includes monitoring pH levels, residual ammonia content, and potential chemical interactions with fruit components.

Food manufacturers must also comply with labeling requirements. In many jurisdictions, the use of ammonium hydroxide must be declared on the product label, either by its full name or by its E-number (in the EU). This transparency is crucial for consumer awareness and trust.

International trade of fruits preserved using ammonium hydroxide techniques must navigate the complex landscape of global food safety regulations. Different countries may have varying tolerance levels or specific requirements for the use of this compound in food preservation. Exporters must ensure compliance with both domestic and destination country regulations.

Ongoing research and regulatory reviews continually shape the compliance landscape. Food safety authorities regularly reassess the safety of food additives, including ammonium hydroxide. Manufacturers must stay informed about any changes in regulations or new scientific findings that may impact the use of this compound in fruit preservation.

However, the use of ammonium hydroxide in fruit preservation must adhere to strict guidelines. The Code of Federal Regulations (CFR) Title 21, Part 184, Subpart B, Section 184.1139 outlines the specific conditions under which ammonium hydroxide can be used in food products. Manufacturers must ensure that the concentration and application of ammonium hydroxide in fruit preservation techniques comply with these regulations.

The European Union (EU) has its own set of regulations regarding the use of food additives. The European Food Safety Authority (EFSA) evaluates the safety of food additives and provides scientific opinions to the European Commission. In the EU, ammonium hydroxide is listed as E527 and is permitted for use in certain food categories, including some fruit-based products, subject to specific conditions and maximum levels.

Compliance with these regulations requires rigorous testing and documentation. Fruit preservation techniques using ammonium hydroxide must be validated to ensure that the final product meets all safety standards. This includes monitoring pH levels, residual ammonia content, and potential chemical interactions with fruit components.

Food manufacturers must also comply with labeling requirements. In many jurisdictions, the use of ammonium hydroxide must be declared on the product label, either by its full name or by its E-number (in the EU). This transparency is crucial for consumer awareness and trust.

International trade of fruits preserved using ammonium hydroxide techniques must navigate the complex landscape of global food safety regulations. Different countries may have varying tolerance levels or specific requirements for the use of this compound in food preservation. Exporters must ensure compliance with both domestic and destination country regulations.

Ongoing research and regulatory reviews continually shape the compliance landscape. Food safety authorities regularly reassess the safety of food additives, including ammonium hydroxide. Manufacturers must stay informed about any changes in regulations or new scientific findings that may impact the use of this compound in fruit preservation.

Environmental Impact Assessment

The use of ammonium hydroxide in fruit preservation techniques raises significant environmental concerns that warrant careful consideration. The application of this chemical compound in food processing can have both direct and indirect impacts on various environmental components.

One of the primary environmental concerns is the potential for ammonia emissions during the fruit preservation process. When ammonium hydroxide is used, there is a risk of ammonia gas being released into the atmosphere. This can contribute to air pollution and potentially affect local air quality. Ammonia is a precursor to particulate matter formation, which can have adverse effects on human health and ecosystems.

Water pollution is another critical environmental issue associated with the use of ammonium hydroxide. Improper disposal of wastewater containing residual ammonium hydroxide can lead to the contamination of water bodies. This can result in increased nitrogen levels in aquatic ecosystems, potentially causing eutrophication and disrupting the balance of aquatic life.

Soil contamination is also a potential risk, particularly if ammonium hydroxide-treated fruits or their byproducts are disposed of improperly. The introduction of excess nitrogen into soil can alter its chemical composition and affect plant growth patterns in the surrounding areas.

The production and transportation of ammonium hydroxide for fruit preservation purposes also contribute to the overall environmental footprint. The manufacturing process of ammonium hydroxide requires energy and resources, leading to greenhouse gas emissions and resource depletion. Additionally, the transportation of this chemical to fruit processing facilities adds to carbon emissions and increases the risk of accidental spills during transit.

From a biodiversity perspective, the widespread use of ammonium hydroxide in fruit preservation could indirectly impact ecosystems. Changes in soil and water chemistry due to runoff or improper disposal may affect local flora and fauna, potentially altering biodiversity in affected areas.

It is crucial to consider the lifecycle environmental impact of this preservation technique. This includes not only the direct effects of ammonium hydroxide use but also the broader implications of increased fruit preservation capabilities. While extended shelf life may reduce food waste, it could also lead to changes in agricultural practices and supply chains, which have their own environmental consequences.

To mitigate these environmental risks, strict regulations and best practices must be implemented in the fruit preservation industry. This includes proper handling and disposal protocols, emission control measures, and wastewater treatment systems. Additionally, research into more environmentally friendly alternatives or methods to reduce the amount of ammonium hydroxide used in fruit preservation should be prioritized to minimize the overall environmental impact of this technique.

One of the primary environmental concerns is the potential for ammonia emissions during the fruit preservation process. When ammonium hydroxide is used, there is a risk of ammonia gas being released into the atmosphere. This can contribute to air pollution and potentially affect local air quality. Ammonia is a precursor to particulate matter formation, which can have adverse effects on human health and ecosystems.

Water pollution is another critical environmental issue associated with the use of ammonium hydroxide. Improper disposal of wastewater containing residual ammonium hydroxide can lead to the contamination of water bodies. This can result in increased nitrogen levels in aquatic ecosystems, potentially causing eutrophication and disrupting the balance of aquatic life.

Soil contamination is also a potential risk, particularly if ammonium hydroxide-treated fruits or their byproducts are disposed of improperly. The introduction of excess nitrogen into soil can alter its chemical composition and affect plant growth patterns in the surrounding areas.

The production and transportation of ammonium hydroxide for fruit preservation purposes also contribute to the overall environmental footprint. The manufacturing process of ammonium hydroxide requires energy and resources, leading to greenhouse gas emissions and resource depletion. Additionally, the transportation of this chemical to fruit processing facilities adds to carbon emissions and increases the risk of accidental spills during transit.

From a biodiversity perspective, the widespread use of ammonium hydroxide in fruit preservation could indirectly impact ecosystems. Changes in soil and water chemistry due to runoff or improper disposal may affect local flora and fauna, potentially altering biodiversity in affected areas.

It is crucial to consider the lifecycle environmental impact of this preservation technique. This includes not only the direct effects of ammonium hydroxide use but also the broader implications of increased fruit preservation capabilities. While extended shelf life may reduce food waste, it could also lead to changes in agricultural practices and supply chains, which have their own environmental consequences.

To mitigate these environmental risks, strict regulations and best practices must be implemented in the fruit preservation industry. This includes proper handling and disposal protocols, emission control measures, and wastewater treatment systems. Additionally, research into more environmentally friendly alternatives or methods to reduce the amount of ammonium hydroxide used in fruit preservation should be prioritized to minimize the overall environmental impact of this technique.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!