Cellulose Acetate: Accelerating the Revolution in Sustainable Tech

Cellulose Acetate Evolution and Research Objectives

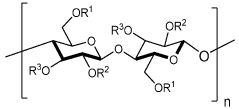

Cellulose acetate has emerged as a pivotal material in the quest for sustainable technologies, with its roots tracing back to the late 19th century. Initially developed as a photographic film base and later used in textiles, cellulose acetate has undergone significant evolution over the past century. Its journey from a niche material to a versatile sustainable solution reflects the growing emphasis on eco-friendly alternatives in various industries.

The technological progression of cellulose acetate has been marked by continuous improvements in production processes and expanding applications. Early developments focused on enhancing its physical properties and durability. As environmental concerns gained prominence, research shifted towards optimizing its biodegradability and reducing the environmental impact of its production. Recent advancements have explored novel formulations and composites, aiming to broaden its utility while maintaining its core sustainable attributes.

Current research objectives in cellulose acetate technology are multifaceted, addressing both immediate challenges and long-term sustainability goals. A primary focus is on improving the material's mechanical properties to expand its applicability in high-performance applications. This includes enhancing tensile strength, flexibility, and thermal stability without compromising its biodegradability. Researchers are also exploring ways to reduce production costs and energy consumption, making cellulose acetate more economically viable for widespread adoption.

Another critical research direction is the development of more efficient and environmentally friendly production methods. This involves investigating alternative solvents and catalysts that minimize toxic byproducts and reduce the overall environmental footprint of cellulose acetate manufacturing. Additionally, there is a growing interest in exploring new sources of cellulose, including agricultural waste and non-food crops, to ensure a sustainable and abundant raw material supply.

The integration of cellulose acetate with other materials and technologies is also a key research objective. This includes developing cellulose acetate-based composites with enhanced properties, such as improved barrier characteristics for packaging applications or increased conductivity for electronic components. Furthermore, researchers are investigating the potential of cellulose acetate in emerging fields like 3D printing and smart materials, aiming to leverage its unique properties in cutting-edge applications.

As the demand for sustainable materials continues to grow, the research objectives for cellulose acetate are increasingly aligned with broader sustainability goals. This includes exploring its potential in carbon capture and storage applications, as well as its role in circular economy models. The ultimate aim is to position cellulose acetate as a versatile, high-performance, and environmentally responsible material that can significantly contribute to the global transition towards more sustainable technologies and practices.

Market Demand for Sustainable Materials

The market demand for sustainable materials has been experiencing a significant surge in recent years, driven by increasing environmental awareness and stringent regulations. Cellulose acetate, a biodegradable and renewable material derived from wood pulp or cotton fibers, has emerged as a promising candidate to meet this growing demand across various industries.

In the packaging sector, there is a strong push towards eco-friendly alternatives to traditional plastics. Cellulose acetate films and sheets are gaining traction as sustainable packaging materials due to their biodegradability and compostability. The food and beverage industry, in particular, is showing keen interest in cellulose acetate-based packaging solutions to reduce their environmental footprint and appeal to environmentally conscious consumers.

The textile industry is another major market for cellulose acetate, especially in the form of fibers. With the rising demand for sustainable fashion, cellulose acetate fibers are being increasingly used in the production of eco-friendly fabrics and garments. These fibers offer a viable alternative to synthetic materials, addressing concerns about microplastic pollution from textile production and use.

In the consumer goods sector, cellulose acetate is finding applications in various products, from eyewear frames to personal care items. The material's versatility, durability, and biodegradability make it an attractive option for manufacturers looking to develop sustainable product lines.

The automotive industry is also exploring the use of cellulose acetate in interior components and lightweight structural materials. As automakers strive to reduce vehicle weight and improve fuel efficiency, bio-based materials like cellulose acetate offer potential solutions that align with sustainability goals.

The electronics industry is showing interest in cellulose acetate for developing biodegradable components and casings. With the growing concern over electronic waste, there is a push towards more sustainable materials in device manufacturing.

Market analysts project a compound annual growth rate (CAGR) for the cellulose acetate market in the high single digits over the next five years. This growth is attributed to the increasing adoption of sustainable materials across industries and the material's versatility in various applications.

However, challenges remain in scaling up production to meet the growing demand while maintaining cost-competitiveness with traditional materials. Investments in research and development are crucial to improve the performance characteristics of cellulose acetate and expand its applicability in high-value markets.

As governments worldwide implement stricter environmental regulations and consumers become more eco-conscious, the demand for sustainable materials like cellulose acetate is expected to continue its upward trajectory. This presents significant opportunities for innovation and market expansion in the coming years.

Current Challenges in Cellulose Acetate Technology

Cellulose acetate technology, while promising in its potential for sustainable applications, faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is the material's inherent moisture sensitivity. Cellulose acetate tends to absorb water from the environment, leading to dimensional instability and potential degradation of its mechanical properties. This hygroscopic nature limits its use in certain applications where moisture resistance is crucial.

Another challenge lies in the production process of cellulose acetate. The traditional manufacturing methods often involve the use of environmentally harmful solvents and chemicals, which contradicts the material's eco-friendly image. Developing greener production techniques that maintain or improve the quality of the final product remains a significant hurdle for researchers and manufacturers alike.

The biodegradability of cellulose acetate, while generally considered an advantage, also presents challenges in terms of controlled degradation. In some applications, the material may degrade too quickly, compromising its functional lifespan. Conversely, in other scenarios, it may not degrade fast enough to meet environmental standards. Striking the right balance between durability and biodegradability is a complex task that requires further research and development.

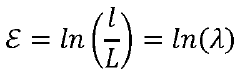

Mechanical properties of cellulose acetate also pose challenges, particularly in high-performance applications. While the material offers good flexibility and impact resistance, its tensile strength and heat resistance are often lower compared to conventional petroleum-based plastics. This limitation restricts its use in certain industrial and consumer products where high strength and temperature resistance are essential.

Furthermore, the cost-effectiveness of cellulose acetate production remains a significant barrier to its widespread adoption. The raw materials and processing costs are often higher than those of traditional plastics, making it less economically viable for many applications. Achieving cost parity or superiority without compromising on quality and sustainability is a major challenge facing the industry.

Lastly, there are technical challenges related to the modification and functionalization of cellulose acetate. While the material offers good compatibility with various additives, achieving specific properties or functionalities often requires complex chemical modifications. Developing efficient and scalable methods for tailoring cellulose acetate to meet diverse application requirements is an ongoing area of research and development in the field.

Existing Cellulose Acetate Applications

01 Cellulose acetate production methods

Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.- Production methods for cellulose acetate: Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.

- Cellulose acetate fibers and films: Techniques for manufacturing cellulose acetate fibers and films are presented, focusing on improving their properties such as strength, flexibility, and durability. These innovations are applicable in textile, packaging, and membrane industries.

- Cellulose acetate composites and blends: Development of cellulose acetate-based composites and blends with other materials to enhance specific properties or functionalities. These innovations aim to expand the application range of cellulose acetate in various industries.

- Modification and functionalization of cellulose acetate: Methods for modifying and functionalizing cellulose acetate to impart new properties or improve existing ones. These techniques include chemical modifications, surface treatments, and incorporation of additives to enhance performance in specific applications.

- Applications of cellulose acetate in various industries: Exploration of novel applications for cellulose acetate in diverse industries such as pharmaceuticals, electronics, environmental protection, and consumer goods. These innovations leverage the unique properties of cellulose acetate to develop new products or improve existing ones.

02 Cellulose acetate fiber applications

Cellulose acetate fibers are utilized in diverse applications such as textiles, filters, and personal care products. The properties of these fibers, including their biodegradability and versatility, make them suitable for various industrial and consumer goods.Expand Specific Solutions03 Cellulose acetate film and membrane technology

Advancements in cellulose acetate film and membrane technology are presented, focusing on improved manufacturing techniques and enhanced properties for applications in separation processes, packaging, and optical films.Expand Specific Solutions04 Cellulose acetate modifications and derivatives

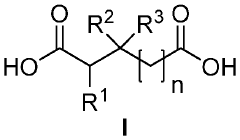

Research on modifying cellulose acetate and creating new derivatives is discussed, including chemical modifications, blending with other polymers, and developing composite materials to enhance performance characteristics for specific applications.Expand Specific Solutions05 Cellulose acetate in sustainable and biodegradable products

The use of cellulose acetate in developing sustainable and biodegradable products is explored, focusing on its potential as an environmentally friendly alternative to conventional plastics in various consumer and industrial applications.Expand Specific Solutions

Key Players in Cellulose Acetate Industry

The research on cellulose acetate is in a growth phase, with increasing market size driven by sustainable technology demands. The global cellulose acetate market is projected to expand significantly, fueled by applications in various industries. Technologically, cellulose acetate is mature but evolving, with companies like Daicel Corp., Eastman Chemical Co., and BASF Corp. leading innovation. Academic institutions such as the Institute of Process Engineering, Chinese Academy of Sciences, and Beijing Forestry University are contributing to advancements. Emerging players like Nantong Cellulose Fibers Co. Ltd. and Zhuhai Cellulose Fibers Co. Ltd. are also making strides, indicating a competitive landscape with diverse participants from industry and academia.

Daicel Corp.

Eastman Chemical Co.

Innovative Cellulose Acetate Research

- A cellulose acetate with a total degree of acetyl substitution not greater than 2.7, a specific ratio of acetyl substitution at different positions, and a sulfate component content of 20-400 ppm, along with additives like magnesium oxide and triacetin, enhances biodegradability in seawater.

- Development of melt-stable cellulose acetates with specific characteristics, such as a heated intrinsic viscosity of at least 0.9 and a metals-to-sulfur molar ratio of at least 1.35, which are combined with plasticizers to create compositions that exhibit reduced color formation and molecular weight retention during processing.

Environmental Impact Assessment

Cellulose acetate, a biodegradable and renewable material derived from wood pulp or cotton fibers, has gained significant attention in the sustainable technology sector. As we assess its environmental impact, it is crucial to consider both the positive and negative aspects throughout its lifecycle.

The production of cellulose acetate begins with the extraction of cellulose from natural sources, primarily wood pulp. This process generally has a lower environmental footprint compared to the production of petroleum-based plastics. The use of renewable resources reduces dependency on fossil fuels and contributes to a more sustainable supply chain. Additionally, the manufacturing process of cellulose acetate typically requires less energy compared to conventional plastic production, resulting in reduced greenhouse gas emissions.

One of the most significant environmental benefits of cellulose acetate is its biodegradability. Unlike traditional plastics that persist in the environment for hundreds of years, cellulose acetate can decompose within a few months to several years, depending on environmental conditions. This characteristic greatly reduces the long-term impact on ecosystems and helps mitigate the global plastic pollution crisis.

However, it is important to note that the biodegradation process of cellulose acetate may release acetate compounds into the environment. While these compounds are generally considered less harmful than microplastics, their potential effects on soil and aquatic ecosystems require further study to ensure long-term environmental safety.

The production of cellulose acetate does involve the use of chemical solvents and additives, which can have environmental implications if not properly managed. Responsible manufacturing practices, including efficient solvent recovery systems and proper waste treatment, are essential to minimize the release of harmful substances into the environment.

When considering the end-of-life phase, cellulose acetate offers advantages in terms of disposal options. It can be composted in industrial facilities, reducing the burden on landfills and incineration plants. However, the availability of appropriate composting infrastructure remains a challenge in many regions, potentially limiting the realization of its full environmental benefits.

In terms of carbon footprint, cellulose acetate generally performs better than traditional plastics. The renewable nature of its raw materials allows for carbon sequestration during the growth phase of the source plants. This, combined with its biodegradability, contributes to a more favorable lifecycle carbon balance compared to fossil fuel-based alternatives.

As research and development in cellulose acetate technology continue to advance, improvements in production efficiency and material properties are expected to further enhance its environmental profile. Ongoing efforts to optimize the biodegradation process and develop more eco-friendly additives will be crucial in maximizing the positive environmental impact of this promising sustainable material.

Regulatory Framework for Bioplastics

The regulatory framework for bioplastics, including cellulose acetate, is evolving rapidly as governments and international organizations recognize the potential of these materials to address environmental concerns. In the European Union, the Packaging and Packaging Waste Directive (PPWD) sets targets for the recycling and recovery of packaging materials, including bioplastics. The directive aims to reduce the environmental impact of packaging waste and promote the use of sustainable materials.

The United States Environmental Protection Agency (EPA) has established guidelines for the labeling and marketing of biodegradable plastics, including cellulose acetate-based products. These guidelines aim to prevent greenwashing and ensure that consumers receive accurate information about the environmental impact of bioplastic products.

In Japan, the Biomass Plastics Introduction Promotion Policy encourages the use of bioplastics, including cellulose acetate, in various industries. The policy provides incentives for companies that incorporate bioplastics into their products and packaging, promoting the transition towards more sustainable materials.

The International Organization for Standardization (ISO) has developed several standards related to bioplastics, such as ISO 17088 for compostable plastics and ISO 16620 for the determination of biobased content. These standards provide a framework for assessing the environmental performance and biodegradability of bioplastic materials, including cellulose acetate.

Many countries have implemented or are considering implementing taxes on single-use plastics, which could indirectly benefit the cellulose acetate industry by making bioplastic alternatives more economically competitive. For example, the United Kingdom introduced a plastic packaging tax in April 2022, which applies to packaging with less than 30% recycled content.

The regulatory landscape for bioplastics is also influenced by broader sustainability initiatives, such as the United Nations Sustainable Development Goals (SDGs) and the Paris Agreement on climate change. These global frameworks encourage the adoption of sustainable materials and practices, creating a favorable environment for the development and use of cellulose acetate and other bioplastics.

As the cellulose acetate industry continues to innovate and expand, it is crucial for manufacturers and researchers to stay informed about evolving regulations and standards. Compliance with these frameworks not only ensures legal adherence but also enhances the marketability and acceptance of cellulose acetate products in an increasingly environmentally conscious global market.