Ethical Sourcing Practices in Blade Battery Material Supply

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Blade Battery Ethics Background and Objectives

The development of blade batteries represents a significant advancement in electric vehicle (EV) technology, offering improved safety, energy density, and cost-effectiveness. However, the ethical sourcing of materials for these batteries has become a critical concern in the industry. This research aims to explore and analyze the ethical sourcing practices in the blade battery material supply chain, with a focus on ensuring sustainable and responsible procurement processes.

The blade battery, introduced by BYD in 2020, utilizes lithium iron phosphate (LFP) chemistry and a unique cell-to-pack design. This innovation has garnered attention due to its enhanced safety features and potential to reduce production costs. As the demand for EVs continues to grow globally, the ethical sourcing of battery materials has become increasingly important to address environmental, social, and governance (ESG) concerns.

The primary objective of this research is to comprehensively examine the current state of ethical sourcing practices in the blade battery material supply chain. This includes investigating the sourcing of key materials such as lithium, iron, and phosphate, as well as other components used in battery production. The study will evaluate existing ethical standards, certifications, and best practices employed by industry leaders and identify areas for improvement.

Furthermore, this research aims to analyze the potential environmental and social impacts associated with blade battery material sourcing. This includes assessing the carbon footprint of extraction and processing activities, evaluating labor conditions in mining operations, and examining the effects on local communities in resource-rich regions. By understanding these impacts, the study seeks to propose strategies for minimizing negative consequences and promoting sustainable practices throughout the supply chain.

Another key objective is to explore innovative approaches to ethical sourcing that can be applied specifically to blade battery materials. This may involve investigating emerging technologies for material traceability, such as blockchain-based supply chain management systems, or examining alternative sourcing methods that prioritize recycled materials and circular economy principles.

The research will also consider the regulatory landscape surrounding ethical sourcing in the battery industry, including current and proposed legislation in major markets. By analyzing these regulatory frameworks, the study aims to identify potential challenges and opportunities for companies operating in the blade battery sector to align their sourcing practices with evolving ethical standards and legal requirements.

Ultimately, this research seeks to provide valuable insights and recommendations for stakeholders in the blade battery industry, including manufacturers, suppliers, policymakers, and investors. By addressing the ethical challenges associated with material sourcing, the study aims to contribute to the development of a more sustainable and responsible EV battery ecosystem, supporting the broader transition to clean energy transportation.

The blade battery, introduced by BYD in 2020, utilizes lithium iron phosphate (LFP) chemistry and a unique cell-to-pack design. This innovation has garnered attention due to its enhanced safety features and potential to reduce production costs. As the demand for EVs continues to grow globally, the ethical sourcing of battery materials has become increasingly important to address environmental, social, and governance (ESG) concerns.

The primary objective of this research is to comprehensively examine the current state of ethical sourcing practices in the blade battery material supply chain. This includes investigating the sourcing of key materials such as lithium, iron, and phosphate, as well as other components used in battery production. The study will evaluate existing ethical standards, certifications, and best practices employed by industry leaders and identify areas for improvement.

Furthermore, this research aims to analyze the potential environmental and social impacts associated with blade battery material sourcing. This includes assessing the carbon footprint of extraction and processing activities, evaluating labor conditions in mining operations, and examining the effects on local communities in resource-rich regions. By understanding these impacts, the study seeks to propose strategies for minimizing negative consequences and promoting sustainable practices throughout the supply chain.

Another key objective is to explore innovative approaches to ethical sourcing that can be applied specifically to blade battery materials. This may involve investigating emerging technologies for material traceability, such as blockchain-based supply chain management systems, or examining alternative sourcing methods that prioritize recycled materials and circular economy principles.

The research will also consider the regulatory landscape surrounding ethical sourcing in the battery industry, including current and proposed legislation in major markets. By analyzing these regulatory frameworks, the study aims to identify potential challenges and opportunities for companies operating in the blade battery sector to align their sourcing practices with evolving ethical standards and legal requirements.

Ultimately, this research seeks to provide valuable insights and recommendations for stakeholders in the blade battery industry, including manufacturers, suppliers, policymakers, and investors. By addressing the ethical challenges associated with material sourcing, the study aims to contribute to the development of a more sustainable and responsible EV battery ecosystem, supporting the broader transition to clean energy transportation.

Market Demand for Ethical Blade Batteries

The market demand for ethically sourced blade batteries has been steadily increasing in recent years, driven by growing consumer awareness and regulatory pressures. As sustainability becomes a key focus for both consumers and governments, the automotive industry, in particular, has seen a significant shift towards more environmentally friendly and socially responsible practices.

Electric vehicle (EV) manufacturers are at the forefront of this trend, recognizing that the ethical sourcing of battery materials is crucial for maintaining their brand reputation and meeting stringent environmental standards. Blade batteries, known for their improved safety and energy density, are gaining popularity in the EV market. However, the sourcing of materials for these batteries, particularly cobalt and lithium, has come under scrutiny due to concerns about human rights violations and environmental degradation in mining practices.

Major automakers and battery manufacturers are responding to this demand by implementing robust supply chain management systems and partnering with suppliers who can demonstrate ethical sourcing practices. This has led to an increase in demand for transparently sourced materials, with some companies even willing to pay a premium for ethically sourced components.

The market for ethically sourced blade batteries is not limited to the automotive sector. As renewable energy storage solutions become more prevalent, there is a growing demand for sustainable battery technologies in the power grid and residential sectors. This expansion of application areas further drives the need for ethically sourced materials.

Consumer electronics manufacturers are also beginning to prioritize ethical sourcing in their supply chains, recognizing the potential for brand differentiation and customer loyalty. As blade battery technology becomes more compact and efficient, its potential applications in portable devices are expanding, creating additional market demand for ethically sourced versions.

Investors and financial institutions are increasingly considering environmental, social, and governance (ESG) factors in their decision-making processes. This has led to greater scrutiny of companies' supply chain practices and a preference for those demonstrating commitment to ethical sourcing. As a result, companies investing in ethical sourcing for blade batteries may find it easier to attract capital and secure favorable financing terms.

The demand for ethically sourced blade batteries is also being driven by regulatory developments. Many countries are introducing or strengthening legislation around supply chain transparency and responsible sourcing. Companies that proactively address these issues are better positioned to comply with current and future regulations, avoiding potential legal and reputational risks.

Electric vehicle (EV) manufacturers are at the forefront of this trend, recognizing that the ethical sourcing of battery materials is crucial for maintaining their brand reputation and meeting stringent environmental standards. Blade batteries, known for their improved safety and energy density, are gaining popularity in the EV market. However, the sourcing of materials for these batteries, particularly cobalt and lithium, has come under scrutiny due to concerns about human rights violations and environmental degradation in mining practices.

Major automakers and battery manufacturers are responding to this demand by implementing robust supply chain management systems and partnering with suppliers who can demonstrate ethical sourcing practices. This has led to an increase in demand for transparently sourced materials, with some companies even willing to pay a premium for ethically sourced components.

The market for ethically sourced blade batteries is not limited to the automotive sector. As renewable energy storage solutions become more prevalent, there is a growing demand for sustainable battery technologies in the power grid and residential sectors. This expansion of application areas further drives the need for ethically sourced materials.

Consumer electronics manufacturers are also beginning to prioritize ethical sourcing in their supply chains, recognizing the potential for brand differentiation and customer loyalty. As blade battery technology becomes more compact and efficient, its potential applications in portable devices are expanding, creating additional market demand for ethically sourced versions.

Investors and financial institutions are increasingly considering environmental, social, and governance (ESG) factors in their decision-making processes. This has led to greater scrutiny of companies' supply chain practices and a preference for those demonstrating commitment to ethical sourcing. As a result, companies investing in ethical sourcing for blade batteries may find it easier to attract capital and secure favorable financing terms.

The demand for ethically sourced blade batteries is also being driven by regulatory developments. Many countries are introducing or strengthening legislation around supply chain transparency and responsible sourcing. Companies that proactively address these issues are better positioned to comply with current and future regulations, avoiding potential legal and reputational risks.

Ethical Sourcing Challenges in Battery Materials

The ethical sourcing of battery materials presents significant challenges in the rapidly growing electric vehicle (EV) and energy storage industries. As demand for lithium-ion batteries surges, concerns about the environmental and social impacts of raw material extraction have intensified. Key materials like lithium, cobalt, nickel, and graphite are often sourced from regions with weak regulatory frameworks, leading to issues such as human rights violations, child labor, and environmental degradation.

One of the primary challenges is the lack of transparency in complex, multi-tiered supply chains. Many battery manufacturers struggle to trace the origin of their raw materials beyond their immediate suppliers, making it difficult to ensure ethical practices throughout the entire supply chain. This opacity creates opportunities for unethical actors to exploit workers and natural resources without detection.

The geographical concentration of certain battery materials exacerbates ethical sourcing challenges. For instance, the Democratic Republic of Congo (DRC) produces about 70% of the world's cobalt, a region plagued by political instability and human rights abuses. Similarly, lithium extraction in South America's "Lithium Triangle" raises concerns about water scarcity and indigenous rights. These geopolitical factors complicate efforts to implement and enforce ethical sourcing standards.

Another significant challenge is the economic pressure to keep battery costs low while maintaining ethical standards. As the EV market grows, there is intense competition to reduce battery prices, which can incentivize cutting corners on ethical sourcing. Balancing cost-effectiveness with responsible sourcing practices requires innovative solutions and industry-wide collaboration.

The lack of standardized ethical sourcing certifications specific to battery materials further complicates the issue. While initiatives like the Responsible Minerals Initiative (RMI) provide some guidance, there is no universally accepted standard for ethical battery material sourcing. This absence of standardization makes it challenging for companies to verify and communicate their ethical sourcing efforts effectively.

Moreover, the rapid technological advancements in battery chemistry and design create a moving target for ethical sourcing efforts. As new materials and production methods emerge, the industry must continuously adapt its ethical sourcing practices to address novel challenges and risks.

Addressing these ethical sourcing challenges requires a multi-faceted approach involving collaboration between governments, industry players, and NGOs. Initiatives such as blockchain-based supply chain tracking, third-party audits, and community engagement programs are being explored to enhance transparency and accountability. However, implementing these solutions at scale remains a significant challenge for the battery industry.

One of the primary challenges is the lack of transparency in complex, multi-tiered supply chains. Many battery manufacturers struggle to trace the origin of their raw materials beyond their immediate suppliers, making it difficult to ensure ethical practices throughout the entire supply chain. This opacity creates opportunities for unethical actors to exploit workers and natural resources without detection.

The geographical concentration of certain battery materials exacerbates ethical sourcing challenges. For instance, the Democratic Republic of Congo (DRC) produces about 70% of the world's cobalt, a region plagued by political instability and human rights abuses. Similarly, lithium extraction in South America's "Lithium Triangle" raises concerns about water scarcity and indigenous rights. These geopolitical factors complicate efforts to implement and enforce ethical sourcing standards.

Another significant challenge is the economic pressure to keep battery costs low while maintaining ethical standards. As the EV market grows, there is intense competition to reduce battery prices, which can incentivize cutting corners on ethical sourcing. Balancing cost-effectiveness with responsible sourcing practices requires innovative solutions and industry-wide collaboration.

The lack of standardized ethical sourcing certifications specific to battery materials further complicates the issue. While initiatives like the Responsible Minerals Initiative (RMI) provide some guidance, there is no universally accepted standard for ethical battery material sourcing. This absence of standardization makes it challenging for companies to verify and communicate their ethical sourcing efforts effectively.

Moreover, the rapid technological advancements in battery chemistry and design create a moving target for ethical sourcing efforts. As new materials and production methods emerge, the industry must continuously adapt its ethical sourcing practices to address novel challenges and risks.

Addressing these ethical sourcing challenges requires a multi-faceted approach involving collaboration between governments, industry players, and NGOs. Initiatives such as blockchain-based supply chain tracking, third-party audits, and community engagement programs are being explored to enhance transparency and accountability. However, implementing these solutions at scale remains a significant challenge for the battery industry.

Current Ethical Sourcing Solutions

01 Supply chain transparency and traceability

Implementing systems to track and verify the origin of battery materials throughout the supply chain. This includes using blockchain technology and digital ledgers to ensure transparency and accountability in sourcing practices.- Supply chain transparency and traceability: Implementing systems to track and verify the origin of battery materials throughout the supply chain. This includes using blockchain technology or other digital platforms to ensure transparency and accountability in sourcing practices.

- Ethical sourcing certification and standards: Developing and adhering to industry-wide standards and certification processes for ethical sourcing of battery materials. This involves third-party audits, compliance with international labor laws, and environmental regulations.

- Sustainable and responsible mining practices: Implementing environmentally friendly and socially responsible mining techniques for battery materials. This includes minimizing environmental impact, ensuring fair labor practices, and supporting local communities in mining regions.

- Recycling and circular economy initiatives: Developing processes for recycling and reusing battery materials to reduce the need for new raw materials. This involves creating a circular economy model for blade batteries, minimizing waste and environmental impact.

- Supplier evaluation and risk assessment: Implementing comprehensive supplier evaluation systems to assess and mitigate risks associated with ethical sourcing. This includes regular audits, risk assessments, and continuous monitoring of suppliers' practices to ensure compliance with ethical standards.

02 Ethical sourcing certification and compliance

Developing and adhering to ethical sourcing standards and certifications for blade batteries. This involves regular audits, compliance checks, and obtaining relevant certifications to ensure responsible sourcing practices.Expand Specific Solutions03 Sustainable and conflict-free material procurement

Sourcing battery materials from sustainable and conflict-free sources. This includes using recycled materials, developing alternative materials, and ensuring that raw materials are not sourced from regions with human rights violations or environmental concerns.Expand Specific Solutions04 Supplier evaluation and risk assessment

Implementing robust supplier evaluation processes and conducting regular risk assessments. This involves vetting suppliers based on their ethical practices, environmental impact, and labor conditions to mitigate risks in the supply chain.Expand Specific Solutions05 Collaboration and industry partnerships

Fostering collaboration among industry stakeholders, NGOs, and governments to establish and promote ethical sourcing practices. This includes participating in industry initiatives, sharing best practices, and collectively addressing challenges in responsible sourcing of blade battery materials.Expand Specific Solutions

Key Players in Ethical Battery Supply Chain

The research on ethical sourcing practices in blade battery material supply is in its early stages, with the market still developing. The competitive landscape is characterized by a mix of established battery manufacturers and emerging technology companies. Key players like Contemporary Amperex Technology, LG Energy Solution, and CALB Group are investing in sustainable sourcing initiatives. The market size is expected to grow significantly as demand for ethical and sustainable battery materials increases. Technological maturity varies, with companies like Automat Solutions and 24M Technologies focusing on innovative approaches to battery material sourcing and production. Overall, the industry is moving towards more transparent and responsible supply chain practices, driven by regulatory pressures and consumer demand for sustainable energy solutions.

Svolt Energy Technology Co., Ltd.

Technical Solution: Svolt Energy Technology has developed a comprehensive ethical sourcing strategy for blade battery materials, focusing on transparency and traceability. They have implemented a blockchain-based supply chain management system that tracks materials from mine to battery, ensuring ethical compliance at every stage[12]. Svolt also invests in developing cobalt-free battery technologies to reduce reliance on ethically problematic materials[13]. The company collaborates with international organizations to establish and adhere to global standards for responsible sourcing in the battery industry[14].

Strengths: Advanced traceability systems, investment in alternative battery technologies, and strong international collaborations. Weaknesses: Potential higher costs associated with blockchain implementation and development of new battery technologies.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a comprehensive ethical sourcing strategy for blade battery materials. They implement a rigorous supplier assessment system, focusing on environmental impact, labor practices, and conflict-free sourcing[1]. CATL utilizes blockchain technology to enhance traceability in their supply chain, allowing real-time monitoring of material origins and ensuring compliance with ethical standards[2]. The company has also invested in developing alternative, more sustainable battery materials to reduce reliance on controversial sources[3].

Strengths: Strong supplier network, advanced traceability systems, and investment in sustainable materials. Weaknesses: Potential higher costs due to stringent sourcing practices, and challenges in maintaining consistent supply in a competitive market.

Innovations in Ethical Material Traceability

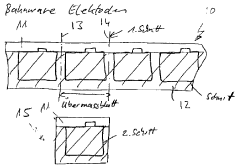

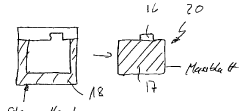

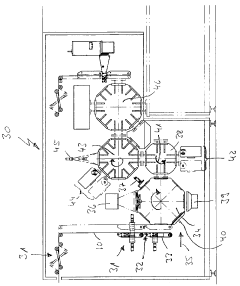

Method for manufacturing electrode blades for battery cells, involves intersecting web material transverse to longitudinal direction into base blade, where web material is sectioned before electrode blades and waste lattices are removed

PatentInactiveDE102012202948A1

Innovation

- The method involves cutting the web material transversely into oversized base sheets, followed by precision cutting to form electrode sheets, using a laser scanner system to minimize debris and ensure accurate dimensions, and employing rotary indexers for handling to dissipate static charge and reduce abrasion.

Environmental Impact of Blade Battery Production

The production of blade batteries has significant environmental implications, spanning from raw material extraction to manufacturing processes and waste management. The primary environmental concerns revolve around the sourcing and processing of key materials, particularly lithium, cobalt, and nickel.

Mining operations for these materials often lead to habitat destruction, soil erosion, and water pollution. Open-pit mining, commonly used for lithium extraction, can result in large-scale landscape alterations and ecosystem disruptions. Furthermore, the extraction process is water-intensive, potentially straining local water resources in arid regions where lithium deposits are often found.

The refining and processing of battery materials contribute to air and water pollution. The production of lithium carbonate, a crucial component in blade batteries, involves energy-intensive processes that emit greenhouse gases. Similarly, cobalt refining can release toxic substances into the environment if not properly managed.

Energy consumption during battery manufacturing is another significant environmental factor. The production of blade batteries requires substantial amounts of electricity, often sourced from fossil fuels in many regions. This reliance on non-renewable energy sources contributes to the overall carbon footprint of battery production.

Waste management presents additional challenges. The disposal of chemical byproducts and the handling of defective batteries pose potential risks to soil and water quality. Proper recycling infrastructure is crucial to mitigate these impacts and recover valuable materials, reducing the need for new raw material extraction.

Water usage in blade battery production is a growing concern, particularly in water-stressed areas. The manufacturing process requires large volumes of water for cooling, cleaning, and material processing. Efficient water management systems and recycling technologies are essential to minimize the strain on local water resources.

To address these environmental challenges, the industry is exploring more sustainable practices. These include developing more efficient extraction methods, increasing the use of renewable energy in manufacturing, improving recycling technologies, and researching alternative materials with lower environmental impacts. The implementation of stringent environmental regulations and the adoption of circular economy principles are also crucial steps towards reducing the environmental footprint of blade battery production.

Mining operations for these materials often lead to habitat destruction, soil erosion, and water pollution. Open-pit mining, commonly used for lithium extraction, can result in large-scale landscape alterations and ecosystem disruptions. Furthermore, the extraction process is water-intensive, potentially straining local water resources in arid regions where lithium deposits are often found.

The refining and processing of battery materials contribute to air and water pollution. The production of lithium carbonate, a crucial component in blade batteries, involves energy-intensive processes that emit greenhouse gases. Similarly, cobalt refining can release toxic substances into the environment if not properly managed.

Energy consumption during battery manufacturing is another significant environmental factor. The production of blade batteries requires substantial amounts of electricity, often sourced from fossil fuels in many regions. This reliance on non-renewable energy sources contributes to the overall carbon footprint of battery production.

Waste management presents additional challenges. The disposal of chemical byproducts and the handling of defective batteries pose potential risks to soil and water quality. Proper recycling infrastructure is crucial to mitigate these impacts and recover valuable materials, reducing the need for new raw material extraction.

Water usage in blade battery production is a growing concern, particularly in water-stressed areas. The manufacturing process requires large volumes of water for cooling, cleaning, and material processing. Efficient water management systems and recycling technologies are essential to minimize the strain on local water resources.

To address these environmental challenges, the industry is exploring more sustainable practices. These include developing more efficient extraction methods, increasing the use of renewable energy in manufacturing, improving recycling technologies, and researching alternative materials with lower environmental impacts. The implementation of stringent environmental regulations and the adoption of circular economy principles are also crucial steps towards reducing the environmental footprint of blade battery production.

Social Responsibility in Battery Manufacturing

Social responsibility in battery manufacturing has become a critical aspect of the industry, particularly in the context of blade battery production. As the demand for electric vehicles and renewable energy storage solutions continues to grow, manufacturers are increasingly focused on implementing ethical sourcing practices and sustainable production methods.

One of the primary concerns in battery manufacturing is the sourcing of raw materials, such as lithium, cobalt, and nickel. These materials are often mined in regions with complex social and environmental challenges. Responsible manufacturers are now implementing rigorous supply chain audits to ensure that their materials are sourced from mines that adhere to strict labor and environmental standards. This includes verifying that child labor is not used, workers are provided with safe working conditions, and local communities benefit from mining activities.

Environmental sustainability is another key aspect of social responsibility in battery manufacturing. Companies are investing in cleaner production processes, reducing water usage, and minimizing waste generation. Some manufacturers are also exploring the use of recycled materials in battery production, which not only reduces the demand for newly mined resources but also addresses the growing concern of battery waste management.

The blade battery, known for its improved safety and energy density, presents unique challenges and opportunities in terms of social responsibility. Manufacturers of blade batteries are focusing on developing more efficient production techniques that reduce energy consumption and minimize the use of harmful chemicals. Additionally, they are investing in research to improve the recyclability of blade batteries, aiming to create a more circular economy within the battery industry.

Transparency and traceability have become essential components of socially responsible battery manufacturing. Leading companies are implementing blockchain technology and other digital solutions to track materials from mine to finished product, providing consumers and regulators with detailed information about the origin and processing of battery components. This level of transparency not only builds trust but also allows for more effective monitoring and improvement of social and environmental practices throughout the supply chain.

Worker welfare and community engagement are also crucial elements of social responsibility in battery manufacturing. Companies are implementing comprehensive health and safety programs, providing fair wages and benefits, and investing in employee training and development. Moreover, many manufacturers are engaging with local communities near their production facilities, supporting education initiatives, healthcare programs, and economic development projects.

As the battery industry continues to evolve, social responsibility will remain a key focus area. Manufacturers are likely to face increasing pressure from consumers, investors, and regulators to demonstrate their commitment to ethical and sustainable practices. This will drive further innovation in responsible sourcing, cleaner production methods, and circular economy solutions, ultimately leading to a more sustainable and socially conscious battery manufacturing sector.

One of the primary concerns in battery manufacturing is the sourcing of raw materials, such as lithium, cobalt, and nickel. These materials are often mined in regions with complex social and environmental challenges. Responsible manufacturers are now implementing rigorous supply chain audits to ensure that their materials are sourced from mines that adhere to strict labor and environmental standards. This includes verifying that child labor is not used, workers are provided with safe working conditions, and local communities benefit from mining activities.

Environmental sustainability is another key aspect of social responsibility in battery manufacturing. Companies are investing in cleaner production processes, reducing water usage, and minimizing waste generation. Some manufacturers are also exploring the use of recycled materials in battery production, which not only reduces the demand for newly mined resources but also addresses the growing concern of battery waste management.

The blade battery, known for its improved safety and energy density, presents unique challenges and opportunities in terms of social responsibility. Manufacturers of blade batteries are focusing on developing more efficient production techniques that reduce energy consumption and minimize the use of harmful chemicals. Additionally, they are investing in research to improve the recyclability of blade batteries, aiming to create a more circular economy within the battery industry.

Transparency and traceability have become essential components of socially responsible battery manufacturing. Leading companies are implementing blockchain technology and other digital solutions to track materials from mine to finished product, providing consumers and regulators with detailed information about the origin and processing of battery components. This level of transparency not only builds trust but also allows for more effective monitoring and improvement of social and environmental practices throughout the supply chain.

Worker welfare and community engagement are also crucial elements of social responsibility in battery manufacturing. Companies are implementing comprehensive health and safety programs, providing fair wages and benefits, and investing in employee training and development. Moreover, many manufacturers are engaging with local communities near their production facilities, supporting education initiatives, healthcare programs, and economic development projects.

As the battery industry continues to evolve, social responsibility will remain a key focus area. Manufacturers are likely to face increasing pressure from consumers, investors, and regulators to demonstrate their commitment to ethical and sustainable practices. This will drive further innovation in responsible sourcing, cleaner production methods, and circular economy solutions, ultimately leading to a more sustainable and socially conscious battery manufacturing sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!