Polyvinyl Acetate in Multifunctional Coating Systems

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc Coating Evolution

The evolution of polyvinyl acetate (PVAc) in multifunctional coating systems represents a significant advancement in materials science and surface technology. Initially developed in the early 20th century, PVAc has undergone substantial transformations to meet the ever-increasing demands of various industries.

In its early stages, PVAc was primarily used as a simple adhesive and binder. However, as coating technologies progressed, researchers began to explore its potential in more complex applications. The 1950s and 1960s saw the first major breakthroughs in PVAc coating formulations, with the introduction of emulsion polymerization techniques that allowed for better control over particle size and distribution.

The 1970s marked a turning point in PVAc coating evolution, as environmental concerns led to the development of water-based PVAc formulations. This shift not only reduced the use of volatile organic compounds (VOCs) but also improved the coating's safety profile and ease of application. Concurrently, researchers began investigating ways to enhance the mechanical properties of PVAc coatings, leading to the incorporation of various additives and cross-linking agents.

The 1980s and 1990s witnessed the emergence of hybrid PVAc systems, where the polymer was combined with other materials such as acrylics or epoxies to create coatings with superior performance characteristics. These advancements expanded the application range of PVAc coatings to include automotive, construction, and even aerospace industries.

In the early 2000s, nanotechnology began to play a crucial role in PVAc coating evolution. The incorporation of nanoparticles into PVAc matrices resulted in coatings with enhanced durability, scratch resistance, and self-cleaning properties. This period also saw the development of smart PVAc coatings capable of responding to environmental stimuli, such as temperature or pH changes.

Recent years have focused on sustainability and multifunctionality in PVAc coating systems. Researchers are now exploring bio-based PVAc formulations and investigating ways to incorporate additional functionalities such as antimicrobial properties, thermal insulation, and even energy harvesting capabilities. The advent of 3D printing technologies has also opened new avenues for PVAc coatings, allowing for precise deposition and customization of coating layers.

As we look to the future, the evolution of PVAc coatings continues to be driven by the need for more sustainable, efficient, and versatile materials. Emerging trends include the development of self-healing PVAc coatings, integration with smart sensors for real-time monitoring, and the exploration of PVAc-based nanocomposites for advanced applications in electronics and biomedical fields.

In its early stages, PVAc was primarily used as a simple adhesive and binder. However, as coating technologies progressed, researchers began to explore its potential in more complex applications. The 1950s and 1960s saw the first major breakthroughs in PVAc coating formulations, with the introduction of emulsion polymerization techniques that allowed for better control over particle size and distribution.

The 1970s marked a turning point in PVAc coating evolution, as environmental concerns led to the development of water-based PVAc formulations. This shift not only reduced the use of volatile organic compounds (VOCs) but also improved the coating's safety profile and ease of application. Concurrently, researchers began investigating ways to enhance the mechanical properties of PVAc coatings, leading to the incorporation of various additives and cross-linking agents.

The 1980s and 1990s witnessed the emergence of hybrid PVAc systems, where the polymer was combined with other materials such as acrylics or epoxies to create coatings with superior performance characteristics. These advancements expanded the application range of PVAc coatings to include automotive, construction, and even aerospace industries.

In the early 2000s, nanotechnology began to play a crucial role in PVAc coating evolution. The incorporation of nanoparticles into PVAc matrices resulted in coatings with enhanced durability, scratch resistance, and self-cleaning properties. This period also saw the development of smart PVAc coatings capable of responding to environmental stimuli, such as temperature or pH changes.

Recent years have focused on sustainability and multifunctionality in PVAc coating systems. Researchers are now exploring bio-based PVAc formulations and investigating ways to incorporate additional functionalities such as antimicrobial properties, thermal insulation, and even energy harvesting capabilities. The advent of 3D printing technologies has also opened new avenues for PVAc coatings, allowing for precise deposition and customization of coating layers.

As we look to the future, the evolution of PVAc coatings continues to be driven by the need for more sustainable, efficient, and versatile materials. Emerging trends include the development of self-healing PVAc coatings, integration with smart sensors for real-time monitoring, and the exploration of PVAc-based nanocomposites for advanced applications in electronics and biomedical fields.

Market Demand Analysis

The market demand for polyvinyl acetate (PVA) in multifunctional coating systems has been experiencing significant growth in recent years. This surge is primarily driven by the increasing need for high-performance, environmentally friendly, and cost-effective coating solutions across various industries.

In the construction sector, PVA-based coatings are gaining traction due to their excellent adhesion properties, durability, and resistance to weathering. The growing emphasis on sustainable building practices has further boosted the demand for PVA coatings, as they are low in volatile organic compounds (VOCs) and offer improved energy efficiency in buildings.

The automotive industry represents another key market for PVA-based multifunctional coatings. With the rising focus on lightweight materials and fuel efficiency, PVA coatings are being increasingly utilized for their ability to provide corrosion protection, sound dampening, and improved aesthetics to vehicle components.

In the packaging industry, PVA coatings are finding applications in food packaging, pharmaceuticals, and consumer goods. The demand is driven by the need for barrier properties against moisture, gases, and oils, as well as the growing preference for recyclable and biodegradable packaging materials.

The textile industry is also contributing to the market growth of PVA in multifunctional coating systems. PVA-based coatings are used to impart water resistance, stain resistance, and improved durability to fabrics, meeting the evolving consumer demands for high-performance textiles.

The global market for PVA in multifunctional coating systems is expected to continue its upward trajectory. Factors such as urbanization, infrastructure development, and increasing disposable incomes in emerging economies are likely to fuel the demand further. Additionally, ongoing research and development efforts to enhance the performance characteristics of PVA-based coatings are expected to open up new application areas and market opportunities.

However, the market also faces certain challenges. Fluctuations in raw material prices and the availability of alternative coating technologies may impact the growth rate. Nevertheless, the overall market outlook remains positive, with manufacturers focusing on product innovations and strategic collaborations to meet the evolving customer requirements and capitalize on the growing market potential.

In the construction sector, PVA-based coatings are gaining traction due to their excellent adhesion properties, durability, and resistance to weathering. The growing emphasis on sustainable building practices has further boosted the demand for PVA coatings, as they are low in volatile organic compounds (VOCs) and offer improved energy efficiency in buildings.

The automotive industry represents another key market for PVA-based multifunctional coatings. With the rising focus on lightweight materials and fuel efficiency, PVA coatings are being increasingly utilized for their ability to provide corrosion protection, sound dampening, and improved aesthetics to vehicle components.

In the packaging industry, PVA coatings are finding applications in food packaging, pharmaceuticals, and consumer goods. The demand is driven by the need for barrier properties against moisture, gases, and oils, as well as the growing preference for recyclable and biodegradable packaging materials.

The textile industry is also contributing to the market growth of PVA in multifunctional coating systems. PVA-based coatings are used to impart water resistance, stain resistance, and improved durability to fabrics, meeting the evolving consumer demands for high-performance textiles.

The global market for PVA in multifunctional coating systems is expected to continue its upward trajectory. Factors such as urbanization, infrastructure development, and increasing disposable incomes in emerging economies are likely to fuel the demand further. Additionally, ongoing research and development efforts to enhance the performance characteristics of PVA-based coatings are expected to open up new application areas and market opportunities.

However, the market also faces certain challenges. Fluctuations in raw material prices and the availability of alternative coating technologies may impact the growth rate. Nevertheless, the overall market outlook remains positive, with manufacturers focusing on product innovations and strategic collaborations to meet the evolving customer requirements and capitalize on the growing market potential.

Technical Challenges

The development of polyvinyl acetate (PVAc) in multifunctional coating systems faces several technical challenges that researchers and industry professionals are actively addressing. One of the primary obstacles is achieving optimal adhesion properties across diverse substrates. PVAc coatings must adhere effectively to a wide range of materials, including wood, metal, plastics, and composites, each with unique surface characteristics. This requires careful formulation and modification of the PVAc polymer to enhance its compatibility and bonding strength with various surfaces.

Another significant challenge lies in improving the water resistance of PVAc-based coatings. While PVAc offers excellent initial adhesion and film-forming properties, its susceptibility to moisture can lead to reduced durability and performance in high-humidity environments or when exposed to water. Researchers are exploring various approaches to enhance the water resistance of PVAc coatings, such as incorporating cross-linking agents, blending with other polymers, or developing novel copolymer structures.

The thermal stability of PVAc coatings presents another area of concern, particularly in applications where the coating may be exposed to elevated temperatures. PVAc has a relatively low glass transition temperature, which can result in softening and loss of mechanical properties at higher temperatures. Improving the thermal resistance of PVAc-based coatings without compromising their flexibility and other desirable characteristics remains a significant technical challenge.

Balancing the mechanical properties of PVAc coatings is crucial for their multifunctional applications. While PVAc offers good flexibility, it often lacks the hardness and abrasion resistance required for certain high-performance coating applications. Researchers are investigating ways to enhance the mechanical strength and wear resistance of PVAc coatings without sacrificing their inherent flexibility and ease of application.

Environmental concerns and regulatory pressures pose additional challenges in the development of PVAc-based coating systems. There is a growing demand for low-VOC (volatile organic compound) and environmentally friendly formulations. Developing water-based PVAc coatings that maintain the performance characteristics of solvent-based systems while meeting stringent environmental regulations is an ongoing area of research and development.

Lastly, the integration of advanced functionalities into PVAc coatings, such as self-healing properties, antimicrobial activity, or smart responsive behaviors, presents both opportunities and challenges. Incorporating these features while maintaining the core performance attributes of PVAc coatings requires innovative approaches in polymer chemistry and nanotechnology. Overcoming these technical hurdles is essential for expanding the application range of PVAc in next-generation multifunctional coating systems.

Another significant challenge lies in improving the water resistance of PVAc-based coatings. While PVAc offers excellent initial adhesion and film-forming properties, its susceptibility to moisture can lead to reduced durability and performance in high-humidity environments or when exposed to water. Researchers are exploring various approaches to enhance the water resistance of PVAc coatings, such as incorporating cross-linking agents, blending with other polymers, or developing novel copolymer structures.

The thermal stability of PVAc coatings presents another area of concern, particularly in applications where the coating may be exposed to elevated temperatures. PVAc has a relatively low glass transition temperature, which can result in softening and loss of mechanical properties at higher temperatures. Improving the thermal resistance of PVAc-based coatings without compromising their flexibility and other desirable characteristics remains a significant technical challenge.

Balancing the mechanical properties of PVAc coatings is crucial for their multifunctional applications. While PVAc offers good flexibility, it often lacks the hardness and abrasion resistance required for certain high-performance coating applications. Researchers are investigating ways to enhance the mechanical strength and wear resistance of PVAc coatings without sacrificing their inherent flexibility and ease of application.

Environmental concerns and regulatory pressures pose additional challenges in the development of PVAc-based coating systems. There is a growing demand for low-VOC (volatile organic compound) and environmentally friendly formulations. Developing water-based PVAc coatings that maintain the performance characteristics of solvent-based systems while meeting stringent environmental regulations is an ongoing area of research and development.

Lastly, the integration of advanced functionalities into PVAc coatings, such as self-healing properties, antimicrobial activity, or smart responsive behaviors, presents both opportunities and challenges. Incorporating these features while maintaining the core performance attributes of PVAc coatings requires innovative approaches in polymer chemistry and nanotechnology. Overcoming these technical hurdles is essential for expanding the application range of PVAc in next-generation multifunctional coating systems.

Current PVAc Solutions

01 Synthesis and polymerization of polyvinyl acetate

Polyvinyl acetate is synthesized through the polymerization of vinyl acetate monomers. Various methods and conditions are employed to control the molecular weight, degree of polymerization, and properties of the resulting polymer. This process often involves the use of initiators, catalysts, and specific reaction conditions to achieve desired characteristics.- Synthesis and polymerization of polyvinyl acetate: Various methods and processes for synthesizing and polymerizing polyvinyl acetate are described. These include techniques for controlling molecular weight, improving reaction efficiency, and optimizing polymerization conditions to achieve desired properties in the final product.

- Modifications and copolymers of polyvinyl acetate: Techniques for modifying polyvinyl acetate or creating copolymers with other monomers are presented. These modifications can enhance properties such as adhesion, water resistance, or compatibility with other materials, expanding the range of applications for polyvinyl acetate-based products.

- Applications of polyvinyl acetate in adhesives and coatings: Polyvinyl acetate is widely used in adhesives and coatings. Various formulations and application methods are described, including improvements in bonding strength, drying time, and resistance to environmental factors for different substrates and use cases.

- Emulsion and dispersion techniques for polyvinyl acetate: Methods for creating stable emulsions and dispersions of polyvinyl acetate are outlined. These techniques are crucial for many applications, including paints, adhesives, and paper coatings, where uniform distribution and specific particle sizes are required.

- Polyvinyl acetate in composite materials and blends: The use of polyvinyl acetate in composite materials and polymer blends is explored. This includes its role as a binder, matrix material, or compatibilizer in various composite systems, enhancing properties such as strength, flexibility, or processability of the final products.

02 Copolymerization with other monomers

Polyvinyl acetate can be copolymerized with other monomers to modify its properties and enhance its performance for specific applications. This process involves combining vinyl acetate with various co-monomers to create copolymers with tailored characteristics, such as improved adhesion, flexibility, or water resistance.Expand Specific Solutions03 Emulsion polymerization techniques

Emulsion polymerization is a common method used to produce polyvinyl acetate. This technique involves dispersing vinyl acetate monomers in water with the help of surfactants and initiators. The resulting emulsion allows for better control over particle size, molecular weight distribution, and overall polymer properties.Expand Specific Solutions04 Modifications and additives for improved performance

Various modifications and additives are incorporated into polyvinyl acetate formulations to enhance its performance in specific applications. These may include plasticizers, crosslinking agents, stabilizers, and other functional additives that improve properties such as adhesion, durability, and resistance to environmental factors.Expand Specific Solutions05 Applications in adhesives and coatings

Polyvinyl acetate finds extensive use in adhesives and coatings due to its unique properties. It is commonly employed in wood glues, paper adhesives, and various coating formulations. The polymer's adhesive strength, film-forming ability, and compatibility with other materials make it suitable for a wide range of industrial and consumer applications.Expand Specific Solutions

Key Industry Players

The research on Polyvinyl Acetate in Multifunctional Coating Systems is in a mature stage, with a growing market driven by increasing demand in various industries. The global market size for polyvinyl acetate is expected to reach significant figures in the coming years. Key players like DuPont de Nemours, Kuraray Co., and BASF Coatings GmbH are leading the technological advancements in this field. These companies, along with others such as Wacker Chemie AG and Sekisui Chemical Co., are investing heavily in R&D to develop innovative applications and improve product performance. The competitive landscape is characterized by strategic partnerships, mergers, and acquisitions to strengthen market positions and expand product portfolios.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced polyvinyl acetate (PVA) formulations for multifunctional coating systems. Their approach involves incorporating nanoparticles into PVA matrices to enhance barrier properties and durability[1]. The company has also introduced cross-linking agents that improve the water resistance and adhesion of PVA-based coatings[3]. DuPont's research focuses on optimizing the molecular weight distribution of PVA to achieve a balance between flexibility and strength in coating applications[5]. Additionally, they have explored the use of PVA in combination with other polymers to create synergistic effects in coating performance[7].

Strengths: Extensive R&D capabilities, strong patent portfolio, and a wide range of applications across industries. Weaknesses: Higher production costs compared to some competitors, and potential environmental concerns related to nanoparticle use.

Covestro Deutschland AG

Technical Solution: Covestro has developed innovative polyurethane-polyvinyl acetate hybrid systems for multifunctional coatings. Their approach combines the flexibility and adhesion properties of PVA with the durability and chemical resistance of polyurethanes[2]. The company has introduced water-based formulations that reduce VOC emissions while maintaining high performance[4]. Covestro's research also focuses on incorporating bio-based raw materials into their PVA-containing coating systems, improving sustainability[6]. They have developed specialized additives that enhance the compatibility between PVA and other coating components, resulting in improved film formation and surface properties[8].

Strengths: Strong focus on sustainability, innovative hybrid technologies, and a broad product portfolio. Weaknesses: Relatively higher costs for bio-based materials and potential limitations in extreme environmental conditions.

Core PVAc Innovations

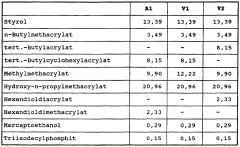

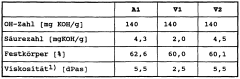

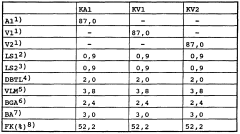

Coating agent on the basis of a polyacrylate resin containing an hydroxyl group, and its use in a method of producing a multiple-layer paint coating

PatentWO1998004642A1

Innovation

- A coating composition featuring a hydroxyl-containing polyacrylate resin with specific monomer ratios and a crosslinking agent, optimized for improved adhesion, petrol resistance, and weathering resistance, which can be cured at low temperatures, maintaining long workability and good application behavior.

Environmental Impact

The environmental impact of polyvinyl acetate (PVA) in multifunctional coating systems is a critical consideration in the development and application of these materials. PVA-based coatings have gained popularity due to their versatility and performance characteristics, but their environmental implications require careful examination.

One of the primary environmental concerns associated with PVA coatings is their potential for volatile organic compound (VOC) emissions. While PVA itself is considered a low-VOC material, some formulations may include additional solvents or additives that contribute to VOC release during application and curing processes. Regulatory bodies worldwide have implemented stringent VOC emission standards, prompting manufacturers to develop water-based PVA coating systems with reduced environmental impact.

The biodegradability of PVA coatings is another crucial aspect of their environmental profile. PVA is inherently biodegradable under certain conditions, which can be advantageous in terms of end-of-life disposal. However, the rate of biodegradation can vary significantly depending on environmental factors and the presence of specific microorganisms. Research efforts are ongoing to enhance the biodegradability of PVA-based coatings without compromising their performance characteristics.

Water pollution is a potential concern when considering the lifecycle of PVA coatings. During the production process, wastewater containing PVA residues may be generated. If not properly treated, these residues can contribute to water pollution and affect aquatic ecosystems. Advanced wastewater treatment technologies and closed-loop manufacturing processes are being developed to mitigate these risks and improve the overall environmental footprint of PVA coating production.

The energy consumption associated with the production and application of PVA coatings also factors into their environmental impact. Efforts to reduce energy requirements through process optimization and the use of renewable energy sources in manufacturing facilities are ongoing. Additionally, the development of low-temperature curing PVA coatings can contribute to reduced energy consumption during the application phase.

Recycling and disposal of PVA-coated products present both challenges and opportunities from an environmental perspective. While PVA is theoretically recyclable, the presence of other components in multifunctional coating systems can complicate the recycling process. Research is being conducted to improve the recyclability of PVA-based coatings and develop effective separation techniques for coated materials.

The potential for microplastic generation from PVA coatings is an emerging area of environmental concern. As these coatings degrade over time, they may release microscopic particles that can persist in the environment. Studies are underway to assess the long-term environmental fate of PVA-derived microplastics and develop strategies to minimize their formation and impact.

One of the primary environmental concerns associated with PVA coatings is their potential for volatile organic compound (VOC) emissions. While PVA itself is considered a low-VOC material, some formulations may include additional solvents or additives that contribute to VOC release during application and curing processes. Regulatory bodies worldwide have implemented stringent VOC emission standards, prompting manufacturers to develop water-based PVA coating systems with reduced environmental impact.

The biodegradability of PVA coatings is another crucial aspect of their environmental profile. PVA is inherently biodegradable under certain conditions, which can be advantageous in terms of end-of-life disposal. However, the rate of biodegradation can vary significantly depending on environmental factors and the presence of specific microorganisms. Research efforts are ongoing to enhance the biodegradability of PVA-based coatings without compromising their performance characteristics.

Water pollution is a potential concern when considering the lifecycle of PVA coatings. During the production process, wastewater containing PVA residues may be generated. If not properly treated, these residues can contribute to water pollution and affect aquatic ecosystems. Advanced wastewater treatment technologies and closed-loop manufacturing processes are being developed to mitigate these risks and improve the overall environmental footprint of PVA coating production.

The energy consumption associated with the production and application of PVA coatings also factors into their environmental impact. Efforts to reduce energy requirements through process optimization and the use of renewable energy sources in manufacturing facilities are ongoing. Additionally, the development of low-temperature curing PVA coatings can contribute to reduced energy consumption during the application phase.

Recycling and disposal of PVA-coated products present both challenges and opportunities from an environmental perspective. While PVA is theoretically recyclable, the presence of other components in multifunctional coating systems can complicate the recycling process. Research is being conducted to improve the recyclability of PVA-based coatings and develop effective separation techniques for coated materials.

The potential for microplastic generation from PVA coatings is an emerging area of environmental concern. As these coatings degrade over time, they may release microscopic particles that can persist in the environment. Studies are underway to assess the long-term environmental fate of PVA-derived microplastics and develop strategies to minimize their formation and impact.

Regulatory Compliance

Regulatory compliance is a critical aspect of the research and development of polyvinyl acetate (PVAc) in multifunctional coating systems. As these coatings find applications across various industries, including construction, automotive, and consumer goods, adherence to regulatory standards is essential for ensuring product safety, environmental protection, and market acceptance.

In the United States, the Environmental Protection Agency (EPA) plays a significant role in regulating the use of PVAc in coating systems. Under the Toxic Substances Control Act (TSCA), manufacturers must comply with reporting, record-keeping, and testing requirements for chemical substances, including PVAc. The EPA also enforces regulations on volatile organic compound (VOC) emissions from coatings, which directly impacts the formulation of PVAc-based systems.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another crucial framework that affects the development and use of PVAc in multifunctional coatings. REACH requires manufacturers to register chemicals, assess their hazards, and communicate safety information to users. For PVAc coatings intended for use in the EU market, compliance with REACH is mandatory.

Food contact applications of PVAc coatings are subject to stringent regulations by the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These agencies set specific migration limits and require extensive testing to ensure the safety of coatings that may come into contact with food products.

In the construction sector, building codes and standards often dictate the performance requirements for coatings, including fire resistance and durability. Organizations such as ASTM International and the International Organization for Standardization (ISO) provide testing methods and specifications that PVAc coating systems must meet to comply with these regulations.

Occupational safety regulations, enforced by agencies like the Occupational Safety and Health Administration (OSHA) in the United States, also impact the development and application of PVAc coatings. These regulations set limits on worker exposure to potentially harmful substances during the manufacturing and application processes.

As environmental concerns grow, many regions are implementing stricter regulations on the disposal and recycling of coated products. Researchers developing PVAc-based multifunctional coatings must consider end-of-life scenarios and design systems that can be safely disposed of or recycled in compliance with local waste management regulations.

The global nature of the coatings industry necessitates a comprehensive understanding of regulatory requirements across different markets. Manufacturers and researchers must navigate a complex landscape of sometimes conflicting regulations, requiring ongoing monitoring of regulatory changes and proactive adaptation of coating formulations to maintain compliance.

In the United States, the Environmental Protection Agency (EPA) plays a significant role in regulating the use of PVAc in coating systems. Under the Toxic Substances Control Act (TSCA), manufacturers must comply with reporting, record-keeping, and testing requirements for chemical substances, including PVAc. The EPA also enforces regulations on volatile organic compound (VOC) emissions from coatings, which directly impacts the formulation of PVAc-based systems.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another crucial framework that affects the development and use of PVAc in multifunctional coatings. REACH requires manufacturers to register chemicals, assess their hazards, and communicate safety information to users. For PVAc coatings intended for use in the EU market, compliance with REACH is mandatory.

Food contact applications of PVAc coatings are subject to stringent regulations by the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These agencies set specific migration limits and require extensive testing to ensure the safety of coatings that may come into contact with food products.

In the construction sector, building codes and standards often dictate the performance requirements for coatings, including fire resistance and durability. Organizations such as ASTM International and the International Organization for Standardization (ISO) provide testing methods and specifications that PVAc coating systems must meet to comply with these regulations.

Occupational safety regulations, enforced by agencies like the Occupational Safety and Health Administration (OSHA) in the United States, also impact the development and application of PVAc coatings. These regulations set limits on worker exposure to potentially harmful substances during the manufacturing and application processes.

As environmental concerns grow, many regions are implementing stricter regulations on the disposal and recycling of coated products. Researchers developing PVAc-based multifunctional coatings must consider end-of-life scenarios and design systems that can be safely disposed of or recycled in compliance with local waste management regulations.

The global nature of the coatings industry necessitates a comprehensive understanding of regulatory requirements across different markets. Manufacturers and researchers must navigate a complex landscape of sometimes conflicting regulations, requiring ongoing monitoring of regulatory changes and proactive adaptation of coating formulations to maintain compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!