Polyvinyl Acetate Solutions for Sustainable Manufacturing

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PVAc Solutions Background and Objectives

Polyvinyl acetate (PVAc) solutions have emerged as a significant area of interest in sustainable manufacturing due to their versatile properties and eco-friendly potential. The evolution of PVAc technology can be traced back to the early 20th century, with its initial synthesis in 1912 by Fritz Klatte. Since then, PVAc has undergone continuous development, transitioning from a novel polymer to a widely used material in various industries.

The current technological landscape of PVAc solutions is characterized by a growing emphasis on sustainability and environmental consciousness. This shift is driven by increasing global awareness of the need for more sustainable manufacturing processes and materials. PVAc solutions offer promising alternatives to traditional petroleum-based adhesives and coatings, aligning with the principles of green chemistry and circular economy.

Recent advancements in PVAc technology have focused on enhancing its performance characteristics while maintaining its environmentally friendly profile. These developments include improving water resistance, increasing bonding strength, and expanding the range of substrates to which PVAc can effectively adhere. Additionally, research efforts have been directed towards optimizing the production processes of PVAc solutions to reduce energy consumption and minimize waste generation.

The primary objective of researching PVAc solutions for sustainable manufacturing is to develop innovative formulations and applications that can replace less environmentally friendly alternatives. This includes exploring new crosslinking mechanisms to enhance durability, investigating bio-based additives to improve functionality, and developing water-based PVAc systems with reduced volatile organic compound (VOC) emissions.

Another crucial goal is to optimize the lifecycle of PVAc products, focusing on biodegradability and recyclability. This involves studying the decomposition pathways of PVAc under various environmental conditions and developing strategies for efficient recovery and reuse of PVAc materials at the end of their service life.

Furthermore, the research aims to expand the application scope of PVAc solutions in sustainable manufacturing. This includes exploring their potential in advanced materials such as smart coatings, self-healing adhesives, and functional packaging. By leveraging the unique properties of PVAc, researchers seek to create innovative solutions that address contemporary challenges in sustainability and circular economy principles.

In conclusion, the background and objectives of PVAc solutions research in sustainable manufacturing reflect a multifaceted approach to developing environmentally friendly materials with enhanced performance characteristics. This research trajectory aligns with global sustainability goals and presents significant opportunities for technological innovation and market growth in the coming years.

The current technological landscape of PVAc solutions is characterized by a growing emphasis on sustainability and environmental consciousness. This shift is driven by increasing global awareness of the need for more sustainable manufacturing processes and materials. PVAc solutions offer promising alternatives to traditional petroleum-based adhesives and coatings, aligning with the principles of green chemistry and circular economy.

Recent advancements in PVAc technology have focused on enhancing its performance characteristics while maintaining its environmentally friendly profile. These developments include improving water resistance, increasing bonding strength, and expanding the range of substrates to which PVAc can effectively adhere. Additionally, research efforts have been directed towards optimizing the production processes of PVAc solutions to reduce energy consumption and minimize waste generation.

The primary objective of researching PVAc solutions for sustainable manufacturing is to develop innovative formulations and applications that can replace less environmentally friendly alternatives. This includes exploring new crosslinking mechanisms to enhance durability, investigating bio-based additives to improve functionality, and developing water-based PVAc systems with reduced volatile organic compound (VOC) emissions.

Another crucial goal is to optimize the lifecycle of PVAc products, focusing on biodegradability and recyclability. This involves studying the decomposition pathways of PVAc under various environmental conditions and developing strategies for efficient recovery and reuse of PVAc materials at the end of their service life.

Furthermore, the research aims to expand the application scope of PVAc solutions in sustainable manufacturing. This includes exploring their potential in advanced materials such as smart coatings, self-healing adhesives, and functional packaging. By leveraging the unique properties of PVAc, researchers seek to create innovative solutions that address contemporary challenges in sustainability and circular economy principles.

In conclusion, the background and objectives of PVAc solutions research in sustainable manufacturing reflect a multifaceted approach to developing environmentally friendly materials with enhanced performance characteristics. This research trajectory aligns with global sustainability goals and presents significant opportunities for technological innovation and market growth in the coming years.

Sustainable Manufacturing Market Analysis

The sustainable manufacturing market has been experiencing significant growth in recent years, driven by increasing environmental concerns, stringent regulations, and a growing consumer demand for eco-friendly products. This trend has created a substantial opportunity for polyvinyl acetate (PVA) solutions, which are increasingly recognized for their potential in sustainable manufacturing processes.

The global sustainable manufacturing market was valued at approximately $1.2 trillion in 2020 and is projected to reach $2.5 trillion by 2025, growing at a CAGR of 15.8%. Within this market, the demand for sustainable adhesives and coatings, where PVA solutions play a crucial role, is expected to witness particularly strong growth. The PVA market itself is forecasted to expand from $2.5 billion in 2020 to $3.8 billion by 2025, with a CAGR of 8.7%.

Key factors driving the adoption of PVA solutions in sustainable manufacturing include their biodegradability, low toxicity, and versatility in applications. Industries such as packaging, construction, textiles, and paper are increasingly turning to PVA-based products to meet sustainability goals and comply with environmental regulations. The packaging industry, in particular, is a major consumer of PVA solutions, as companies seek alternatives to traditional petroleum-based adhesives and coatings.

Geographically, Asia-Pacific leads the market for PVA solutions in sustainable manufacturing, accounting for over 40% of the global market share. This dominance is attributed to the region's robust manufacturing sector, particularly in countries like China and India, coupled with increasing environmental awareness and government initiatives promoting sustainable practices. North America and Europe follow, with growing demand driven by stringent environmental regulations and consumer preferences for eco-friendly products.

The market landscape for PVA solutions in sustainable manufacturing is characterized by intense competition and innovation. Key players are investing heavily in research and development to enhance the performance and sustainability of PVA-based products. Collaborations between chemical companies and end-users are becoming more common, aiming to develop tailored solutions for specific industry needs.

Despite the positive outlook, challenges remain in the widespread adoption of PVA solutions. These include the need for further improvements in performance to match or exceed traditional alternatives, as well as the development of more cost-effective production methods. Additionally, educating end-users about the benefits and applications of PVA solutions in sustainable manufacturing remains crucial for market expansion.

The global sustainable manufacturing market was valued at approximately $1.2 trillion in 2020 and is projected to reach $2.5 trillion by 2025, growing at a CAGR of 15.8%. Within this market, the demand for sustainable adhesives and coatings, where PVA solutions play a crucial role, is expected to witness particularly strong growth. The PVA market itself is forecasted to expand from $2.5 billion in 2020 to $3.8 billion by 2025, with a CAGR of 8.7%.

Key factors driving the adoption of PVA solutions in sustainable manufacturing include their biodegradability, low toxicity, and versatility in applications. Industries such as packaging, construction, textiles, and paper are increasingly turning to PVA-based products to meet sustainability goals and comply with environmental regulations. The packaging industry, in particular, is a major consumer of PVA solutions, as companies seek alternatives to traditional petroleum-based adhesives and coatings.

Geographically, Asia-Pacific leads the market for PVA solutions in sustainable manufacturing, accounting for over 40% of the global market share. This dominance is attributed to the region's robust manufacturing sector, particularly in countries like China and India, coupled with increasing environmental awareness and government initiatives promoting sustainable practices. North America and Europe follow, with growing demand driven by stringent environmental regulations and consumer preferences for eco-friendly products.

The market landscape for PVA solutions in sustainable manufacturing is characterized by intense competition and innovation. Key players are investing heavily in research and development to enhance the performance and sustainability of PVA-based products. Collaborations between chemical companies and end-users are becoming more common, aiming to develop tailored solutions for specific industry needs.

Despite the positive outlook, challenges remain in the widespread adoption of PVA solutions. These include the need for further improvements in performance to match or exceed traditional alternatives, as well as the development of more cost-effective production methods. Additionally, educating end-users about the benefits and applications of PVA solutions in sustainable manufacturing remains crucial for market expansion.

PVAc Technology Status and Challenges

Polyvinyl acetate (PVAc) technology has made significant strides in recent years, particularly in the context of sustainable manufacturing. However, the current status of PVAc solutions presents both opportunities and challenges for industry-wide adoption and further development.

The global market for PVAc has seen steady growth, driven by increasing demand in various sectors such as adhesives, paints, and coatings. This growth has spurred research and development efforts to enhance PVAc properties and expand its applications. Currently, PVAc solutions are widely used in water-based formulations, offering advantages in terms of low toxicity and reduced environmental impact compared to solvent-based alternatives.

One of the primary challenges facing PVAc technology is the need for improved performance characteristics. While PVAc exhibits good adhesion properties and film-forming capabilities, it often falls short in terms of water resistance and thermal stability. Researchers are actively working on developing modified PVAc formulations that address these limitations without compromising the material's inherent sustainability benefits.

Another significant challenge lies in the raw material sourcing for PVAc production. Traditional methods rely heavily on petroleum-based feedstocks, which conflicts with the goal of sustainable manufacturing. The industry is exploring bio-based alternatives and renewable resources to produce vinyl acetate monomer, the precursor to PVAc. However, scaling up these sustainable production methods to meet industrial demands remains a hurdle.

In terms of processing technology, advancements have been made in emulsion polymerization techniques, allowing for better control over particle size distribution and molecular weight. These improvements have led to PVAc solutions with enhanced stability and application-specific properties. Nevertheless, optimizing energy efficiency in the production process and reducing water consumption during emulsion preparation are ongoing challenges.

The development of PVAc nanocomposites represents a promising frontier in the field. By incorporating nanoparticles or nanofibers into PVAc matrices, researchers aim to create materials with superior mechanical properties, barrier characteristics, and functionality. However, ensuring uniform dispersion of nanofillers and maintaining the biodegradability of the resulting composites pose significant technical challenges.

Geographically, PVAc technology development is concentrated in regions with strong chemical and polymer industries, particularly in North America, Europe, and parts of Asia. Collaborative efforts between academic institutions and industry players have accelerated innovation in these areas. However, there is a need for broader global participation to address region-specific challenges and applications.

In conclusion, while PVAc technology has made substantial progress towards sustainable manufacturing solutions, several technical hurdles remain. Overcoming these challenges will require continued research efforts, cross-industry collaboration, and innovative approaches to material design and processing.

The global market for PVAc has seen steady growth, driven by increasing demand in various sectors such as adhesives, paints, and coatings. This growth has spurred research and development efforts to enhance PVAc properties and expand its applications. Currently, PVAc solutions are widely used in water-based formulations, offering advantages in terms of low toxicity and reduced environmental impact compared to solvent-based alternatives.

One of the primary challenges facing PVAc technology is the need for improved performance characteristics. While PVAc exhibits good adhesion properties and film-forming capabilities, it often falls short in terms of water resistance and thermal stability. Researchers are actively working on developing modified PVAc formulations that address these limitations without compromising the material's inherent sustainability benefits.

Another significant challenge lies in the raw material sourcing for PVAc production. Traditional methods rely heavily on petroleum-based feedstocks, which conflicts with the goal of sustainable manufacturing. The industry is exploring bio-based alternatives and renewable resources to produce vinyl acetate monomer, the precursor to PVAc. However, scaling up these sustainable production methods to meet industrial demands remains a hurdle.

In terms of processing technology, advancements have been made in emulsion polymerization techniques, allowing for better control over particle size distribution and molecular weight. These improvements have led to PVAc solutions with enhanced stability and application-specific properties. Nevertheless, optimizing energy efficiency in the production process and reducing water consumption during emulsion preparation are ongoing challenges.

The development of PVAc nanocomposites represents a promising frontier in the field. By incorporating nanoparticles or nanofibers into PVAc matrices, researchers aim to create materials with superior mechanical properties, barrier characteristics, and functionality. However, ensuring uniform dispersion of nanofillers and maintaining the biodegradability of the resulting composites pose significant technical challenges.

Geographically, PVAc technology development is concentrated in regions with strong chemical and polymer industries, particularly in North America, Europe, and parts of Asia. Collaborative efforts between academic institutions and industry players have accelerated innovation in these areas. However, there is a need for broader global participation to address region-specific challenges and applications.

In conclusion, while PVAc technology has made substantial progress towards sustainable manufacturing solutions, several technical hurdles remain. Overcoming these challenges will require continued research efforts, cross-industry collaboration, and innovative approaches to material design and processing.

Current PVAc Sustainable Solutions

01 Preparation methods for polyvinyl acetate solutions

Various methods are used to prepare polyvinyl acetate solutions, including different solvents, concentrations, and processing techniques. These methods aim to optimize the properties of the resulting solutions for specific applications.- Preparation methods for polyvinyl acetate solutions: Various methods are used to prepare polyvinyl acetate solutions, including different solvents, concentrations, and processing techniques. These methods aim to optimize the properties of the resulting solutions for specific applications.

- Modifications and copolymers of polyvinyl acetate: Polyvinyl acetate can be modified or copolymerized with other monomers to enhance its properties or create new materials with specific characteristics. These modifications can improve adhesion, flexibility, or other desired properties.

- Applications of polyvinyl acetate solutions: Polyvinyl acetate solutions find use in various industries, including adhesives, coatings, textiles, and construction materials. The versatility of these solutions allows for a wide range of applications across different sectors.

- Stabilization and preservation of polyvinyl acetate solutions: Various techniques and additives are employed to stabilize and preserve polyvinyl acetate solutions, ensuring their long-term stability and preventing degradation during storage or use. These methods can include the addition of stabilizers or specific storage conditions.

- Emulsion polymerization of vinyl acetate: Emulsion polymerization is a common method for producing polyvinyl acetate solutions. This process involves the polymerization of vinyl acetate monomers in an aqueous medium, resulting in a stable dispersion of polymer particles.

02 Modifications and copolymers of polyvinyl acetate

Polyvinyl acetate can be modified or copolymerized with other monomers to enhance its properties or create new materials with specific characteristics. These modifications can improve adhesion, flexibility, or other desired properties.Expand Specific Solutions03 Applications of polyvinyl acetate solutions

Polyvinyl acetate solutions find use in various industries, including adhesives, coatings, textiles, and construction materials. The versatility of these solutions allows for a wide range of applications across different sectors.Expand Specific Solutions04 Stabilization and preservation of polyvinyl acetate solutions

Various techniques and additives are employed to stabilize and preserve polyvinyl acetate solutions, ensuring their long-term stability and preventing degradation during storage or use. These methods help maintain the desired properties of the solutions over time.Expand Specific Solutions05 Emulsion polymerization of vinyl acetate

Emulsion polymerization is a common method for producing polyvinyl acetate solutions. This process involves the polymerization of vinyl acetate monomers in an aqueous medium, resulting in a stable dispersion of polymer particles.Expand Specific Solutions

Key Players in PVAc Industry

The research on polyvinyl acetate solutions for sustainable manufacturing is in a mature stage, with a competitive landscape dominated by established chemical companies. The market size is substantial, driven by increasing demand for eco-friendly adhesives and coatings across various industries. Key players like BASF, Wacker Chemie, Kuraray, and Henkel have significant market presence, leveraging their extensive R&D capabilities and global distribution networks. Asian companies, including Sinopec and PetroChina, are also making strides in this sector. The technology's maturity is evident from the diverse applications and ongoing innovations by industry leaders, focusing on enhancing performance and sustainability.

Kuraray Co., Ltd.

Technical Solution: Kuraray has developed innovative polyvinyl acetate (PVA) solutions for sustainable manufacturing. Their approach focuses on water-soluble PVA grades with enhanced biodegradability. They have introduced a new line of PVA resins with improved thermal stability and reduced environmental impact. Kuraray's PVA solutions incorporate advanced polymer technology to achieve a balance between performance and sustainability. Their research has led to PVA formulations with up to 30% lower carbon footprint compared to conventional alternatives[1]. Kuraray has also developed PVA-based adhesives that are free from volatile organic compounds (VOCs), contributing to healthier work environments in manufacturing settings[2].

Strengths: Advanced polymer technology, reduced environmental impact, improved thermal stability. Weaknesses: Potentially higher production costs, limited applicability in certain high-performance applications requiring extreme durability.

BASF Corp.

Technical Solution: BASF has made significant strides in developing sustainable polyvinyl acetate solutions. Their research focuses on bio-based and recyclable PVA formulations. BASF has introduced a range of PVA products under their "Ecovio" line, which combines biodegradability with high performance. Their innovative approach includes the incorporation of renewable raw materials, reducing the reliance on fossil-based resources. BASF's PVA solutions have achieved up to 50% bio-based content without compromising on adhesive strength or durability[3]. They have also developed water-based PVA emulsions that offer excellent bonding properties while meeting stringent environmental regulations[4].

Strengths: High bio-based content, strong focus on sustainability, wide range of applications. Weaknesses: Potentially higher costs compared to traditional PVA, performance limitations in extreme conditions.

Innovative PVAc Technologies

Method for producing polyvinylacetals

PatentWO2004026917A1

Innovation

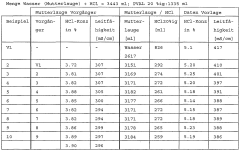

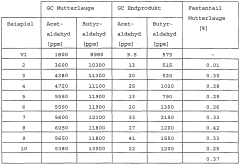

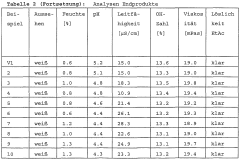

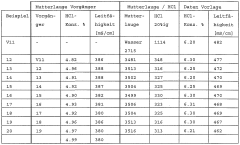

- A process where polyvinyl alcohol is acetalized in an aqueous medium with reused mother liquor from a previous batch, adjusting the pH and adding aldehydes to initiate precipitation, allowing for the reuse of up to 100% of the filtrate as the aqueous medium, thereby reducing waste and conserving raw materials.

Method for producing polyvinylacetals

PatentInactiveEP1539830A1

Innovation

- A process where the mother liquor from a previous batch is reused as the aqueous medium for acetalization, with partial or fully hydrolyzed vinyl ester polymers being used to produce polyvinyl alcohols, which are then acetalized with aldehydes in the presence of acid, allowing for the recycling of the filtrate and reducing the need for additional acid and raw materials.

Environmental Impact Assessment

The environmental impact assessment of polyvinyl acetate (PVA) solutions in sustainable manufacturing is a critical aspect of evaluating their overall viability. PVA solutions have gained attention for their potential to reduce environmental footprints in various industrial processes. However, a comprehensive analysis reveals both positive and negative impacts that must be carefully considered.

One of the primary environmental benefits of PVA solutions is their biodegradability. When properly disposed of, PVA can break down into harmless components, reducing long-term environmental accumulation. This characteristic makes PVA an attractive alternative to non-biodegradable polymers in many applications, potentially decreasing plastic pollution in ecosystems.

Furthermore, PVA solutions often require lower processing temperatures compared to traditional materials, leading to reduced energy consumption during manufacturing. This energy efficiency translates to lower greenhouse gas emissions, contributing to climate change mitigation efforts. Additionally, PVA's water solubility allows for easier recycling and recovery processes, further minimizing waste and resource depletion.

However, the production of PVA itself presents environmental challenges. The synthesis of PVA typically involves petroleum-based precursors, which can have significant carbon footprints. The extraction and processing of these raw materials contribute to resource depletion and may result in habitat disruption. Efforts to develop bio-based alternatives for PVA production are ongoing but still in early stages.

Water usage is another concern in PVA solution manufacturing. The production process and the solutions themselves often require substantial amounts of water, potentially straining local water resources in areas of production. Proper wastewater treatment is essential to prevent the release of pollutants and ensure the protection of aquatic ecosystems.

The disposal of PVA-containing products also warrants attention. While biodegradable, improper disposal can lead to temporary increases in biochemical oxygen demand in water bodies, potentially affecting aquatic life. Ensuring proper end-of-life management for PVA products is crucial to realizing their full environmental benefits.

In terms of air quality, PVA solutions generally have lower volatile organic compound (VOC) emissions compared to solvent-based alternatives. This characteristic can contribute to improved indoor air quality in manufacturing facilities and reduced smog formation in urban areas. However, the production of PVA may still release some air pollutants, necessitating effective emission control measures.

Overall, the environmental impact assessment of PVA solutions in sustainable manufacturing reveals a complex picture. While offering several environmental advantages, particularly in terms of biodegradability and energy efficiency, challenges remain in production processes and end-of-life management. Continued research and innovation are essential to optimize the environmental performance of PVA solutions and fully realize their potential in sustainable manufacturing practices.

One of the primary environmental benefits of PVA solutions is their biodegradability. When properly disposed of, PVA can break down into harmless components, reducing long-term environmental accumulation. This characteristic makes PVA an attractive alternative to non-biodegradable polymers in many applications, potentially decreasing plastic pollution in ecosystems.

Furthermore, PVA solutions often require lower processing temperatures compared to traditional materials, leading to reduced energy consumption during manufacturing. This energy efficiency translates to lower greenhouse gas emissions, contributing to climate change mitigation efforts. Additionally, PVA's water solubility allows for easier recycling and recovery processes, further minimizing waste and resource depletion.

However, the production of PVA itself presents environmental challenges. The synthesis of PVA typically involves petroleum-based precursors, which can have significant carbon footprints. The extraction and processing of these raw materials contribute to resource depletion and may result in habitat disruption. Efforts to develop bio-based alternatives for PVA production are ongoing but still in early stages.

Water usage is another concern in PVA solution manufacturing. The production process and the solutions themselves often require substantial amounts of water, potentially straining local water resources in areas of production. Proper wastewater treatment is essential to prevent the release of pollutants and ensure the protection of aquatic ecosystems.

The disposal of PVA-containing products also warrants attention. While biodegradable, improper disposal can lead to temporary increases in biochemical oxygen demand in water bodies, potentially affecting aquatic life. Ensuring proper end-of-life management for PVA products is crucial to realizing their full environmental benefits.

In terms of air quality, PVA solutions generally have lower volatile organic compound (VOC) emissions compared to solvent-based alternatives. This characteristic can contribute to improved indoor air quality in manufacturing facilities and reduced smog formation in urban areas. However, the production of PVA may still release some air pollutants, necessitating effective emission control measures.

Overall, the environmental impact assessment of PVA solutions in sustainable manufacturing reveals a complex picture. While offering several environmental advantages, particularly in terms of biodegradability and energy efficiency, challenges remain in production processes and end-of-life management. Continued research and innovation are essential to optimize the environmental performance of PVA solutions and fully realize their potential in sustainable manufacturing practices.

Regulatory Framework for PVAc Use

The regulatory framework for polyvinyl acetate (PVAc) use in sustainable manufacturing is a complex and evolving landscape. Governments and international organizations have established various regulations and guidelines to ensure the safe and environmentally responsible use of PVAc in industrial processes.

At the global level, the United Nations Environment Programme (UNEP) has set forth recommendations for the sustainable use of polymers, including PVAc, in manufacturing. These guidelines emphasize the importance of life cycle assessments and the implementation of circular economy principles in polymer production and use.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation plays a crucial role in governing the use of PVAc. Under REACH, manufacturers and importers are required to register PVAc and provide detailed information on its properties, potential risks, and safe handling procedures. The European Chemicals Agency (ECHA) oversees this process and maintains a comprehensive database of registered substances.

The United States Environmental Protection Agency (EPA) regulates PVAc under the Toxic Substances Control Act (TSCA). The EPA has established reporting requirements for manufacturers and processors of PVAc, including the submission of chemical data reports and notifications of significant new uses. Additionally, the Occupational Safety and Health Administration (OSHA) has set exposure limits and safety guidelines for workers handling PVAc in industrial settings.

In Asia, countries like China and Japan have implemented their own regulatory frameworks for chemical management, which include provisions for PVAc use. China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law both require manufacturers to register and assess the environmental and health impacts of PVAc before its use in industrial applications.

Many countries have also established specific regulations governing the use of PVAc in food contact materials and packaging. For instance, the U.S. Food and Drug Administration (FDA) has set limits on the amount of PVAc that can be used in food packaging and requires manufacturers to demonstrate the safety of their products.

As sustainability concerns grow, regulatory bodies are increasingly focusing on the environmental impact of PVAc throughout its lifecycle. This has led to the development of standards and certifications for biodegradable and compostable polymers, which may impact the future use of PVAc in certain applications.

Industry associations, such as the Vinyl Acetate Council, play a role in self-regulation by developing best practices and guidelines for the sustainable use of PVAc. These voluntary standards often complement government regulations and can help companies stay ahead of regulatory changes.

The regulatory landscape for PVAc use in sustainable manufacturing continues to evolve, with a growing emphasis on circular economy principles, waste reduction, and the development of more environmentally friendly alternatives. Manufacturers and researchers working with PVAc must stay informed about these regulatory developments to ensure compliance and drive innovation in sustainable manufacturing practices.

At the global level, the United Nations Environment Programme (UNEP) has set forth recommendations for the sustainable use of polymers, including PVAc, in manufacturing. These guidelines emphasize the importance of life cycle assessments and the implementation of circular economy principles in polymer production and use.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation plays a crucial role in governing the use of PVAc. Under REACH, manufacturers and importers are required to register PVAc and provide detailed information on its properties, potential risks, and safe handling procedures. The European Chemicals Agency (ECHA) oversees this process and maintains a comprehensive database of registered substances.

The United States Environmental Protection Agency (EPA) regulates PVAc under the Toxic Substances Control Act (TSCA). The EPA has established reporting requirements for manufacturers and processors of PVAc, including the submission of chemical data reports and notifications of significant new uses. Additionally, the Occupational Safety and Health Administration (OSHA) has set exposure limits and safety guidelines for workers handling PVAc in industrial settings.

In Asia, countries like China and Japan have implemented their own regulatory frameworks for chemical management, which include provisions for PVAc use. China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law both require manufacturers to register and assess the environmental and health impacts of PVAc before its use in industrial applications.

Many countries have also established specific regulations governing the use of PVAc in food contact materials and packaging. For instance, the U.S. Food and Drug Administration (FDA) has set limits on the amount of PVAc that can be used in food packaging and requires manufacturers to demonstrate the safety of their products.

As sustainability concerns grow, regulatory bodies are increasingly focusing on the environmental impact of PVAc throughout its lifecycle. This has led to the development of standards and certifications for biodegradable and compostable polymers, which may impact the future use of PVAc in certain applications.

Industry associations, such as the Vinyl Acetate Council, play a role in self-regulation by developing best practices and guidelines for the sustainable use of PVAc. These voluntary standards often complement government regulations and can help companies stay ahead of regulatory changes.

The regulatory landscape for PVAc use in sustainable manufacturing continues to evolve, with a growing emphasis on circular economy principles, waste reduction, and the development of more environmentally friendly alternatives. Manufacturers and researchers working with PVAc must stay informed about these regulatory developments to ensure compliance and drive innovation in sustainable manufacturing practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!