Quasicrystal for Ultra-Low Friction Surface Coatings

Quasicrystal Coatings: Background and Objectives

Quasicrystals, discovered in 1982 by Dan Shechtman, represent a unique class of materials that exhibit long-range order but lack periodicity. This groundbreaking discovery challenged the conventional understanding of crystalline structures and opened up new avenues for materials science research. The potential application of quasicrystals in ultra-low friction surface coatings has garnered significant attention in recent years due to their exceptional mechanical and tribological properties.

The development of quasicrystal coatings for ultra-low friction surfaces aims to address the growing demand for high-performance, energy-efficient materials in various industries. These coatings offer the promise of reduced wear, improved durability, and enhanced energy efficiency in mechanical systems, making them particularly attractive for automotive, aerospace, and industrial applications.

The evolution of quasicrystal research has been marked by several key milestones. Following their initial discovery, the 1990s saw increased efforts to understand the formation mechanisms and structural characteristics of quasicrystals. The early 2000s witnessed a shift towards exploring their potential applications, with surface coatings emerging as a promising area of focus.

Recent technological advancements have enabled the synthesis of stable quasicrystalline phases and the development of deposition techniques suitable for creating thin films and coatings. These breakthroughs have paved the way for practical applications of quasicrystal coatings in tribological systems.

The primary objective of research on quasicrystal coatings for ultra-low friction surfaces is to optimize their composition, structure, and deposition methods to achieve superior tribological performance. This involves investigating the relationship between the unique atomic arrangement of quasicrystals and their friction-reducing properties, as well as developing scalable production techniques for commercial applications.

Key research goals include enhancing the adhesion of quasicrystal coatings to various substrates, improving their stability under diverse operating conditions, and maximizing their wear resistance. Additionally, efforts are focused on understanding the mechanisms of friction reduction at the nanoscale and exploring potential synergies with other advanced materials and lubricants.

The development of quasicrystal coatings aligns with broader technological trends in materials science, such as the pursuit of sustainable and energy-efficient solutions. As industries seek to reduce energy consumption and extend the lifespan of mechanical components, ultra-low friction coatings based on quasicrystals offer a promising pathway to achieve these objectives.

Market Analysis for Ultra-Low Friction Coatings

The market for ultra-low friction coatings is experiencing significant growth, driven by increasing demand across various industries. The automotive sector stands out as a primary consumer, seeking to enhance fuel efficiency and reduce wear in engine components. Aerospace and defense industries also show substantial interest, aiming to improve the performance and longevity of critical parts in aircraft and military equipment.

In the industrial machinery sector, ultra-low friction coatings are gaining traction for their ability to extend equipment lifespan and reduce maintenance costs. The medical device industry is another emerging market, where these coatings can improve the functionality of implants and surgical instruments.

The global market for advanced coatings, including ultra-low friction variants, is projected to expand at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is fueled by ongoing technological advancements and the increasing adoption of these coatings in new applications.

Geographically, North America and Europe currently dominate the market, owing to their strong presence in automotive and aerospace industries. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization and increasing investments in research and development.

Key market drivers include stringent environmental regulations promoting fuel efficiency, growing awareness of the benefits of friction reduction in industrial processes, and the continuous push for innovation in material sciences. The development of quasicrystal-based ultra-low friction coatings represents a significant technological advancement in this field.

Challenges in the market include the high initial costs associated with advanced coating technologies and the need for specialized application processes. However, the long-term benefits of reduced friction, improved durability, and enhanced performance are expected to outweigh these initial barriers.

The market is characterized by intense competition among key players, including global chemical companies and specialized coating manufacturers. These companies are investing heavily in research and development to create innovative solutions and gain a competitive edge.

As industries continue to seek ways to improve efficiency and reduce operational costs, the demand for ultra-low friction coatings is expected to rise. The potential applications of quasicrystal-based coatings in this market segment present significant opportunities for growth and technological advancement in the coming years.

Current Challenges in Quasicrystal Surface Technology

Despite the promising potential of quasicrystals for ultra-low friction surface coatings, several significant challenges persist in their development and application. One of the primary obstacles is the difficulty in synthesizing large-scale, high-quality quasicrystalline coatings. The complex atomic structure of quasicrystals, characterized by long-range order but no periodicity, makes their formation process highly sensitive to growth conditions.

The stability of quasicrystalline coatings under various environmental conditions remains a concern. While quasicrystals exhibit remarkable hardness and wear resistance, their performance can degrade when exposed to extreme temperatures, pressures, or corrosive environments. This limitation restricts their potential applications in certain industrial sectors where harsh operating conditions are common.

Another challenge lies in the precise control of the quasicrystalline phase during the coating process. The formation of quasicrystals often competes with the crystallization of periodic phases, leading to the presence of unwanted crystalline domains within the coating. These impurities can significantly affect the overall performance and properties of the surface coating.

The adhesion of quasicrystalline coatings to various substrate materials presents another hurdle. Ensuring strong and durable bonding between the quasicrystalline layer and the underlying substrate is crucial for the long-term stability and effectiveness of the coating. Current techniques often struggle to achieve consistent adhesion across different substrate materials and geometries.

Cost-effective production of quasicrystalline coatings at an industrial scale remains a significant challenge. The complex processing requirements and the need for precise control over growth conditions contribute to high production costs, limiting widespread adoption in commercial applications.

Furthermore, the mechanisms underlying the ultra-low friction properties of quasicrystalline surfaces are not fully understood. This knowledge gap hinders the optimization of coating compositions and structures for specific applications. Advanced characterization techniques and theoretical models are needed to elucidate the fundamental principles governing the tribological behavior of quasicrystalline surfaces.

Lastly, the integration of quasicrystalline coatings into existing manufacturing processes and product designs poses technical challenges. Adapting current production lines and developing new application methods compatible with various substrate materials and geometries require significant research and development efforts.

Existing Ultra-Low Friction Coating Solutions

01 Quasicrystal coatings for friction reduction

Quasicrystal materials are used as coatings on various surfaces to reduce friction. These coatings exhibit unique properties due to their aperiodic atomic structure, which can lead to improved wear resistance and lower friction coefficients compared to traditional crystalline materials.- Quasicrystal coatings for friction reduction: Quasicrystal materials are used as coatings on various surfaces to reduce friction. These coatings exhibit unique properties due to their aperiodic atomic structure, which can lead to low friction coefficients and improved wear resistance. The application of quasicrystal coatings can enhance the performance and longevity of mechanical components subject to friction.

- Quasicrystal-based composites for tribological applications: Composite materials incorporating quasicrystals are developed for applications requiring low friction and high wear resistance. These composites combine the unique properties of quasicrystals with other materials to create synergistic effects, resulting in improved tribological performance. Such composites can be used in various industries, including automotive and aerospace.

- Surface modification techniques for quasicrystal friction control: Various surface modification techniques are employed to optimize the friction properties of quasicrystal materials. These methods may include ion implantation, laser treatment, or chemical etching to alter the surface structure and composition of quasicrystals. The modified surfaces can exhibit enhanced friction characteristics and improved wear resistance.

- Quasicrystal-based lubricants and additives: Quasicrystal particles or derivatives are used as lubricants or additives in lubricating systems to reduce friction and wear. These materials can be incorporated into oils, greases, or other lubricating media to enhance their tribological properties. The unique structure of quasicrystals contributes to their effectiveness as solid lubricants or friction modifiers.

- Characterization and modeling of quasicrystal friction behavior: Advanced techniques are developed for characterizing and modeling the friction behavior of quasicrystal materials. These methods may include atomic-scale simulations, in-situ friction measurements, and advanced microscopy techniques. Understanding the fundamental mechanisms of friction in quasicrystals enables the design of more effective friction-reducing strategies and applications.

02 Quasicrystal-based lubricants

Quasicrystals are incorporated into lubricants to enhance their friction-reducing properties. These materials can be used as additives in oils or greases, providing improved lubrication and potentially extending the life of mechanical components in various applications.Expand Specific Solutions03 Quasicrystal surface texturing for friction control

Surface texturing techniques are applied to create quasicrystalline patterns on materials, which can help control friction characteristics. This approach can be used to optimize the tribological properties of surfaces in specific applications, such as in automotive or aerospace industries.Expand Specific Solutions04 Quasicrystal-polymer composites for low-friction applications

Quasicrystals are combined with polymers to create composite materials with enhanced friction properties. These composites can offer a balance of low friction, wear resistance, and other desirable mechanical properties, making them suitable for use in bearings, seals, and other tribological applications.Expand Specific Solutions05 Quasicrystal friction in nanotechnology

The unique frictional properties of quasicrystals are explored at the nanoscale for potential applications in nanotechnology. This includes the development of nanodevices with improved tribological performance and the study of friction mechanisms in quasicrystalline nanostructures.Expand Specific Solutions

Key Players in Quasicrystal Coating Industry

The research on quasicrystal for ultra-low friction surface coatings is in an emerging stage, with growing market potential due to its applications in various industries. The global market for advanced coatings is expanding, driven by demand for improved surface properties. Technologically, the field is still developing, with varying levels of maturity among key players. Companies like Centre National de la Recherche Scientifique, Uchicago Argonne LLC, and Zhejiang University are at the forefront of research, while industrial players such as General Electric Technology GmbH and Praxair S.T. Technology, Inc. are working on practical applications. The competitive landscape is diverse, with academic institutions, national laboratories, and multinational corporations all contributing to advancements in quasicrystal coatings technology.

Centre National de la Recherche Scientifique

Uchicago Argonne LLC

Innovations in Quasicrystal Surface Engineering

- The method of electrocodepositing particles of quasicrystalline metal alloys within a matrix of elemental metals onto a substrate, using an electroplating bath with suspended quasicrystalline metal alloy particles and controlled conditions to achieve a composite coating with enhanced properties, such as high hardness and low friction.

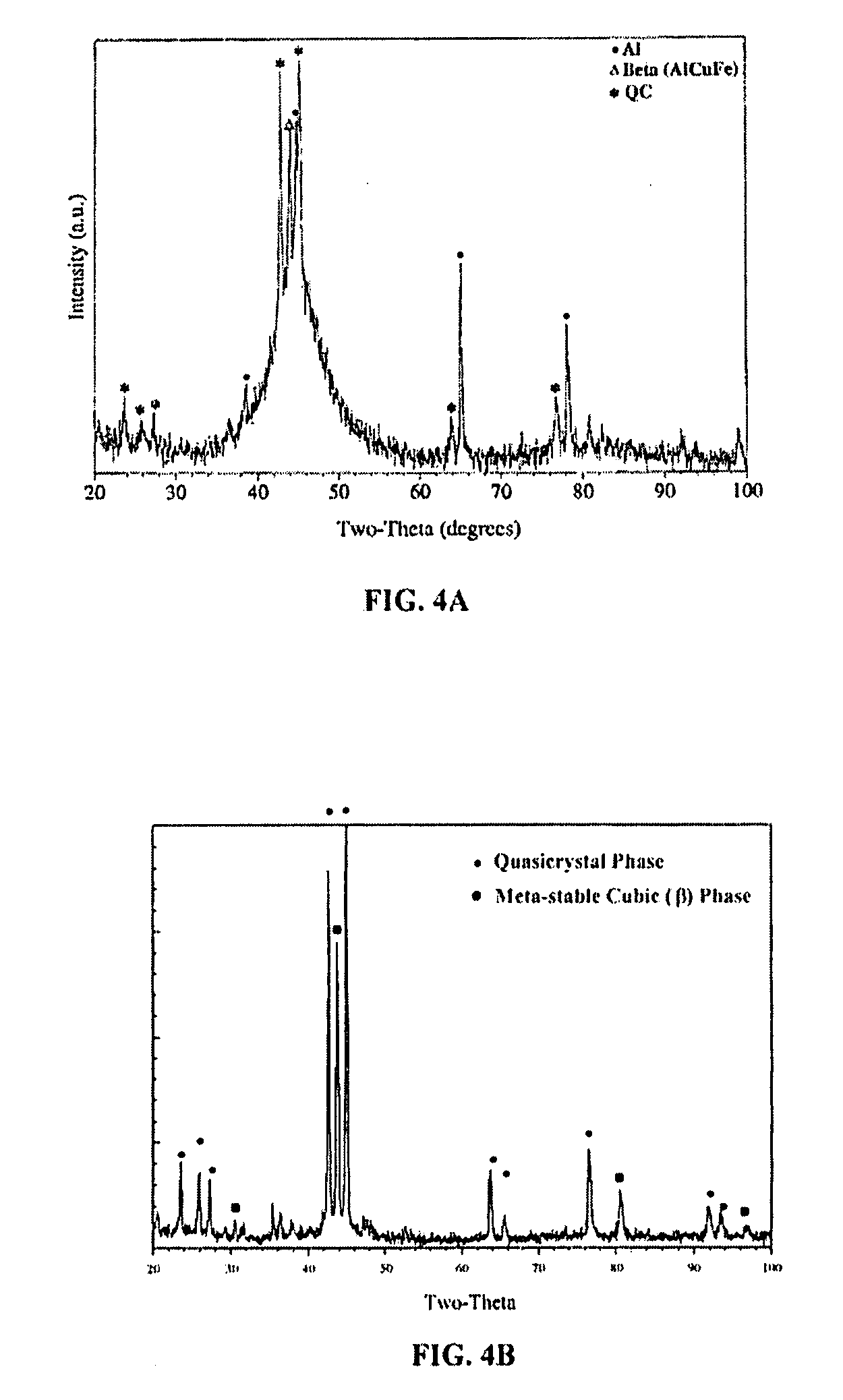

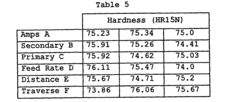

- A thermally sprayed coating composed of an Al-Cu-Fe alloy with a specific weight percentage of Cu, Fe, Cr, Co, Ni, Mo, and W, containing at least 50% ψ phase, is developed to achieve high hardness, density, and surface smoothness, utilizing rapid thermal spraying to avoid detrimental δ phase formation and optimize phase equilibria through controlled cooling rates and plasma spraying parameters.

Environmental Impact of Quasicrystal Coatings

The environmental impact of quasicrystal coatings is a crucial aspect to consider in their development and application. These innovative surface treatments offer promising benefits in terms of friction reduction and wear resistance, but their potential effects on the environment must be carefully evaluated.

One of the primary environmental advantages of quasicrystal coatings is their potential to reduce energy consumption in various mechanical systems. By significantly lowering friction, these coatings can improve the efficiency of engines, turbines, and other machinery, leading to decreased fuel consumption and reduced greenhouse gas emissions. This aligns with global efforts to combat climate change and promote sustainable technologies.

However, the production process of quasicrystal coatings may raise environmental concerns. The synthesis of quasicrystalline materials often involves complex procedures and the use of rare or potentially toxic elements. It is essential to assess the environmental footprint of these manufacturing processes, including energy consumption, waste generation, and the potential release of harmful substances.

The durability of quasicrystal coatings is another factor that influences their environmental impact. If these coatings prove to be long-lasting and resistant to wear, they could significantly extend the lifespan of coated components. This would result in reduced material consumption and waste generation over time, contributing to resource conservation and sustainability.

The end-of-life management of quasicrystal-coated products is an important consideration. Research is needed to determine the recyclability and disposal methods for these materials. If quasicrystal coatings can be effectively recycled or safely disposed of, it would mitigate potential environmental risks associated with their accumulation in landfills or ecosystems.

Potential ecological effects of quasicrystal coatings should also be investigated. This includes studying their behavior in different environmental conditions, such as exposure to water, soil, or air, and assessing any potential leaching or degradation products that could impact ecosystems.

As quasicrystal coatings gain traction in various industries, it is crucial to conduct comprehensive life cycle assessments. These studies should evaluate the environmental impacts from raw material extraction to manufacturing, use, and disposal. Such assessments will provide valuable insights into the overall sustainability of quasicrystal coatings compared to conventional alternatives.

Regulatory compliance and environmental standards must be considered in the development and application of quasicrystal coatings. Ensuring that these materials meet or exceed existing environmental regulations will be essential for their widespread adoption and long-term viability in the market.

Tribological Performance Evaluation Methods

The evaluation of tribological performance for quasicrystal ultra-low friction surface coatings requires a comprehensive set of methods to assess their effectiveness and durability. These evaluation techniques can be broadly categorized into laboratory-based tests and field trials, each providing valuable insights into different aspects of the coating's performance.

Laboratory-based evaluations typically involve controlled experiments using specialized equipment. One common method is the pin-on-disk test, where a pin or ball is pressed against a rotating disk coated with the quasicrystal material. This test allows for precise measurement of friction coefficients and wear rates under various loads and speeds. Another widely used technique is the ball-on-flat reciprocating test, which simulates linear sliding motion and can provide data on friction and wear behavior over extended periods.

Nanoindentation tests are crucial for assessing the hardness and elastic modulus of the quasicrystal coatings. These properties are essential for predicting the coating's resistance to deformation and its overall durability. Scratch tests, where a stylus is drawn across the coated surface under increasing load, can evaluate the coating's adhesion strength and resistance to failure.

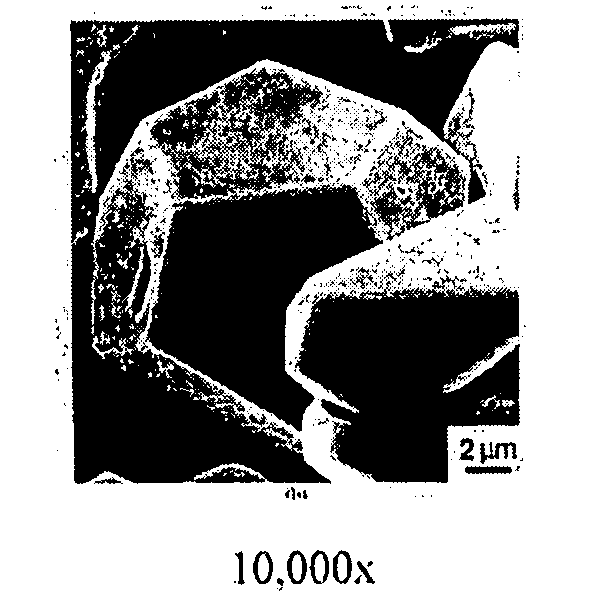

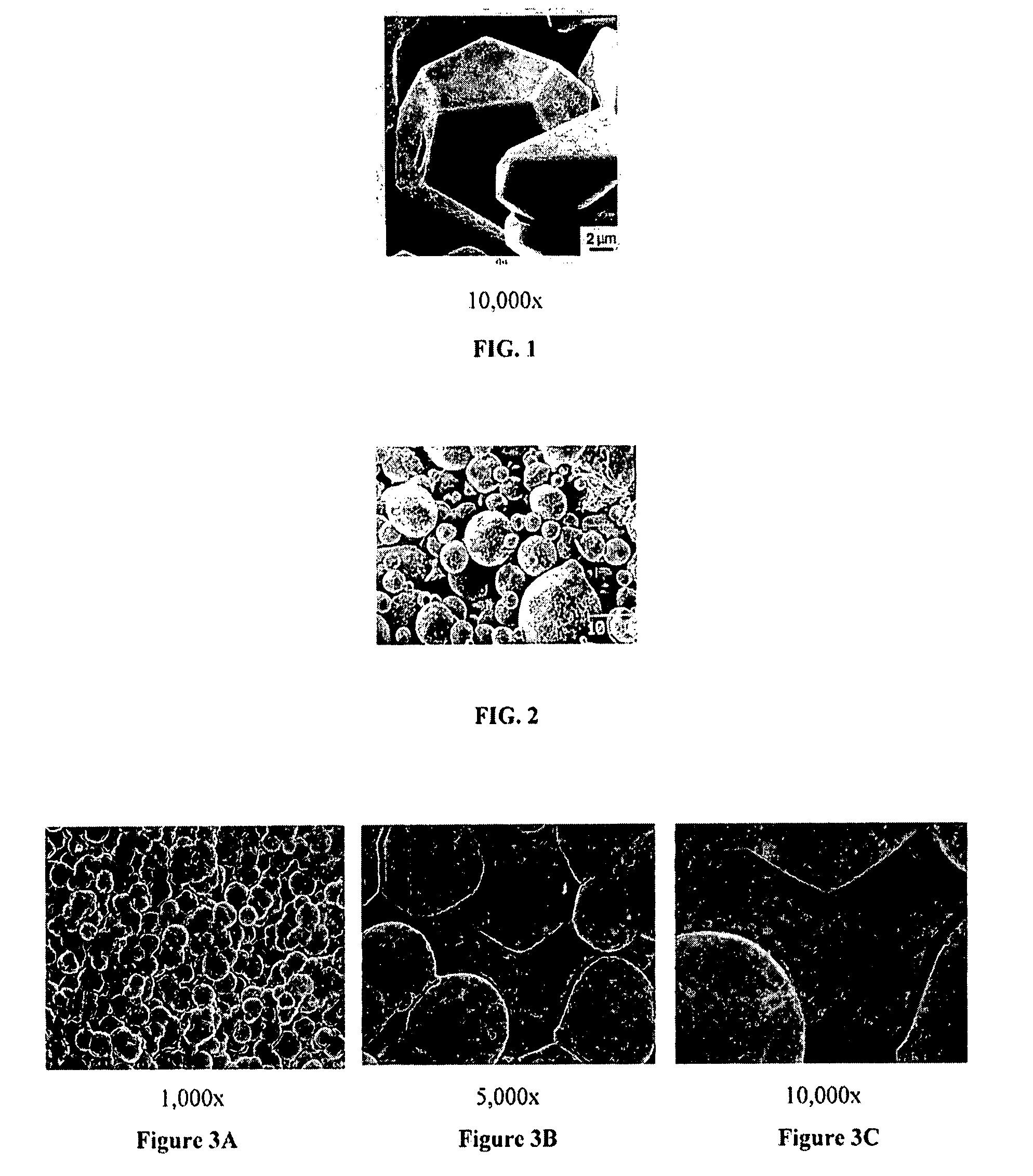

Surface analysis techniques play a vital role in understanding the tribological performance of quasicrystal coatings. Atomic force microscopy (AFM) and scanning electron microscopy (SEM) can provide detailed information about surface topography and wear mechanisms at the micro and nanoscale. X-ray photoelectron spectroscopy (XPS) and Raman spectroscopy are valuable for analyzing the chemical composition and structural changes of the coating surface before and after tribological testing.

Field trials are essential for validating laboratory results and assessing real-world performance. These may involve installing coated components in actual machinery or vehicles and monitoring their performance over extended periods. Factors such as operating temperature, environmental conditions, and lubricant compatibility are critical considerations during field evaluations.

High-temperature tribological tests are particularly relevant for quasicrystal coatings, as many potential applications involve elevated temperatures. Specialized high-temperature tribometers can simulate these conditions and provide data on friction and wear behavior at temperatures up to several hundred degrees Celsius.

Corrosion resistance testing is another crucial aspect of evaluating quasicrystal coatings, especially for applications in harsh environments. Salt spray tests and electrochemical impedance spectroscopy can assess the coating's ability to protect the underlying substrate from corrosive attack.

Long-term durability tests, such as thermal cycling and fatigue testing, are essential for predicting the coating's performance over its intended lifespan. These tests can reveal potential failure modes and help in optimizing the coating composition and deposition parameters.