Quasicrystal: Revolutionizing Novel Engineering Solutions

Quasicrystal Evolution

The evolution of quasicrystals represents a fascinating journey in materials science, marked by groundbreaking discoveries and paradigm shifts in our understanding of atomic structures. Initially discovered in 1982 by Dan Shechtman, quasicrystals challenged the long-held belief that all crystals must have periodic atomic arrangements. This discovery, which earned Shechtman the Nobel Prize in Chemistry in 2011, opened up a new field of research with far-reaching implications for materials science and engineering.

The early stages of quasicrystal research focused primarily on understanding their unique atomic structure and properties. Scientists discovered that these materials possess long-range order but lack periodicity, exhibiting symmetries that were previously thought impossible in crystals, such as five-fold rotational symmetry. This period was characterized by intense theoretical work to explain the formation and stability of quasicrystals, leading to the development of new mathematical models and computational techniques.

As research progressed, the focus shifted towards exploring the potential applications of quasicrystals. Their unique atomic arrangement confers properties that are distinct from both crystalline and amorphous materials. For instance, quasicrystals exhibit low friction, high hardness, and unusual thermal and electrical conductivity characteristics. These properties sparked interest in various industrial sectors, including aerospace, automotive, and energy.

The late 1990s and early 2000s saw significant advancements in the synthesis and characterization of quasicrystals. Researchers developed new methods to produce larger, purer samples, enabling more detailed studies of their properties and potential applications. This period also witnessed the discovery of natural quasicrystals in meteorite samples, providing insights into their formation under extreme conditions and their stability over geological timescales.

Recent years have seen a resurgence of interest in quasicrystals, driven by advances in nanotechnology and materials engineering. Researchers are now exploring the potential of quasicrystals in fields such as photonics, where their unique structural properties can be harnessed to create novel optical devices. Additionally, the discovery of soft-matter quasicrystals has expanded the field beyond metallic alloys, opening up new possibilities in polymer science and self-assembly.

Looking forward, the evolution of quasicrystal research is likely to continue along several exciting paths. There is growing interest in leveraging machine learning and artificial intelligence to predict and design new quasicrystalline materials with tailored properties. Furthermore, the potential of quasicrystals in quantum computing and spintronics is an emerging area of research that could lead to revolutionary advances in information technology.

Market Applications

Quasicrystals, with their unique structural properties, are poised to revolutionize various engineering applications across multiple industries. In the aerospace sector, quasicrystal coatings are being explored for their exceptional thermal resistance and low friction properties. These coatings can significantly enhance the performance and longevity of aircraft engines, potentially reducing fuel consumption and maintenance costs. The automotive industry is also investigating quasicrystals for similar applications, particularly in engine components subjected to high temperatures and wear.

The electronics industry stands to benefit greatly from quasicrystal technology. Their unusual electronic properties make them promising candidates for novel semiconductor materials. Quasicrystalline alloys could lead to the development of more efficient and faster electronic devices, potentially transforming the landscape of computing and telecommunications.

In the energy sector, quasicrystals are being researched for their thermoelectric properties. Their unique atomic structure could enable the creation of more efficient thermoelectric materials, capable of converting waste heat into electricity. This application has significant implications for improving energy efficiency in various industrial processes and power generation systems.

The medical field is another area where quasicrystals show promise. Their biocompatibility and resistance to corrosion make them attractive for use in medical implants and prosthetics. Quasicrystalline coatings on medical devices could enhance their durability and reduce the risk of rejection by the human body.

In the field of optics, quasicrystals' distinctive light-scattering properties are being explored for potential applications in photonic devices. This could lead to advancements in optical computing, telecommunications, and sensing technologies.

The construction industry is also showing interest in quasicrystalline materials. Their high strength-to-weight ratio and resistance to wear make them potential candidates for structural materials in demanding environments. Additionally, their unique surface properties could be exploited in the development of self-cleaning or anti-fouling coatings for buildings and infrastructure.

As research in quasicrystals progresses, new applications are likely to emerge. The field of nanotechnology, in particular, may benefit from the unique properties of quasicrystalline nanostructures. These could find applications in areas such as catalysis, filtration, and advanced sensing technologies.

Technical Challenges

The field of quasicrystal research faces several significant technical challenges that hinder its widespread application in engineering solutions. One of the primary obstacles is the difficulty in synthesizing large-scale, high-quality quasicrystals with consistent properties. The unique atomic structure of quasicrystals, characterized by long-range order without periodicity, makes their formation process complex and hard to control. This challenge limits the ability to produce quasicrystals in quantities and sizes suitable for industrial applications.

Another major hurdle is the limited understanding of the mechanical properties of quasicrystals at different scales. While quasicrystals exhibit intriguing characteristics such as high hardness and low friction, their behavior under various stress conditions and in different environments is not fully comprehended. This knowledge gap impedes the development of reliable engineering solutions that can leverage the full potential of quasicrystalline materials.

The integration of quasicrystals with other materials in composite structures presents additional technical difficulties. The interface between quasicrystals and conventional crystalline materials often suffers from poor adhesion and compatibility issues, leading to potential structural weaknesses. Overcoming these integration challenges is crucial for creating hybrid materials that combine the unique properties of quasicrystals with the strengths of traditional engineering materials.

Furthermore, the characterization and modeling of quasicrystals pose significant technical challenges. Traditional crystallographic techniques are often inadequate for fully describing the complex structure of quasicrystals, necessitating the development of new analytical methods and computational models. This lack of comprehensive characterization tools hampers the ability to predict and optimize the performance of quasicrystal-based engineering solutions.

The processing and machining of quasicrystals also present technical hurdles. Their high hardness and brittleness make conventional manufacturing techniques less effective, requiring the development of specialized processing methods. This challenge is particularly evident in shaping quasicrystals into specific geometries needed for engineering applications, limiting their versatility in product design and manufacturing.

Lastly, the long-term stability and performance of quasicrystals in various operational environments remain areas of concern. The behavior of quasicrystalline materials under prolonged exposure to heat, stress, and corrosive substances is not fully understood, raising questions about their reliability in long-term engineering applications. Addressing these durability concerns is essential for establishing quasicrystals as viable materials in advanced engineering solutions.

Current Synthesis Methods

01 Quasicrystal structure and composition

Quasicrystals are unique materials with aperiodic atomic structures that exhibit long-range order but lack translational symmetry. They often contain aluminum and transition metals, displaying unusual physical and chemical properties. The composition and structure of quasicrystals are crucial for their unique characteristics and potential applications.- Quasicrystal structure and composition: Quasicrystals are unique materials with aperiodic atomic structures that exhibit long-range order but lack translational symmetry. They are typically composed of metallic alloys and possess unusual physical properties. The composition and structure of quasicrystals are crucial for their formation and stability.

- Manufacturing methods for quasicrystals: Various techniques are employed to produce quasicrystals, including rapid solidification, melt spinning, and vapor deposition. These methods often involve precise control of cooling rates and composition to achieve the desired quasicrystalline structure. Advanced manufacturing processes can enhance the quality and yield of quasicrystals.

- Applications of quasicrystals: Quasicrystals find applications in various fields due to their unique properties. They are used in non-stick coatings, thermal barriers, and as reinforcement materials in composites. Their low friction and wear resistance make them suitable for mechanical components. Quasicrystals also show promise in electronic and optical applications.

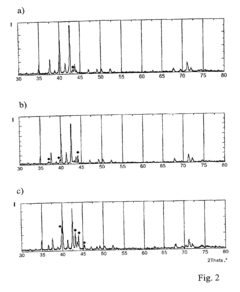

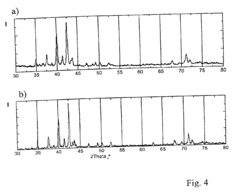

- Characterization and analysis of quasicrystals: Advanced analytical techniques are employed to study the structure and properties of quasicrystals. These include X-ray diffraction, electron microscopy, and spectroscopic methods. Characterization is essential for understanding the unique atomic arrangements and physical behaviors of quasicrystals.

- Quasicrystal-based composites and coatings: Quasicrystals are incorporated into composite materials and coatings to enhance their properties. These composites often exhibit improved mechanical strength, thermal stability, and wear resistance. Quasicrystal-based coatings can provide unique surface properties for various industrial applications.

02 Manufacturing methods for quasicrystals

Various techniques are employed to produce quasicrystals, including rapid solidification, melt spinning, and vapor deposition. These methods aim to create the specific conditions necessary for quasicrystal formation, often involving precise control of cooling rates and composition. Advanced manufacturing processes can lead to improved quasicrystal quality and novel compositions.Expand Specific Solutions03 Applications of quasicrystals in coatings and surface treatments

Quasicrystals find applications in coatings and surface treatments due to their unique properties such as low friction, high hardness, and corrosion resistance. They can be used to enhance the performance of various materials and components in industries such as automotive, aerospace, and manufacturing.Expand Specific Solutions04 Quasicrystal-based alloys and composites

Quasicrystals can be incorporated into alloys and composites to create materials with enhanced properties. These materials may exhibit improved strength, thermal stability, and wear resistance compared to conventional alloys. Research focuses on developing new quasicrystal-based alloys and composites for specific industrial applications.Expand Specific Solutions05 Characterization and analysis of quasicrystals

Advanced techniques are used to characterize and analyze quasicrystals, including electron microscopy, X-ray diffraction, and spectroscopic methods. These analytical approaches help researchers understand the unique structure and properties of quasicrystals, enabling further development and optimization of these materials for various applications.Expand Specific Solutions

Key Research Groups

The research on quasicrystals is in a nascent stage, with significant potential for novel engineering solutions. The market size is relatively small but growing, as industries recognize the unique properties of quasicrystals. Technologically, it's still in the early development phase, with academic institutions like the University of Arkansas, University of California, and Massachusetts Institute of Technology leading fundamental research. Companies such as Samsung Electronics and General Electric Technology GmbH are exploring practical applications. The field is characterized by a mix of academic and industrial players, with universities from various countries contributing to the knowledge base. As the technology matures, we can expect increased involvement from major tech companies and specialized materials firms.

The Regents of the University of California

Samsung Electronics Co., Ltd.

Structural Properties

- A novel quasicrystalline compound with a composition of TivCrwAlxSiyOz, where v=60-65, w=25-30, x=0-6, y=8-15, and z=8-20, specifically optimized to form an icosahedral or approximant structure with 8-15% oxygen and 2-5% aluminum, forming a diffusion barrier and exhibiting low thermal conductivity and high oxidation stability.

- A thermally sprayed coating with a quasicrystal-containing alloy composition of 10-45 Cu, 7-22 Fe, 0-30 Cr, 0-30 Co, 0-20 Ni, 0-7.5 W, and balance aluminum, with less than 30% ψ phase and at least 65% δ phase, applied subsonically to achieve reduced macrohardness and enhanced bond strength, incorporating chromium or cobalt for corrosion resistance.

Material Characterization

Material characterization of quasicrystals presents unique challenges due to their complex atomic structures and unusual symmetries. Traditional crystallographic techniques often fall short in fully describing these materials, necessitating the development of specialized methods and tools.

X-ray diffraction (XRD) remains a fundamental technique for quasicrystal analysis, but with modifications to account for their aperiodic nature. High-resolution transmission electron microscopy (HRTEM) has proven invaluable in visualizing the local atomic arrangements and identifying characteristic features such as Penrose tiling patterns. Scanning tunneling microscopy (STM) provides insights into surface structures and local electronic properties, crucial for understanding the unique physical behaviors of quasicrystals.

Spectroscopic methods, including Raman spectroscopy and X-ray photoelectron spectroscopy (XPS), offer complementary information about chemical bonding and elemental composition. These techniques are particularly useful for investigating the role of phasons, collective excitations unique to quasicrystals, in determining material properties.

Thermal analysis techniques, such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), are employed to study phase transitions and thermal stability, which are critical for potential high-temperature applications of quasicrystals. Mechanical testing methods have been adapted to evaluate the unusual combination of high hardness and low friction coefficients exhibited by many quasicrystalline materials.

Advanced computational modeling and simulation techniques play an increasingly important role in quasicrystal characterization. Density functional theory (DFT) calculations and molecular dynamics simulations help interpret experimental data and predict material properties, bridging the gap between atomic structure and macroscopic behavior.

The development of multi-scale characterization approaches is crucial for a comprehensive understanding of quasicrystals. Combining techniques that probe different length scales, from atomic to macroscopic, allows researchers to correlate local structural features with bulk properties. This integrated approach is essential for unlocking the full potential of quasicrystals in novel engineering applications.

As research in quasicrystals progresses, there is a growing need for standardized characterization protocols and reference materials. This standardization will facilitate comparisons between different studies and accelerate the translation of fundamental research into practical applications. Additionally, in situ and operando characterization methods are being developed to study quasicrystals under realistic operating conditions, providing crucial insights for their implementation in advanced technologies.

Industrial Implications

Quasicrystals, with their unique structural properties, are poised to revolutionize various industrial sectors. Their aperiodic yet ordered structure offers a combination of properties that could lead to groundbreaking applications across multiple fields.

In the aerospace industry, quasicrystals show immense potential for developing lightweight, high-strength materials. Their unusual atomic arrangement contributes to enhanced mechanical properties, potentially leading to more fuel-efficient aircraft and spacecraft. The thermal stability of quasicrystals at high temperatures makes them ideal candidates for use in jet engine components, potentially improving engine efficiency and longevity.

The automotive sector stands to benefit significantly from quasicrystal research. The material's low friction coefficient could lead to the development of more durable and efficient engine parts, reducing wear and tear and improving fuel economy. Additionally, quasicrystals' unique electronic properties may find applications in advanced sensors and control systems for autonomous vehicles.

In the energy sector, quasicrystals could play a crucial role in improving the efficiency of thermoelectric devices. Their complex atomic structure results in low thermal conductivity while maintaining good electrical conductivity, making them excellent candidates for waste heat recovery systems in industrial processes and power generation.

The electronics industry may see a paradigm shift with the integration of quasicrystals. Their unusual electronic properties could lead to the development of novel semiconductor materials, potentially revolutionizing the design of electronic devices. Quasicrystals may also find applications in photonic devices, leveraging their unique interaction with electromagnetic waves.

In the field of materials science, quasicrystals open up new possibilities for surface coatings with enhanced hardness and corrosion resistance. This could lead to the development of more durable and long-lasting industrial equipment, reducing maintenance costs and improving operational efficiency across various sectors.

The medical industry could also benefit from quasicrystal research. Their biocompatibility and unique surface properties make them potential candidates for developing advanced implant materials and drug delivery systems. The antimicrobial properties observed in some quasicrystalline materials could lead to the development of new types of medical instruments and surfaces resistant to bacterial growth.

As research in quasicrystals progresses, we can expect to see a surge in cross-industry collaborations and innovations. The unique properties of these materials are likely to inspire new design paradigms and manufacturing processes, potentially leading to the creation of entirely new industries and product categories.