Reaction Mechanisms in Glacial Acetic Acid-mediated Esterification

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Esterification Background and Objectives

Esterification is a fundamental reaction in organic chemistry, playing a crucial role in various industrial processes and the synthesis of numerous compounds. The reaction involves the condensation of an alcohol and a carboxylic acid to form an ester and water. While this process has been widely studied and applied, the use of glacial acetic acid as a reaction medium presents unique challenges and opportunities that warrant further investigation.

The historical development of esterification reactions can be traced back to the early 19th century, with significant advancements made in understanding reaction mechanisms and improving yields throughout the 20th century. However, the specific role of glacial acetic acid in mediating these reactions has not been fully elucidated, presenting a gap in our knowledge that this research aims to address.

The primary objective of this study is to gain a comprehensive understanding of the reaction mechanisms involved in glacial acetic acid-mediated esterification. This includes investigating the kinetics, thermodynamics, and potential catalytic effects of the glacial acetic acid medium. By exploring these aspects, we aim to optimize reaction conditions and potentially develop novel synthetic routes for industrially relevant esters.

One of the key areas of focus is the examination of how glacial acetic acid influences the reaction equilibrium and rate. Unlike traditional esterification processes that often require the removal of water to drive the reaction to completion, the use of glacial acetic acid may alter this dynamic. Understanding these mechanisms could lead to more efficient and cost-effective esterification processes in industrial applications.

Additionally, this research seeks to explore the potential of glacial acetic acid as both a solvent and a reactant in esterification reactions. This dual role could simplify reaction setups and potentially lead to the development of one-pot synthesis methods for certain esters. The study will also investigate how the high acidity and low water content of glacial acetic acid affect the reaction pathway and product distribution.

Furthermore, the research aims to elucidate any unique intermediates or transition states that may form in the glacial acetic acid medium. This knowledge could provide insights into designing new catalysts or reaction conditions that exploit these intermediates to enhance reaction efficiency or selectivity.

By addressing these objectives, this study intends to bridge the gap between theoretical understanding and practical application of glacial acetic acid-mediated esterification. The findings are expected to contribute significantly to the field of organic synthesis and potentially revolutionize industrial esterification processes, leading to more sustainable and economical production methods for a wide range of ester-based products.

The historical development of esterification reactions can be traced back to the early 19th century, with significant advancements made in understanding reaction mechanisms and improving yields throughout the 20th century. However, the specific role of glacial acetic acid in mediating these reactions has not been fully elucidated, presenting a gap in our knowledge that this research aims to address.

The primary objective of this study is to gain a comprehensive understanding of the reaction mechanisms involved in glacial acetic acid-mediated esterification. This includes investigating the kinetics, thermodynamics, and potential catalytic effects of the glacial acetic acid medium. By exploring these aspects, we aim to optimize reaction conditions and potentially develop novel synthetic routes for industrially relevant esters.

One of the key areas of focus is the examination of how glacial acetic acid influences the reaction equilibrium and rate. Unlike traditional esterification processes that often require the removal of water to drive the reaction to completion, the use of glacial acetic acid may alter this dynamic. Understanding these mechanisms could lead to more efficient and cost-effective esterification processes in industrial applications.

Additionally, this research seeks to explore the potential of glacial acetic acid as both a solvent and a reactant in esterification reactions. This dual role could simplify reaction setups and potentially lead to the development of one-pot synthesis methods for certain esters. The study will also investigate how the high acidity and low water content of glacial acetic acid affect the reaction pathway and product distribution.

Furthermore, the research aims to elucidate any unique intermediates or transition states that may form in the glacial acetic acid medium. This knowledge could provide insights into designing new catalysts or reaction conditions that exploit these intermediates to enhance reaction efficiency or selectivity.

By addressing these objectives, this study intends to bridge the gap between theoretical understanding and practical application of glacial acetic acid-mediated esterification. The findings are expected to contribute significantly to the field of organic synthesis and potentially revolutionize industrial esterification processes, leading to more sustainable and economical production methods for a wide range of ester-based products.

Market Analysis for Ester Products

The ester market has experienced significant growth in recent years, driven by increasing demand across various industries. Esters, produced through the esterification process, find applications in diverse sectors such as cosmetics, pharmaceuticals, food and beverages, and industrial lubricants. The global ester market size was valued at approximately $85 billion in 2020 and is projected to reach $125 billion by 2027, growing at a CAGR of 5.7% during the forecast period.

The cosmetics and personal care industry represents a major consumer of esters, particularly in the production of fragrances, emollients, and moisturizers. The rising consumer awareness regarding personal grooming and increasing disposable income in developing economies have contributed to the growth of this segment. Additionally, the pharmaceutical sector utilizes esters in drug formulations and as excipients, further driving market demand.

In the food and beverage industry, esters play a crucial role as flavoring agents and food additives. The growing preference for natural and organic products has led to an increased demand for naturally derived esters, presenting new opportunities for market players. The industrial sector also contributes significantly to ester consumption, with applications in lubricants, plasticizers, and solvents.

Geographically, Asia-Pacific dominates the ester market, accounting for the largest share of global consumption. This can be attributed to the rapid industrialization, growing population, and increasing disposable income in countries like China and India. North America and Europe follow closely, driven by the presence of established cosmetics and pharmaceutical industries.

The market for ester products is highly competitive, with key players focusing on product innovation and strategic partnerships to gain a competitive edge. Major companies in the market include BASF SE, Dow Chemical Company, Evonik Industries, and Mitsubishi Chemical Corporation. These companies are investing heavily in research and development to develop novel ester products and improve existing formulations.

Environmental concerns and stringent regulations regarding the use of certain chemicals in consumer products pose challenges to the ester market. However, this has also led to the development of bio-based and environmentally friendly esters, opening up new avenues for growth. The shift towards sustainable and green chemistry is expected to shape the future of the ester market, with increasing focus on renewable raw materials and eco-friendly production processes.

The cosmetics and personal care industry represents a major consumer of esters, particularly in the production of fragrances, emollients, and moisturizers. The rising consumer awareness regarding personal grooming and increasing disposable income in developing economies have contributed to the growth of this segment. Additionally, the pharmaceutical sector utilizes esters in drug formulations and as excipients, further driving market demand.

In the food and beverage industry, esters play a crucial role as flavoring agents and food additives. The growing preference for natural and organic products has led to an increased demand for naturally derived esters, presenting new opportunities for market players. The industrial sector also contributes significantly to ester consumption, with applications in lubricants, plasticizers, and solvents.

Geographically, Asia-Pacific dominates the ester market, accounting for the largest share of global consumption. This can be attributed to the rapid industrialization, growing population, and increasing disposable income in countries like China and India. North America and Europe follow closely, driven by the presence of established cosmetics and pharmaceutical industries.

The market for ester products is highly competitive, with key players focusing on product innovation and strategic partnerships to gain a competitive edge. Major companies in the market include BASF SE, Dow Chemical Company, Evonik Industries, and Mitsubishi Chemical Corporation. These companies are investing heavily in research and development to develop novel ester products and improve existing formulations.

Environmental concerns and stringent regulations regarding the use of certain chemicals in consumer products pose challenges to the ester market. However, this has also led to the development of bio-based and environmentally friendly esters, opening up new avenues for growth. The shift towards sustainable and green chemistry is expected to shape the future of the ester market, with increasing focus on renewable raw materials and eco-friendly production processes.

Current Challenges in Glacial Acetic Acid Esterification

Glacial acetic acid-mediated esterification faces several significant challenges that hinder its widespread industrial application and efficiency. One of the primary issues is the reversibility of the reaction, which limits the overall yield of the desired ester product. This equilibrium-driven process often requires the removal of water or the use of excess reagents to drive the reaction towards completion, adding complexity to the process design and increasing operational costs.

Another major challenge is the corrosive nature of glacial acetic acid, which necessitates the use of specialized equipment and materials. This corrosivity not only increases the capital investment required for industrial-scale operations but also poses safety concerns and potential environmental risks. The selection of appropriate catalysts that can withstand the acidic environment while maintaining high activity and selectivity remains a critical area of research.

The reaction kinetics in glacial acetic acid-mediated esterification are often complex and highly dependent on the specific substrates involved. This complexity makes it difficult to develop universally applicable reaction models and optimization strategies. Researchers struggle to predict reaction outcomes accurately, especially when scaling up from laboratory to industrial processes, leading to inefficiencies in process development and scale-up efforts.

Side reactions and the formation of unwanted byproducts present another significant challenge. These secondary reactions can reduce the yield of the desired ester and complicate downstream purification processes. The identification and suppression of these side reactions require a deep understanding of the reaction mechanisms and careful control of reaction conditions, which is not always straightforward in industrial settings.

The energy intensity of the process is also a concern, particularly in light of growing emphasis on sustainable and green chemistry practices. Esterification reactions often require elevated temperatures to achieve reasonable reaction rates, leading to high energy consumption. Developing more energy-efficient processes or alternative reaction pathways that can operate under milder conditions remains an active area of research.

Lastly, the recovery and recycling of unreacted acetic acid and catalysts pose both economic and environmental challenges. Efficient separation and purification techniques are crucial for maintaining the economic viability of the process and minimizing waste generation. However, the development of such techniques that are both effective and economically feasible at industrial scales continues to be a significant hurdle in the field of glacial acetic acid-mediated esterification.

Another major challenge is the corrosive nature of glacial acetic acid, which necessitates the use of specialized equipment and materials. This corrosivity not only increases the capital investment required for industrial-scale operations but also poses safety concerns and potential environmental risks. The selection of appropriate catalysts that can withstand the acidic environment while maintaining high activity and selectivity remains a critical area of research.

The reaction kinetics in glacial acetic acid-mediated esterification are often complex and highly dependent on the specific substrates involved. This complexity makes it difficult to develop universally applicable reaction models and optimization strategies. Researchers struggle to predict reaction outcomes accurately, especially when scaling up from laboratory to industrial processes, leading to inefficiencies in process development and scale-up efforts.

Side reactions and the formation of unwanted byproducts present another significant challenge. These secondary reactions can reduce the yield of the desired ester and complicate downstream purification processes. The identification and suppression of these side reactions require a deep understanding of the reaction mechanisms and careful control of reaction conditions, which is not always straightforward in industrial settings.

The energy intensity of the process is also a concern, particularly in light of growing emphasis on sustainable and green chemistry practices. Esterification reactions often require elevated temperatures to achieve reasonable reaction rates, leading to high energy consumption. Developing more energy-efficient processes or alternative reaction pathways that can operate under milder conditions remains an active area of research.

Lastly, the recovery and recycling of unreacted acetic acid and catalysts pose both economic and environmental challenges. Efficient separation and purification techniques are crucial for maintaining the economic viability of the process and minimizing waste generation. However, the development of such techniques that are both effective and economically feasible at industrial scales continues to be a significant hurdle in the field of glacial acetic acid-mediated esterification.

Existing Glacial Acetic Acid Esterification Methods

01 Reaction mechanism of glacial acetic acid-mediated esterification

The esterification reaction mediated by glacial acetic acid involves the nucleophilic addition of an alcohol to the carbonyl group of acetic acid. This process is typically catalyzed by a strong acid, such as sulfuric acid. The reaction proceeds through the formation of a tetrahedral intermediate, followed by the elimination of water to yield the ester product. The use of glacial acetic acid ensures a high concentration of reactants, promoting the forward reaction.- Reaction mechanism of glacial acetic acid-mediated esterification: The esterification reaction mediated by glacial acetic acid involves the nucleophilic addition of an alcohol to the carbonyl group of acetic acid. This process is typically catalyzed by a strong acid, such as sulfuric acid. The reaction proceeds through the formation of a tetrahedral intermediate, followed by the elimination of water to yield the ester product. The use of glacial acetic acid ensures a high concentration of reactants, promoting efficient esterification.

- Catalysts for glacial acetic acid-mediated esterification: Various catalysts can be employed to enhance the rate and efficiency of glacial acetic acid-mediated esterification reactions. Common catalysts include strong mineral acids (e.g., sulfuric acid, hydrochloric acid), solid acid catalysts (e.g., ion-exchange resins, zeolites), and enzymes (e.g., lipases). These catalysts work by activating the carbonyl group of acetic acid, facilitating the nucleophilic attack by the alcohol, and promoting water elimination.

- Reaction conditions and optimization: Optimizing reaction conditions is crucial for efficient glacial acetic acid-mediated esterification. Key parameters include temperature, reaction time, reactant ratios, and catalyst concentration. Elevated temperatures generally accelerate the reaction rate but may lead to side reactions. Excess acetic acid or alcohol can drive the equilibrium towards product formation. Removing water from the reaction mixture, such as through azeotropic distillation or using molecular sieves, can further enhance conversion and yield.

- Applications of glacial acetic acid-mediated esterification: Glacial acetic acid-mediated esterification finds applications in various industries. It is commonly used in the production of fragrances, flavors, and pharmaceutical intermediates. This reaction is also employed in the synthesis of biodiesel, where fatty acids are esterified with methanol or ethanol. Additionally, it plays a role in the modification of natural polymers, such as cellulose, to produce cellulose acetate for various applications.

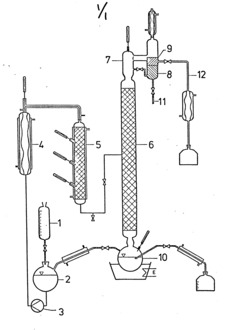

- Continuous flow processes for glacial acetic acid-mediated esterification: Continuous flow reactors offer advantages for glacial acetic acid-mediated esterification, including improved heat and mass transfer, precise control of reaction parameters, and enhanced safety. These systems often employ fixed-bed catalysts or microreactors, allowing for efficient mixing and heat exchange. Continuous processes can lead to higher yields, shorter reaction times, and easier scale-up compared to batch reactions.

02 Catalysts for glacial acetic acid-mediated esterification

Various catalysts can be employed to enhance the rate and efficiency of glacial acetic acid-mediated esterification reactions. Common catalysts include strong mineral acids (e.g., sulfuric acid, hydrochloric acid), solid acid catalysts (e.g., ion-exchange resins, zeolites), and enzymes (e.g., lipases). These catalysts work by protonating the carbonyl oxygen of acetic acid, making it more susceptible to nucleophilic attack by the alcohol.Expand Specific Solutions03 Reaction conditions and optimization

The efficiency of glacial acetic acid-mediated esterification can be optimized by controlling various reaction parameters. These include temperature, reaction time, molar ratio of reactants, and water removal techniques. Elevated temperatures generally increase reaction rates but may lead to side reactions. Continuous removal of water, often through azeotropic distillation or the use of molecular sieves, helps drive the equilibrium towards product formation.Expand Specific Solutions04 Applications of glacial acetic acid-mediated esterification

Glacial acetic acid-mediated esterification finds applications in various industries. It is commonly used in the production of fragrances, flavors, and pharmaceutical intermediates. The process is also employed in the synthesis of biodiesel, where fatty acids are esterified with methanol or ethanol. Additionally, this reaction is utilized in the production of various industrial solvents and plasticizers.Expand Specific Solutions05 Green chemistry approaches to esterification

Recent developments in glacial acetic acid-mediated esterification focus on more environmentally friendly approaches. These include the use of recyclable heterogeneous catalysts, microwave-assisted reactions, and continuous flow processes. Biocatalytic methods using enzymes are also being explored as a sustainable alternative. These green chemistry approaches aim to reduce waste, improve energy efficiency, and minimize the use of harmful solvents and catalysts.Expand Specific Solutions

Key Players in Esterification Industry

The research on reaction mechanisms in glacial acetic acid-mediated esterification is in a mature stage of development, with a significant market presence and established technological foundations. The global esterification market is substantial, driven by diverse applications in industries such as pharmaceuticals, cosmetics, and food. Companies like BASF Corp., Dow Global Technologies LLC, and Eastman Chemical Co. are at the forefront of this technology, leveraging their extensive R&D capabilities and market experience. The involvement of academic institutions like Jiangnan University and Beijing Institute of Petrochemical Technology indicates ongoing efforts to refine and innovate esterification processes. The competitive landscape is characterized by a mix of large chemical corporations and specialized firms, suggesting a balanced market with opportunities for both established players and niche innovators.

BASF Corp.

Technical Solution: BASF Corp. has developed an innovative approach to glacial acetic acid-mediated esterification, focusing on optimizing reaction conditions and catalyst selection. Their research has led to the development of a novel heterogeneous catalyst system that significantly enhances reaction rates and selectivity[1]. This system incorporates nanostructured metal oxides with tailored surface properties, allowing for efficient proton transfer and improved substrate activation. BASF's method also employs a continuous flow reactor design, which enables better control over reaction parameters and facilitates easier scale-up for industrial applications[3]. The company has further refined the process by implementing in-situ water removal techniques, effectively shifting the equilibrium towards product formation and increasing overall yield[5].

Strengths: High catalytic efficiency, improved selectivity, and scalability for industrial use. Weaknesses: Potential high costs associated with specialized catalyst production and continuous flow reactor setup.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has made significant strides in understanding and optimizing glacial acetic acid-mediated esterification reactions. Their approach focuses on the development of a hybrid catalyst system that combines the benefits of homogeneous and heterogeneous catalysis[2]. This innovative system utilizes functionalized polymeric supports with grafted acidic groups, providing a high surface area for reaction while maintaining the advantages of homogeneous catalysis. Dow's research has also led to the implementation of advanced process intensification techniques, such as reactive distillation, which allows for simultaneous reaction and product separation, thereby overcoming equilibrium limitations[4]. Additionally, the company has explored the use of microwave-assisted heating to enhance reaction kinetics and reduce energy consumption in the esterification process[6].

Strengths: Efficient catalyst design, process intensification capabilities, and potential for energy savings. Weaknesses: Complexity in catalyst synthesis and potential limitations in large-scale applications of microwave heating.

Core Reaction Mechanisms in Acetic Acid Esterification

Process for the production of {8 2-acetoacetyl-aminothiazolyl-(4)-{9 -acetic acid ethyl ester

PatentInactiveUS4070364A

Innovation

- A process involving the reaction of [2-aminothiazolyl-(4)]-acetic acid ethyl ester with diketene in the presence of 5 to 15 percent glacial acetic acid in an organic solvent at temperatures between 30°C and 80°C, using preferred solvents like butyl acetate, to achieve high yields and purity of [2-acetoacetylaminothiazolyl-(4)]-acetic acid ethyl ester.

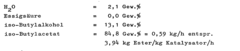

Esterification process of acetic acid by C2 to C5 alcohols

PatentInactiveEP0066059A1

Innovation

- The process employs strongly acidic cation exchangers, specifically gel-like or macroporous ones with a particle size of 0.4 to 1.3 mm, which are swollen in alcohol to constant volume, and used in fixed-bed reactors under controlled pressure and temperature, allowing for efficient esterification and azeotropic distillation to achieve high-purity acetic acid esters with improved yield.

Green Chemistry Aspects of Esterification

Green chemistry principles have become increasingly important in the field of esterification reactions, particularly in the context of glacial acetic acid-mediated processes. This approach aims to minimize environmental impact while maintaining or improving reaction efficiency and product quality.

One of the key aspects of green chemistry in esterification is the use of environmentally benign catalysts. Traditional methods often rely on strong mineral acids, which can be corrosive and hazardous. In contrast, green chemistry approaches favor the use of solid acid catalysts, such as ion-exchange resins or heterogeneous acid catalysts. These materials offer several advantages, including ease of separation, recyclability, and reduced waste generation.

Another important consideration is the choice of solvents. Glacial acetic acid, while effective, is not considered a green solvent due to its corrosive nature and potential environmental impact. Researchers are exploring alternative reaction media, such as ionic liquids or supercritical carbon dioxide, which offer improved safety profiles and reduced environmental footprint. These novel solvents can also enhance reaction rates and selectivity in some cases.

Process intensification is a crucial aspect of green chemistry in esterification reactions. This involves optimizing reaction conditions to reduce energy consumption and improve atom economy. Techniques such as microwave-assisted synthesis and continuous flow reactors have shown promise in this regard, allowing for faster reaction times and improved yields while reducing overall energy requirements.

The use of renewable feedstocks is another key principle of green chemistry that is being applied to esterification reactions. Researchers are investigating the use of bio-based alcohols and acids derived from agricultural waste or other sustainable sources. This approach not only reduces reliance on petrochemical-derived reagents but also contributes to the circular economy by valorizing waste materials.

Waste reduction and recycling strategies are also being implemented in green esterification processes. This includes the development of efficient separation and purification techniques to maximize product recovery and minimize byproduct formation. Additionally, researchers are exploring ways to recycle and reuse catalysts and solvents, further reducing the environmental impact of these reactions.

In conclusion, the application of green chemistry principles to glacial acetic acid-mediated esterification reactions is driving innovation in catalyst design, solvent selection, process optimization, and feedstock sourcing. These advancements are not only improving the environmental sustainability of esterification processes but also opening up new possibilities for more efficient and cost-effective chemical synthesis.

One of the key aspects of green chemistry in esterification is the use of environmentally benign catalysts. Traditional methods often rely on strong mineral acids, which can be corrosive and hazardous. In contrast, green chemistry approaches favor the use of solid acid catalysts, such as ion-exchange resins or heterogeneous acid catalysts. These materials offer several advantages, including ease of separation, recyclability, and reduced waste generation.

Another important consideration is the choice of solvents. Glacial acetic acid, while effective, is not considered a green solvent due to its corrosive nature and potential environmental impact. Researchers are exploring alternative reaction media, such as ionic liquids or supercritical carbon dioxide, which offer improved safety profiles and reduced environmental footprint. These novel solvents can also enhance reaction rates and selectivity in some cases.

Process intensification is a crucial aspect of green chemistry in esterification reactions. This involves optimizing reaction conditions to reduce energy consumption and improve atom economy. Techniques such as microwave-assisted synthesis and continuous flow reactors have shown promise in this regard, allowing for faster reaction times and improved yields while reducing overall energy requirements.

The use of renewable feedstocks is another key principle of green chemistry that is being applied to esterification reactions. Researchers are investigating the use of bio-based alcohols and acids derived from agricultural waste or other sustainable sources. This approach not only reduces reliance on petrochemical-derived reagents but also contributes to the circular economy by valorizing waste materials.

Waste reduction and recycling strategies are also being implemented in green esterification processes. This includes the development of efficient separation and purification techniques to maximize product recovery and minimize byproduct formation. Additionally, researchers are exploring ways to recycle and reuse catalysts and solvents, further reducing the environmental impact of these reactions.

In conclusion, the application of green chemistry principles to glacial acetic acid-mediated esterification reactions is driving innovation in catalyst design, solvent selection, process optimization, and feedstock sourcing. These advancements are not only improving the environmental sustainability of esterification processes but also opening up new possibilities for more efficient and cost-effective chemical synthesis.

Industrial Applications of Glacial Acetic Acid Esters

Glacial acetic acid esters have found widespread industrial applications due to their unique properties and versatility. These esters are extensively used in the production of various chemicals, pharmaceuticals, and consumer goods, making them integral to numerous manufacturing processes.

In the chemical industry, glacial acetic acid esters serve as important solvents and intermediates. They are employed in the synthesis of polymers, resins, and plasticizers, contributing to the production of a wide range of materials with diverse applications. The automotive sector, for instance, utilizes these esters in the manufacture of coatings and adhesives, enhancing the durability and appearance of vehicles.

The pharmaceutical industry relies heavily on glacial acetic acid esters for the synthesis of active pharmaceutical ingredients (APIs) and drug intermediates. These compounds play a crucial role in the production of various medications, including analgesics, antibiotics, and anti-inflammatory drugs. Their use in pharmaceutical manufacturing processes ensures the efficient and cost-effective production of essential medicines.

In the fragrance and flavor industry, glacial acetic acid esters are valued for their aromatic properties. They are used as key ingredients in the creation of perfumes, cosmetics, and food additives. The ability of these esters to impart specific scents and flavors makes them indispensable in the development of consumer products that require precise olfactory and gustatory characteristics.

The textile industry also benefits from the applications of glacial acetic acid esters. These compounds are used in the production of dyes and fabric finishes, enhancing the color fastness and overall quality of textiles. Additionally, they play a role in the manufacturing of synthetic fibers, contributing to the development of innovative and high-performance materials.

In the electronics sector, glacial acetic acid esters find applications in the production of printed circuit boards and electronic components. They are used as solvents in the manufacturing process, facilitating the etching and cleaning of electronic substrates. This application is particularly important in the production of advanced electronic devices and components.

The paint and coatings industry utilizes glacial acetic acid esters as solvents and additives in various formulations. These compounds contribute to the improved performance of paints, varnishes, and lacquers, enhancing their drying properties, durability, and resistance to environmental factors.

Furthermore, glacial acetic acid esters play a significant role in the production of biodegradable plastics and environmentally friendly products. As sustainability becomes increasingly important in industrial processes, these esters offer potential solutions for developing more eco-friendly alternatives to traditional petrochemical-based materials.

In the chemical industry, glacial acetic acid esters serve as important solvents and intermediates. They are employed in the synthesis of polymers, resins, and plasticizers, contributing to the production of a wide range of materials with diverse applications. The automotive sector, for instance, utilizes these esters in the manufacture of coatings and adhesives, enhancing the durability and appearance of vehicles.

The pharmaceutical industry relies heavily on glacial acetic acid esters for the synthesis of active pharmaceutical ingredients (APIs) and drug intermediates. These compounds play a crucial role in the production of various medications, including analgesics, antibiotics, and anti-inflammatory drugs. Their use in pharmaceutical manufacturing processes ensures the efficient and cost-effective production of essential medicines.

In the fragrance and flavor industry, glacial acetic acid esters are valued for their aromatic properties. They are used as key ingredients in the creation of perfumes, cosmetics, and food additives. The ability of these esters to impart specific scents and flavors makes them indispensable in the development of consumer products that require precise olfactory and gustatory characteristics.

The textile industry also benefits from the applications of glacial acetic acid esters. These compounds are used in the production of dyes and fabric finishes, enhancing the color fastness and overall quality of textiles. Additionally, they play a role in the manufacturing of synthetic fibers, contributing to the development of innovative and high-performance materials.

In the electronics sector, glacial acetic acid esters find applications in the production of printed circuit boards and electronic components. They are used as solvents in the manufacturing process, facilitating the etching and cleaning of electronic substrates. This application is particularly important in the production of advanced electronic devices and components.

The paint and coatings industry utilizes glacial acetic acid esters as solvents and additives in various formulations. These compounds contribute to the improved performance of paints, varnishes, and lacquers, enhancing their drying properties, durability, and resistance to environmental factors.

Furthermore, glacial acetic acid esters play a significant role in the production of biodegradable plastics and environmentally friendly products. As sustainability becomes increasingly important in industrial processes, these esters offer potential solutions for developing more eco-friendly alternatives to traditional petrochemical-based materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!