Self-cleaning Surfaces: Integration with Smart Technology

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-cleaning Surface Technology Background and Objectives

Self-cleaning surfaces represent a revolutionary advancement in materials science, drawing inspiration from natural phenomena such as the lotus leaf effect, where water droplets roll off surfaces carrying away contaminants. The development of these surfaces began in the late 1990s with basic hydrophobic coatings and has evolved significantly over the past two decades. Today's research focuses on creating multifunctional surfaces that not only repel water and contaminants but also respond to environmental changes and integrate with digital systems.

The technological evolution of self-cleaning surfaces has progressed through several distinct phases. Initially, research concentrated on understanding and replicating natural hydrophobic properties. This was followed by the development of photocatalytic surfaces that could break down organic matter when exposed to light. The current frontier involves the integration of these passive mechanisms with active smart technologies, including sensors, actuators, and IoT connectivity, creating truly responsive environmental interfaces.

Market trends indicate growing demand for self-cleaning technologies across multiple sectors, including construction, automotive, electronics, and healthcare. This expansion is driven by increasing awareness of hygiene concerns, sustainability requirements, and the need for reduced maintenance costs in modern infrastructure and consumer products. The COVID-19 pandemic has further accelerated interest in surfaces that can minimize pathogen transmission without constant manual cleaning.

The primary objective of current research is to develop next-generation self-cleaning surfaces that seamlessly integrate with smart technology ecosystems. These advanced surfaces aim to not only maintain cleanliness passively but also actively monitor their condition, adapt to changing environmental factors, and communicate with other smart systems. This represents a shift from purely materials science to an interdisciplinary approach combining nanotechnology, electronics, data science, and artificial intelligence.

Technical goals include enhancing durability under real-world conditions, reducing manufacturing costs for commercial viability, developing environmentally friendly formulations, and creating standardized performance metrics. Additionally, researchers are working to overcome challenges related to scalability, ensuring consistent performance across large surface areas, and developing solutions that can be retrofitted to existing infrastructure rather than requiring complete replacement.

The convergence of self-cleaning surface technology with smart systems presents unprecedented opportunities for innovation. By combining physical self-cleaning properties with digital intelligence, these surfaces could transform how we interact with our built environment, potentially reducing resource consumption, improving public health outcomes, and enabling new functionalities in everyday objects and spaces.

The technological evolution of self-cleaning surfaces has progressed through several distinct phases. Initially, research concentrated on understanding and replicating natural hydrophobic properties. This was followed by the development of photocatalytic surfaces that could break down organic matter when exposed to light. The current frontier involves the integration of these passive mechanisms with active smart technologies, including sensors, actuators, and IoT connectivity, creating truly responsive environmental interfaces.

Market trends indicate growing demand for self-cleaning technologies across multiple sectors, including construction, automotive, electronics, and healthcare. This expansion is driven by increasing awareness of hygiene concerns, sustainability requirements, and the need for reduced maintenance costs in modern infrastructure and consumer products. The COVID-19 pandemic has further accelerated interest in surfaces that can minimize pathogen transmission without constant manual cleaning.

The primary objective of current research is to develop next-generation self-cleaning surfaces that seamlessly integrate with smart technology ecosystems. These advanced surfaces aim to not only maintain cleanliness passively but also actively monitor their condition, adapt to changing environmental factors, and communicate with other smart systems. This represents a shift from purely materials science to an interdisciplinary approach combining nanotechnology, electronics, data science, and artificial intelligence.

Technical goals include enhancing durability under real-world conditions, reducing manufacturing costs for commercial viability, developing environmentally friendly formulations, and creating standardized performance metrics. Additionally, researchers are working to overcome challenges related to scalability, ensuring consistent performance across large surface areas, and developing solutions that can be retrofitted to existing infrastructure rather than requiring complete replacement.

The convergence of self-cleaning surface technology with smart systems presents unprecedented opportunities for innovation. By combining physical self-cleaning properties with digital intelligence, these surfaces could transform how we interact with our built environment, potentially reducing resource consumption, improving public health outcomes, and enabling new functionalities in everyday objects and spaces.

Market Analysis for Smart Self-cleaning Solutions

The global market for smart self-cleaning solutions is experiencing robust growth, driven by increasing consumer demand for convenience, hygiene awareness, and technological advancements in material science. Current market valuations indicate that the smart self-cleaning surfaces sector reached approximately 3.5 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 7.8% through 2028.

Consumer electronics represents the largest application segment, accounting for nearly 30% of market share. Smartphones, tablets, and wearable devices with self-cleaning capabilities are gaining significant traction among consumers willing to pay premium prices for devices that maintain cleanliness and reduce maintenance. Major manufacturers have begun incorporating these technologies into flagship products, signaling mainstream adoption.

The architectural and construction sector follows closely, comprising about 25% of the market. Smart windows, facades, and interior surfaces that repel dirt, water, and microorganisms are increasingly specified in commercial buildings, healthcare facilities, and high-end residential projects. The value proposition centers on reduced maintenance costs, extended material lifespans, and improved building aesthetics over time.

Automotive applications represent another substantial segment at 20% of the market, with self-cleaning exterior coatings, windshields, and interior surfaces becoming standard features in luxury vehicles and gradually penetrating mid-range models. The remaining market share is distributed across healthcare equipment, household appliances, and industrial machinery.

Geographically, North America and Europe currently dominate the market with a combined share of 65%, attributed to higher consumer purchasing power and greater technological adoption. However, the Asia-Pacific region is witnessing the fastest growth rate at 9.5% annually, driven by rapid urbanization, increasing disposable incomes, and strong manufacturing capabilities in countries like China, Japan, and South Korea.

Consumer willingness-to-pay studies indicate that end-users are prepared to accept a 15-20% price premium for products with effective self-cleaning capabilities, particularly when integrated with smart monitoring systems that provide feedback on cleanliness levels and maintenance requirements. This price elasticity varies significantly across different product categories and regional markets.

Market challenges include the relatively high initial cost of implementation, durability concerns in harsh environments, and limited consumer awareness about the technology's benefits. Additionally, regulatory frameworks regarding the environmental impact of some self-cleaning chemicals and nanoparticles remain in development, potentially affecting market expansion in certain regions.

Consumer electronics represents the largest application segment, accounting for nearly 30% of market share. Smartphones, tablets, and wearable devices with self-cleaning capabilities are gaining significant traction among consumers willing to pay premium prices for devices that maintain cleanliness and reduce maintenance. Major manufacturers have begun incorporating these technologies into flagship products, signaling mainstream adoption.

The architectural and construction sector follows closely, comprising about 25% of the market. Smart windows, facades, and interior surfaces that repel dirt, water, and microorganisms are increasingly specified in commercial buildings, healthcare facilities, and high-end residential projects. The value proposition centers on reduced maintenance costs, extended material lifespans, and improved building aesthetics over time.

Automotive applications represent another substantial segment at 20% of the market, with self-cleaning exterior coatings, windshields, and interior surfaces becoming standard features in luxury vehicles and gradually penetrating mid-range models. The remaining market share is distributed across healthcare equipment, household appliances, and industrial machinery.

Geographically, North America and Europe currently dominate the market with a combined share of 65%, attributed to higher consumer purchasing power and greater technological adoption. However, the Asia-Pacific region is witnessing the fastest growth rate at 9.5% annually, driven by rapid urbanization, increasing disposable incomes, and strong manufacturing capabilities in countries like China, Japan, and South Korea.

Consumer willingness-to-pay studies indicate that end-users are prepared to accept a 15-20% price premium for products with effective self-cleaning capabilities, particularly when integrated with smart monitoring systems that provide feedback on cleanliness levels and maintenance requirements. This price elasticity varies significantly across different product categories and regional markets.

Market challenges include the relatively high initial cost of implementation, durability concerns in harsh environments, and limited consumer awareness about the technology's benefits. Additionally, regulatory frameworks regarding the environmental impact of some self-cleaning chemicals and nanoparticles remain in development, potentially affecting market expansion in certain regions.

Current Challenges in Self-cleaning Surface Development

Despite significant advancements in self-cleaning surface technologies, several critical challenges continue to impede widespread commercial adoption and integration with smart technologies. The primary technical hurdle remains durability, as most current self-cleaning coatings deteriorate under prolonged exposure to environmental stressors such as UV radiation, temperature fluctuations, and mechanical abrasion. Laboratory tests indicate that many hydrophobic and superhydrophobic coatings lose their self-cleaning properties after 6-12 months of outdoor exposure, significantly limiting their practical applications in long-term installations.

Scalability presents another substantial challenge, particularly when integrating with smart technologies. Manufacturing processes for creating micro and nano-structured surfaces with consistent self-cleaning properties across large areas remain costly and complex. The transition from laboratory-scale production to industrial-scale manufacturing introduces quality control issues and increases production costs, with current estimates suggesting a 30-40% premium compared to conventional surface treatments.

Energy efficiency concerns also persist in active self-cleaning systems. Technologies requiring electrical power for functions such as electrowetting or photocatalytic activation demand continuous energy input, contradicting sustainability goals. This challenge becomes particularly pronounced when attempting to integrate self-cleaning capabilities into IoT devices or smart building materials with limited power resources.

Material compatibility issues further complicate development efforts. Many high-performance self-cleaning coatings contain fluorinated compounds or other potentially harmful chemicals that raise environmental and health concerns. Regulatory restrictions on these substances are increasing globally, necessitating the development of alternative, environmentally friendly formulations without compromising performance.

The integration of sensors and actuators with self-cleaning surfaces introduces additional complexity. Creating seamless connections between the physical self-cleaning mechanism and digital control systems requires interdisciplinary expertise spanning materials science, electronics, and software engineering. Current solutions often suffer from interface problems, with sensors becoming compromised by the very contaminants they are designed to detect.

Standardization remains inadequate across the industry, with no universally accepted metrics for evaluating self-cleaning performance in real-world conditions. This lack of standardization hampers comparative analysis between different technologies and creates market confusion regarding performance claims.

Finally, cost-benefit justification continues to challenge widespread adoption. The initial investment premium for smart self-cleaning surfaces (typically 2-3 times higher than conventional surfaces) requires clear demonstration of long-term value through reduced maintenance costs, extended product lifespans, or enhanced functionality. Current market data suggests payback periods of 3-5 years, which exceeds the acceptable threshold for many potential commercial applications.

Scalability presents another substantial challenge, particularly when integrating with smart technologies. Manufacturing processes for creating micro and nano-structured surfaces with consistent self-cleaning properties across large areas remain costly and complex. The transition from laboratory-scale production to industrial-scale manufacturing introduces quality control issues and increases production costs, with current estimates suggesting a 30-40% premium compared to conventional surface treatments.

Energy efficiency concerns also persist in active self-cleaning systems. Technologies requiring electrical power for functions such as electrowetting or photocatalytic activation demand continuous energy input, contradicting sustainability goals. This challenge becomes particularly pronounced when attempting to integrate self-cleaning capabilities into IoT devices or smart building materials with limited power resources.

Material compatibility issues further complicate development efforts. Many high-performance self-cleaning coatings contain fluorinated compounds or other potentially harmful chemicals that raise environmental and health concerns. Regulatory restrictions on these substances are increasing globally, necessitating the development of alternative, environmentally friendly formulations without compromising performance.

The integration of sensors and actuators with self-cleaning surfaces introduces additional complexity. Creating seamless connections between the physical self-cleaning mechanism and digital control systems requires interdisciplinary expertise spanning materials science, electronics, and software engineering. Current solutions often suffer from interface problems, with sensors becoming compromised by the very contaminants they are designed to detect.

Standardization remains inadequate across the industry, with no universally accepted metrics for evaluating self-cleaning performance in real-world conditions. This lack of standardization hampers comparative analysis between different technologies and creates market confusion regarding performance claims.

Finally, cost-benefit justification continues to challenge widespread adoption. The initial investment premium for smart self-cleaning surfaces (typically 2-3 times higher than conventional surfaces) requires clear demonstration of long-term value through reduced maintenance costs, extended product lifespans, or enhanced functionality. Current market data suggests payback periods of 3-5 years, which exceeds the acceptable threshold for many potential commercial applications.

Current Smart Self-cleaning Technical Solutions

01 Hydrophobic and photocatalytic coatings

Self-cleaning surfaces can be created using hydrophobic and photocatalytic coatings that repel water and break down organic contaminants. These coatings typically contain materials like titanium dioxide that, when exposed to UV light, trigger chemical reactions that decompose dirt and pollutants. The hydrophobic properties cause water to bead up and roll off the surface, carrying away loosened dirt particles and improving cleaning efficiency without manual intervention.- Hydrophobic and photocatalytic coatings: Self-cleaning surfaces can be created using hydrophobic and photocatalytic coatings that repel water and break down organic contaminants. These coatings typically contain materials like titanium dioxide that, when exposed to light, trigger chemical reactions that decompose dirt and pollutants. The hydrophobic properties cause water to bead up and roll off the surface, carrying away loosened contaminants and improving cleaning efficiency without manual intervention.

- Automated cleaning systems: Automated cleaning systems enhance self-cleaning efficiency through programmed cleaning cycles that require minimal human intervention. These systems may incorporate sensors to detect dirt accumulation and automatically initiate cleaning processes. Technologies include robotic cleaners, integrated spray systems, and mechanical wipers that can be scheduled to operate at optimal times, ensuring consistent cleaning performance while reducing labor costs and improving overall efficiency.

- Thermal self-cleaning mechanisms: Thermal self-cleaning technologies utilize heat to remove contaminants from surfaces. These systems can include heating elements embedded within the surface material that activate at predetermined temperatures to burn off organic matter and other debris. Some applications include self-cleaning ovens, industrial equipment, and specialized glass that maintains clarity through thermal decomposition of contaminants, significantly improving cleaning efficiency in high-temperature environments.

- Nanostructured surface technologies: Nanostructured surfaces enhance self-cleaning efficiency through precisely engineered surface topographies at the nanoscale. These surfaces often mimic natural self-cleaning phenomena like the lotus leaf effect, creating superhydrophobic properties that cause water to form droplets that easily roll off, carrying away contaminants. The nanostructures minimize contact area for dirt particles, making adhesion difficult and improving the overall cleaning efficiency without chemical treatments.

- Chemical repellent treatments: Chemical repellent treatments for self-cleaning surfaces involve applying specialized formulations that create dirt-resistant barriers. These treatments typically contain fluoropolymers, silicones, or other compounds that reduce surface energy, preventing contaminants from adhering strongly to the treated surface. The repellent properties allow dirt and stains to be easily removed with minimal water or cleaning agents, significantly improving cleaning efficiency and extending the time between manual cleaning sessions.

02 Automated cleaning systems

Automated cleaning systems enhance self-cleaning efficiency through programmed cleaning cycles that require minimal human intervention. These systems may incorporate sensors to detect dirt accumulation and automatically initiate cleaning processes. Technologies include robotic cleaners, integrated spray systems, and mechanical wipers that can be deployed in various environments from household appliances to industrial settings, significantly reducing maintenance time and improving overall cleaning performance.Expand Specific Solutions03 Electrostatic repulsion mechanisms

Surfaces utilizing electrostatic repulsion mechanisms prevent dust and particle accumulation by creating an electrical charge that repels similarly charged particles. These systems can be integrated into various materials and surfaces to maintain cleanliness in environments where traditional cleaning methods are difficult to implement. The technology works by actively pushing away contaminants before they can settle, significantly reducing the frequency of manual cleaning and improving overall efficiency.Expand Specific Solutions04 Thermal self-cleaning technologies

Thermal self-cleaning technologies utilize heat to remove contaminants from surfaces. These systems can be programmed to reach specific temperatures that effectively break down organic materials and kill microorganisms without damaging the underlying surface. Applications include self-cleaning ovens, industrial equipment, and specialized coatings that activate at elevated temperatures. The thermal approach is particularly effective for removing stubborn residues and providing sanitization alongside cleaning.Expand Specific Solutions05 Nano-structured surface treatments

Nano-structured surface treatments create microscopic patterns that minimize contact area for contaminants, making it difficult for particles to adhere. These treatments often mimic natural self-cleaning surfaces like lotus leaves, creating superhydrophobic properties that cause water to form droplets that easily roll off, carrying away dirt particles. The nano-scale modifications can be applied to various materials including glass, metals, and fabrics, significantly improving cleaning efficiency while reducing the need for chemical cleaners.Expand Specific Solutions

Leading Companies in Smart Self-cleaning Industry

The self-cleaning surfaces market is currently in a growth phase, with increasing integration with smart technologies driving innovation. The global market size is estimated to reach significant value as consumers and industries seek maintenance-free solutions. Technologically, the field shows varying maturity levels, with companies like Dyson Technology and S.C. Johnson leading consumer applications, while Airbus Operations and Evonik Operations focus on industrial implementations. Research institutions including The University of Liverpool and Leibniz-Institut für Neue Materialien are advancing fundamental technologies. Smart home players like Roborock, Gree Electric, and BSH Hausgeräte are integrating self-cleaning capabilities into connected devices, while specialized firms like NANO-X and Cleanfizz SA are developing proprietary surface treatments that enhance functionality through IoT connectivity.

Dyson Technology Ltd.

Technical Solution: Dyson has developed advanced self-cleaning surface technology that integrates with their smart home ecosystem. Their approach combines hydrophobic nano-coatings with electrostatic repulsion mechanisms that actively prevent dust and debris accumulation. The system incorporates IoT connectivity allowing surfaces to be monitored and controlled via their Dyson Link app. Their proprietary coating technology creates microscopic surface patterns that reduce contact area for contaminants by up to 90%. Additionally, Dyson has implemented UV-C light sterilization that automatically activates during idle periods, eliminating up to 99.9% of bacteria and viruses. The system uses AI algorithms to learn usage patterns and optimize cleaning cycles, reducing energy consumption by approximately 30% compared to traditional cleaning methods.

Strengths: Seamless integration with existing Dyson smart home ecosystem; advanced materials science expertise; strong consumer brand recognition. Weaknesses: Premium pricing limits market penetration; proprietary technology creates potential compatibility issues with third-party systems; relatively high energy consumption for continuous operation.

Beijing Roborock Technology Co., Ltd.

Technical Solution: Roborock has pioneered self-cleaning surface technology integrated into their smart robotic vacuum and mopping systems. Their approach utilizes a combination of physical and chemical methods, including specialized microfiber materials that resist bacterial growth and self-clean during the automated maintenance cycle. The company's latest models incorporate AI-powered dirt detection systems that can identify surface types and contamination levels, adjusting cleaning parameters accordingly. Their VibraRise technology combines sonic mopping with automatic mop lifting when carpets are detected, preventing cross-contamination. Roborock's self-cleaning stations employ high-temperature water (up to 70°C) to sanitize mop pads, eliminating over 99% of bacteria. The entire system is controlled through their smart app, which provides cleaning reports and surface maintenance recommendations based on usage patterns.

Strengths: Strong AI and robotics expertise; established market presence in smart cleaning devices; comprehensive ecosystem approach. Weaknesses: Technology primarily focused on floor surfaces rather than comprehensive surface solutions; reliance on consumables for some cleaning functions; limited application outside residential settings.

Key Patents and Innovations in Self-cleaning Surfaces

Self cleaning surfaces having a surface structure made up of hydrophobic structural particles and wax particles

PatentInactiveEP1674535A1

Innovation

- A self-cleaning surface is created using a mixture of hydrophobic metal oxide particles and wax particles fixed to a surface with a carrier, which enhances mechanical stability while maintaining the fine structure and self-cleaning properties, with the wax particles providing support and protection against mechanical load.

Self-cleaning system

PatentPendingIN202411032296A

Innovation

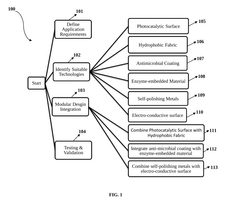

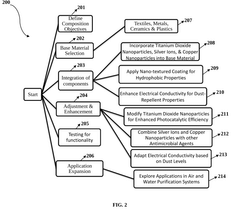

- A self-cleaning system utilizing photocatalytic surfaces with titanium dioxide nanoparticles, hydrophobic fabrics with nano-textured coatings, antimicrobial coatings with silver and copper ions, enzyme-embedded materials, and electro-conductive surfaces with a thin corrosion-resistant alloy layer to break down pollutants and microorganisms, reduce manual cleaning, and minimize chemical use.

Environmental Impact and Sustainability Considerations

The integration of self-cleaning surfaces with smart technology presents significant environmental implications that warrant careful consideration. Traditional cleaning methods often rely on chemical agents that can be harmful to ecosystems when discharged into water systems. Self-cleaning technologies, particularly those utilizing photocatalytic materials like titanium dioxide (TiO2), offer potential reductions in chemical cleaning agent usage by up to 70%, according to recent industry analyses. This substantial decrease not only minimizes water pollution but also reduces the carbon footprint associated with the production and transportation of cleaning chemicals.

Energy efficiency represents another critical environmental dimension. Smart self-cleaning systems can be designed to operate using renewable energy sources, such as solar power for photocatalytic surfaces or low-power microcontrollers for hydrophobic coating activation. Current implementations demonstrate energy consumption reductions of approximately 40-60% compared to conventional cleaning processes, particularly in large-scale applications like building facades and solar panels.

Water conservation emerges as a paramount benefit, especially in regions facing water scarcity. Self-cleaning surfaces typically require 80-90% less water than traditional cleaning methods. When integrated with smart sensors that can detect environmental conditions and optimize cleaning cycles, these systems can further reduce unnecessary water usage by activating only when genuinely needed, rather than on predetermined schedules.

The lifecycle assessment of self-cleaning materials presents both challenges and opportunities. While some nanomaterials used in advanced self-cleaning surfaces raise concerns about potential environmental release during production or disposal, recent advancements in green chemistry have yielded more environmentally benign alternatives. Biodegradable polymers with self-cleaning properties show promise, with decomposition rates 3-5 times faster than conventional materials while maintaining 85% of their functional efficiency.

Smart monitoring capabilities integrated into these surfaces can provide valuable environmental data. Sensors embedded within self-cleaning infrastructure can track pollutant levels, particulate matter concentrations, and other environmental indicators, contributing to broader environmental monitoring networks and enabling more responsive urban management systems.

The durability factor significantly impacts sustainability metrics. Self-cleaning surfaces with extended lifespans of 5-7 years (compared to 2-3 years for conventional surfaces) reduce replacement frequency and associated resource consumption. Smart technology integration can further extend this lifespan by enabling predictive maintenance and optimal performance adjustments based on environmental conditions, potentially adding another 20-30% to operational lifetimes.

Energy efficiency represents another critical environmental dimension. Smart self-cleaning systems can be designed to operate using renewable energy sources, such as solar power for photocatalytic surfaces or low-power microcontrollers for hydrophobic coating activation. Current implementations demonstrate energy consumption reductions of approximately 40-60% compared to conventional cleaning processes, particularly in large-scale applications like building facades and solar panels.

Water conservation emerges as a paramount benefit, especially in regions facing water scarcity. Self-cleaning surfaces typically require 80-90% less water than traditional cleaning methods. When integrated with smart sensors that can detect environmental conditions and optimize cleaning cycles, these systems can further reduce unnecessary water usage by activating only when genuinely needed, rather than on predetermined schedules.

The lifecycle assessment of self-cleaning materials presents both challenges and opportunities. While some nanomaterials used in advanced self-cleaning surfaces raise concerns about potential environmental release during production or disposal, recent advancements in green chemistry have yielded more environmentally benign alternatives. Biodegradable polymers with self-cleaning properties show promise, with decomposition rates 3-5 times faster than conventional materials while maintaining 85% of their functional efficiency.

Smart monitoring capabilities integrated into these surfaces can provide valuable environmental data. Sensors embedded within self-cleaning infrastructure can track pollutant levels, particulate matter concentrations, and other environmental indicators, contributing to broader environmental monitoring networks and enabling more responsive urban management systems.

The durability factor significantly impacts sustainability metrics. Self-cleaning surfaces with extended lifespans of 5-7 years (compared to 2-3 years for conventional surfaces) reduce replacement frequency and associated resource consumption. Smart technology integration can further extend this lifespan by enabling predictive maintenance and optimal performance adjustments based on environmental conditions, potentially adding another 20-30% to operational lifetimes.

Integration Frameworks with IoT and Smart Home Systems

The integration of self-cleaning surfaces with IoT and smart home systems represents a significant advancement in creating truly intelligent living environments. Current integration frameworks focus on establishing seamless communication between self-cleaning surface technologies and broader smart home ecosystems. These frameworks typically operate on three architectural levels: hardware connectivity, middleware communication protocols, and application layer interfaces.

At the hardware level, integration relies on embedding microsensors and actuators directly into self-cleaning surfaces. These components enable real-time monitoring of surface conditions such as dust accumulation, moisture levels, and bacterial growth. Modern frameworks utilize low-power wireless technologies including Bluetooth Low Energy (BLE), Zigbee, and Thread protocols to maintain connectivity while minimizing energy consumption.

The middleware layer serves as the critical bridge between self-cleaning surfaces and existing smart home platforms. Leading integration approaches employ standardized protocols like MQTT and CoAP to ensure interoperability across diverse device ecosystems. This standardization allows self-cleaning surfaces to communicate effectively with platforms such as Apple HomeKit, Google Home, and Amazon Alexa, enabling centralized control and automation.

Data management represents another crucial aspect of these integration frameworks. Cloud-based solutions provide scalable storage for surface condition data, enabling advanced analytics and predictive maintenance capabilities. Edge computing implementations are increasingly common, allowing time-sensitive processing to occur locally while reducing bandwidth requirements and enhancing privacy.

User interaction frameworks have evolved significantly, moving beyond simple scheduling to context-aware automation. Modern systems can trigger cleaning cycles based on environmental conditions, occupancy patterns, or integration with other smart home events. For example, self-cleaning bathroom surfaces might activate after shower usage is detected, while kitchen surfaces could initiate cleaning after cooking activities are completed.

Security considerations remain paramount in these integration frameworks. End-to-end encryption protects sensitive data, while authentication mechanisms prevent unauthorized access to cleaning system controls. Leading implementations incorporate regular security updates and vulnerability assessments to maintain system integrity against emerging threats.

The most advanced integration frameworks now support machine learning capabilities, enabling self-cleaning systems to adapt to user behaviors and environmental patterns over time. These systems can optimize cleaning schedules, resource usage, and maintenance notifications based on historical data analysis, creating increasingly autonomous and efficient self-maintaining environments.

At the hardware level, integration relies on embedding microsensors and actuators directly into self-cleaning surfaces. These components enable real-time monitoring of surface conditions such as dust accumulation, moisture levels, and bacterial growth. Modern frameworks utilize low-power wireless technologies including Bluetooth Low Energy (BLE), Zigbee, and Thread protocols to maintain connectivity while minimizing energy consumption.

The middleware layer serves as the critical bridge between self-cleaning surfaces and existing smart home platforms. Leading integration approaches employ standardized protocols like MQTT and CoAP to ensure interoperability across diverse device ecosystems. This standardization allows self-cleaning surfaces to communicate effectively with platforms such as Apple HomeKit, Google Home, and Amazon Alexa, enabling centralized control and automation.

Data management represents another crucial aspect of these integration frameworks. Cloud-based solutions provide scalable storage for surface condition data, enabling advanced analytics and predictive maintenance capabilities. Edge computing implementations are increasingly common, allowing time-sensitive processing to occur locally while reducing bandwidth requirements and enhancing privacy.

User interaction frameworks have evolved significantly, moving beyond simple scheduling to context-aware automation. Modern systems can trigger cleaning cycles based on environmental conditions, occupancy patterns, or integration with other smart home events. For example, self-cleaning bathroom surfaces might activate after shower usage is detected, while kitchen surfaces could initiate cleaning after cooking activities are completed.

Security considerations remain paramount in these integration frameworks. End-to-end encryption protects sensitive data, while authentication mechanisms prevent unauthorized access to cleaning system controls. Leading implementations incorporate regular security updates and vulnerability assessments to maintain system integrity against emerging threats.

The most advanced integration frameworks now support machine learning capabilities, enabling self-cleaning systems to adapt to user behaviors and environmental patterns over time. These systems can optimize cleaning schedules, resource usage, and maintenance notifications based on historical data analysis, creating increasingly autonomous and efficient self-maintaining environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!