Sodium Acetate as a Key Component in Biodegradable Thermoplastics

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate in Bioplastics: Background and Objectives

Sodium acetate has emerged as a promising component in the development of biodegradable thermoplastics, addressing the growing concern over plastic pollution and the need for sustainable materials. This research focuses on exploring the potential of sodium acetate as a key ingredient in bioplastic formulations, aiming to enhance the biodegradability and performance of these eco-friendly alternatives to conventional plastics.

The evolution of bioplastics can be traced back to the early 20th century, with significant advancements occurring in recent decades. As environmental awareness has increased, so has the demand for biodegradable materials that can replace traditional petroleum-based plastics. Sodium acetate, a simple organic compound, has gained attention due to its unique properties and potential to contribute to the development of more effective and environmentally friendly thermoplastics.

Historically, the use of sodium acetate in various industries, including food preservation and textile manufacturing, has been well-established. However, its application in bioplastics represents a relatively new and exciting frontier. The compound's ability to form crystalline structures and its potential to enhance the thermal and mechanical properties of biopolymers make it an attractive candidate for further investigation in the field of biodegradable thermoplastics.

The primary objective of this research is to comprehensively evaluate the role of sodium acetate in improving the characteristics of biodegradable thermoplastics. This includes assessing its impact on material properties such as tensile strength, flexibility, and thermal stability, as well as its influence on the biodegradation rate and environmental impact of the resulting bioplastics.

Furthermore, this study aims to explore the optimal formulations and processing techniques for incorporating sodium acetate into various biopolymer matrices. By understanding the interactions between sodium acetate and other components in bioplastic formulations, researchers hope to develop more efficient and cost-effective production methods for these sustainable materials.

Another crucial aspect of this research is to investigate the scalability and commercial viability of sodium acetate-based biodegradable thermoplastics. This involves analyzing the availability and cost of raw materials, assessing the compatibility of these new formulations with existing manufacturing processes, and evaluating the potential market acceptance of the resulting products.

As the global community continues to seek solutions to reduce plastic waste and minimize environmental impact, the development of innovative biodegradable materials becomes increasingly important. This research on sodium acetate as a key component in biodegradable thermoplastics represents a significant step towards creating more sustainable and environmentally responsible alternatives to conventional plastics, potentially revolutionizing various industries and contributing to a greener future.

The evolution of bioplastics can be traced back to the early 20th century, with significant advancements occurring in recent decades. As environmental awareness has increased, so has the demand for biodegradable materials that can replace traditional petroleum-based plastics. Sodium acetate, a simple organic compound, has gained attention due to its unique properties and potential to contribute to the development of more effective and environmentally friendly thermoplastics.

Historically, the use of sodium acetate in various industries, including food preservation and textile manufacturing, has been well-established. However, its application in bioplastics represents a relatively new and exciting frontier. The compound's ability to form crystalline structures and its potential to enhance the thermal and mechanical properties of biopolymers make it an attractive candidate for further investigation in the field of biodegradable thermoplastics.

The primary objective of this research is to comprehensively evaluate the role of sodium acetate in improving the characteristics of biodegradable thermoplastics. This includes assessing its impact on material properties such as tensile strength, flexibility, and thermal stability, as well as its influence on the biodegradation rate and environmental impact of the resulting bioplastics.

Furthermore, this study aims to explore the optimal formulations and processing techniques for incorporating sodium acetate into various biopolymer matrices. By understanding the interactions between sodium acetate and other components in bioplastic formulations, researchers hope to develop more efficient and cost-effective production methods for these sustainable materials.

Another crucial aspect of this research is to investigate the scalability and commercial viability of sodium acetate-based biodegradable thermoplastics. This involves analyzing the availability and cost of raw materials, assessing the compatibility of these new formulations with existing manufacturing processes, and evaluating the potential market acceptance of the resulting products.

As the global community continues to seek solutions to reduce plastic waste and minimize environmental impact, the development of innovative biodegradable materials becomes increasingly important. This research on sodium acetate as a key component in biodegradable thermoplastics represents a significant step towards creating more sustainable and environmentally responsible alternatives to conventional plastics, potentially revolutionizing various industries and contributing to a greener future.

Market Analysis for Biodegradable Thermoplastics

The global market for biodegradable thermoplastics has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations on plastic waste. The incorporation of sodium acetate as a key component in these materials presents a promising avenue for market expansion and product innovation.

The biodegradable thermoplastics market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to exceed 10% over the next five years. This growth is primarily fueled by the rising demand for sustainable packaging solutions across various industries, including food and beverage, consumer goods, and healthcare.

Sodium acetate-based biodegradable thermoplastics offer several advantages that align with market demands. These materials exhibit improved thermal stability, enhanced mechanical properties, and faster biodegradation rates compared to conventional biodegradable plastics. Such characteristics make them particularly attractive for applications in single-use packaging, disposable cutlery, and agricultural films.

The packaging industry represents the largest market segment for biodegradable thermoplastics, accounting for over 40% of the total market share. The food packaging sector, in particular, shows strong potential for sodium acetate-based materials due to their non-toxic nature and compatibility with food contact applications.

Geographically, Europe leads the market for biodegradable thermoplastics, followed closely by North America and Asia-Pacific. European countries have implemented strict regulations on single-use plastics, creating a favorable environment for the adoption of biodegradable alternatives. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing environmental awareness and government initiatives to reduce plastic pollution.

Consumer awareness and willingness to pay for eco-friendly products are key factors influencing market growth. A recent survey indicated that over 60% of consumers are willing to pay a premium for products made from biodegradable materials, highlighting the market's potential for value-added offerings.

However, the market faces challenges such as higher production costs compared to conventional plastics and the need for proper waste management infrastructure to ensure effective biodegradation. Addressing these challenges through technological advancements and policy support will be crucial for realizing the full market potential of sodium acetate-based biodegradable thermoplastics.

In conclusion, the market analysis reveals a strong growth potential for biodegradable thermoplastics incorporating sodium acetate. The combination of favorable regulatory environments, increasing consumer demand for sustainable products, and the material's superior properties positions it well for widespread adoption across various industries and geographical regions.

The biodegradable thermoplastics market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to exceed 10% over the next five years. This growth is primarily fueled by the rising demand for sustainable packaging solutions across various industries, including food and beverage, consumer goods, and healthcare.

Sodium acetate-based biodegradable thermoplastics offer several advantages that align with market demands. These materials exhibit improved thermal stability, enhanced mechanical properties, and faster biodegradation rates compared to conventional biodegradable plastics. Such characteristics make them particularly attractive for applications in single-use packaging, disposable cutlery, and agricultural films.

The packaging industry represents the largest market segment for biodegradable thermoplastics, accounting for over 40% of the total market share. The food packaging sector, in particular, shows strong potential for sodium acetate-based materials due to their non-toxic nature and compatibility with food contact applications.

Geographically, Europe leads the market for biodegradable thermoplastics, followed closely by North America and Asia-Pacific. European countries have implemented strict regulations on single-use plastics, creating a favorable environment for the adoption of biodegradable alternatives. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing environmental awareness and government initiatives to reduce plastic pollution.

Consumer awareness and willingness to pay for eco-friendly products are key factors influencing market growth. A recent survey indicated that over 60% of consumers are willing to pay a premium for products made from biodegradable materials, highlighting the market's potential for value-added offerings.

However, the market faces challenges such as higher production costs compared to conventional plastics and the need for proper waste management infrastructure to ensure effective biodegradation. Addressing these challenges through technological advancements and policy support will be crucial for realizing the full market potential of sodium acetate-based biodegradable thermoplastics.

In conclusion, the market analysis reveals a strong growth potential for biodegradable thermoplastics incorporating sodium acetate. The combination of favorable regulatory environments, increasing consumer demand for sustainable products, and the material's superior properties positions it well for widespread adoption across various industries and geographical regions.

Current Challenges in Sodium Acetate-based Bioplastics

The development of sodium acetate-based bioplastics faces several significant challenges that hinder their widespread adoption and commercialization. One of the primary obstacles is the material's inherent hygroscopic nature, which leads to moisture absorption and subsequent degradation of mechanical properties. This characteristic limits the application of these bioplastics in high-humidity environments and reduces their shelf life.

Another major challenge lies in achieving a balance between biodegradability and durability. While rapid biodegradation is desirable for environmental reasons, it often compromises the material's strength and longevity during use. Researchers are grappling with the task of developing formulations that maintain structural integrity for the intended product lifespan while ensuring complete biodegradation after disposal.

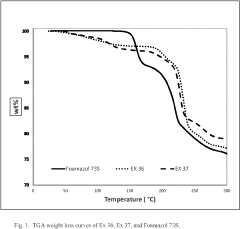

The thermal stability of sodium acetate-based bioplastics presents another hurdle. These materials often exhibit lower heat resistance compared to conventional plastics, limiting their use in applications involving elevated temperatures. This constraint narrows the potential market for these bioplastics, particularly in sectors such as automotive and electronics.

Cost-effectiveness remains a significant challenge in the production of sodium acetate-based bioplastics. The current manufacturing processes are often more expensive than those for traditional petroleum-based plastics, making it difficult for bioplastics to compete in price-sensitive markets. Scaling up production while maintaining quality and reducing costs is a key focus area for researchers and industry players.

Additionally, there are technical challenges related to processing and molding sodium acetate-based bioplastics. These materials often require specialized equipment and techniques, which can be a barrier to adoption for manufacturers accustomed to working with conventional plastics. Improving the processability and compatibility with existing manufacturing infrastructure is crucial for wider industrial acceptance.

The variability in feedstock quality and availability poses another challenge. Sodium acetate derived from different sources may have varying properties, affecting the consistency and performance of the final bioplastic product. Establishing reliable supply chains and standardizing raw material quality are essential steps in overcoming this hurdle.

Lastly, there is a need for comprehensive life cycle assessments to fully understand the environmental impact of sodium acetate-based bioplastics. While these materials offer potential benefits in terms of biodegradability, their overall ecological footprint, including production energy requirements and end-of-life scenarios, must be thoroughly evaluated to ensure they truly represent a more sustainable alternative to conventional plastics.

Another major challenge lies in achieving a balance between biodegradability and durability. While rapid biodegradation is desirable for environmental reasons, it often compromises the material's strength and longevity during use. Researchers are grappling with the task of developing formulations that maintain structural integrity for the intended product lifespan while ensuring complete biodegradation after disposal.

The thermal stability of sodium acetate-based bioplastics presents another hurdle. These materials often exhibit lower heat resistance compared to conventional plastics, limiting their use in applications involving elevated temperatures. This constraint narrows the potential market for these bioplastics, particularly in sectors such as automotive and electronics.

Cost-effectiveness remains a significant challenge in the production of sodium acetate-based bioplastics. The current manufacturing processes are often more expensive than those for traditional petroleum-based plastics, making it difficult for bioplastics to compete in price-sensitive markets. Scaling up production while maintaining quality and reducing costs is a key focus area for researchers and industry players.

Additionally, there are technical challenges related to processing and molding sodium acetate-based bioplastics. These materials often require specialized equipment and techniques, which can be a barrier to adoption for manufacturers accustomed to working with conventional plastics. Improving the processability and compatibility with existing manufacturing infrastructure is crucial for wider industrial acceptance.

The variability in feedstock quality and availability poses another challenge. Sodium acetate derived from different sources may have varying properties, affecting the consistency and performance of the final bioplastic product. Establishing reliable supply chains and standardizing raw material quality are essential steps in overcoming this hurdle.

Lastly, there is a need for comprehensive life cycle assessments to fully understand the environmental impact of sodium acetate-based bioplastics. While these materials offer potential benefits in terms of biodegradability, their overall ecological footprint, including production energy requirements and end-of-life scenarios, must be thoroughly evaluated to ensure they truly represent a more sustainable alternative to conventional plastics.

Existing Sodium Acetate Bioplastic Formulations

01 Biodegradable sodium acetate-based compositions

Various compositions incorporating sodium acetate have been developed with a focus on biodegradability. These formulations are designed to break down naturally in the environment, reducing their ecological impact. The compositions may include additional components to enhance biodegradability or serve specific purposes while maintaining environmentally friendly characteristics.- Biodegradable sodium acetate compositions: Compositions containing sodium acetate are developed with a focus on biodegradability. These formulations are designed to break down naturally in the environment, reducing their ecological impact. The compositions may include additional components to enhance biodegradability or serve specific applications while maintaining environmentally friendly properties.

- Sodium acetate in biodegradable packaging materials: Sodium acetate is incorporated into biodegradable packaging materials to improve their properties or functionality. These materials are designed to decompose naturally after use, contributing to reduced environmental waste. The inclusion of sodium acetate may enhance the material's performance while maintaining its biodegradable characteristics.

- Biodegradation processes involving sodium acetate: Various biodegradation processes are developed that involve sodium acetate, either as a substrate or as part of the degradation mechanism. These processes aim to break down complex organic compounds or waste materials into simpler, environmentally benign substances. Sodium acetate may play a role in facilitating or enhancing the biodegradation process.

- Sodium acetate in biodegradable personal care products: Biodegradable personal care products are formulated incorporating sodium acetate. These products are designed to break down naturally after use, reducing their environmental impact. Sodium acetate may serve various functions in these formulations while contributing to the overall biodegradability of the product.

- Environmental impact assessment of sodium acetate: Studies and assessments are conducted to evaluate the environmental impact and biodegradability of sodium acetate in various applications. These assessments aim to understand the fate of sodium acetate in different ecosystems and its potential effects on the environment. The results contribute to the development of more sustainable practices and products involving sodium acetate.

02 Sodium acetate in biodegradable packaging materials

Sodium acetate is utilized in the development of biodegradable packaging materials. These materials are designed to decompose naturally over time, reducing plastic waste and environmental pollution. The incorporation of sodium acetate may contribute to improved biodegradability or serve other functional purposes in the packaging.Expand Specific Solutions03 Biodegradable sodium acetate-based cleaning products

Cleaning products formulated with sodium acetate as a key ingredient have been developed with a focus on biodegradability. These products are designed to effectively clean surfaces while minimizing environmental impact through their ability to break down naturally. The formulations may include additional biodegradable components to enhance cleaning efficacy.Expand Specific Solutions04 Sodium acetate in biodegradable agricultural applications

Sodium acetate is utilized in various agricultural applications with a focus on biodegradability. These applications may include fertilizers, soil amendments, or pest control products that are designed to break down naturally in the environment. The use of sodium acetate in these contexts aims to reduce the accumulation of harmful residues in soil and water systems.Expand Specific Solutions05 Biodegradation studies and improvements for sodium acetate

Research has been conducted to study and improve the biodegradability of sodium acetate and its derivatives. These studies may focus on enhancing the rate of biodegradation, identifying optimal environmental conditions for breakdown, or developing new formulations with improved biodegradable properties. The findings contribute to the development of more environmentally friendly products and processes involving sodium acetate.Expand Specific Solutions

Key Players in Bioplastic Industry

The research on sodium acetate as a key component in biodegradable thermoplastics is in an emerging stage, with growing market potential due to increasing environmental concerns. The global biodegradable plastics market is expanding rapidly, driven by regulatory pressures and consumer demand for sustainable materials. Technologically, the field is still evolving, with companies like Eastman Chemical, Novamont, and BASF leading innovation. Academic institutions such as Kaunas University of Technology and Sichuan University are contributing to fundamental research. While some companies have commercialized products, further advancements are needed to improve performance and reduce costs for widespread adoption.

Eastman Chemical Co.

Technical Solution: Eastman Chemical Co. has developed a novel approach to biodegradable thermoplastics using sodium acetate as a key component. Their technology involves incorporating sodium acetate into cellulose-based polymers to enhance biodegradability and improve mechanical properties. The company has created a proprietary blend that combines cellulose acetate with sodium acetate, resulting in a material that breaks down more rapidly in various environmental conditions[1]. This innovative formulation allows for the production of durable yet biodegradable products with applications in packaging, consumer goods, and agricultural films. Eastman's research has shown that the addition of sodium acetate can accelerate the degradation process by up to 50% compared to traditional cellulose acetate materials[3], while maintaining the desired physical properties during the product's intended lifespan.

Strengths: Accelerated biodegradation, maintained durability during use, versatile applications. Weaknesses: Potential higher production costs, limited long-term performance data in various environments.

Novamont SpA

Technical Solution: Novamont SpA has pioneered the use of sodium acetate in their MATER-BI® line of biodegradable and compostable bioplastics. Their approach integrates sodium acetate as a plasticizer and biodegradation enhancer in starch-based polymers. The company's patented process involves creating a complex network of starch, biodegradable polyesters, and sodium acetate, which results in a material with improved flexibility and faster decomposition rates[2]. Novamont's research has demonstrated that the inclusion of sodium acetate can reduce the overall decomposition time by up to 30% in industrial composting conditions[4]. The MATER-BI® products have found success in various applications, including food packaging, agricultural mulch films, and disposable tableware, offering a sustainable alternative to traditional plastics.

Strengths: Established market presence, proven biodegradability in various applications, reduced environmental impact. Weaknesses: Higher cost compared to conventional plastics, limited high-temperature resistance.

Core Innovations in Sodium Acetate Bioplastic Research

Biodegradable compositions and articles made from cellulose acetate

PatentPendingUS20230045673A1

Innovation

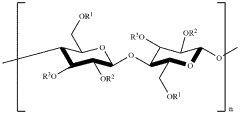

- A biodegradable cellulose acetate composition is developed, comprising cellulose acetate, a plasticizer, and additional components such as fillers, additives, or biodegradable polymers, which is melt-processable and can be formed into films that disintegrate over 90% within 12 weeks under industrial composting conditions.

Biodegradable material, and film product and application thereof

PatentPendingEP4442760A1

Innovation

- Incorporating a compatibilizer with active multifunctional groups, such as epoxy or maleic anhydride, to enhance the interfacial compatibility and mechanical properties of cellulose acetate and biodegradable polyester blends through reaction extrusion, allowing for improved thermal processing and film production.

Environmental Impact Assessment

The environmental impact assessment of sodium acetate as a key component in biodegradable thermoplastics reveals both positive and negative aspects. On the positive side, the use of sodium acetate contributes to the development of more sustainable and eco-friendly plastic alternatives. Biodegradable thermoplastics made with sodium acetate have the potential to significantly reduce plastic pollution and its associated environmental harm.

These materials can decompose naturally in various environmental conditions, including soil, water, and compost, without leaving harmful residues. This characteristic addresses one of the most pressing environmental issues of our time – the accumulation of plastic waste in ecosystems. The biodegradation process of these thermoplastics typically results in harmless byproducts such as water, carbon dioxide, and biomass, which can be assimilated back into natural cycles.

Furthermore, the production of sodium acetate-based biodegradable thermoplastics often requires less energy compared to conventional plastic manufacturing processes. This lower energy demand translates to reduced greenhouse gas emissions and a smaller carbon footprint throughout the product lifecycle. Additionally, these materials can be derived from renewable resources, further enhancing their environmental credentials.

However, there are potential drawbacks to consider. The production of sodium acetate itself may involve chemical processes that could have environmental impacts if not properly managed. The sourcing of raw materials for sodium acetate production, depending on the method used, might also raise sustainability concerns. It is crucial to ensure that the entire supply chain, from raw material extraction to final product disposal, adheres to strict environmental standards.

Another consideration is the end-of-life management of these biodegradable thermoplastics. While they are designed to decompose, improper disposal or mismanagement could lead to unintended consequences. For instance, if these materials end up in conventional recycling streams, they might contaminate other recyclable plastics, potentially compromising the recycling process.

The environmental impact of sodium acetate-based biodegradable thermoplastics also depends on their specific applications and usage patterns. While they offer significant benefits in single-use or short-term applications, their environmental advantage may be less pronounced in long-term use scenarios where durability is a key factor. It is essential to conduct comprehensive life cycle assessments to fully understand the environmental implications across different use cases and disposal scenarios.

In conclusion, while sodium acetate as a key component in biodegradable thermoplastics presents a promising solution to plastic pollution, its overall environmental impact must be carefully evaluated. Continued research and development are necessary to optimize production processes, improve material properties, and ensure responsible end-of-life management to maximize the environmental benefits of these innovative materials.

These materials can decompose naturally in various environmental conditions, including soil, water, and compost, without leaving harmful residues. This characteristic addresses one of the most pressing environmental issues of our time – the accumulation of plastic waste in ecosystems. The biodegradation process of these thermoplastics typically results in harmless byproducts such as water, carbon dioxide, and biomass, which can be assimilated back into natural cycles.

Furthermore, the production of sodium acetate-based biodegradable thermoplastics often requires less energy compared to conventional plastic manufacturing processes. This lower energy demand translates to reduced greenhouse gas emissions and a smaller carbon footprint throughout the product lifecycle. Additionally, these materials can be derived from renewable resources, further enhancing their environmental credentials.

However, there are potential drawbacks to consider. The production of sodium acetate itself may involve chemical processes that could have environmental impacts if not properly managed. The sourcing of raw materials for sodium acetate production, depending on the method used, might also raise sustainability concerns. It is crucial to ensure that the entire supply chain, from raw material extraction to final product disposal, adheres to strict environmental standards.

Another consideration is the end-of-life management of these biodegradable thermoplastics. While they are designed to decompose, improper disposal or mismanagement could lead to unintended consequences. For instance, if these materials end up in conventional recycling streams, they might contaminate other recyclable plastics, potentially compromising the recycling process.

The environmental impact of sodium acetate-based biodegradable thermoplastics also depends on their specific applications and usage patterns. While they offer significant benefits in single-use or short-term applications, their environmental advantage may be less pronounced in long-term use scenarios where durability is a key factor. It is essential to conduct comprehensive life cycle assessments to fully understand the environmental implications across different use cases and disposal scenarios.

In conclusion, while sodium acetate as a key component in biodegradable thermoplastics presents a promising solution to plastic pollution, its overall environmental impact must be carefully evaluated. Continued research and development are necessary to optimize production processes, improve material properties, and ensure responsible end-of-life management to maximize the environmental benefits of these innovative materials.

Regulatory Framework for Bioplastic Materials

The regulatory framework for bioplastic materials, including those incorporating sodium acetate as a key component in biodegradable thermoplastics, is evolving rapidly to address the growing demand for sustainable alternatives to conventional plastics. At the international level, organizations such as the International Organization for Standardization (ISO) have developed standards for biodegradable plastics, including ISO 17088 for compostable plastics and ISO 14855 for aerobic biodegradability testing.

In the European Union, the European Committee for Standardization (CEN) has established EN 13432, which sets criteria for packaging recoverable through composting and biodegradation. This standard is widely recognized and serves as a benchmark for many national regulations. The EU has also implemented the Single-Use Plastics Directive, which promotes the use of sustainable alternatives to single-use plastics, potentially benefiting biodegradable thermoplastics containing sodium acetate.

In the United States, the regulatory landscape is more fragmented, with different states implementing their own policies. However, the Federal Trade Commission (FTC) has issued guidelines on environmental marketing claims, including those related to biodegradability and compostability. The ASTM International has developed standards such as ASTM D6400 for compostable plastics, which are widely used in the industry.

Many countries have introduced or are considering legislation to reduce plastic waste and promote biodegradable alternatives. For instance, Japan has implemented the Act on the Promotion of Resource Circulation for Plastics, which encourages the use of biodegradable materials. Similarly, India has banned certain single-use plastics and is promoting alternatives, including biodegradable options.

Regulatory bodies are increasingly focusing on the entire lifecycle of bioplastic materials, from production to disposal. This includes considerations of raw material sourcing, manufacturing processes, and end-of-life management. For biodegradable thermoplastics containing sodium acetate, regulations may address aspects such as the sourcing of sodium acetate, the biodegradation rate of the final product, and potential environmental impacts.

As research on sodium acetate in biodegradable thermoplastics progresses, it is crucial for manufacturers and researchers to stay informed about evolving regulations and standards. Compliance with these frameworks will be essential for market acceptance and environmental credibility. Additionally, proactive engagement with regulatory bodies and participation in standard-setting processes can help shape future regulations that support the development and adoption of innovative biodegradable materials.

In the European Union, the European Committee for Standardization (CEN) has established EN 13432, which sets criteria for packaging recoverable through composting and biodegradation. This standard is widely recognized and serves as a benchmark for many national regulations. The EU has also implemented the Single-Use Plastics Directive, which promotes the use of sustainable alternatives to single-use plastics, potentially benefiting biodegradable thermoplastics containing sodium acetate.

In the United States, the regulatory landscape is more fragmented, with different states implementing their own policies. However, the Federal Trade Commission (FTC) has issued guidelines on environmental marketing claims, including those related to biodegradability and compostability. The ASTM International has developed standards such as ASTM D6400 for compostable plastics, which are widely used in the industry.

Many countries have introduced or are considering legislation to reduce plastic waste and promote biodegradable alternatives. For instance, Japan has implemented the Act on the Promotion of Resource Circulation for Plastics, which encourages the use of biodegradable materials. Similarly, India has banned certain single-use plastics and is promoting alternatives, including biodegradable options.

Regulatory bodies are increasingly focusing on the entire lifecycle of bioplastic materials, from production to disposal. This includes considerations of raw material sourcing, manufacturing processes, and end-of-life management. For biodegradable thermoplastics containing sodium acetate, regulations may address aspects such as the sourcing of sodium acetate, the biodegradation rate of the final product, and potential environmental impacts.

As research on sodium acetate in biodegradable thermoplastics progresses, it is crucial for manufacturers and researchers to stay informed about evolving regulations and standards. Compliance with these frameworks will be essential for market acceptance and environmental credibility. Additionally, proactive engagement with regulatory bodies and participation in standard-setting processes can help shape future regulations that support the development and adoption of innovative biodegradable materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!