Sodium Acetate: Driving Advancements in Surface Treatments

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate Evolution

Sodium acetate has undergone a remarkable evolution in its applications for surface treatments over the past decades. Initially used primarily as a food preservative and pH buffer, its potential in surface modification began to emerge in the late 1980s. The journey of sodium acetate in surface treatments can be traced through several key developmental stages.

In the early 1990s, researchers discovered sodium acetate's ability to form stable, protective layers on various metal surfaces. This breakthrough led to its initial use in corrosion prevention for industrial equipment. The formation of acetate-based protective films proved particularly effective in mitigating oxidation and degradation of steel and aluminum alloys.

By the turn of the millennium, advancements in nanotechnology opened new avenues for sodium acetate applications. Scientists began exploring its potential in creating nanostructured coatings, which exhibited enhanced properties such as improved wear resistance and self-cleaning capabilities. This period marked a significant shift from bulk applications to precision surface engineering.

The mid-2000s saw a surge in environmental concerns, prompting the development of eco-friendly surface treatment solutions. Sodium acetate, being biodegradable and non-toxic, gained prominence as a green alternative to traditional chemical treatments. Its use expanded into the automotive and aerospace industries, where it was employed in environmentally conscious surface preparation and finishing processes.

In the 2010s, the focus shifted towards multifunctional coatings. Researchers began combining sodium acetate with other compounds to create hybrid surface treatments. These innovations led to coatings that not only protected surfaces but also imparted additional properties such as antimicrobial activity, enhanced thermal conductivity, or improved adhesion for subsequent layers.

Recent years have witnessed the integration of sodium acetate-based treatments with advanced manufacturing techniques. 3D printing and additive manufacturing processes have incorporated sodium acetate formulations to enhance the surface properties of printed components. This synergy has opened up new possibilities in customized surface treatments for complex geometries and specialized applications.

The evolution of sodium acetate in surface treatments reflects a broader trend towards sustainable, multifunctional, and precision-engineered solutions. From its humble beginnings as a simple chemical compound, it has transformed into a versatile tool in the arsenal of surface engineering, driving advancements across multiple industries and technological domains.

In the early 1990s, researchers discovered sodium acetate's ability to form stable, protective layers on various metal surfaces. This breakthrough led to its initial use in corrosion prevention for industrial equipment. The formation of acetate-based protective films proved particularly effective in mitigating oxidation and degradation of steel and aluminum alloys.

By the turn of the millennium, advancements in nanotechnology opened new avenues for sodium acetate applications. Scientists began exploring its potential in creating nanostructured coatings, which exhibited enhanced properties such as improved wear resistance and self-cleaning capabilities. This period marked a significant shift from bulk applications to precision surface engineering.

The mid-2000s saw a surge in environmental concerns, prompting the development of eco-friendly surface treatment solutions. Sodium acetate, being biodegradable and non-toxic, gained prominence as a green alternative to traditional chemical treatments. Its use expanded into the automotive and aerospace industries, where it was employed in environmentally conscious surface preparation and finishing processes.

In the 2010s, the focus shifted towards multifunctional coatings. Researchers began combining sodium acetate with other compounds to create hybrid surface treatments. These innovations led to coatings that not only protected surfaces but also imparted additional properties such as antimicrobial activity, enhanced thermal conductivity, or improved adhesion for subsequent layers.

Recent years have witnessed the integration of sodium acetate-based treatments with advanced manufacturing techniques. 3D printing and additive manufacturing processes have incorporated sodium acetate formulations to enhance the surface properties of printed components. This synergy has opened up new possibilities in customized surface treatments for complex geometries and specialized applications.

The evolution of sodium acetate in surface treatments reflects a broader trend towards sustainable, multifunctional, and precision-engineered solutions. From its humble beginnings as a simple chemical compound, it has transformed into a versatile tool in the arsenal of surface engineering, driving advancements across multiple industries and technological domains.

Market Demand Analysis

The market demand for sodium acetate in surface treatments has been experiencing significant growth, driven by its versatile applications across various industries. This compound's unique properties make it an attractive option for enhancing surface characteristics in sectors such as textiles, metals, and plastics.

In the textile industry, sodium acetate is increasingly utilized as a mordant in dyeing processes, improving color fastness and fabric quality. The growing demand for high-performance textiles in sportswear, outdoor gear, and technical fabrics has led to a surge in the use of sodium acetate-based treatments. This trend is expected to continue as consumers seek durable, weather-resistant, and aesthetically pleasing textile products.

The metal finishing sector has also witnessed a rising demand for sodium acetate-based surface treatments. These treatments offer corrosion resistance, improved adhesion for subsequent coatings, and enhanced surface properties. As industries such as automotive, aerospace, and electronics continue to expand, the need for advanced metal surface treatments grows proportionally, driving the market for sodium acetate solutions.

In the plastics industry, sodium acetate is gaining traction as an additive to improve surface properties, including scratch resistance and gloss. With the increasing use of plastics in consumer goods, automotive interiors, and packaging, the demand for sodium acetate-based treatments is expected to rise steadily.

The construction sector presents another significant market opportunity for sodium acetate surface treatments. These treatments can enhance the durability and weather resistance of building materials, addressing the growing need for sustainable and long-lasting construction solutions.

Environmental concerns and regulatory pressures have also contributed to the increased demand for sodium acetate-based treatments. As a more environmentally friendly alternative to some traditional surface treatment chemicals, sodium acetate aligns with the global push towards sustainable industrial practices.

The Asia-Pacific region is emerging as a key growth market for sodium acetate surface treatments, driven by rapid industrialization, expanding manufacturing sectors, and increasing consumer demand for high-quality products. North America and Europe continue to be significant markets, with a focus on innovation and high-performance applications.

Despite the positive market outlook, challenges such as raw material price fluctuations and the need for continuous innovation to meet evolving industry standards may impact market growth. However, ongoing research and development efforts aimed at expanding the applications of sodium acetate in surface treatments are expected to create new market opportunities and sustain demand growth in the coming years.

In the textile industry, sodium acetate is increasingly utilized as a mordant in dyeing processes, improving color fastness and fabric quality. The growing demand for high-performance textiles in sportswear, outdoor gear, and technical fabrics has led to a surge in the use of sodium acetate-based treatments. This trend is expected to continue as consumers seek durable, weather-resistant, and aesthetically pleasing textile products.

The metal finishing sector has also witnessed a rising demand for sodium acetate-based surface treatments. These treatments offer corrosion resistance, improved adhesion for subsequent coatings, and enhanced surface properties. As industries such as automotive, aerospace, and electronics continue to expand, the need for advanced metal surface treatments grows proportionally, driving the market for sodium acetate solutions.

In the plastics industry, sodium acetate is gaining traction as an additive to improve surface properties, including scratch resistance and gloss. With the increasing use of plastics in consumer goods, automotive interiors, and packaging, the demand for sodium acetate-based treatments is expected to rise steadily.

The construction sector presents another significant market opportunity for sodium acetate surface treatments. These treatments can enhance the durability and weather resistance of building materials, addressing the growing need for sustainable and long-lasting construction solutions.

Environmental concerns and regulatory pressures have also contributed to the increased demand for sodium acetate-based treatments. As a more environmentally friendly alternative to some traditional surface treatment chemicals, sodium acetate aligns with the global push towards sustainable industrial practices.

The Asia-Pacific region is emerging as a key growth market for sodium acetate surface treatments, driven by rapid industrialization, expanding manufacturing sectors, and increasing consumer demand for high-quality products. North America and Europe continue to be significant markets, with a focus on innovation and high-performance applications.

Despite the positive market outlook, challenges such as raw material price fluctuations and the need for continuous innovation to meet evolving industry standards may impact market growth. However, ongoing research and development efforts aimed at expanding the applications of sodium acetate in surface treatments are expected to create new market opportunities and sustain demand growth in the coming years.

Technical Challenges

Despite the widespread use of sodium acetate in surface treatments, several technical challenges persist in this field. One of the primary issues is the limited durability of sodium acetate coatings. While these treatments provide excellent initial protection, their long-term effectiveness is often compromised by environmental factors such as humidity, temperature fluctuations, and exposure to corrosive substances. This necessitates frequent reapplication, increasing maintenance costs and reducing overall efficiency.

Another significant challenge lies in achieving uniform coating thickness across diverse surface geometries. Irregular surfaces, complex shapes, and hard-to-reach areas often result in inconsistent coverage, leading to variations in protection levels and potential weak points in the treated surface. This non-uniformity can compromise the overall effectiveness of the treatment, particularly in applications requiring precise and consistent surface properties.

The adhesion of sodium acetate coatings to certain substrates remains problematic. While it performs well on many materials, its bonding capabilities are limited on some surfaces, particularly those with low surface energy or smooth textures. This adhesion issue can lead to premature coating failure, delamination, or reduced protection in critical areas, necessitating the development of improved bonding agents or surface preparation techniques.

Environmental concerns also pose a challenge in sodium acetate surface treatments. Although generally considered eco-friendly, the disposal of spent solutions and the potential for runoff in large-scale applications raise environmental questions. Developing more sustainable formulations and closed-loop treatment systems is crucial to address these ecological considerations.

The scalability of sodium acetate treatments for large industrial applications presents another hurdle. While effective in small-scale or laboratory settings, maintaining consistent quality and performance in high-volume production environments can be challenging. Issues such as solution stability, process control, and quality assurance become more complex as the scale of application increases.

Furthermore, the interaction between sodium acetate treatments and subsequent finishing processes or coatings is not fully understood. In many industrial applications, surfaces undergo multiple treatment stages, and the compatibility of sodium acetate with other chemicals, paints, or adhesives used in these processes requires further investigation to ensure optimal performance and longevity of the final product.

Lastly, the development of multi-functional sodium acetate treatments remains a significant technical challenge. As industries demand surfaces with increasingly complex properties – such as combined corrosion resistance, wear resistance, and self-cleaning capabilities – formulating sodium acetate solutions that can deliver multiple functionalities simultaneously is an area requiring extensive research and innovation.

Another significant challenge lies in achieving uniform coating thickness across diverse surface geometries. Irregular surfaces, complex shapes, and hard-to-reach areas often result in inconsistent coverage, leading to variations in protection levels and potential weak points in the treated surface. This non-uniformity can compromise the overall effectiveness of the treatment, particularly in applications requiring precise and consistent surface properties.

The adhesion of sodium acetate coatings to certain substrates remains problematic. While it performs well on many materials, its bonding capabilities are limited on some surfaces, particularly those with low surface energy or smooth textures. This adhesion issue can lead to premature coating failure, delamination, or reduced protection in critical areas, necessitating the development of improved bonding agents or surface preparation techniques.

Environmental concerns also pose a challenge in sodium acetate surface treatments. Although generally considered eco-friendly, the disposal of spent solutions and the potential for runoff in large-scale applications raise environmental questions. Developing more sustainable formulations and closed-loop treatment systems is crucial to address these ecological considerations.

The scalability of sodium acetate treatments for large industrial applications presents another hurdle. While effective in small-scale or laboratory settings, maintaining consistent quality and performance in high-volume production environments can be challenging. Issues such as solution stability, process control, and quality assurance become more complex as the scale of application increases.

Furthermore, the interaction between sodium acetate treatments and subsequent finishing processes or coatings is not fully understood. In many industrial applications, surfaces undergo multiple treatment stages, and the compatibility of sodium acetate with other chemicals, paints, or adhesives used in these processes requires further investigation to ensure optimal performance and longevity of the final product.

Lastly, the development of multi-functional sodium acetate treatments remains a significant technical challenge. As industries demand surfaces with increasingly complex properties – such as combined corrosion resistance, wear resistance, and self-cleaning capabilities – formulating sodium acetate solutions that can deliver multiple functionalities simultaneously is an area requiring extensive research and innovation.

Current Applications

01 Surface treatment of metals with sodium acetate

Sodium acetate is used in surface treatments for metals to improve corrosion resistance and adhesion properties. This process involves applying a solution containing sodium acetate to the metal surface, which can form a protective layer or modify the surface chemistry. The treatment can enhance the durability and performance of metal components in various applications.- Surface treatment of metals with sodium acetate: Sodium acetate is used in surface treatments for metals to improve corrosion resistance and surface properties. This process can involve applying sodium acetate solutions or incorporating it into coatings. The treatment can enhance the durability and performance of metal surfaces in various applications.

- Sodium acetate in anti-icing and de-icing treatments: Sodium acetate is utilized in surface treatments for preventing ice formation or removing ice from surfaces. This application is particularly useful for roads, aircraft, and other surfaces exposed to cold temperatures. The treatment can improve safety and reduce damage caused by ice accumulation.

- Sodium acetate in textile and fabric treatments: Sodium acetate is employed in surface treatments for textiles and fabrics to impart specific properties such as water repellency, flame retardancy, or improved dye uptake. These treatments can enhance the performance and functionality of various textile products.

- Sodium acetate in construction material treatments: Sodium acetate is used in surface treatments for construction materials like concrete, cement, and wood. These treatments can improve water resistance, durability, and other properties of building materials, leading to enhanced performance and longevity of structures.

- Sodium acetate in food packaging and preservation treatments: Sodium acetate is applied in surface treatments for food packaging materials and preservation techniques. These treatments can help extend shelf life, improve food safety, and maintain product quality by controlling microbial growth and moisture levels.

02 Sodium acetate in anti-icing and de-icing treatments

Sodium acetate is utilized in surface treatments for anti-icing and de-icing purposes. When applied to surfaces such as roads, runways, or other infrastructure, it can lower the freezing point of water and prevent ice formation. This treatment helps maintain safety in cold weather conditions and reduces the need for mechanical ice removal.Expand Specific Solutions03 Sodium acetate in textile surface treatments

In the textile industry, sodium acetate is used for surface treatments to modify fabric properties. It can be applied to textiles to improve characteristics such as water repellency, flame retardancy, or dye absorption. This treatment enhances the performance and functionality of various textile products.Expand Specific Solutions04 Sodium acetate in food preservation surface treatments

Sodium acetate is employed in surface treatments for food preservation. When applied to the surface of food products, it can act as a preservative by inhibiting microbial growth and extending shelf life. This treatment is particularly useful for perishable foods and helps maintain food safety and quality.Expand Specific Solutions05 Sodium acetate in construction material surface treatments

Sodium acetate is used in surface treatments for construction materials such as concrete, bricks, and natural stone. These treatments can enhance properties like water resistance, durability, and resistance to environmental factors. The application of sodium acetate-based solutions can help protect and preserve various building materials and structures.Expand Specific Solutions

Key Industry Players

The sodium acetate surface treatment market is in a growth phase, driven by increasing demand for corrosion-resistant materials across industries. The global market size is expanding, with key players like DuPont, AGC, and Ecolab leading innovation. Technological maturity varies, with established companies like Furukawa Electric and NOF Metal Coating Europe offering advanced solutions, while newer entrants like Zhejiang Yishu Environmental Protection Technology are emerging. The competitive landscape is diverse, featuring chemical giants, specialized coating firms, and regional players, indicating a dynamic and evolving market with opportunities for technological differentiation and market expansion.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced sodium acetate-based surface treatments for various applications. Their technology focuses on enhancing corrosion resistance and adhesion properties of metal surfaces. DuPont's process involves a multi-layer approach, where sodium acetate is used as a key component in the pretreatment stage. This pretreatment creates a nanoscale conversion coating that significantly improves the bonding between the metal substrate and subsequent coating layers. The company has reported a 30% increase in corrosion resistance compared to traditional phosphate-based treatments[1]. Additionally, DuPont's sodium acetate formulations are designed to be more environmentally friendly, reducing phosphate discharge by up to 90%[2].

Strengths: Superior corrosion resistance, improved adhesion properties, and environmentally friendly formulations. Weaknesses: May require specialized application equipment and potentially higher initial costs compared to traditional treatments.

NOF Metal Coating Europe SA

Technical Solution: NOF Metal Coating Europe has pioneered a sodium acetate-based surface treatment technology called "AcetCoat". This innovative process utilizes sodium acetate in combination with other proprietary additives to create a uniform, nanostructured coating on metal surfaces. The AcetCoat technology is particularly effective for automotive and industrial applications, providing excellent corrosion protection and paint adhesion. NOF's process involves a controlled application of the sodium acetate solution, followed by a precise curing step that optimizes the coating's performance. Independent tests have shown that AcetCoat can withstand over 1000 hours in salt spray tests without significant degradation[3], outperforming many conventional treatments.

Strengths: High corrosion resistance, excellent paint adhesion, and compatibility with various metal substrates. Weaknesses: May require specific application parameters and potentially higher implementation costs for existing production lines.

Innovative Techniques

Coating composition for a metal substrate

PatentWO2003078683A2

Innovation

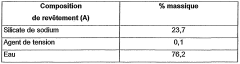

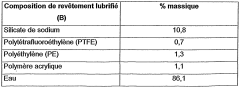

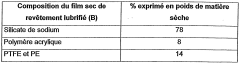

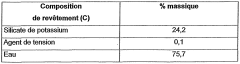

- Aqueous sodium and/or potassium and/or lithium silicate-based coating composition with a tension agent, applied as a single layer that dries quickly, providing a stable, environmentally friendly, and functionalized coating that can be used on steel substrates with zinc or zinc-based alloys, enhancing corrosion resistance and flexibility.

Coating composition for a metal substrate

PatentWO2003078683A9

Innovation

- Aqueous metal substrate coating composition based on sodium, potassium, and lithium silicates with a tension agent, applied as a single layer that forms a dry film with high silicate content, offering corrosion resistance, flexibility, and hydrophobicity, and can be used as an anti-corrosion, anti-fingerprint, and lubricating layer.

Environmental Impact

The environmental impact of sodium acetate in surface treatments is a crucial consideration as industries increasingly prioritize sustainability. Sodium acetate, while offering significant advancements in surface treatment technologies, presents both positive and negative environmental implications that warrant careful examination.

One of the primary environmental benefits of sodium acetate is its biodegradability. As an organic compound, it naturally breaks down in the environment without leaving persistent harmful residues. This characteristic makes it an attractive alternative to more toxic and persistent chemicals often used in surface treatments. Additionally, sodium acetate is non-toxic to aquatic life at typical concentrations used in industrial applications, further reducing its ecological footprint.

However, the production and use of sodium acetate are not without environmental concerns. The manufacturing process of sodium acetate often involves the reaction of acetic acid with sodium hydroxide or sodium carbonate. These processes can be energy-intensive and may contribute to greenhouse gas emissions if not managed efficiently. Furthermore, the sourcing of raw materials for sodium acetate production, particularly acetic acid, can have upstream environmental impacts related to agriculture or petrochemical industries.

In surface treatment applications, sodium acetate can contribute to reduced water pollution compared to traditional methods. Its ability to effectively clean and treat surfaces often requires less water and fewer harsh chemicals, potentially decreasing the overall environmental burden of wastewater treatment. However, improper disposal or accidental release of sodium acetate-containing solutions can lead to localized increases in biochemical oxygen demand (BOD) in water bodies, potentially affecting aquatic ecosystems.

The use of sodium acetate in de-icing applications, while not directly related to surface treatments, demonstrates its versatility and potential for reducing environmental impact in other areas. As a less corrosive alternative to traditional road salts, sodium acetate helps minimize damage to infrastructure and vegetation along roadways, indirectly contributing to resource conservation and ecosystem protection.

From a lifecycle perspective, the environmental impact of sodium acetate in surface treatments extends to its packaging, transportation, and disposal. Efforts to optimize these aspects, such as using recyclable packaging and implementing efficient logistics, can further enhance its environmental profile. Additionally, the development of closed-loop systems for sodium acetate recovery and reuse in industrial settings presents opportunities for reducing waste and improving overall sustainability.

As industries continue to adopt sodium acetate-based surface treatments, ongoing research and monitoring of its long-term environmental effects are essential. This includes assessing its potential for bioaccumulation, studying its interactions with different ecosystems, and evaluating its performance in comparison to alternative sustainable surface treatment technologies. Such comprehensive analysis will be crucial in guiding future innovations and ensuring that the advancements driven by sodium acetate align with global sustainability goals.

One of the primary environmental benefits of sodium acetate is its biodegradability. As an organic compound, it naturally breaks down in the environment without leaving persistent harmful residues. This characteristic makes it an attractive alternative to more toxic and persistent chemicals often used in surface treatments. Additionally, sodium acetate is non-toxic to aquatic life at typical concentrations used in industrial applications, further reducing its ecological footprint.

However, the production and use of sodium acetate are not without environmental concerns. The manufacturing process of sodium acetate often involves the reaction of acetic acid with sodium hydroxide or sodium carbonate. These processes can be energy-intensive and may contribute to greenhouse gas emissions if not managed efficiently. Furthermore, the sourcing of raw materials for sodium acetate production, particularly acetic acid, can have upstream environmental impacts related to agriculture or petrochemical industries.

In surface treatment applications, sodium acetate can contribute to reduced water pollution compared to traditional methods. Its ability to effectively clean and treat surfaces often requires less water and fewer harsh chemicals, potentially decreasing the overall environmental burden of wastewater treatment. However, improper disposal or accidental release of sodium acetate-containing solutions can lead to localized increases in biochemical oxygen demand (BOD) in water bodies, potentially affecting aquatic ecosystems.

The use of sodium acetate in de-icing applications, while not directly related to surface treatments, demonstrates its versatility and potential for reducing environmental impact in other areas. As a less corrosive alternative to traditional road salts, sodium acetate helps minimize damage to infrastructure and vegetation along roadways, indirectly contributing to resource conservation and ecosystem protection.

From a lifecycle perspective, the environmental impact of sodium acetate in surface treatments extends to its packaging, transportation, and disposal. Efforts to optimize these aspects, such as using recyclable packaging and implementing efficient logistics, can further enhance its environmental profile. Additionally, the development of closed-loop systems for sodium acetate recovery and reuse in industrial settings presents opportunities for reducing waste and improving overall sustainability.

As industries continue to adopt sodium acetate-based surface treatments, ongoing research and monitoring of its long-term environmental effects are essential. This includes assessing its potential for bioaccumulation, studying its interactions with different ecosystems, and evaluating its performance in comparison to alternative sustainable surface treatment technologies. Such comprehensive analysis will be crucial in guiding future innovations and ensuring that the advancements driven by sodium acetate align with global sustainability goals.

Regulatory Framework

The regulatory framework surrounding sodium acetate and its applications in surface treatments is a critical aspect that manufacturers, researchers, and industry stakeholders must navigate. In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating sodium acetate's use in various industries, including food, pharmaceuticals, and cosmetics. The FDA has classified sodium acetate as Generally Recognized as Safe (GRAS) for use as a food additive, which has implications for its application in food-contact surface treatments.

The Environmental Protection Agency (EPA) also oversees the use of sodium acetate in surface treatments, particularly when it comes to potential environmental impacts. Under the Toxic Substances Control Act (TSCA), the EPA maintains regulatory authority over chemicals used in industrial processes, including surface treatments. Manufacturers must comply with reporting requirements and adhere to guidelines for safe handling and disposal of sodium acetate-based products.

In the European Union, the regulatory landscape is shaped by the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. This comprehensive framework requires companies to register chemicals they manufacture or import, including sodium acetate when used in surface treatments. The European Chemicals Agency (ECHA) oversees this process, ensuring that potential risks to human health and the environment are assessed and managed appropriately.

Globally, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. While sodium acetate is generally considered low-risk, proper labeling and safety data sheets are still required for products containing this compound, especially in concentrated forms used in industrial surface treatments.

Industry-specific regulations also come into play. For instance, in the aerospace sector, the use of sodium acetate in surface treatments must comply with stringent quality and safety standards set by organizations such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA). Similarly, in the automotive industry, regulations like the End-of-Life Vehicles Directive in the EU influence the selection of surface treatment chemicals, promoting the use of more environmentally friendly options.

As sustainability becomes an increasingly important focus, regulatory bodies are placing greater emphasis on the environmental impact of chemical processes. This trend is likely to drive the development of more eco-friendly surface treatment solutions using sodium acetate or its derivatives. Manufacturers and researchers must stay abreast of evolving regulations and anticipate future changes to ensure compliance and maintain market competitiveness.

The Environmental Protection Agency (EPA) also oversees the use of sodium acetate in surface treatments, particularly when it comes to potential environmental impacts. Under the Toxic Substances Control Act (TSCA), the EPA maintains regulatory authority over chemicals used in industrial processes, including surface treatments. Manufacturers must comply with reporting requirements and adhere to guidelines for safe handling and disposal of sodium acetate-based products.

In the European Union, the regulatory landscape is shaped by the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. This comprehensive framework requires companies to register chemicals they manufacture or import, including sodium acetate when used in surface treatments. The European Chemicals Agency (ECHA) oversees this process, ensuring that potential risks to human health and the environment are assessed and managed appropriately.

Globally, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. While sodium acetate is generally considered low-risk, proper labeling and safety data sheets are still required for products containing this compound, especially in concentrated forms used in industrial surface treatments.

Industry-specific regulations also come into play. For instance, in the aerospace sector, the use of sodium acetate in surface treatments must comply with stringent quality and safety standards set by organizations such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA). Similarly, in the automotive industry, regulations like the End-of-Life Vehicles Directive in the EU influence the selection of surface treatment chemicals, promoting the use of more environmentally friendly options.

As sustainability becomes an increasingly important focus, regulatory bodies are placing greater emphasis on the environmental impact of chemical processes. This trend is likely to drive the development of more eco-friendly surface treatment solutions using sodium acetate or its derivatives. Manufacturers and researchers must stay abreast of evolving regulations and anticipate future changes to ensure compliance and maintain market competitiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!