Sodium Acetate in the Revolution of Circular Economy Models

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate Background and Circular Economy Goals

Sodium acetate, a versatile compound with the chemical formula CH3COONa, has been utilized in various industries for decades. Its journey from a simple chemical to a key player in circular economy models represents a significant evolution in sustainable practices. The compound's history dates back to its discovery in the early 19th century, with initial applications primarily in the textile and food industries. As environmental concerns grew in the late 20th century, researchers began exploring sodium acetate's potential in more sustainable applications.

The circular economy concept, which aims to eliminate waste and maximize resource efficiency, has gained traction in recent years as a response to the global challenges of resource depletion and environmental degradation. In this context, sodium acetate has emerged as a promising material due to its unique properties and potential for recycling and reuse. The compound's ability to store and release thermal energy, coupled with its non-toxic nature, has positioned it as a valuable asset in the development of sustainable technologies.

The evolution of sodium acetate's role in circular economy models has been driven by advancements in materials science and a growing understanding of its chemical properties. Research has focused on expanding its applications beyond traditional uses, exploring innovative ways to incorporate the compound into closed-loop systems. This has led to the development of new technologies in areas such as energy storage, waste management, and sustainable manufacturing processes.

One of the primary goals in the research of sodium acetate within circular economy models is to optimize its production and utilization while minimizing environmental impact. This involves developing more efficient synthesis methods, exploring bio-based production routes, and creating novel applications that leverage the compound's unique characteristics. Additionally, researchers aim to enhance the recyclability and reusability of sodium acetate-based products, ensuring that they can be easily reintegrated into production cycles with minimal waste.

Another crucial objective is to integrate sodium acetate into broader circular economy strategies across various industries. This includes identifying synergies between different sectors where the compound can serve multiple purposes, thereby maximizing its value and reducing overall resource consumption. By fostering collaboration between researchers, industry stakeholders, and policymakers, the aim is to create a comprehensive framework for sodium acetate's sustainable use and management throughout its lifecycle.

As research in this field progresses, the ultimate goal is to establish sodium acetate as a model compound for circular economy principles, demonstrating how traditional chemicals can be reimagined and repurposed to support sustainable development. This endeavor not only contributes to the advancement of circular economy practices but also serves as a blueprint for the transformation of other materials and processes in the pursuit of a more sustainable and resource-efficient future.

The circular economy concept, which aims to eliminate waste and maximize resource efficiency, has gained traction in recent years as a response to the global challenges of resource depletion and environmental degradation. In this context, sodium acetate has emerged as a promising material due to its unique properties and potential for recycling and reuse. The compound's ability to store and release thermal energy, coupled with its non-toxic nature, has positioned it as a valuable asset in the development of sustainable technologies.

The evolution of sodium acetate's role in circular economy models has been driven by advancements in materials science and a growing understanding of its chemical properties. Research has focused on expanding its applications beyond traditional uses, exploring innovative ways to incorporate the compound into closed-loop systems. This has led to the development of new technologies in areas such as energy storage, waste management, and sustainable manufacturing processes.

One of the primary goals in the research of sodium acetate within circular economy models is to optimize its production and utilization while minimizing environmental impact. This involves developing more efficient synthesis methods, exploring bio-based production routes, and creating novel applications that leverage the compound's unique characteristics. Additionally, researchers aim to enhance the recyclability and reusability of sodium acetate-based products, ensuring that they can be easily reintegrated into production cycles with minimal waste.

Another crucial objective is to integrate sodium acetate into broader circular economy strategies across various industries. This includes identifying synergies between different sectors where the compound can serve multiple purposes, thereby maximizing its value and reducing overall resource consumption. By fostering collaboration between researchers, industry stakeholders, and policymakers, the aim is to create a comprehensive framework for sodium acetate's sustainable use and management throughout its lifecycle.

As research in this field progresses, the ultimate goal is to establish sodium acetate as a model compound for circular economy principles, demonstrating how traditional chemicals can be reimagined and repurposed to support sustainable development. This endeavor not only contributes to the advancement of circular economy practices but also serves as a blueprint for the transformation of other materials and processes in the pursuit of a more sustainable and resource-efficient future.

Market Demand Analysis for Sodium Acetate in Circular Economy

The market demand for sodium acetate in the circular economy context is experiencing significant growth, driven by increasing environmental concerns and the push for sustainable industrial practices. As industries seek to reduce waste and maximize resource efficiency, sodium acetate has emerged as a versatile compound with numerous applications in circular economy models.

In the chemical industry, sodium acetate is gaining traction as a key component in green chemistry initiatives. Its role as a buffering agent and pH regulator in various processes aligns well with the principles of circular economy, as it can be easily recovered and reused. This has led to a surge in demand from manufacturers looking to implement closed-loop systems and reduce their environmental footprint.

The textile sector represents another major market for sodium acetate in circular economy applications. As the industry moves towards more sustainable dyeing processes, sodium acetate is being utilized as an eco-friendly mordant and dye-fixing agent. This shift is driven by consumer demand for environmentally responsible products and stringent regulations on textile waste management.

In the food industry, sodium acetate is finding increased use as a preservative and flavoring agent in circular economy models. Its natural occurrence and biodegradability make it an attractive alternative to synthetic preservatives, aligning with the growing consumer preference for clean-label products. The ability to produce sodium acetate from renewable resources further enhances its appeal in circular economy strategies.

The construction sector is also contributing to the rising demand for sodium acetate in circular economy applications. Its use in concrete admixtures for improved setting time and durability is gaining attention, particularly in projects focused on sustainable building practices. The potential for sodium acetate to be derived from industrial waste streams makes it an attractive option for circular economy-minded construction firms.

Energy storage systems represent an emerging market for sodium acetate in the circular economy landscape. Research into phase change materials for thermal energy storage has highlighted sodium acetate trihydrate as a promising candidate. This application could see significant growth as renewable energy integration and energy efficiency become increasingly important in circular economy models.

The global push towards circular economy practices is expected to continue driving the demand for sodium acetate across various industries. As companies seek innovative solutions to close material loops and reduce environmental impact, the versatility and sustainability of sodium acetate position it as a key player in the transition to more circular business models.

In the chemical industry, sodium acetate is gaining traction as a key component in green chemistry initiatives. Its role as a buffering agent and pH regulator in various processes aligns well with the principles of circular economy, as it can be easily recovered and reused. This has led to a surge in demand from manufacturers looking to implement closed-loop systems and reduce their environmental footprint.

The textile sector represents another major market for sodium acetate in circular economy applications. As the industry moves towards more sustainable dyeing processes, sodium acetate is being utilized as an eco-friendly mordant and dye-fixing agent. This shift is driven by consumer demand for environmentally responsible products and stringent regulations on textile waste management.

In the food industry, sodium acetate is finding increased use as a preservative and flavoring agent in circular economy models. Its natural occurrence and biodegradability make it an attractive alternative to synthetic preservatives, aligning with the growing consumer preference for clean-label products. The ability to produce sodium acetate from renewable resources further enhances its appeal in circular economy strategies.

The construction sector is also contributing to the rising demand for sodium acetate in circular economy applications. Its use in concrete admixtures for improved setting time and durability is gaining attention, particularly in projects focused on sustainable building practices. The potential for sodium acetate to be derived from industrial waste streams makes it an attractive option for circular economy-minded construction firms.

Energy storage systems represent an emerging market for sodium acetate in the circular economy landscape. Research into phase change materials for thermal energy storage has highlighted sodium acetate trihydrate as a promising candidate. This application could see significant growth as renewable energy integration and energy efficiency become increasingly important in circular economy models.

The global push towards circular economy practices is expected to continue driving the demand for sodium acetate across various industries. As companies seek innovative solutions to close material loops and reduce environmental impact, the versatility and sustainability of sodium acetate position it as a key player in the transition to more circular business models.

Current State and Challenges in Sodium Acetate Utilization

Sodium acetate has gained significant attention in recent years as a key component in circular economy models. The current state of sodium acetate utilization is characterized by its widespread application across various industries, including textiles, food preservation, and pharmaceuticals. However, the full potential of this versatile compound in promoting sustainable practices remains largely untapped.

In the textile industry, sodium acetate is primarily used as a pH buffer and dyeing auxiliary. Its ability to maintain stable pH levels during fabric processing has made it an essential ingredient in many textile manufacturing processes. However, the recovery and reuse of sodium acetate from textile wastewater streams present a significant challenge, limiting its circularity in this sector.

The food industry employs sodium acetate as a preservative and flavoring agent. Its effectiveness in inhibiting microbial growth has made it a popular choice for extending the shelf life of various food products. Nevertheless, the current utilization often follows a linear model, with limited focus on recovery and recycling of the compound after its initial use.

In pharmaceuticals, sodium acetate serves as a buffering agent in intravenous fluids and dialysis solutions. While its use in this sector is well-established, the challenges lie in developing more sustainable production methods and exploring potential recovery techniques from medical waste streams.

One of the primary challenges in sodium acetate utilization is the lack of efficient recovery systems across industries. The development of cost-effective and energy-efficient methods for reclaiming sodium acetate from waste streams is crucial for enhancing its circularity. Additionally, the varying purity requirements across different applications pose a challenge in establishing standardized recovery and recycling processes.

Another significant hurdle is the limited awareness and adoption of circular economy principles in sodium acetate usage. Many industries continue to operate within traditional linear models, overlooking the potential environmental and economic benefits of implementing closed-loop systems for this compound.

The geographical distribution of sodium acetate production and consumption also presents challenges. With production concentrated in certain regions, transportation and distribution costs can hinder the widespread adoption of circular practices, particularly in areas with limited access to recycling infrastructure.

Technological limitations in the purification and transformation of recovered sodium acetate further complicate its reintegration into various industrial processes. Developing advanced purification techniques and exploring novel applications for recovered sodium acetate are essential steps in overcoming these barriers.

In the textile industry, sodium acetate is primarily used as a pH buffer and dyeing auxiliary. Its ability to maintain stable pH levels during fabric processing has made it an essential ingredient in many textile manufacturing processes. However, the recovery and reuse of sodium acetate from textile wastewater streams present a significant challenge, limiting its circularity in this sector.

The food industry employs sodium acetate as a preservative and flavoring agent. Its effectiveness in inhibiting microbial growth has made it a popular choice for extending the shelf life of various food products. Nevertheless, the current utilization often follows a linear model, with limited focus on recovery and recycling of the compound after its initial use.

In pharmaceuticals, sodium acetate serves as a buffering agent in intravenous fluids and dialysis solutions. While its use in this sector is well-established, the challenges lie in developing more sustainable production methods and exploring potential recovery techniques from medical waste streams.

One of the primary challenges in sodium acetate utilization is the lack of efficient recovery systems across industries. The development of cost-effective and energy-efficient methods for reclaiming sodium acetate from waste streams is crucial for enhancing its circularity. Additionally, the varying purity requirements across different applications pose a challenge in establishing standardized recovery and recycling processes.

Another significant hurdle is the limited awareness and adoption of circular economy principles in sodium acetate usage. Many industries continue to operate within traditional linear models, overlooking the potential environmental and economic benefits of implementing closed-loop systems for this compound.

The geographical distribution of sodium acetate production and consumption also presents challenges. With production concentrated in certain regions, transportation and distribution costs can hinder the widespread adoption of circular practices, particularly in areas with limited access to recycling infrastructure.

Technological limitations in the purification and transformation of recovered sodium acetate further complicate its reintegration into various industrial processes. Developing advanced purification techniques and exploring novel applications for recovered sodium acetate are essential steps in overcoming these barriers.

Existing Circular Economy Models Using Sodium Acetate

01 Use of sodium acetate in chemical processes

Sodium acetate is widely used in various chemical processes as a reagent, catalyst, or buffer. It plays a role in reactions such as acetylation, esterification, and pH control. Its properties make it valuable in industrial applications and laboratory settings.- Use of sodium acetate in chemical processes: Sodium acetate is widely used in various chemical processes as a reagent, catalyst, or buffer. It plays a role in reactions such as acetylation, esterification, and pH control. Its properties make it valuable in industrial applications and laboratory settings.

- Application in heat storage and thermal management: Sodium acetate trihydrate is utilized in heat storage systems and thermal management applications. It can absorb and release heat through phase change, making it useful in heating pads, hand warmers, and energy storage devices.

- Use in food and beverage industry: Sodium acetate is employed as a food additive and preservative. It acts as a flavoring agent, acidity regulator, and antimicrobial agent in various food products and beverages, helping to extend shelf life and improve taste.

- Application in textile and leather industries: Sodium acetate finds use in textile and leather processing. It serves as a dyeing auxiliary, pH regulator, and finishing agent, improving color fastness and fabric properties in textile manufacturing and leather treatment.

- Environmental and waste treatment applications: Sodium acetate is utilized in environmental remediation and waste treatment processes. It can be used as a carbon source for biological treatment of wastewater, in flue gas desulfurization, and as a de-icing agent with reduced environmental impact compared to traditional salt-based de-icers.

02 Application in heat storage and thermal management

Sodium acetate trihydrate is utilized in heat storage systems and thermal management applications. It undergoes phase changes that allow it to store and release heat effectively, making it useful in heating and cooling systems, as well as in thermal energy storage devices.Expand Specific Solutions03 Use in food and beverage industry

Sodium acetate finds applications in the food and beverage industry as a preservative, flavoring agent, and acidity regulator. It helps extend shelf life, enhance taste, and maintain pH balance in various food products.Expand Specific Solutions04 Application in textile and leather processing

In the textile and leather industries, sodium acetate is used in dyeing processes, as a mordant, and for pH adjustment. It helps improve color fastness, fabric softness, and overall quality of the finished products.Expand Specific Solutions05 Use in pharmaceutical and personal care products

Sodium acetate is employed in pharmaceutical formulations and personal care products. It serves as a buffering agent, pH adjuster, and in some cases, as an active ingredient. Its properties make it suitable for various medicinal and cosmetic applications.Expand Specific Solutions

Key Players in Sodium Acetate and Circular Economy Industries

The research on sodium acetate in circular economy models is in an emerging stage, with growing market potential due to increasing focus on sustainability. The technology is still developing, with varying levels of maturity across different applications. Key players like Sunamp Ltd., Daicel Corp., and PTT Global Chemical Plc are advancing thermal energy storage and chemical production applications. Academic institutions such as CSIC and Chinese Academy of Science are contributing to fundamental research. The market is characterized by a mix of established chemical companies and innovative startups, indicating a dynamic competitive landscape with opportunities for technological breakthroughs and market expansion.

Sunamp Ltd.

Technical Solution: Sunamp Ltd. has developed innovative thermal storage technology using sodium acetate as a phase change material (PCM). Their UniQ heat batteries store energy as latent heat in sodium acetate trihydrate, which undergoes a phase change at 58°C. This allows for efficient heat storage and release, supporting circular economy models by reducing energy waste. The company has implemented this technology in various applications, including domestic hot water systems, electric vehicle battery thermal management, and grid-scale energy storage[1][2]. Sunamp's sodium acetate-based thermal batteries can store 4 times more energy than water for a given volume, providing a compact and efficient solution for heat storage and management in circular economy systems[3].

Strengths: High energy density, compact design, and versatility in applications. Weaknesses: Potential for supercooling and need for nucleation triggers to initiate crystallization.

Daicel Corp.

Technical Solution: Daicel Corporation has developed a bio-based sodium acetate production process as part of its commitment to circular economy principles. The company utilizes renewable resources, such as biomass-derived acetic acid, to produce sodium acetate through a fermentation process. This approach reduces reliance on fossil fuel-based feedstocks and contributes to a more sustainable production cycle. Daicel's bio-based sodium acetate finds applications in various industries, including textiles, food preservation, and pharmaceuticals[4]. The company has reported a 30% reduction in carbon footprint compared to traditional petrochemical-based production methods, aligning with circular economy goals of resource efficiency and waste reduction[5].

Strengths: Sustainable production process, reduced carbon footprint, and versatile product applications. Weaknesses: Potential higher production costs compared to conventional methods and dependence on biomass availability.

Core Innovations in Sodium Acetate Circular Economy Applications

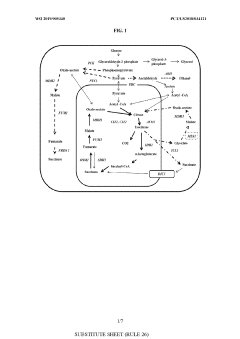

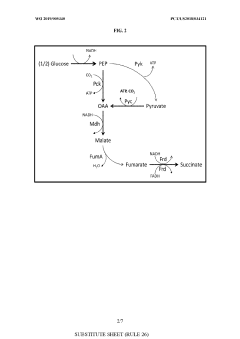

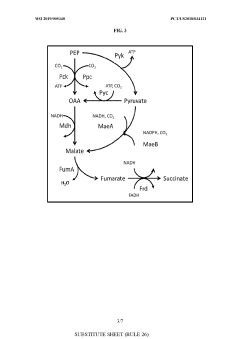

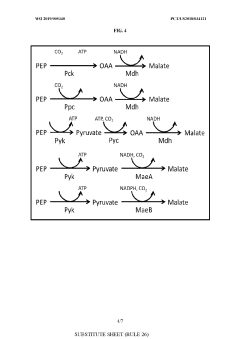

Genetically modified yeast with increased succinic acid production

PatentWO2019005340A1

Innovation

- Genetically modified yeast cells with altered metabolic pathways, including a reductive succinic acid pathway operational in the cytoplasm, enhanced pentose phosphate pathway activity, and a modified glyoxylate shunt, to facilitate succinic acid production and redox balance, utilizing enzymes like pyruvate kinase, malic enzyme, fumarase, and formate dehydrogenase to produce succinate in the cytoplasm.

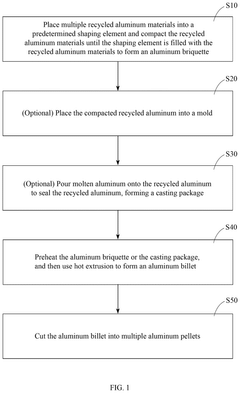

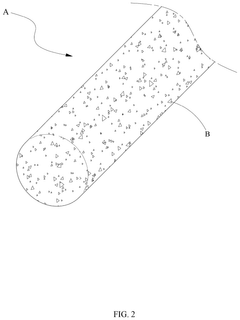

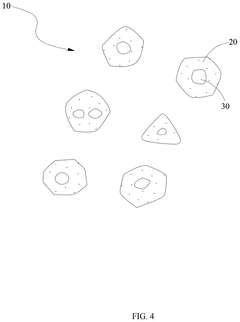

Aluminum alloy deoxidizer with carbon compounds

PatentPendingUS20240360527A1

Innovation

- An aluminum alloy deoxidizer with carbon compounds is developed, comprising elemental aluminum pellets with carbon or organic compounds, produced without melting, using recycled aluminum and incorporating additional elements like magnesium and silicon, which are cut into pellets with concave surfaces and hollow cavities to enhance deoxidation efficiency.

Environmental Impact Assessment of Sodium Acetate Usage

The environmental impact assessment of sodium acetate usage in circular economy models reveals both positive and negative effects on ecosystems and resource management. Sodium acetate, a versatile compound with applications in various industries, plays a significant role in sustainable practices due to its biodegradability and potential for recycling.

One of the primary environmental benefits of sodium acetate is its ability to reduce waste and promote resource efficiency. In circular economy models, sodium acetate can be recovered and reused in multiple cycles, minimizing the need for raw material extraction and reducing the overall environmental footprint of production processes. This closed-loop approach aligns with the principles of circular economy, contributing to the conservation of natural resources and energy.

However, the production and use of sodium acetate are not without environmental concerns. The manufacturing process may involve energy-intensive steps and the use of chemical precursors, potentially leading to greenhouse gas emissions and water pollution if not properly managed. Additionally, the disposal of sodium acetate-containing products at the end of their lifecycle requires careful consideration to prevent soil and water contamination.

In terms of biodegradability, sodium acetate offers advantages over many synthetic compounds. When released into the environment, it can be broken down by microorganisms into harmless components, reducing the long-term impact on ecosystems. This characteristic is particularly valuable in applications where the compound may come into contact with natural environments, such as in de-icing formulations or food preservation.

The use of sodium acetate in circular economy models also contributes to the reduction of landfill waste. By enabling the recovery and reuse of materials, it helps to extend the lifespan of products and resources, thereby decreasing the volume of waste sent to landfills. This not only conserves land but also mitigates the release of methane and other greenhouse gases associated with waste decomposition.

From a water management perspective, sodium acetate presents both opportunities and challenges. While its biodegradability reduces the risk of persistent water pollution, high concentrations in wastewater can lead to increased biological oxygen demand (BOD) in aquatic ecosystems. Proper wastewater treatment and monitoring are essential to mitigate these potential impacts and ensure the protection of water resources.

In conclusion, the environmental impact assessment of sodium acetate usage in circular economy models reveals a complex interplay of benefits and risks. While it offers significant advantages in terms of resource efficiency, waste reduction, and biodegradability, careful management and monitoring are necessary to minimize potential negative impacts on ecosystems and water resources. As circular economy practices continue to evolve, ongoing research and innovation in sodium acetate applications will be crucial to optimize its environmental performance and contribute to sustainable development goals.

One of the primary environmental benefits of sodium acetate is its ability to reduce waste and promote resource efficiency. In circular economy models, sodium acetate can be recovered and reused in multiple cycles, minimizing the need for raw material extraction and reducing the overall environmental footprint of production processes. This closed-loop approach aligns with the principles of circular economy, contributing to the conservation of natural resources and energy.

However, the production and use of sodium acetate are not without environmental concerns. The manufacturing process may involve energy-intensive steps and the use of chemical precursors, potentially leading to greenhouse gas emissions and water pollution if not properly managed. Additionally, the disposal of sodium acetate-containing products at the end of their lifecycle requires careful consideration to prevent soil and water contamination.

In terms of biodegradability, sodium acetate offers advantages over many synthetic compounds. When released into the environment, it can be broken down by microorganisms into harmless components, reducing the long-term impact on ecosystems. This characteristic is particularly valuable in applications where the compound may come into contact with natural environments, such as in de-icing formulations or food preservation.

The use of sodium acetate in circular economy models also contributes to the reduction of landfill waste. By enabling the recovery and reuse of materials, it helps to extend the lifespan of products and resources, thereby decreasing the volume of waste sent to landfills. This not only conserves land but also mitigates the release of methane and other greenhouse gases associated with waste decomposition.

From a water management perspective, sodium acetate presents both opportunities and challenges. While its biodegradability reduces the risk of persistent water pollution, high concentrations in wastewater can lead to increased biological oxygen demand (BOD) in aquatic ecosystems. Proper wastewater treatment and monitoring are essential to mitigate these potential impacts and ensure the protection of water resources.

In conclusion, the environmental impact assessment of sodium acetate usage in circular economy models reveals a complex interplay of benefits and risks. While it offers significant advantages in terms of resource efficiency, waste reduction, and biodegradability, careful management and monitoring are necessary to minimize potential negative impacts on ecosystems and water resources. As circular economy practices continue to evolve, ongoing research and innovation in sodium acetate applications will be crucial to optimize its environmental performance and contribute to sustainable development goals.

Policy Framework for Promoting Sodium Acetate in Circular Economy

The development of a comprehensive policy framework is crucial for promoting the adoption of sodium acetate in circular economy models. This framework should address various aspects of the circular economy, including production, consumption, waste management, and resource efficiency.

At the production level, policies should incentivize manufacturers to incorporate sodium acetate into their processes as a sustainable alternative to traditional materials. This can be achieved through tax breaks, grants, or subsidies for companies that demonstrate a significant reduction in their environmental footprint by using sodium acetate. Additionally, regulations should be implemented to encourage the use of sodium acetate in specific industries where it can replace more harmful substances.

Consumption-oriented policies should focus on raising awareness among consumers about the benefits of products containing sodium acetate. This can be done through eco-labeling schemes, public education campaigns, and partnerships with retailers to promote sustainable choices. Governments can also implement green procurement policies, prioritizing products that incorporate sodium acetate in public sector purchases.

Waste management policies play a critical role in the circular economy model for sodium acetate. Legislation should be enacted to mandate the proper collection and recycling of sodium acetate-containing products at the end of their lifecycle. This may include extended producer responsibility schemes, where manufacturers are responsible for the entire lifecycle of their products, including disposal and recycling.

To enhance resource efficiency, policies should promote research and development in sodium acetate applications. This can be achieved through funding programs, academic-industry partnerships, and the establishment of innovation hubs focused on circular economy solutions. Furthermore, regulations should be put in place to standardize the quality and purity of recycled sodium acetate, ensuring its suitability for reuse in various applications.

Cross-sector collaboration is essential for the success of these policies. Governments should create platforms for stakeholders from different industries to share knowledge and best practices related to sodium acetate use in circular economy models. This collaborative approach can lead to the development of more effective and innovative solutions.

Monitoring and evaluation mechanisms should be integrated into the policy framework to assess the impact of sodium acetate adoption on circular economy goals. This may include regular reporting requirements for businesses, lifecycle assessments of products, and the development of key performance indicators to measure progress towards a more circular economy.

At the production level, policies should incentivize manufacturers to incorporate sodium acetate into their processes as a sustainable alternative to traditional materials. This can be achieved through tax breaks, grants, or subsidies for companies that demonstrate a significant reduction in their environmental footprint by using sodium acetate. Additionally, regulations should be implemented to encourage the use of sodium acetate in specific industries where it can replace more harmful substances.

Consumption-oriented policies should focus on raising awareness among consumers about the benefits of products containing sodium acetate. This can be done through eco-labeling schemes, public education campaigns, and partnerships with retailers to promote sustainable choices. Governments can also implement green procurement policies, prioritizing products that incorporate sodium acetate in public sector purchases.

Waste management policies play a critical role in the circular economy model for sodium acetate. Legislation should be enacted to mandate the proper collection and recycling of sodium acetate-containing products at the end of their lifecycle. This may include extended producer responsibility schemes, where manufacturers are responsible for the entire lifecycle of their products, including disposal and recycling.

To enhance resource efficiency, policies should promote research and development in sodium acetate applications. This can be achieved through funding programs, academic-industry partnerships, and the establishment of innovation hubs focused on circular economy solutions. Furthermore, regulations should be put in place to standardize the quality and purity of recycled sodium acetate, ensuring its suitability for reuse in various applications.

Cross-sector collaboration is essential for the success of these policies. Governments should create platforms for stakeholders from different industries to share knowledge and best practices related to sodium acetate use in circular economy models. This collaborative approach can lead to the development of more effective and innovative solutions.

Monitoring and evaluation mechanisms should be integrated into the policy framework to assess the impact of sodium acetate adoption on circular economy goals. This may include regular reporting requirements for businesses, lifecycle assessments of products, and the development of key performance indicators to measure progress towards a more circular economy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!