Sodium Acetate's Role in Sustainable Integral Chemical Strategies

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate Overview and Sustainability Goals

Sodium acetate, a versatile compound with the chemical formula CH3COONa, plays a crucial role in sustainable integral chemical strategies. This salt of acetic acid and sodium hydroxide has gained significant attention in recent years due to its wide range of applications and potential for promoting sustainability in various industries.

The compound's unique properties make it an ideal candidate for sustainable practices. Sodium acetate is non-toxic, biodegradable, and can be produced from renewable resources, aligning with the principles of green chemistry. Its ability to act as a buffer, sequestering agent, and food preservative has led to its widespread use in food, pharmaceutical, and industrial applications.

In the context of sustainability, sodium acetate offers several advantages. Its production can be achieved through environmentally friendly processes, such as the fermentation of biomass or the neutralization of acetic acid with sodium hydroxide. These methods reduce reliance on fossil fuel-derived chemicals and minimize carbon footprint, contributing to the overall goal of sustainable chemical production.

One of the primary sustainability goals associated with sodium acetate is its potential to replace more harmful chemicals in various applications. For instance, in the textile industry, sodium acetate can be used as an eco-friendly alternative to conventional mordants, reducing the environmental impact of dyeing processes. Similarly, in de-icing applications, sodium acetate-based de-icers are less corrosive and more environmentally friendly compared to traditional chloride-based products.

The compound's role in energy storage and thermal management systems also aligns with sustainability objectives. Sodium acetate trihydrate, a phase change material, can store and release large amounts of latent heat, making it valuable in renewable energy systems and energy-efficient building designs. This property contributes to reducing energy consumption and promoting the use of clean energy sources.

Furthermore, sodium acetate's potential in carbon capture and utilization strategies is being explored. Its ability to form stable complexes with carbon dioxide opens up possibilities for developing novel CO2 sequestration technologies, addressing one of the most pressing environmental challenges of our time.

As industries strive to adopt more sustainable practices, the integration of sodium acetate into chemical processes and product formulations represents a step towards achieving circular economy principles. Its biodegradability ensures that it does not persist in the environment, reducing long-term ecological impacts. Additionally, the possibility of recovering and recycling sodium acetate from various processes further enhances its sustainability profile.

The compound's unique properties make it an ideal candidate for sustainable practices. Sodium acetate is non-toxic, biodegradable, and can be produced from renewable resources, aligning with the principles of green chemistry. Its ability to act as a buffer, sequestering agent, and food preservative has led to its widespread use in food, pharmaceutical, and industrial applications.

In the context of sustainability, sodium acetate offers several advantages. Its production can be achieved through environmentally friendly processes, such as the fermentation of biomass or the neutralization of acetic acid with sodium hydroxide. These methods reduce reliance on fossil fuel-derived chemicals and minimize carbon footprint, contributing to the overall goal of sustainable chemical production.

One of the primary sustainability goals associated with sodium acetate is its potential to replace more harmful chemicals in various applications. For instance, in the textile industry, sodium acetate can be used as an eco-friendly alternative to conventional mordants, reducing the environmental impact of dyeing processes. Similarly, in de-icing applications, sodium acetate-based de-icers are less corrosive and more environmentally friendly compared to traditional chloride-based products.

The compound's role in energy storage and thermal management systems also aligns with sustainability objectives. Sodium acetate trihydrate, a phase change material, can store and release large amounts of latent heat, making it valuable in renewable energy systems and energy-efficient building designs. This property contributes to reducing energy consumption and promoting the use of clean energy sources.

Furthermore, sodium acetate's potential in carbon capture and utilization strategies is being explored. Its ability to form stable complexes with carbon dioxide opens up possibilities for developing novel CO2 sequestration technologies, addressing one of the most pressing environmental challenges of our time.

As industries strive to adopt more sustainable practices, the integration of sodium acetate into chemical processes and product formulations represents a step towards achieving circular economy principles. Its biodegradability ensures that it does not persist in the environment, reducing long-term ecological impacts. Additionally, the possibility of recovering and recycling sodium acetate from various processes further enhances its sustainability profile.

Market Analysis for Sustainable Chemical Applications

The market for sustainable chemical applications has been experiencing significant growth in recent years, driven by increasing environmental concerns and regulatory pressures. Sodium acetate, a versatile compound with various industrial applications, is positioned to play a crucial role in this expanding market. The global sodium acetate market was valued at approximately $180 million in 2020 and is projected to reach $220 million by 2025, growing at a CAGR of 4.1% during the forecast period.

One of the key drivers for the growth of sodium acetate in sustainable chemical applications is its use as a green de-icing agent. Traditional de-icing chemicals, such as rock salt, have been associated with environmental damage and corrosion of infrastructure. Sodium acetate offers a more environmentally friendly alternative, as it is less corrosive and biodegradable. The aviation industry, in particular, has been adopting sodium acetate-based de-icers, contributing to market growth.

In the textile industry, sodium acetate is gaining traction as a sustainable mordant for dyeing processes. As consumers become more conscious of the environmental impact of their clothing choices, there is a growing demand for eco-friendly textile production methods. Sodium acetate's ability to improve dye fixation while reducing water and energy consumption aligns well with these sustainability goals.

The food industry represents another significant market for sodium acetate in sustainable applications. As a food preservative and acidity regulator, sodium acetate is increasingly being used as a natural alternative to synthetic additives. The clean label trend and consumer preference for natural ingredients are driving the adoption of sodium acetate in various food products.

In the pharmaceutical sector, sodium acetate is finding applications in sustainable drug formulations and as a buffering agent in intravenous fluids. The growing emphasis on green chemistry in pharmaceutical manufacturing is expected to further boost the demand for sodium acetate in this sector.

The construction industry is also exploring the use of sodium acetate in sustainable concrete admixtures. Research has shown that sodium acetate can improve the strength and durability of concrete while reducing its carbon footprint. As the construction sector faces pressure to reduce its environmental impact, such innovative applications of sodium acetate are likely to gain momentum.

Geographically, North America and Europe are currently the largest markets for sodium acetate in sustainable chemical applications, owing to stringent environmental regulations and high adoption rates of green technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization and increasing environmental awareness in countries like China and India.

One of the key drivers for the growth of sodium acetate in sustainable chemical applications is its use as a green de-icing agent. Traditional de-icing chemicals, such as rock salt, have been associated with environmental damage and corrosion of infrastructure. Sodium acetate offers a more environmentally friendly alternative, as it is less corrosive and biodegradable. The aviation industry, in particular, has been adopting sodium acetate-based de-icers, contributing to market growth.

In the textile industry, sodium acetate is gaining traction as a sustainable mordant for dyeing processes. As consumers become more conscious of the environmental impact of their clothing choices, there is a growing demand for eco-friendly textile production methods. Sodium acetate's ability to improve dye fixation while reducing water and energy consumption aligns well with these sustainability goals.

The food industry represents another significant market for sodium acetate in sustainable applications. As a food preservative and acidity regulator, sodium acetate is increasingly being used as a natural alternative to synthetic additives. The clean label trend and consumer preference for natural ingredients are driving the adoption of sodium acetate in various food products.

In the pharmaceutical sector, sodium acetate is finding applications in sustainable drug formulations and as a buffering agent in intravenous fluids. The growing emphasis on green chemistry in pharmaceutical manufacturing is expected to further boost the demand for sodium acetate in this sector.

The construction industry is also exploring the use of sodium acetate in sustainable concrete admixtures. Research has shown that sodium acetate can improve the strength and durability of concrete while reducing its carbon footprint. As the construction sector faces pressure to reduce its environmental impact, such innovative applications of sodium acetate are likely to gain momentum.

Geographically, North America and Europe are currently the largest markets for sodium acetate in sustainable chemical applications, owing to stringent environmental regulations and high adoption rates of green technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization and increasing environmental awareness in countries like China and India.

Current State and Challenges in Sodium Acetate Utilization

Sodium acetate has gained significant attention in recent years as a key component in sustainable integral chemical strategies. The current state of sodium acetate utilization is characterized by its widespread application across various industries, including textiles, food preservation, and pharmaceuticals. As a versatile compound, sodium acetate serves multiple functions, such as pH regulation, flavor enhancement, and as a buffering agent.

In the textile industry, sodium acetate is extensively used as a dyeing auxiliary, improving color fastness and fabric quality. Its role in food preservation has been well-established, with applications in extending the shelf life of various products. The pharmaceutical sector utilizes sodium acetate in drug formulations and as a buffering agent in intravenous solutions.

Despite its broad applications, the current utilization of sodium acetate faces several challenges. One primary concern is the environmental impact of its production and disposal. Traditional manufacturing processes often rely on petrochemical feedstocks, contributing to carbon emissions and resource depletion. This has led to a growing demand for more sustainable production methods.

Another significant challenge lies in optimizing the efficiency of sodium acetate in various applications. While its effectiveness is well-documented, there is room for improvement in terms of dosage requirements and overall performance. This is particularly crucial in industries where cost-effectiveness and resource optimization are paramount.

The scalability of sustainable sodium acetate production presents another hurdle. As demand increases, developing economically viable large-scale production methods that align with green chemistry principles becomes essential. This challenge is compounded by the need to maintain product quality and consistency across different batches and production scales.

Regulatory compliance and safety considerations also pose challenges in sodium acetate utilization. As environmental regulations become more stringent, industries must adapt their processes to meet new standards while maintaining product efficacy. This often requires significant investment in research and development to find alternative formulations or production methods.

The integration of sodium acetate into circular economy models represents both an opportunity and a challenge. While its potential for recycling and reuse is promising, developing efficient recovery and purification processes remains a technical hurdle. This aspect is crucial for maximizing the compound's sustainability profile and reducing waste in various industrial applications.

In conclusion, while sodium acetate plays a vital role in sustainable integral chemical strategies, its current utilization faces multifaceted challenges. Addressing these issues requires a concerted effort from researchers, industry stakeholders, and policymakers to drive innovation, improve efficiency, and enhance the overall sustainability of sodium acetate production and use.

In the textile industry, sodium acetate is extensively used as a dyeing auxiliary, improving color fastness and fabric quality. Its role in food preservation has been well-established, with applications in extending the shelf life of various products. The pharmaceutical sector utilizes sodium acetate in drug formulations and as a buffering agent in intravenous solutions.

Despite its broad applications, the current utilization of sodium acetate faces several challenges. One primary concern is the environmental impact of its production and disposal. Traditional manufacturing processes often rely on petrochemical feedstocks, contributing to carbon emissions and resource depletion. This has led to a growing demand for more sustainable production methods.

Another significant challenge lies in optimizing the efficiency of sodium acetate in various applications. While its effectiveness is well-documented, there is room for improvement in terms of dosage requirements and overall performance. This is particularly crucial in industries where cost-effectiveness and resource optimization are paramount.

The scalability of sustainable sodium acetate production presents another hurdle. As demand increases, developing economically viable large-scale production methods that align with green chemistry principles becomes essential. This challenge is compounded by the need to maintain product quality and consistency across different batches and production scales.

Regulatory compliance and safety considerations also pose challenges in sodium acetate utilization. As environmental regulations become more stringent, industries must adapt their processes to meet new standards while maintaining product efficacy. This often requires significant investment in research and development to find alternative formulations or production methods.

The integration of sodium acetate into circular economy models represents both an opportunity and a challenge. While its potential for recycling and reuse is promising, developing efficient recovery and purification processes remains a technical hurdle. This aspect is crucial for maximizing the compound's sustainability profile and reducing waste in various industrial applications.

In conclusion, while sodium acetate plays a vital role in sustainable integral chemical strategies, its current utilization faces multifaceted challenges. Addressing these issues requires a concerted effort from researchers, industry stakeholders, and policymakers to drive innovation, improve efficiency, and enhance the overall sustainability of sodium acetate production and use.

Existing Sustainable Applications of Sodium Acetate

01 Use of sodium acetate in chemical processes

Sodium acetate is widely used in various chemical processes as a reagent, catalyst, or buffer. It plays a role in reactions such as acetylation, esterification, and pH control. Its properties make it valuable in industrial applications and laboratory settings.- Use of sodium acetate in chemical processes: Sodium acetate is widely used in various chemical processes as a reagent, catalyst, or buffer. It plays a role in reactions such as acetylation, esterification, and pH control. Its properties make it valuable in industrial applications, particularly in organic synthesis and chemical manufacturing.

- Application in heat storage and thermal management: Sodium acetate trihydrate is utilized in heat storage systems and thermal management applications. It undergoes a phase change at specific temperatures, allowing it to store and release latent heat. This property is exploited in heat packs, building materials for temperature regulation, and energy storage systems.

- Use in food and beverage industry: Sodium acetate finds applications in the food and beverage industry as a preservative, acidity regulator, and flavoring agent. It helps extend shelf life, control pH, and enhance taste in various food products. Its use is regulated and approved by food safety authorities in many countries.

- Application in textile and leather processing: In the textile and leather industries, sodium acetate is used in dyeing processes, as a mordant, and for pH adjustment. It helps improve color fastness, fabric softness, and overall quality of the finished products. Its effectiveness in these applications is due to its buffering properties and interaction with dyes and fibers.

- Use in environmental and wastewater treatment: Sodium acetate is employed in environmental and wastewater treatment processes. It serves as a carbon source for biological denitrification, helps in heavy metal removal, and can be used in certain bioremediation applications. Its biodegradability and non-toxic nature make it suitable for these environmental applications.

02 Application in heat storage and thermal management

Sodium acetate trihydrate is utilized in heat storage systems and thermal management applications. It undergoes phase changes at specific temperatures, allowing it to store and release heat effectively. This property is exploited in heat packs, building materials, and energy storage systems.Expand Specific Solutions03 Use in food and pharmaceutical industries

Sodium acetate finds applications in food preservation and as a flavoring agent. In the pharmaceutical industry, it is used in drug formulations and as a buffering agent. Its safety profile and regulatory approval make it suitable for these sensitive applications.Expand Specific Solutions04 Environmental and waste treatment applications

Sodium acetate is employed in environmental remediation and waste treatment processes. It can be used in the treatment of industrial effluents, as a deicer for roads, and in certain bioremediation applications. Its biodegradability makes it an environmentally friendly option in some scenarios.Expand Specific Solutions05 Use in material science and manufacturing

In material science and manufacturing, sodium acetate is used in the production of certain polymers, as a component in specialty coatings, and in textile processing. It can modify material properties, act as a crosslinking agent, or serve as a precursor in the synthesis of other compounds.Expand Specific Solutions

Key Players in Sustainable Chemical Production

The market for sustainable integral chemical strategies involving sodium acetate is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Ecolab USA, Inc. and Sunamp Ltd. leading innovation in sustainable chemical solutions and thermal energy storage, respectively. Other key players such as Cognis Deutschland GmbH & Co. KG and Terra CO2 Technology Holdings, Inc. are contributing to the development of eco-friendly alternatives in various industrial applications. The competitive landscape is diverse, with both established chemical companies and innovative startups vying for market share in this evolving sector.

Ecolab USA, Inc.

Technical Solution: Ecolab has integrated sodium acetate into its sustainable cleaning and sanitizing solutions for various industries. The company utilizes sodium acetate's properties as a buffering agent and mild descaler in formulations designed for food and beverage processing, healthcare, and industrial applications. Ecolab's approach focuses on minimizing water and energy use while maximizing cleaning efficiency. Their proprietary technology incorporates sodium acetate into low-temperature cleaning solutions, reducing energy consumption by up to 40% compared to traditional hot water sanitizing methods[2]. Additionally, Ecolab has developed sodium acetate-based scale inhibitors for water treatment systems, extending equipment life and improving operational efficiency[4].

Strengths: Strong presence in institutional and industrial markets, expertise in water and hygiene solutions. Weaknesses: Reliance on chemical-intensive solutions may face scrutiny in increasingly environmentally conscious markets.

Celanese International Corp.

Technical Solution: Celanese has leveraged sodium acetate in its sustainable chemical strategies, particularly in the production of eco-friendly acetate fibers and films. The company has developed a proprietary process that uses sodium acetate as an intermediate in the production of cellulose acetate, a biodegradable material used in textiles, packaging, and filtration applications. This process reduces energy consumption and waste generation compared to traditional methods[7]. Celanese has also explored the use of sodium acetate in the development of green solvents for various industrial applications, aiming to replace more harmful alternatives. Additionally, the company has invested in research to utilize sodium acetate in the production of bio-based acetic acid, potentially reducing reliance on fossil fuel-derived feedstocks[8].

Strengths: Strong position in acetyl chain products, vertically integrated production capabilities. Weaknesses: Significant exposure to cyclical end markets may impact consistent investment in sustainability initiatives.

Innovative Uses of Sodium Acetate in Green Chemistry

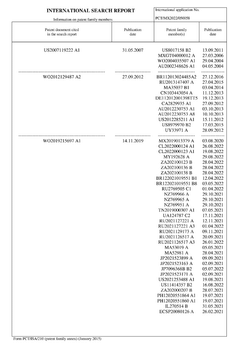

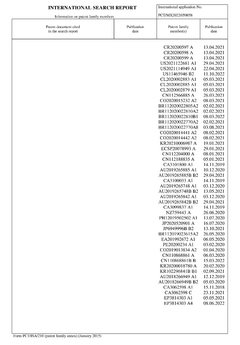

Formulation and method for obtaining nutritional acids from plants

PatentPendingEP4491026A1

Innovation

- Development of fertilizers based on acetates of potassium, calcium, magnesium, iron, zinc, manganese, and copper, which are highly efficient, stable, and environmentally friendly, minimizing nutrient losses and absorption challenges by using a formulation that includes potassium acetate, calcium acetate, magnesium acetate, iron acetate, zinc acetate, manganese acetate, copper acetate, and their bicarbonates, along with acetic acid, to enhance solubility and absorption without forming precipitates that clog application equipment.

Patent

Innovation

- Utilization of sodium acetate as a sustainable and eco-friendly alternative in chemical processes, reducing environmental impact.

- Development of integrated chemical strategies incorporating sodium acetate to enhance overall process efficiency and sustainability.

- Implementation of sodium acetate in closed-loop systems to minimize waste and maximize resource utilization.

Environmental Impact Assessment of Sodium Acetate

The environmental impact assessment of sodium acetate reveals both positive and negative aspects of its use in sustainable integral chemical strategies. On the positive side, sodium acetate is considered a relatively benign chemical compound with low toxicity to aquatic life and minimal bioaccumulation potential. Its biodegradability contributes to reduced long-term environmental persistence compared to many synthetic alternatives.

In terms of production, sodium acetate can be synthesized through environmentally friendly processes, such as the reaction of acetic acid with sodium carbonate or sodium hydroxide. These methods often utilize renewable resources and generate fewer harmful by-products compared to the production of more complex chemical compounds. Additionally, the use of sodium acetate in certain applications can lead to reduced energy consumption and greenhouse gas emissions.

However, the environmental impact of sodium acetate is not entirely negligible. Large-scale production and use can contribute to increased sodium levels in aquatic ecosystems, potentially affecting osmotic balance for some organisms. The compound's high solubility in water means it can easily enter waterways if not properly managed, leading to potential eutrophication issues in sensitive aquatic environments.

The production of sodium acetate also requires energy and resources, contributing to carbon emissions and resource depletion. While these impacts are generally lower than those associated with more complex chemicals, they are still a consideration in comprehensive environmental assessments. Furthermore, the transportation and distribution of sodium acetate contribute to the overall carbon footprint of its use in various applications.

In the context of waste management, sodium acetate presents both challenges and opportunities. Its high solubility can make it difficult to remove from wastewater streams using conventional treatment methods. However, its biodegradability allows for effective treatment in biological wastewater systems, potentially reducing the need for more energy-intensive chemical treatments.

When considering the life cycle assessment of products incorporating sodium acetate, it is important to evaluate the compound's role in extending product lifespans or improving efficiency. For instance, its use as a phase change material in thermal energy storage systems can lead to significant energy savings over time, potentially offsetting the environmental costs of its production and distribution.

The environmental impact of sodium acetate must also be considered in the broader context of chemical substitution. In many cases, sodium acetate serves as a more environmentally friendly alternative to harsher chemicals, contributing to overall reductions in environmental impact when viewed from a systems perspective. However, this substitution effect should be carefully evaluated on a case-by-case basis to ensure that unintended consequences are not overlooked.

In terms of production, sodium acetate can be synthesized through environmentally friendly processes, such as the reaction of acetic acid with sodium carbonate or sodium hydroxide. These methods often utilize renewable resources and generate fewer harmful by-products compared to the production of more complex chemical compounds. Additionally, the use of sodium acetate in certain applications can lead to reduced energy consumption and greenhouse gas emissions.

However, the environmental impact of sodium acetate is not entirely negligible. Large-scale production and use can contribute to increased sodium levels in aquatic ecosystems, potentially affecting osmotic balance for some organisms. The compound's high solubility in water means it can easily enter waterways if not properly managed, leading to potential eutrophication issues in sensitive aquatic environments.

The production of sodium acetate also requires energy and resources, contributing to carbon emissions and resource depletion. While these impacts are generally lower than those associated with more complex chemicals, they are still a consideration in comprehensive environmental assessments. Furthermore, the transportation and distribution of sodium acetate contribute to the overall carbon footprint of its use in various applications.

In the context of waste management, sodium acetate presents both challenges and opportunities. Its high solubility can make it difficult to remove from wastewater streams using conventional treatment methods. However, its biodegradability allows for effective treatment in biological wastewater systems, potentially reducing the need for more energy-intensive chemical treatments.

When considering the life cycle assessment of products incorporating sodium acetate, it is important to evaluate the compound's role in extending product lifespans or improving efficiency. For instance, its use as a phase change material in thermal energy storage systems can lead to significant energy savings over time, potentially offsetting the environmental costs of its production and distribution.

The environmental impact of sodium acetate must also be considered in the broader context of chemical substitution. In many cases, sodium acetate serves as a more environmentally friendly alternative to harsher chemicals, contributing to overall reductions in environmental impact when viewed from a systems perspective. However, this substitution effect should be carefully evaluated on a case-by-case basis to ensure that unintended consequences are not overlooked.

Regulatory Framework for Sustainable Chemicals

The regulatory framework for sustainable chemicals plays a crucial role in shaping the adoption and implementation of sustainable integral chemical strategies, including those involving sodium acetate. This framework encompasses a complex web of laws, regulations, and guidelines at national and international levels, designed to promote the development and use of environmentally friendly chemicals while minimizing risks to human health and the environment.

At the forefront of this regulatory landscape is the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation. REACH places the burden of proof on companies to demonstrate the safety of their chemical products, including sodium acetate when used in sustainable applications. This comprehensive approach requires manufacturers and importers to register their substances and provide detailed information on their properties, hazards, and potential risks.

In the United States, the Toxic Substances Control Act (TSCA), as amended by the Frank R. Lautenberg Chemical Safety for the 21st Century Act, provides the Environmental Protection Agency (EPA) with authority to regulate chemicals. The EPA's Safer Choice program encourages the use of safer chemical ingredients in products, which could potentially include sodium acetate in certain sustainable applications.

Globally, the United Nations' Strategic Approach to International Chemicals Management (SAICM) provides a policy framework to promote chemical safety around the world. This voluntary initiative aims to achieve the sound management of chemicals throughout their life cycle, aligning with sustainable development goals and supporting the transition to more sustainable chemical strategies.

Specific to sodium acetate and its role in sustainable integral chemical strategies, regulations often focus on its use in food applications, as it is widely used as a food additive. The Food and Drug Administration (FDA) in the US and the European Food Safety Authority (EFSA) in the EU have established guidelines for its safe use in food products. These regulations indirectly influence the development of sustainable strategies involving sodium acetate by ensuring its safety and acceptability in various applications.

Furthermore, as sustainability becomes increasingly important, new regulations are emerging that specifically target the promotion of green chemistry and sustainable chemical processes. For instance, the EU's Circular Economy Action Plan includes measures to encourage the design of sustainable chemicals and materials, which could potentially benefit sodium acetate-based strategies due to its biodegradability and low toxicity.

In conclusion, the regulatory framework for sustainable chemicals is a dynamic and evolving landscape that significantly influences the development and implementation of sustainable integral chemical strategies involving sodium acetate. As global efforts to promote sustainability intensify, it is likely that this regulatory framework will continue to evolve, potentially creating new opportunities and challenges for the use of sodium acetate in sustainable applications.

At the forefront of this regulatory landscape is the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation. REACH places the burden of proof on companies to demonstrate the safety of their chemical products, including sodium acetate when used in sustainable applications. This comprehensive approach requires manufacturers and importers to register their substances and provide detailed information on their properties, hazards, and potential risks.

In the United States, the Toxic Substances Control Act (TSCA), as amended by the Frank R. Lautenberg Chemical Safety for the 21st Century Act, provides the Environmental Protection Agency (EPA) with authority to regulate chemicals. The EPA's Safer Choice program encourages the use of safer chemical ingredients in products, which could potentially include sodium acetate in certain sustainable applications.

Globally, the United Nations' Strategic Approach to International Chemicals Management (SAICM) provides a policy framework to promote chemical safety around the world. This voluntary initiative aims to achieve the sound management of chemicals throughout their life cycle, aligning with sustainable development goals and supporting the transition to more sustainable chemical strategies.

Specific to sodium acetate and its role in sustainable integral chemical strategies, regulations often focus on its use in food applications, as it is widely used as a food additive. The Food and Drug Administration (FDA) in the US and the European Food Safety Authority (EFSA) in the EU have established guidelines for its safe use in food products. These regulations indirectly influence the development of sustainable strategies involving sodium acetate by ensuring its safety and acceptability in various applications.

Furthermore, as sustainability becomes increasingly important, new regulations are emerging that specifically target the promotion of green chemistry and sustainable chemical processes. For instance, the EU's Circular Economy Action Plan includes measures to encourage the design of sustainable chemicals and materials, which could potentially benefit sodium acetate-based strategies due to its biodegradability and low toxicity.

In conclusion, the regulatory framework for sustainable chemicals is a dynamic and evolving landscape that significantly influences the development and implementation of sustainable integral chemical strategies involving sodium acetate. As global efforts to promote sustainability intensify, it is likely that this regulatory framework will continue to evolve, potentially creating new opportunities and challenges for the use of sodium acetate in sustainable applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!