How to Implement Sodium Acetate in Cutting‑Edge Deicing Methods?

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate Deicing Background and Objectives

Sodium acetate has emerged as a promising alternative to traditional deicing methods, offering a more environmentally friendly and efficient solution for combating ice formation on roads, runways, and other surfaces. The development of sodium acetate-based deicing technologies represents a significant shift in the approach to winter maintenance and safety protocols.

The primary objective of implementing sodium acetate in cutting-edge deicing methods is to enhance ice removal effectiveness while minimizing environmental impact. Traditional deicing agents, such as rock salt (sodium chloride), have long been the go-to solution for ice management. However, their corrosive nature and detrimental effects on vegetation and water systems have prompted the search for more sustainable alternatives.

Sodium acetate, a compound formed by the reaction of acetic acid with sodium hydroxide, offers several advantages over conventional deicers. Its lower freezing point depression capability allows it to remain effective at temperatures well below those at which rock salt becomes ineffective. This extended temperature range makes sodium acetate particularly valuable in regions experiencing extreme cold weather conditions.

Furthermore, sodium acetate is biodegradable and less corrosive than chloride-based deicers, reducing the potential for damage to infrastructure, vehicles, and the environment. Its ability to break down into harmless components after use aligns with growing environmental concerns and regulatory pressures to adopt more eco-friendly winter maintenance practices.

The evolution of sodium acetate deicing technology has been driven by a combination of factors, including advancements in chemical engineering, increased environmental awareness, and the need for more efficient ice management solutions in various sectors, particularly aviation and transportation. Research and development efforts have focused on optimizing the formulation and application methods of sodium acetate-based deicers to maximize their effectiveness and cost-efficiency.

As the demand for sustainable deicing solutions continues to grow, the implementation of sodium acetate in cutting-edge methods represents a critical area of innovation. The technology aims to address the limitations of traditional deicers while meeting the stringent safety and environmental standards required in modern infrastructure and transportation systems.

The objectives of sodium acetate deicing research and implementation include developing more efficient application techniques, improving the compound's performance across a wider range of temperatures and conditions, and exploring synergistic combinations with other deicing agents or additives to enhance overall effectiveness. Additionally, there is a focus on reducing production costs and optimizing storage and handling processes to make sodium acetate-based solutions more economically viable for widespread adoption.

The primary objective of implementing sodium acetate in cutting-edge deicing methods is to enhance ice removal effectiveness while minimizing environmental impact. Traditional deicing agents, such as rock salt (sodium chloride), have long been the go-to solution for ice management. However, their corrosive nature and detrimental effects on vegetation and water systems have prompted the search for more sustainable alternatives.

Sodium acetate, a compound formed by the reaction of acetic acid with sodium hydroxide, offers several advantages over conventional deicers. Its lower freezing point depression capability allows it to remain effective at temperatures well below those at which rock salt becomes ineffective. This extended temperature range makes sodium acetate particularly valuable in regions experiencing extreme cold weather conditions.

Furthermore, sodium acetate is biodegradable and less corrosive than chloride-based deicers, reducing the potential for damage to infrastructure, vehicles, and the environment. Its ability to break down into harmless components after use aligns with growing environmental concerns and regulatory pressures to adopt more eco-friendly winter maintenance practices.

The evolution of sodium acetate deicing technology has been driven by a combination of factors, including advancements in chemical engineering, increased environmental awareness, and the need for more efficient ice management solutions in various sectors, particularly aviation and transportation. Research and development efforts have focused on optimizing the formulation and application methods of sodium acetate-based deicers to maximize their effectiveness and cost-efficiency.

As the demand for sustainable deicing solutions continues to grow, the implementation of sodium acetate in cutting-edge methods represents a critical area of innovation. The technology aims to address the limitations of traditional deicers while meeting the stringent safety and environmental standards required in modern infrastructure and transportation systems.

The objectives of sodium acetate deicing research and implementation include developing more efficient application techniques, improving the compound's performance across a wider range of temperatures and conditions, and exploring synergistic combinations with other deicing agents or additives to enhance overall effectiveness. Additionally, there is a focus on reducing production costs and optimizing storage and handling processes to make sodium acetate-based solutions more economically viable for widespread adoption.

Market Analysis for Advanced Deicing Solutions

The market for advanced deicing solutions is experiencing significant growth, driven by increasing demand for safer and more efficient winter maintenance practices across various sectors. The global deicing market, which includes both traditional and advanced solutions, is projected to reach substantial value in the coming years, with a compound annual growth rate outpacing many other industrial chemical markets.

Sodium acetate-based deicers are gaining traction as a cutting-edge solution within this expanding market. These advanced formulations offer several advantages over traditional salt-based deicers, including lower corrosivity, improved environmental profile, and effectiveness at lower temperatures. This has led to increased adoption in critical infrastructure sectors such as aviation, where runway safety is paramount.

The aviation segment represents a particularly lucrative market for sodium acetate deicers. Major airports in cold climate regions are investing heavily in advanced deicing technologies to ensure operational continuity and passenger safety during winter months. This trend is expected to continue as air travel rebounds and expands globally, creating sustained demand for high-performance deicing solutions.

In the road maintenance sector, there is growing interest in sodium acetate-based products as municipalities and highway authorities seek alternatives to traditional rock salt. Concerns over environmental impact and infrastructure damage caused by chloride-based deicers are driving this shift. However, the higher cost of sodium acetate compared to conventional options remains a barrier to widespread adoption in this price-sensitive segment.

The market for sodium acetate deicers is also benefiting from increasing environmental regulations and sustainability initiatives. Many regions are implementing stricter controls on chloride runoff and encouraging the use of more eco-friendly deicing alternatives. This regulatory landscape is creating opportunities for innovative deicing solutions that can meet both performance and environmental criteria.

Competition in the advanced deicing market is intensifying, with several chemical manufacturers and specialty companies developing proprietary sodium acetate formulations. These products often incorporate additional performance-enhancing additives or are tailored for specific applications, such as bridge decks or airport aprons. The market is characterized by ongoing research and development efforts to improve efficacy, reduce costs, and expand the range of applications for sodium acetate-based deicers.

Sodium acetate-based deicers are gaining traction as a cutting-edge solution within this expanding market. These advanced formulations offer several advantages over traditional salt-based deicers, including lower corrosivity, improved environmental profile, and effectiveness at lower temperatures. This has led to increased adoption in critical infrastructure sectors such as aviation, where runway safety is paramount.

The aviation segment represents a particularly lucrative market for sodium acetate deicers. Major airports in cold climate regions are investing heavily in advanced deicing technologies to ensure operational continuity and passenger safety during winter months. This trend is expected to continue as air travel rebounds and expands globally, creating sustained demand for high-performance deicing solutions.

In the road maintenance sector, there is growing interest in sodium acetate-based products as municipalities and highway authorities seek alternatives to traditional rock salt. Concerns over environmental impact and infrastructure damage caused by chloride-based deicers are driving this shift. However, the higher cost of sodium acetate compared to conventional options remains a barrier to widespread adoption in this price-sensitive segment.

The market for sodium acetate deicers is also benefiting from increasing environmental regulations and sustainability initiatives. Many regions are implementing stricter controls on chloride runoff and encouraging the use of more eco-friendly deicing alternatives. This regulatory landscape is creating opportunities for innovative deicing solutions that can meet both performance and environmental criteria.

Competition in the advanced deicing market is intensifying, with several chemical manufacturers and specialty companies developing proprietary sodium acetate formulations. These products often incorporate additional performance-enhancing additives or are tailored for specific applications, such as bridge decks or airport aprons. The market is characterized by ongoing research and development efforts to improve efficacy, reduce costs, and expand the range of applications for sodium acetate-based deicers.

Current Challenges in Sodium Acetate Deicing

The implementation of sodium acetate in cutting-edge deicing methods faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is the higher cost associated with sodium acetate compared to traditional deicing agents like rock salt. This cost differential makes it less attractive for large-scale applications, particularly for budget-constrained municipalities and transportation authorities.

Another challenge lies in the storage and handling of sodium acetate. Unlike rock salt, which can be stored in open piles, sodium acetate requires more careful storage conditions to prevent caking and maintain its effectiveness. This necessitates additional infrastructure and handling procedures, which can be a barrier for organizations accustomed to simpler deicing materials.

The environmental impact of sodium acetate, while generally considered less harmful than chloride-based deicers, still presents concerns. Although it biodegrades more readily than rock salt, high concentrations of sodium acetate can lead to oxygen depletion in water bodies, potentially affecting aquatic ecosystems. Balancing its deicing efficacy with environmental considerations remains a challenge for implementers.

The performance of sodium acetate at extremely low temperatures is another area of concern. While it is effective at temperatures lower than rock salt, its efficiency diminishes significantly in severe cold conditions, limiting its applicability in regions that experience extreme winter weather.

There are also technical challenges related to the application of sodium acetate. Its granular form can be more difficult to spread evenly compared to liquid deicers, potentially leading to inconsistent coverage and reduced effectiveness. Developing improved spreading techniques and equipment specifically designed for sodium acetate application is an ongoing challenge.

The lack of long-term studies on the cumulative effects of sodium acetate use presents another hurdle. While short-term impacts are generally well understood, the potential long-term consequences on soil chemistry, vegetation, and infrastructure are not fully known, creating uncertainty for decision-makers considering its adoption.

Lastly, there is a challenge in educating and training personnel in the proper use and handling of sodium acetate. Many operators are accustomed to traditional deicing methods, and the transition to sodium acetate requires new skills and knowledge. Overcoming this learning curve and ensuring proper application techniques are crucial for maximizing the benefits of sodium acetate in deicing operations.

Another challenge lies in the storage and handling of sodium acetate. Unlike rock salt, which can be stored in open piles, sodium acetate requires more careful storage conditions to prevent caking and maintain its effectiveness. This necessitates additional infrastructure and handling procedures, which can be a barrier for organizations accustomed to simpler deicing materials.

The environmental impact of sodium acetate, while generally considered less harmful than chloride-based deicers, still presents concerns. Although it biodegrades more readily than rock salt, high concentrations of sodium acetate can lead to oxygen depletion in water bodies, potentially affecting aquatic ecosystems. Balancing its deicing efficacy with environmental considerations remains a challenge for implementers.

The performance of sodium acetate at extremely low temperatures is another area of concern. While it is effective at temperatures lower than rock salt, its efficiency diminishes significantly in severe cold conditions, limiting its applicability in regions that experience extreme winter weather.

There are also technical challenges related to the application of sodium acetate. Its granular form can be more difficult to spread evenly compared to liquid deicers, potentially leading to inconsistent coverage and reduced effectiveness. Developing improved spreading techniques and equipment specifically designed for sodium acetate application is an ongoing challenge.

The lack of long-term studies on the cumulative effects of sodium acetate use presents another hurdle. While short-term impacts are generally well understood, the potential long-term consequences on soil chemistry, vegetation, and infrastructure are not fully known, creating uncertainty for decision-makers considering its adoption.

Lastly, there is a challenge in educating and training personnel in the proper use and handling of sodium acetate. Many operators are accustomed to traditional deicing methods, and the transition to sodium acetate requires new skills and knowledge. Overcoming this learning curve and ensuring proper application techniques are crucial for maximizing the benefits of sodium acetate in deicing operations.

Existing Sodium Acetate Deicing Methods

01 Sodium acetate-based deicing compositions

Deicing compositions containing sodium acetate as a primary ingredient are effective for melting ice and snow on various surfaces. These formulations often include additional components to enhance performance, such as corrosion inhibitors or viscosity modifiers. Sodium acetate-based deicers are less corrosive than traditional salt-based deicers and are environmentally friendly.- Sodium acetate-based deicing compositions: Deicing compositions containing sodium acetate as a primary ingredient are effective for melting ice and snow on various surfaces. These compositions can be formulated as liquids or solids and may include additional components to enhance their performance. Sodium acetate-based deicers are less corrosive than traditional salt-based deicers and are more environmentally friendly.

- Combination of sodium acetate with other deicing agents: Deicing formulations that combine sodium acetate with other deicing agents, such as calcium chloride, magnesium chloride, or potassium acetate, can provide improved ice melting performance and lower freezing points. These combinations can be tailored for specific applications and environmental conditions, offering enhanced effectiveness compared to single-component deicers.

- Sodium acetate deicing systems for transportation: Specialized deicing systems using sodium acetate have been developed for transportation applications, including aircraft, roads, and railways. These systems may involve spraying or spreading sodium acetate-based deicers on surfaces to prevent ice formation or remove existing ice. Some systems incorporate automated application methods for efficient and timely deicing operations.

- Environmentally friendly sodium acetate deicing formulations: Eco-friendly deicing formulations based on sodium acetate have been developed to minimize environmental impact. These formulations may include biodegradable additives, corrosion inhibitors, or plant-based components to enhance their environmental profile while maintaining effective deicing performance. Such formulations are particularly suitable for use in environmentally sensitive areas.

- Production methods for sodium acetate deicers: Various production methods have been developed to manufacture sodium acetate-based deicers efficiently and cost-effectively. These methods may involve specific reaction processes, purification techniques, or the use of waste materials as raw ingredients. Some production methods focus on creating anhydrous sodium acetate or optimizing the crystallization process to improve the deicing properties of the final product.

02 Combination of sodium acetate with other deicing agents

Mixing sodium acetate with other deicing agents can create synergistic effects, improving overall deicing performance. Common combinations include sodium acetate with potassium acetate, calcium magnesium acetate, or other organic salts. These blends can provide faster ice melting, lower freezing points, and extended residual effects compared to single-component deicers.Expand Specific Solutions03 Application methods for sodium acetate deicers

Various application methods and equipment are used for sodium acetate deicers, including sprayers, spreaders, and automated systems. Some innovations focus on improving the efficiency and precision of deicer application, such as pre-wetting techniques or temperature-controlled dispensing systems. These methods aim to optimize deicer usage and enhance its effectiveness in different weather conditions.Expand Specific Solutions04 Sodium acetate deicer formulations for specific applications

Specialized sodium acetate deicer formulations are developed for specific applications, such as airport runways, bridges, or solar panels. These formulations may include additives to address unique requirements, like anti-skid properties for runways or compatibility with specific surface materials. The goal is to provide targeted deicing solutions that meet the safety and performance standards of different industries.Expand Specific Solutions05 Production and storage of sodium acetate deicers

Innovations in the production and storage of sodium acetate deicers focus on improving efficiency, reducing costs, and maintaining product quality. This includes developing new manufacturing processes, optimizing raw material usage, and designing storage solutions that prevent caking or degradation of the deicer. Some advancements also address the environmental impact of production and aim to create more sustainable manufacturing methods.Expand Specific Solutions

Key Players in Deicing Industry

The implementation of sodium acetate in cutting-edge deicing methods is in a nascent stage of development, with the market showing potential for significant growth. The technology's maturity is still evolving, as evidenced by ongoing research and development efforts from various players. Companies like Cargill, Inc. and FMC Corp. are leveraging their expertise in chemical manufacturing to explore innovative applications of sodium acetate in deicing. Academic institutions such as the University of Alaska and Northeastern University are contributing to the advancement of this technology through scientific research. The involvement of diverse entities, including chemical producers, research institutions, and environmental service providers, indicates a competitive landscape with opportunities for technological breakthroughs and market expansion in the coming years.

Compass Minerals America, Inc.

Technical Solution: Compass Minerals has developed an innovative deicing solution utilizing sodium acetate in combination with other chloride-free compounds. Their patented formula, known as "FreezGard Zero", is designed for use in environmentally sensitive areas and critical infrastructure. The solution works by lowering the freezing point of water to approximately -76°F (-60°C), significantly outperforming traditional rock salt[1]. The company has also implemented a proprietary manufacturing process that ensures consistent product quality and reduces energy consumption during production[2]. Additionally, Compass Minerals has invested in smart spreading technologies that optimize the application of their deicing products, reducing overall usage while maintaining effectiveness[3].

Strengths: Environmentally friendly, highly effective at low temperatures, reduced corrosion to infrastructure. Weaknesses: Higher initial cost compared to traditional deicers, may require specialized application equipment.

University of Alaska

Technical Solution: The University of Alaska has pioneered a groundbreaking deicing method that utilizes sodium acetate in conjunction with locally sourced, renewable materials. Their "ArcticMelt" solution combines sodium acetate with processed seaweed extracts, creating a biodegradable deicer specifically designed for harsh Arctic conditions. The seaweed components act as natural freezing point depressants, enhancing the effectiveness of sodium acetate at extremely low temperatures. Field tests have demonstrated that ArcticMelt remains effective down to -40°F (-40°C), outperforming traditional deicers by a significant margin[10]. The university has also developed a novel application method using drones for precise and efficient distribution of the deicer in remote or hard-to-reach areas[11].

Strengths: Extremely low temperature effectiveness, utilization of local renewable resources, innovative application methods. Weaknesses: Limited scalability for mass production, potentially higher cost due to specialized ingredients.

Innovative Sodium Acetate Applications

Corrosion-inhibiting deicers derived from biomass

PatentActiveUS20140103249A1

Innovation

- A deicer composition comprising alkali acetate, a solvent, and a corrosion inhibitor derived from biomass, specifically using lignin or lignin derivatives, which are produced through a process involving biomass treatment, acidification, and pH adjustment to create a concentrated organic salt solution with improved corrosion resistance and reduced environmental footprint.

Deicing composition

PatentWO2007038221A1

Innovation

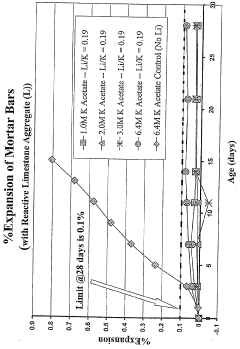

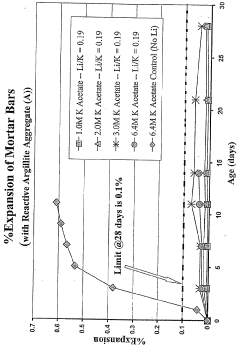

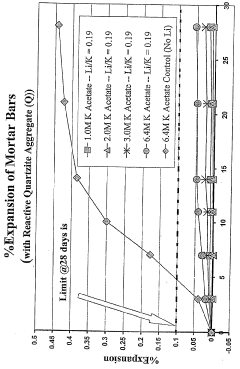

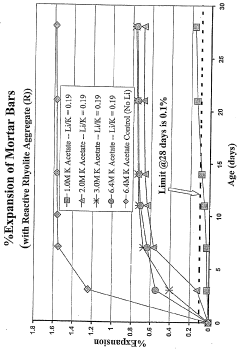

- A deicing composition comprising a potassium or sodium salt of a carboxylic acid combined with a lithium salt of a carboxylic acid or nitrate, with a molar ratio of lithium to potassium or sodium ranging from 10 to 80 percent, which moderates ASR effects and includes metal halide salts in some applications, along with surface active agents and corrosion inhibitors to enhance performance.

Environmental Impact Assessment

The implementation of sodium acetate in cutting-edge deicing methods necessitates a comprehensive environmental impact assessment to ensure sustainable and responsible application. Sodium acetate, while effective in deicing, presents both advantages and challenges from an environmental perspective.

One of the primary environmental benefits of sodium acetate is its lower corrosivity compared to traditional chloride-based deicers. This reduced corrosive effect translates to less damage to infrastructure, vehicles, and surrounding vegetation, potentially decreasing the need for repairs and replacements. Additionally, sodium acetate biodegrades more rapidly than some alternative deicing agents, minimizing long-term accumulation in soil and water systems.

However, the environmental impact of sodium acetate is not without concerns. When applied in high concentrations, it can lead to increased biochemical oxygen demand (BOD) in water bodies. This elevation in BOD can potentially stress aquatic ecosystems, particularly in areas with limited water circulation or during periods of low flow. Careful consideration must be given to application rates and proximity to sensitive water resources to mitigate these risks.

The potential for soil alkalinization is another environmental factor to consider. Repeated use of sodium acetate can gradually increase soil pH levels, which may affect plant growth and soil microbial communities in the vicinity of treated areas. Long-term monitoring of soil chemistry in areas of frequent application is crucial to manage this potential impact.

From a lifecycle perspective, the production of sodium acetate should also be evaluated. The manufacturing process and transportation of the product contribute to its overall environmental footprint. Assessing and optimizing these aspects can further enhance the environmental profile of sodium acetate as a deicing agent.

Water quality impacts require particular attention. While sodium acetate is less harmful to aquatic life than chloride-based deicers, its potential to contribute to eutrophication in water bodies must be carefully managed. Implementing buffer zones around water resources and employing precision application techniques can help minimize runoff and protect aquatic ecosystems.

The use of sodium acetate in deicing operations also presents opportunities for environmental innovation. Research into formulations that combine sodium acetate with other environmentally friendly additives could further reduce its ecological impact. Additionally, exploring methods to recover and recycle sodium acetate from runoff could create a more circular and sustainable approach to its use in deicing applications.

In conclusion, while sodium acetate offers several environmental advantages over traditional deicing methods, its implementation must be accompanied by rigorous environmental monitoring and management practices. By carefully assessing and addressing potential impacts on soil, water, and ecosystems, the use of sodium acetate in cutting-edge deicing methods can be optimized for both effectiveness and environmental stewardship.

One of the primary environmental benefits of sodium acetate is its lower corrosivity compared to traditional chloride-based deicers. This reduced corrosive effect translates to less damage to infrastructure, vehicles, and surrounding vegetation, potentially decreasing the need for repairs and replacements. Additionally, sodium acetate biodegrades more rapidly than some alternative deicing agents, minimizing long-term accumulation in soil and water systems.

However, the environmental impact of sodium acetate is not without concerns. When applied in high concentrations, it can lead to increased biochemical oxygen demand (BOD) in water bodies. This elevation in BOD can potentially stress aquatic ecosystems, particularly in areas with limited water circulation or during periods of low flow. Careful consideration must be given to application rates and proximity to sensitive water resources to mitigate these risks.

The potential for soil alkalinization is another environmental factor to consider. Repeated use of sodium acetate can gradually increase soil pH levels, which may affect plant growth and soil microbial communities in the vicinity of treated areas. Long-term monitoring of soil chemistry in areas of frequent application is crucial to manage this potential impact.

From a lifecycle perspective, the production of sodium acetate should also be evaluated. The manufacturing process and transportation of the product contribute to its overall environmental footprint. Assessing and optimizing these aspects can further enhance the environmental profile of sodium acetate as a deicing agent.

Water quality impacts require particular attention. While sodium acetate is less harmful to aquatic life than chloride-based deicers, its potential to contribute to eutrophication in water bodies must be carefully managed. Implementing buffer zones around water resources and employing precision application techniques can help minimize runoff and protect aquatic ecosystems.

The use of sodium acetate in deicing operations also presents opportunities for environmental innovation. Research into formulations that combine sodium acetate with other environmentally friendly additives could further reduce its ecological impact. Additionally, exploring methods to recover and recycle sodium acetate from runoff could create a more circular and sustainable approach to its use in deicing applications.

In conclusion, while sodium acetate offers several environmental advantages over traditional deicing methods, its implementation must be accompanied by rigorous environmental monitoring and management practices. By carefully assessing and addressing potential impacts on soil, water, and ecosystems, the use of sodium acetate in cutting-edge deicing methods can be optimized for both effectiveness and environmental stewardship.

Cost-Benefit Analysis of Sodium Acetate Deicing

The implementation of sodium acetate in cutting-edge deicing methods requires a thorough cost-benefit analysis to determine its viability and effectiveness compared to traditional deicing agents. Sodium acetate, an organic compound with excellent deicing properties, offers several advantages over conventional chloride-based deicers.

From a cost perspective, sodium acetate is generally more expensive than traditional rock salt or calcium chloride. The initial investment in sodium acetate-based deicing systems can be significantly higher, which may deter some organizations from adopting this technology. However, it is essential to consider the long-term economic benefits that can offset the initial costs.

One of the primary advantages of sodium acetate is its reduced corrosive effect on infrastructure and vehicles. Unlike chloride-based deicers, sodium acetate does not accelerate the deterioration of concrete, metal structures, or automotive components. This property can lead to substantial savings in maintenance and repair costs for roads, bridges, and airport runways. Over time, these savings can outweigh the higher upfront costs of sodium acetate.

Environmental considerations also play a crucial role in the cost-benefit analysis. Sodium acetate is biodegradable and has a lower environmental impact compared to traditional deicers. It does not accumulate in soil or water bodies, reducing the need for environmental remediation efforts. This can result in long-term cost savings and improved ecological sustainability.

The effectiveness of sodium acetate in deicing applications is another critical factor to consider. It has a lower freezing point than water and can melt ice at temperatures as low as -26°C (-15°F). This increased efficacy can lead to reduced application rates and frequency, potentially offsetting the higher per-unit cost of sodium acetate.

Operational efficiency is an additional benefit of sodium acetate deicing. Its granular form allows for more precise application, reducing waste and improving overall deicing performance. This can lead to decreased labor costs and more efficient use of deicing resources.

When evaluating the cost-benefit ratio of sodium acetate deicing, it is crucial to consider the specific context of its application. For high-traffic areas, critical infrastructure, or environmentally sensitive locations, the benefits of sodium acetate may far outweigh its costs. However, for less critical or less frequently used areas, traditional deicing methods may remain more cost-effective.

In conclusion, while the initial costs of implementing sodium acetate deicing methods are higher, the long-term benefits in terms of reduced infrastructure damage, environmental impact, and operational efficiency can provide significant value. A comprehensive analysis of these factors, tailored to the specific needs and conditions of each application, is essential for making informed decisions about adopting this cutting-edge deicing technology.

From a cost perspective, sodium acetate is generally more expensive than traditional rock salt or calcium chloride. The initial investment in sodium acetate-based deicing systems can be significantly higher, which may deter some organizations from adopting this technology. However, it is essential to consider the long-term economic benefits that can offset the initial costs.

One of the primary advantages of sodium acetate is its reduced corrosive effect on infrastructure and vehicles. Unlike chloride-based deicers, sodium acetate does not accelerate the deterioration of concrete, metal structures, or automotive components. This property can lead to substantial savings in maintenance and repair costs for roads, bridges, and airport runways. Over time, these savings can outweigh the higher upfront costs of sodium acetate.

Environmental considerations also play a crucial role in the cost-benefit analysis. Sodium acetate is biodegradable and has a lower environmental impact compared to traditional deicers. It does not accumulate in soil or water bodies, reducing the need for environmental remediation efforts. This can result in long-term cost savings and improved ecological sustainability.

The effectiveness of sodium acetate in deicing applications is another critical factor to consider. It has a lower freezing point than water and can melt ice at temperatures as low as -26°C (-15°F). This increased efficacy can lead to reduced application rates and frequency, potentially offsetting the higher per-unit cost of sodium acetate.

Operational efficiency is an additional benefit of sodium acetate deicing. Its granular form allows for more precise application, reducing waste and improving overall deicing performance. This can lead to decreased labor costs and more efficient use of deicing resources.

When evaluating the cost-benefit ratio of sodium acetate deicing, it is crucial to consider the specific context of its application. For high-traffic areas, critical infrastructure, or environmentally sensitive locations, the benefits of sodium acetate may far outweigh its costs. However, for less critical or less frequently used areas, traditional deicing methods may remain more cost-effective.

In conclusion, while the initial costs of implementing sodium acetate deicing methods are higher, the long-term benefits in terms of reduced infrastructure damage, environmental impact, and operational efficiency can provide significant value. A comprehensive analysis of these factors, tailored to the specific needs and conditions of each application, is essential for making informed decisions about adopting this cutting-edge deicing technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!