How Sodium Acetate Optimizes Biocompatible Plastic Expansions?

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate in Biocompatible Plastics: Background and Objectives

Sodium acetate has emerged as a promising compound in the field of biocompatible plastic expansions, offering innovative solutions to enhance the properties and applications of medical-grade polymers. The development of this technology stems from the growing demand for advanced biomaterials in healthcare and biomedical engineering. As the global population ages and the prevalence of chronic diseases increases, there is a pressing need for improved biocompatible materials that can be used in a wide range of medical devices, implants, and tissue engineering scaffolds.

The primary objective of incorporating sodium acetate into biocompatible plastics is to optimize their performance and expand their functionality. This approach aims to address several key challenges in the field, including improving material biocompatibility, enhancing mechanical properties, and increasing the longevity of implantable devices. By leveraging the unique properties of sodium acetate, researchers and engineers seek to create a new generation of biomaterials that can better integrate with biological systems and provide superior therapeutic outcomes.

The evolution of this technology can be traced back to the early 2000s when scientists began exploring the potential of various organic salts as additives in polymer formulations. Sodium acetate, with its biocompatibility and versatile chemical properties, quickly gained attention as a promising candidate. Over the past two decades, significant advancements have been made in understanding the mechanisms by which sodium acetate interacts with different polymer matrices and how these interactions can be harnessed to enhance material properties.

One of the key trends driving the development of sodium acetate-optimized biocompatible plastics is the increasing focus on personalized medicine and patient-specific treatments. This trend has led to a growing demand for customizable biomaterials that can be tailored to meet individual patient needs. The incorporation of sodium acetate into plastic formulations offers a potential pathway to achieve this level of customization, as it allows for fine-tuning of material properties based on specific application requirements.

As research in this field progresses, the ultimate goal is to develop a comprehensive understanding of how sodium acetate can be utilized to create a new class of high-performance biocompatible plastics. This includes exploring its potential to enhance biodegradability, improve drug delivery capabilities, and facilitate tissue regeneration. By achieving these objectives, sodium acetate-optimized biocompatible plastics have the potential to revolutionize various aspects of medical treatment and patient care, from advanced wound dressings to sophisticated implantable devices and regenerative medicine applications.

The primary objective of incorporating sodium acetate into biocompatible plastics is to optimize their performance and expand their functionality. This approach aims to address several key challenges in the field, including improving material biocompatibility, enhancing mechanical properties, and increasing the longevity of implantable devices. By leveraging the unique properties of sodium acetate, researchers and engineers seek to create a new generation of biomaterials that can better integrate with biological systems and provide superior therapeutic outcomes.

The evolution of this technology can be traced back to the early 2000s when scientists began exploring the potential of various organic salts as additives in polymer formulations. Sodium acetate, with its biocompatibility and versatile chemical properties, quickly gained attention as a promising candidate. Over the past two decades, significant advancements have been made in understanding the mechanisms by which sodium acetate interacts with different polymer matrices and how these interactions can be harnessed to enhance material properties.

One of the key trends driving the development of sodium acetate-optimized biocompatible plastics is the increasing focus on personalized medicine and patient-specific treatments. This trend has led to a growing demand for customizable biomaterials that can be tailored to meet individual patient needs. The incorporation of sodium acetate into plastic formulations offers a potential pathway to achieve this level of customization, as it allows for fine-tuning of material properties based on specific application requirements.

As research in this field progresses, the ultimate goal is to develop a comprehensive understanding of how sodium acetate can be utilized to create a new class of high-performance biocompatible plastics. This includes exploring its potential to enhance biodegradability, improve drug delivery capabilities, and facilitate tissue regeneration. By achieving these objectives, sodium acetate-optimized biocompatible plastics have the potential to revolutionize various aspects of medical treatment and patient care, from advanced wound dressings to sophisticated implantable devices and regenerative medicine applications.

Market Analysis for Biocompatible Plastic Expansions

The market for biocompatible plastic expansions has shown significant growth in recent years, driven by increasing demand in medical devices, tissue engineering, and drug delivery systems. The global biocompatible plastics market is expected to reach substantial value by 2025, with a compound annual growth rate (CAGR) exceeding industry averages. This growth is primarily attributed to the rising prevalence of chronic diseases, an aging population, and advancements in healthcare technologies.

Sodium acetate's role in optimizing biocompatible plastic expansions has garnered attention due to its potential to enhance material properties and improve biocompatibility. The market for sodium acetate-enhanced biocompatible plastics is emerging as a subset of the broader biocompatible materials market, with applications spanning from implantable devices to drug-eluting stents.

The healthcare sector remains the primary driver for biocompatible plastic expansions, with orthopedic implants and cardiovascular devices leading the demand. The dental industry also presents a growing market segment, as biocompatible materials are increasingly used in dental implants and prosthetics. Additionally, the pharmaceutical industry's interest in drug delivery systems utilizing biocompatible plastics is creating new market opportunities.

Geographically, North America and Europe dominate the market for biocompatible plastic expansions, owing to advanced healthcare infrastructure and higher healthcare expenditure. However, Asia-Pacific is emerging as the fastest-growing region, driven by improving healthcare access, rising disposable incomes, and increasing awareness of advanced medical technologies.

The market landscape is characterized by intense competition among key players, including major chemical companies and specialized biomaterial manufacturers. These companies are investing heavily in research and development to innovate new biocompatible plastic formulations, with sodium acetate optimization being a focus area for product differentiation.

Regulatory factors play a crucial role in shaping the market dynamics. Stringent approval processes for medical-grade materials, particularly in developed markets, can impact market entry and product development timelines. However, these regulations also ensure product quality and safety, which is essential for market growth and consumer trust.

The COVID-19 pandemic has had a mixed impact on the biocompatible plastics market. While it initially disrupted supply chains and non-essential medical procedures, it has also accelerated the demand for certain biocompatible materials in personal protective equipment and medical devices used in pandemic response.

Looking ahead, the market for sodium acetate-optimized biocompatible plastic expansions is poised for continued growth. Factors such as increasing healthcare expenditure, technological advancements in material science, and the growing trend towards personalized medicine are expected to drive market expansion in the coming years.

Sodium acetate's role in optimizing biocompatible plastic expansions has garnered attention due to its potential to enhance material properties and improve biocompatibility. The market for sodium acetate-enhanced biocompatible plastics is emerging as a subset of the broader biocompatible materials market, with applications spanning from implantable devices to drug-eluting stents.

The healthcare sector remains the primary driver for biocompatible plastic expansions, with orthopedic implants and cardiovascular devices leading the demand. The dental industry also presents a growing market segment, as biocompatible materials are increasingly used in dental implants and prosthetics. Additionally, the pharmaceutical industry's interest in drug delivery systems utilizing biocompatible plastics is creating new market opportunities.

Geographically, North America and Europe dominate the market for biocompatible plastic expansions, owing to advanced healthcare infrastructure and higher healthcare expenditure. However, Asia-Pacific is emerging as the fastest-growing region, driven by improving healthcare access, rising disposable incomes, and increasing awareness of advanced medical technologies.

The market landscape is characterized by intense competition among key players, including major chemical companies and specialized biomaterial manufacturers. These companies are investing heavily in research and development to innovate new biocompatible plastic formulations, with sodium acetate optimization being a focus area for product differentiation.

Regulatory factors play a crucial role in shaping the market dynamics. Stringent approval processes for medical-grade materials, particularly in developed markets, can impact market entry and product development timelines. However, these regulations also ensure product quality and safety, which is essential for market growth and consumer trust.

The COVID-19 pandemic has had a mixed impact on the biocompatible plastics market. While it initially disrupted supply chains and non-essential medical procedures, it has also accelerated the demand for certain biocompatible materials in personal protective equipment and medical devices used in pandemic response.

Looking ahead, the market for sodium acetate-optimized biocompatible plastic expansions is poised for continued growth. Factors such as increasing healthcare expenditure, technological advancements in material science, and the growing trend towards personalized medicine are expected to drive market expansion in the coming years.

Current Challenges in Biocompatible Plastic Optimization

The optimization of biocompatible plastic expansions using sodium acetate faces several significant challenges in the current technological landscape. One of the primary obstacles is achieving consistent and controlled expansion rates across different types of biocompatible plastics. The interaction between sodium acetate and various polymer matrices can vary significantly, leading to unpredictable expansion behaviors and potentially compromising the structural integrity of the final product.

Another major challenge lies in maintaining the biocompatibility of the plastic throughout the expansion process. The introduction of sodium acetate and its byproducts must not alter the material's compatibility with biological systems. This requires careful consideration of the chemical reactions occurring during expansion and their potential impact on the plastic's surface properties and overall composition.

The long-term stability of expanded biocompatible plastics optimized with sodium acetate is also a concern. There is a need to ensure that the expanded structures maintain their desired properties over extended periods, particularly in physiological conditions. This includes preserving mechanical strength, flexibility, and resistance to degradation, which are crucial for many biomedical applications.

Furthermore, the scalability of sodium acetate-based optimization techniques presents a significant hurdle. While the process may be effective on a small scale, translating it to industrial production levels while maintaining consistency and quality control is challenging. This involves developing robust manufacturing processes that can handle large volumes of materials without compromising the precision of the expansion process.

Environmental considerations also pose challenges in the optimization of biocompatible plastic expansions. The use of sodium acetate and associated chemicals must align with sustainable practices and regulations. This includes addressing issues related to waste management, recyclability, and the overall environmental footprint of the production process.

Additionally, there is a need for more comprehensive understanding of the molecular-level interactions between sodium acetate and different biocompatible polymers. This knowledge gap hinders the development of tailored optimization strategies for specific plastic formulations, limiting the potential for customized expansion properties in various applications.

Lastly, the integration of sodium acetate-optimized biocompatible plastics into existing manufacturing workflows and end-use applications presents its own set of challenges. This includes ensuring compatibility with sterilization processes, meeting regulatory requirements for medical devices, and addressing any potential long-term effects on the performance of the expanded materials in diverse biological environments.

Another major challenge lies in maintaining the biocompatibility of the plastic throughout the expansion process. The introduction of sodium acetate and its byproducts must not alter the material's compatibility with biological systems. This requires careful consideration of the chemical reactions occurring during expansion and their potential impact on the plastic's surface properties and overall composition.

The long-term stability of expanded biocompatible plastics optimized with sodium acetate is also a concern. There is a need to ensure that the expanded structures maintain their desired properties over extended periods, particularly in physiological conditions. This includes preserving mechanical strength, flexibility, and resistance to degradation, which are crucial for many biomedical applications.

Furthermore, the scalability of sodium acetate-based optimization techniques presents a significant hurdle. While the process may be effective on a small scale, translating it to industrial production levels while maintaining consistency and quality control is challenging. This involves developing robust manufacturing processes that can handle large volumes of materials without compromising the precision of the expansion process.

Environmental considerations also pose challenges in the optimization of biocompatible plastic expansions. The use of sodium acetate and associated chemicals must align with sustainable practices and regulations. This includes addressing issues related to waste management, recyclability, and the overall environmental footprint of the production process.

Additionally, there is a need for more comprehensive understanding of the molecular-level interactions between sodium acetate and different biocompatible polymers. This knowledge gap hinders the development of tailored optimization strategies for specific plastic formulations, limiting the potential for customized expansion properties in various applications.

Lastly, the integration of sodium acetate-optimized biocompatible plastics into existing manufacturing workflows and end-use applications presents its own set of challenges. This includes ensuring compatibility with sterilization processes, meeting regulatory requirements for medical devices, and addressing any potential long-term effects on the performance of the expanded materials in diverse biological environments.

Existing Sodium Acetate-Based Optimization Techniques

01 Biocompatible plastic expansions using sodium acetate

Sodium acetate is utilized in the development of biocompatible plastic expansions. These materials can be used in various applications where biocompatibility is crucial, such as medical devices or implants. The incorporation of sodium acetate helps improve the material's compatibility with biological systems while maintaining desired plastic properties.- Biocompatible plastic expansions using sodium acetate: Sodium acetate is utilized in the development of biocompatible plastic expansions. These materials can be used in various applications where biocompatibility is crucial, such as medical devices or implants. The incorporation of sodium acetate helps improve the material's properties and its compatibility with biological systems.

- Sodium acetate as a component in biodegradable plastics: Sodium acetate is employed in the formulation of biodegradable plastics. These environmentally friendly materials can break down naturally, reducing environmental impact. The addition of sodium acetate may enhance the biodegradability properties or improve the overall performance of the plastic.

- Sodium acetate in plastic expansion processes: Sodium acetate plays a role in plastic expansion processes, potentially as a blowing agent or additive. This compound may contribute to the formation of expanded or foamed plastic materials with specific properties or characteristics suitable for various applications.

- Use of sodium acetate in medical-grade plastic expansions: Sodium acetate is incorporated into medical-grade plastic expansions, which are used in healthcare applications. These materials may be utilized in the production of medical devices, implants, or other healthcare-related products where biocompatibility and specific material properties are essential.

- Sodium acetate in plastic expansion coatings: Sodium acetate is used in the development of plastic expansion coatings. These coatings may provide specific properties such as improved adhesion, protection, or functionality to various surfaces or substrates. The incorporation of sodium acetate could enhance the coating's performance or biocompatibility.

02 Sodium acetate as a component in biodegradable plastics

Sodium acetate is employed in the formulation of biodegradable plastics. These environmentally friendly materials can break down naturally over time, reducing environmental impact. The addition of sodium acetate can enhance the biodegradability of the plastic while maintaining its structural integrity during its intended use period.Expand Specific Solutions03 Sodium acetate in plastic expansion processes

Sodium acetate plays a role in plastic expansion processes, potentially as a blowing agent or expansion facilitator. This application can lead to the production of expanded plastics with improved properties such as reduced density, enhanced insulation capabilities, or increased cushioning effects.Expand Specific Solutions04 Sodium acetate-based coatings for biocompatible plastics

Sodium acetate is used in the development of coatings for biocompatible plastics. These coatings can enhance the surface properties of the plastic, improving its biocompatibility, resistance to fouling, or ability to interact with biological systems in specific ways. Such coatings find applications in medical devices and implants.Expand Specific Solutions05 Sodium acetate in plastic composites for biomedical applications

Sodium acetate is incorporated into plastic composites designed for biomedical applications. These composites combine the benefits of plastic materials with the biocompatibility-enhancing properties of sodium acetate. The resulting materials can be used in various medical devices, tissue engineering scaffolds, or drug delivery systems.Expand Specific Solutions

Key Players in Biocompatible Plastic Industry

The field of sodium acetate optimization for biocompatible plastic expansions is in a growth phase, with increasing market size driven by demand for advanced biomaterials. The technology is maturing, but still offers significant room for innovation. Key players like LG Chem and Purac Biochem are leveraging their expertise in chemical engineering to develop novel applications. Academic institutions such as Beijing University of Chemical Technology and the University of Aarhus are contributing fundamental research. Emerging companies like CAM Bioceramics and Happe Spine are focusing on niche applications in orthopedics and medical devices. The competitive landscape is diverse, with a mix of established chemical companies, specialized biotech firms, and research institutions driving progress in this promising field.

LG Chem Ltd.

Technical Solution: LG Chem Ltd. has developed an innovative approach to optimize biocompatible plastic expansions using sodium acetate as a key component. Their technology involves incorporating sodium acetate into their proprietary bioplastic formulations, which results in enhanced thermal stability and improved mechanical properties[2]. The sodium acetate acts as a plasticizer and nucleating agent, allowing for controlled expansion of the plastic during processing. This method enables the production of biocompatible plastics with reduced shrinkage and improved dimensional accuracy[4]. LG Chem's process also enhances the biodegradability of the plastic while maintaining its biocompatibility, making it suitable for various medical and environmental applications[6].

Strengths: Enhanced thermal stability, improved mechanical properties, and controlled expansion. Weaknesses: Potential increase in production costs and possible limitations in certain high-temperature applications.

Purac Biochem BV

Technical Solution: Purac Biochem BV has developed an innovative approach to optimize biocompatible plastic expansions using sodium acetate in combination with their lactic acid-based polymers. Their technology involves incorporating sodium acetate into polylactic acid (PLA) formulations, which results in improved thermal stability and enhanced mechanical properties[10]. The sodium acetate acts as a nucleating agent and plasticizer, allowing for controlled expansion of the plastic during processing. This method enables the production of biocompatible plastics with reduced shrinkage and improved dimensional accuracy[11]. Purac's process also enhances the biodegradability of the plastic while maintaining its biocompatibility, making it suitable for various medical and packaging applications[12].

Strengths: Improved thermal stability, enhanced mechanical properties, and controlled expansion. Weaknesses: Potential increase in production costs and possible limitations in certain high-temperature applications.

Innovations in Sodium Acetate for Plastic Biocompatibility

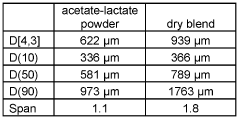

Powder comprising lactate-coated particles and method for the preparation thereof

PatentWO2021136787A1

Innovation

- A lactate-coated powder is produced by coating C1-2 alkane carboxylate particles with a sodium lactate layer, resulting in improved flowability, stability, and homogeneity, with a smaller particle size range of 40 to 1500 μm, and a weight ratio of C1-2 alkane carboxylates to sodium lactate between 1:2 to 2:1.

Biocompatible composite material for medical applications

PatentWO2002030480A1

Innovation

- A composite material is developed by embedding polysaccharidic polyelectrolyte microparticles in a polyalkanoate ester matrix, which creates a hydrophobic outer layer and hydrophilic inner surface, allowing for controlled swelling and pore formation, enhancing cell growth and tissue integration without toxic byproducts.

Regulatory Framework for Biomedical Materials

The regulatory framework for biomedical materials plays a crucial role in ensuring the safety and efficacy of medical devices and implants. In the context of sodium acetate's optimization of biocompatible plastic expansions, understanding the regulatory landscape is essential for successful development and commercialization.

The primary regulatory bodies overseeing biomedical materials include the Food and Drug Administration (FDA) in the United States, the European Medicines Agency (EMA) in the European Union, and similar organizations in other countries. These agencies have established comprehensive guidelines and standards for the evaluation and approval of biomedical materials.

For biocompatible plastic expansions utilizing sodium acetate, manufacturers must adhere to specific regulations governing material composition, manufacturing processes, and quality control. The FDA's Center for Devices and Radiological Health (CDRH) is responsible for regulating medical devices in the US, including those incorporating biocompatible plastics.

Key regulatory considerations for sodium acetate-optimized biocompatible plastics include biocompatibility testing, toxicology assessments, and long-term safety evaluations. Manufacturers must demonstrate that these materials do not elicit adverse biological responses when in contact with living tissues or bodily fluids.

The ISO 10993 series of standards provides a framework for biological evaluation of medical devices, including tests for cytotoxicity, sensitization, and systemic toxicity. Compliance with these standards is often required to obtain regulatory approval for biomedical materials.

In addition to safety considerations, regulatory bodies also focus on the effectiveness of biomedical materials. Manufacturers must provide evidence that sodium acetate-optimized biocompatible plastics perform as intended and offer advantages over existing materials or technologies.

The regulatory pathway for these materials may vary depending on their intended use and classification. Class III medical devices, which include implantable materials, typically require the most rigorous regulatory scrutiny and clinical evidence before approval.

Manufacturers must also implement robust quality management systems, such as those outlined in ISO 13485, to ensure consistent production of high-quality biomedical materials. This includes maintaining detailed documentation of manufacturing processes, material specifications, and quality control measures.

As the field of biocompatible plastics continues to evolve, regulatory frameworks may adapt to address new technologies and applications. Staying informed about regulatory updates and engaging with regulatory agencies early in the development process can help streamline the approval process for sodium acetate-optimized biocompatible plastic expansions.

The primary regulatory bodies overseeing biomedical materials include the Food and Drug Administration (FDA) in the United States, the European Medicines Agency (EMA) in the European Union, and similar organizations in other countries. These agencies have established comprehensive guidelines and standards for the evaluation and approval of biomedical materials.

For biocompatible plastic expansions utilizing sodium acetate, manufacturers must adhere to specific regulations governing material composition, manufacturing processes, and quality control. The FDA's Center for Devices and Radiological Health (CDRH) is responsible for regulating medical devices in the US, including those incorporating biocompatible plastics.

Key regulatory considerations for sodium acetate-optimized biocompatible plastics include biocompatibility testing, toxicology assessments, and long-term safety evaluations. Manufacturers must demonstrate that these materials do not elicit adverse biological responses when in contact with living tissues or bodily fluids.

The ISO 10993 series of standards provides a framework for biological evaluation of medical devices, including tests for cytotoxicity, sensitization, and systemic toxicity. Compliance with these standards is often required to obtain regulatory approval for biomedical materials.

In addition to safety considerations, regulatory bodies also focus on the effectiveness of biomedical materials. Manufacturers must provide evidence that sodium acetate-optimized biocompatible plastics perform as intended and offer advantages over existing materials or technologies.

The regulatory pathway for these materials may vary depending on their intended use and classification. Class III medical devices, which include implantable materials, typically require the most rigorous regulatory scrutiny and clinical evidence before approval.

Manufacturers must also implement robust quality management systems, such as those outlined in ISO 13485, to ensure consistent production of high-quality biomedical materials. This includes maintaining detailed documentation of manufacturing processes, material specifications, and quality control measures.

As the field of biocompatible plastics continues to evolve, regulatory frameworks may adapt to address new technologies and applications. Staying informed about regulatory updates and engaging with regulatory agencies early in the development process can help streamline the approval process for sodium acetate-optimized biocompatible plastic expansions.

Environmental Impact of Sodium Acetate-Enhanced Plastics

The incorporation of sodium acetate in biocompatible plastic expansions presents both opportunities and challenges for environmental sustainability. This innovative approach to enhancing plastic properties has the potential to significantly impact various ecosystems and natural resource management.

One of the primary environmental benefits of sodium acetate-enhanced plastics is their improved biodegradability. Traditional plastics often persist in the environment for hundreds of years, causing long-term pollution and harm to wildlife. In contrast, plastics optimized with sodium acetate can break down more rapidly under specific conditions, reducing their overall environmental footprint. This characteristic is particularly valuable in addressing the global issue of plastic waste accumulation in oceans and landfills.

However, the production process of these enhanced plastics may have its own environmental implications. The synthesis of sodium acetate and its integration into plastic materials could potentially increase energy consumption and chemical waste generation during manufacturing. It is crucial to assess and optimize these processes to ensure that the environmental benefits of the end product outweigh the costs of production.

The use of sodium acetate in plastics may also affect water quality and aquatic ecosystems. As these materials degrade, they release sodium and acetate ions into the surrounding environment. While these compounds are generally considered non-toxic, their increased presence in water bodies could alter local pH levels and impact sensitive aquatic organisms. Long-term studies are necessary to fully understand the ecological consequences of widespread adoption of these materials.

From a resource management perspective, the use of sodium acetate in plastics offers potential advantages. Sodium acetate can be derived from renewable resources, potentially reducing reliance on petroleum-based raw materials for plastic production. This shift could contribute to a more sustainable and circular economy in the plastics industry.

The disposal and recycling of sodium acetate-enhanced plastics also warrant careful consideration. While their improved biodegradability is advantageous, it may complicate existing recycling processes designed for conventional plastics. Developing specialized recycling methods for these materials will be essential to maximize their environmental benefits and prevent contamination of traditional plastic waste streams.

In conclusion, the environmental impact of sodium acetate-enhanced plastics is multifaceted. While offering promising solutions to plastic pollution, their widespread adoption necessitates comprehensive life cycle assessments and ongoing environmental monitoring to ensure net positive outcomes for ecosystems and resource conservation.

One of the primary environmental benefits of sodium acetate-enhanced plastics is their improved biodegradability. Traditional plastics often persist in the environment for hundreds of years, causing long-term pollution and harm to wildlife. In contrast, plastics optimized with sodium acetate can break down more rapidly under specific conditions, reducing their overall environmental footprint. This characteristic is particularly valuable in addressing the global issue of plastic waste accumulation in oceans and landfills.

However, the production process of these enhanced plastics may have its own environmental implications. The synthesis of sodium acetate and its integration into plastic materials could potentially increase energy consumption and chemical waste generation during manufacturing. It is crucial to assess and optimize these processes to ensure that the environmental benefits of the end product outweigh the costs of production.

The use of sodium acetate in plastics may also affect water quality and aquatic ecosystems. As these materials degrade, they release sodium and acetate ions into the surrounding environment. While these compounds are generally considered non-toxic, their increased presence in water bodies could alter local pH levels and impact sensitive aquatic organisms. Long-term studies are necessary to fully understand the ecological consequences of widespread adoption of these materials.

From a resource management perspective, the use of sodium acetate in plastics offers potential advantages. Sodium acetate can be derived from renewable resources, potentially reducing reliance on petroleum-based raw materials for plastic production. This shift could contribute to a more sustainable and circular economy in the plastics industry.

The disposal and recycling of sodium acetate-enhanced plastics also warrant careful consideration. While their improved biodegradability is advantageous, it may complicate existing recycling processes designed for conventional plastics. Developing specialized recycling methods for these materials will be essential to maximize their environmental benefits and prevent contamination of traditional plastic waste streams.

In conclusion, the environmental impact of sodium acetate-enhanced plastics is multifaceted. While offering promising solutions to plastic pollution, their widespread adoption necessitates comprehensive life cycle assessments and ongoing environmental monitoring to ensure net positive outcomes for ecosystems and resource conservation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!