Sodium Acetate in Food Industry: Efficiency and Safety

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate Overview

Sodium acetate, a versatile compound with the chemical formula CH3COONa, plays a significant role in the food industry. This salt of acetic acid is widely recognized for its multifaceted applications, ranging from flavor enhancement to preservation. As a food additive, it is commonly identified by its E number, E262.

The compound's history in food applications dates back several decades, with its use becoming increasingly prevalent due to its effectiveness and safety profile. Sodium acetate occurs naturally in many foods and is also produced synthetically for commercial use. Its production typically involves the neutralization of acetic acid with sodium hydroxide or sodium carbonate.

In the food industry, sodium acetate serves various functions. Primarily, it acts as a preservative, inhibiting the growth of bacteria and fungi, thus extending the shelf life of food products. Its ability to control acidity makes it valuable in maintaining the pH balance of foods, which is crucial for both taste and preservation. Additionally, sodium acetate contributes to flavor enhancement, particularly in savory foods, where it imparts a mild, salty taste.

The compound's efficiency in food applications is attributed to its unique chemical properties. Its high solubility in water allows for easy incorporation into various food matrices. The acetate ion, derived from sodium acetate, acts as a buffer, helping to stabilize pH levels in food products. This buffering action is particularly beneficial in processed foods, where maintaining consistent acidity is essential for quality and safety.

From a safety perspective, sodium acetate is generally recognized as safe (GRAS) by the U.S. Food and Drug Administration (FDA). Extensive toxicological studies have shown that it poses minimal risk when used within recommended levels. Its low toxicity profile makes it a preferred choice over some other preservatives, especially in products marketed as 'natural' or 'clean label'.

The use of sodium acetate extends beyond preservation and flavor enhancement. It finds applications in meat processing, where it helps in retaining moisture and improving texture. In bakery products, it contributes to dough conditioning and helps control mold growth. The compound is also used in dairy products, particularly in cheese production, where it aids in controlling acidity and enhancing flavor profiles.

As consumer preferences shift towards cleaner labels and more natural ingredients, the food industry is increasingly turning to compounds like sodium acetate. Its dual role as a preservative and flavor enhancer aligns well with the trend towards multifunctional ingredients. This trend is driving research into optimizing its use in various food applications, exploring new formulations, and studying its interactions with other food components.

The compound's history in food applications dates back several decades, with its use becoming increasingly prevalent due to its effectiveness and safety profile. Sodium acetate occurs naturally in many foods and is also produced synthetically for commercial use. Its production typically involves the neutralization of acetic acid with sodium hydroxide or sodium carbonate.

In the food industry, sodium acetate serves various functions. Primarily, it acts as a preservative, inhibiting the growth of bacteria and fungi, thus extending the shelf life of food products. Its ability to control acidity makes it valuable in maintaining the pH balance of foods, which is crucial for both taste and preservation. Additionally, sodium acetate contributes to flavor enhancement, particularly in savory foods, where it imparts a mild, salty taste.

The compound's efficiency in food applications is attributed to its unique chemical properties. Its high solubility in water allows for easy incorporation into various food matrices. The acetate ion, derived from sodium acetate, acts as a buffer, helping to stabilize pH levels in food products. This buffering action is particularly beneficial in processed foods, where maintaining consistent acidity is essential for quality and safety.

From a safety perspective, sodium acetate is generally recognized as safe (GRAS) by the U.S. Food and Drug Administration (FDA). Extensive toxicological studies have shown that it poses minimal risk when used within recommended levels. Its low toxicity profile makes it a preferred choice over some other preservatives, especially in products marketed as 'natural' or 'clean label'.

The use of sodium acetate extends beyond preservation and flavor enhancement. It finds applications in meat processing, where it helps in retaining moisture and improving texture. In bakery products, it contributes to dough conditioning and helps control mold growth. The compound is also used in dairy products, particularly in cheese production, where it aids in controlling acidity and enhancing flavor profiles.

As consumer preferences shift towards cleaner labels and more natural ingredients, the food industry is increasingly turning to compounds like sodium acetate. Its dual role as a preservative and flavor enhancer aligns well with the trend towards multifunctional ingredients. This trend is driving research into optimizing its use in various food applications, exploring new formulations, and studying its interactions with other food components.

Food Industry Demand

The food industry has witnessed a growing demand for sodium acetate due to its versatile applications and beneficial properties. As a food additive, sodium acetate serves multiple purposes, including preserving food, enhancing flavor, and regulating acidity. The increasing consumer preference for convenience foods and ready-to-eat meals has significantly contributed to the rising demand for sodium acetate in the food sector.

One of the primary drivers of sodium acetate demand is its effectiveness as a preservative. With the global population growth and urbanization, there is an escalating need for food products with extended shelf life. Sodium acetate's ability to inhibit microbial growth and maintain food quality aligns perfectly with this requirement, making it a sought-after ingredient in various food products, particularly in processed and packaged foods.

The expanding fast-food industry and the surge in demand for processed meats have further fueled the market for sodium acetate. Its role in enhancing flavor profiles and maintaining the texture of meat products has made it an essential component in the meat processing sector. Additionally, the growing popularity of convenience foods among the working population has led to increased usage of sodium acetate in ready-to-eat meals and snacks.

In the dairy industry, sodium acetate finds applications in cheese production, where it acts as an emulsifier and helps control acidity. The global rise in cheese consumption, particularly in developing economies, has contributed to the increased demand for sodium acetate in this segment.

The beverage industry also plays a significant role in driving the demand for sodium acetate. Its use as a flavoring agent and pH regulator in various drinks, including sports drinks and flavored water, has gained traction. The growing health consciousness among consumers and the subsequent rise in the consumption of functional beverages have indirectly boosted the demand for sodium acetate.

Furthermore, the clean label trend and consumer preference for natural ingredients have prompted food manufacturers to seek alternatives to synthetic additives. Sodium acetate, being derived from natural sources, aligns well with this trend, making it an attractive option for food producers aiming to meet consumer demands for cleaner labels.

The increasing focus on food safety and quality control measures across the food industry has also contributed to the rising demand for sodium acetate. Its ability to control microbial growth and extend shelf life without compromising food quality makes it a valuable ingredient in ensuring food safety standards are met.

One of the primary drivers of sodium acetate demand is its effectiveness as a preservative. With the global population growth and urbanization, there is an escalating need for food products with extended shelf life. Sodium acetate's ability to inhibit microbial growth and maintain food quality aligns perfectly with this requirement, making it a sought-after ingredient in various food products, particularly in processed and packaged foods.

The expanding fast-food industry and the surge in demand for processed meats have further fueled the market for sodium acetate. Its role in enhancing flavor profiles and maintaining the texture of meat products has made it an essential component in the meat processing sector. Additionally, the growing popularity of convenience foods among the working population has led to increased usage of sodium acetate in ready-to-eat meals and snacks.

In the dairy industry, sodium acetate finds applications in cheese production, where it acts as an emulsifier and helps control acidity. The global rise in cheese consumption, particularly in developing economies, has contributed to the increased demand for sodium acetate in this segment.

The beverage industry also plays a significant role in driving the demand for sodium acetate. Its use as a flavoring agent and pH regulator in various drinks, including sports drinks and flavored water, has gained traction. The growing health consciousness among consumers and the subsequent rise in the consumption of functional beverages have indirectly boosted the demand for sodium acetate.

Furthermore, the clean label trend and consumer preference for natural ingredients have prompted food manufacturers to seek alternatives to synthetic additives. Sodium acetate, being derived from natural sources, aligns well with this trend, making it an attractive option for food producers aiming to meet consumer demands for cleaner labels.

The increasing focus on food safety and quality control measures across the food industry has also contributed to the rising demand for sodium acetate. Its ability to control microbial growth and extend shelf life without compromising food quality makes it a valuable ingredient in ensuring food safety standards are met.

Current Applications

Sodium acetate has found widespread applications in the food industry, primarily due to its versatility as a preservative, flavor enhancer, and pH regulator. As a food additive, it is commonly known as E262 and is utilized in various food products to extend shelf life and improve taste profiles.

One of the most significant current applications of sodium acetate in the food industry is its use as a preservative. It effectively inhibits the growth of bacteria, molds, and yeasts, thereby extending the shelf life of processed foods. This property is particularly valuable in products such as baked goods, meats, and dairy items, where microbial growth can lead to spoilage and potential health risks.

In addition to its preservative properties, sodium acetate serves as a flavor enhancer in many food products. It imparts a mild, salty taste that can complement and intensify other flavors in a dish. This application is especially prevalent in snack foods, condiments, and prepared meals, where it contributes to a more complex and appealing flavor profile.

The pH regulating capabilities of sodium acetate make it an essential ingredient in various food processing applications. It acts as a buffering agent, helping to maintain a stable pH level in food products. This property is crucial in preventing undesirable changes in texture, color, and flavor that can occur due to pH fluctuations during storage or processing.

Sodium acetate also finds application in the production of modified food starches. It is used as a reagent in the acetylation process, which alters the properties of starches to improve their stability, texture, and functionality in food products. This modified starch is widely used in frozen foods, sauces, and baked goods to enhance texture and prevent syneresis.

In the meat processing industry, sodium acetate is employed as a curing agent and flavor enhancer. It contributes to the development of desirable flavors and aromas in cured meats while also aiding in moisture retention and improving overall product quality. This application is particularly important in the production of processed meats such as sausages, ham, and bacon.

The dairy industry also benefits from the use of sodium acetate, particularly in cheese production. It serves as an emulsifying salt, helping to improve the melting properties of processed cheeses and preventing the separation of fats and proteins. This application is crucial in producing consistent, high-quality cheese products with desirable texture and meltability.

Furthermore, sodium acetate is utilized in the production of various beverages, including sports drinks and energy drinks. In these applications, it functions as an electrolyte replacement and helps to balance the pH of the beverage, contributing to both the nutritional profile and taste of the final product.

One of the most significant current applications of sodium acetate in the food industry is its use as a preservative. It effectively inhibits the growth of bacteria, molds, and yeasts, thereby extending the shelf life of processed foods. This property is particularly valuable in products such as baked goods, meats, and dairy items, where microbial growth can lead to spoilage and potential health risks.

In addition to its preservative properties, sodium acetate serves as a flavor enhancer in many food products. It imparts a mild, salty taste that can complement and intensify other flavors in a dish. This application is especially prevalent in snack foods, condiments, and prepared meals, where it contributes to a more complex and appealing flavor profile.

The pH regulating capabilities of sodium acetate make it an essential ingredient in various food processing applications. It acts as a buffering agent, helping to maintain a stable pH level in food products. This property is crucial in preventing undesirable changes in texture, color, and flavor that can occur due to pH fluctuations during storage or processing.

Sodium acetate also finds application in the production of modified food starches. It is used as a reagent in the acetylation process, which alters the properties of starches to improve their stability, texture, and functionality in food products. This modified starch is widely used in frozen foods, sauces, and baked goods to enhance texture and prevent syneresis.

In the meat processing industry, sodium acetate is employed as a curing agent and flavor enhancer. It contributes to the development of desirable flavors and aromas in cured meats while also aiding in moisture retention and improving overall product quality. This application is particularly important in the production of processed meats such as sausages, ham, and bacon.

The dairy industry also benefits from the use of sodium acetate, particularly in cheese production. It serves as an emulsifying salt, helping to improve the melting properties of processed cheeses and preventing the separation of fats and proteins. This application is crucial in producing consistent, high-quality cheese products with desirable texture and meltability.

Furthermore, sodium acetate is utilized in the production of various beverages, including sports drinks and energy drinks. In these applications, it functions as an electrolyte replacement and helps to balance the pH of the beverage, contributing to both the nutritional profile and taste of the final product.

Existing Usage Methods

01 Efficiency in heat storage applications

Sodium acetate is utilized in heat storage systems due to its high latent heat of fusion and phase change properties. It can efficiently store and release thermal energy, making it suitable for various applications including heating and cooling systems.- Efficiency in heat storage applications: Sodium acetate is utilized in heat storage systems due to its high latent heat of fusion and phase change properties. It can efficiently store and release thermal energy, making it suitable for various applications including heating and cooling systems.

- Safety in food preservation: Sodium acetate is widely used as a food preservative due to its antimicrobial properties and low toxicity. It helps extend the shelf life of various food products while maintaining food safety standards.

- Environmental applications: Sodium acetate is employed in environmental protection applications, such as wastewater treatment and air purification. It can effectively remove contaminants and neutralize harmful substances, contributing to improved environmental safety.

- Industrial process efficiency: In various industrial processes, sodium acetate is used to enhance efficiency and product quality. It serves as a buffering agent, pH regulator, and catalyst in chemical reactions, improving overall process performance and yield.

- Safety in pharmaceutical applications: Sodium acetate is utilized in pharmaceutical formulations due to its safety profile and compatibility with various drug compounds. It acts as a buffering agent, stabilizer, and diluent in drug preparations, ensuring product efficacy and patient safety.

02 Safety in food preservation

Sodium acetate is widely used as a food preservative due to its antimicrobial properties and low toxicity. It helps extend the shelf life of various food products while maintaining food safety standards.Expand Specific Solutions03 Environmental applications

Sodium acetate is employed in environmental protection applications, such as wastewater treatment and air purification. It can effectively remove contaminants and neutralize acidic substances, contributing to pollution control and environmental safety.Expand Specific Solutions04 Industrial process efficiency

In various industrial processes, sodium acetate is used to enhance efficiency and product quality. It serves as a buffering agent, pH regulator, and catalyst in chemical reactions, improving overall process performance and yield.Expand Specific Solutions05 Safety in pharmaceutical applications

Sodium acetate is utilized in pharmaceutical formulations due to its safety profile and versatile properties. It acts as a buffering agent, stabilizer, and diluent in various drug preparations, ensuring product stability and efficacy.Expand Specific Solutions

Key Industry Players

The sodium acetate market in the food industry is in a mature stage, characterized by established players and steady growth. The global market size is estimated to be in the hundreds of millions of dollars, driven by increasing demand for food preservatives and flavor enhancers. Technologically, sodium acetate production is well-developed, with major companies like Cargill, Unilever, and Purac Biochem leading in innovation and production efficiency. These industry giants, along with specialized firms such as Nantong Acetic Acid Chemical and IsoAge Technologies, are continuously improving product quality and exploring new applications, indicating a competitive landscape focused on incremental advancements rather than disruptive innovations.

Cargill, Inc.

Technical Solution: Cargill has developed a proprietary sodium acetate production process that enhances efficiency and purity. Their method involves the controlled reaction of acetic acid with sodium hydroxide, followed by advanced purification techniques. This results in high-quality sodium acetate with a purity level exceeding 99.5%[1]. The company has also implemented a closed-loop system that recycles water and minimizes waste, reducing environmental impact. Cargill's sodium acetate is widely used in the food industry as a preservative and flavor enhancer, particularly in bakery products, snacks, and processed meats[2]. Their production facilities are equipped with state-of-the-art quality control measures, ensuring consistent product quality and safety.

Strengths: High purity product, environmentally friendly production process, consistent quality. Weaknesses: Potentially higher production costs due to advanced purification techniques, limited to food-grade applications.

Frito-Lay North America, Inc.

Technical Solution: Frito-Lay has innovated in the application of sodium acetate in snack food production. They have developed a patented process that incorporates sodium acetate into their seasoning blends, enhancing flavor retention and extending shelf life[3]. This method involves micro-encapsulation of sodium acetate particles, which allows for controlled release of the compound during consumption. The company has also explored the use of sodium acetate as a natural preservative in their "clean label" product lines, addressing consumer demand for fewer artificial ingredients[4]. Frito-Lay's research has shown that their sodium acetate application can reduce the need for other artificial preservatives by up to 30% in certain snack products.

Strengths: Innovative application in snack foods, improved flavor retention, supports clean label initiatives. Weaknesses: Limited to snack food applications, may require consumer education on the benefits of sodium acetate.

Safety Innovations

Acetate powder and method for the preparation thereof

PatentWO2019091970A1

Innovation

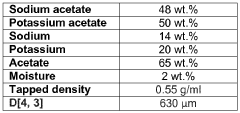

- A process involving the production of coated acetate particles with a high sodium acetate core and a potassium acetate coating, achieving a stable and free-flowing powder with a specific molar ratio and particle size range, which is achieved through a fluidized bed spray coating and drying method.

<p>Practical methods for preserving food products</p>

PatentPendingTH2101004027A

Innovation

- Combining sodium acetate with phosphate compounds for enhanced food preservation.

- Using high-temperature liquid (80°C or higher) containing sodium acetate and phosphates for food treatment.

- Addition of glycine to the preservation liquid to maintain food flavor while achieving antimicrobial effects.

Regulatory Framework

The regulatory framework surrounding sodium acetate in the food industry is complex and multifaceted, involving various international and national bodies. The Food and Drug Administration (FDA) in the United States classifies sodium acetate as Generally Recognized as Safe (GRAS), allowing its use in food products within specified limits. The European Food Safety Authority (EFSA) has also evaluated sodium acetate and approved its use as a food additive, designating it with the E-number E262.

In the European Union, Regulation (EC) No 1333/2008 on food additives provides the overarching framework for the use of sodium acetate. This regulation sets out the conditions under which food additives may be used, including maximum levels and specific food categories. The Joint FAO/WHO Expert Committee on Food Additives (JECFA) has established an Acceptable Daily Intake (ADI) for sodium acetate, which guides regulatory bodies worldwide in setting safe consumption levels.

Many countries have adopted these international standards into their national regulations. For instance, in Canada, sodium acetate is regulated under the Food and Drug Regulations, where it is listed as a permitted food additive. Similarly, Australia and New Zealand regulate sodium acetate through the Food Standards Code, which specifies its permitted uses and maximum levels in various food categories.

Regulatory bodies also require manufacturers to adhere to Good Manufacturing Practices (GMP) when using sodium acetate in food production. This ensures that the additive is used at levels no higher than necessary to achieve its intended technical effect. Additionally, labeling requirements mandate that sodium acetate be declared in the list of ingredients on food packaging, allowing consumers to make informed choices.

The regulatory landscape for sodium acetate is not static. Ongoing research and safety assessments may lead to updates in regulations. For example, the FDA periodically reviews the safety of food additives, and new scientific evidence can prompt reassessment of existing approvals. Similarly, the EFSA conducts re-evaluations of food additives on a regular basis to ensure their continued safety in light of new scientific data.

Compliance with these regulations is crucial for food manufacturers. Failure to adhere to prescribed limits or proper usage guidelines can result in product recalls, fines, or other regulatory actions. As such, companies operating in the food industry must stay informed about the latest regulatory developments and adjust their practices accordingly to ensure both efficiency and safety in the use of sodium acetate.

In the European Union, Regulation (EC) No 1333/2008 on food additives provides the overarching framework for the use of sodium acetate. This regulation sets out the conditions under which food additives may be used, including maximum levels and specific food categories. The Joint FAO/WHO Expert Committee on Food Additives (JECFA) has established an Acceptable Daily Intake (ADI) for sodium acetate, which guides regulatory bodies worldwide in setting safe consumption levels.

Many countries have adopted these international standards into their national regulations. For instance, in Canada, sodium acetate is regulated under the Food and Drug Regulations, where it is listed as a permitted food additive. Similarly, Australia and New Zealand regulate sodium acetate through the Food Standards Code, which specifies its permitted uses and maximum levels in various food categories.

Regulatory bodies also require manufacturers to adhere to Good Manufacturing Practices (GMP) when using sodium acetate in food production. This ensures that the additive is used at levels no higher than necessary to achieve its intended technical effect. Additionally, labeling requirements mandate that sodium acetate be declared in the list of ingredients on food packaging, allowing consumers to make informed choices.

The regulatory landscape for sodium acetate is not static. Ongoing research and safety assessments may lead to updates in regulations. For example, the FDA periodically reviews the safety of food additives, and new scientific evidence can prompt reassessment of existing approvals. Similarly, the EFSA conducts re-evaluations of food additives on a regular basis to ensure their continued safety in light of new scientific data.

Compliance with these regulations is crucial for food manufacturers. Failure to adhere to prescribed limits or proper usage guidelines can result in product recalls, fines, or other regulatory actions. As such, companies operating in the food industry must stay informed about the latest regulatory developments and adjust their practices accordingly to ensure both efficiency and safety in the use of sodium acetate.

Environmental Impact

The use of sodium acetate in the food industry has significant environmental implications that warrant careful consideration. As a food additive and preservative, sodium acetate's production, application, and disposal can impact various aspects of the environment.

In terms of production, the manufacturing process of sodium acetate typically involves the reaction of acetic acid with sodium hydroxide or sodium carbonate. This process requires energy inputs and may result in emissions of greenhouse gases, depending on the energy source used. Additionally, the production of raw materials, particularly acetic acid, can have its own environmental footprint, including potential air and water pollution if not properly managed.

The application of sodium acetate in food products generally has minimal direct environmental impact during use. However, its role in extending the shelf life of food products can indirectly contribute to reducing food waste, which is a significant environmental concern. By preserving food for longer periods, sodium acetate may help decrease the amount of spoiled food that ends up in landfills, thus potentially reducing methane emissions from decomposing organic matter.

Disposal of food products containing sodium acetate does not typically pose significant environmental risks, as the compound is biodegradable and non-toxic at the concentrations used in food. However, the packaging materials used for these food products can contribute to environmental issues if not properly recycled or disposed of.

From a broader perspective, the use of sodium acetate in food preservation can impact transportation and storage requirements for food products. By extending shelf life, it may reduce the need for frequent transportation and cold storage, potentially leading to lower energy consumption and reduced carbon emissions in the food supply chain.

Water usage and wastewater management are also important considerations in the environmental impact assessment of sodium acetate. The production process may require significant water inputs, and proper treatment of wastewater from manufacturing facilities is crucial to prevent water pollution and protect aquatic ecosystems.

In terms of biodiversity, the direct impact of sodium acetate is generally low. However, indirect effects through the food industry's practices and supply chain can influence land use patterns and potentially affect natural habitats.

As the food industry continues to evolve, there is growing interest in sustainable alternatives and green chemistry approaches to food preservation. Research into more environmentally friendly production methods for sodium acetate, as well as exploration of natural preservatives, may help mitigate some of the environmental concerns associated with its use.

In terms of production, the manufacturing process of sodium acetate typically involves the reaction of acetic acid with sodium hydroxide or sodium carbonate. This process requires energy inputs and may result in emissions of greenhouse gases, depending on the energy source used. Additionally, the production of raw materials, particularly acetic acid, can have its own environmental footprint, including potential air and water pollution if not properly managed.

The application of sodium acetate in food products generally has minimal direct environmental impact during use. However, its role in extending the shelf life of food products can indirectly contribute to reducing food waste, which is a significant environmental concern. By preserving food for longer periods, sodium acetate may help decrease the amount of spoiled food that ends up in landfills, thus potentially reducing methane emissions from decomposing organic matter.

Disposal of food products containing sodium acetate does not typically pose significant environmental risks, as the compound is biodegradable and non-toxic at the concentrations used in food. However, the packaging materials used for these food products can contribute to environmental issues if not properly recycled or disposed of.

From a broader perspective, the use of sodium acetate in food preservation can impact transportation and storage requirements for food products. By extending shelf life, it may reduce the need for frequent transportation and cold storage, potentially leading to lower energy consumption and reduced carbon emissions in the food supply chain.

Water usage and wastewater management are also important considerations in the environmental impact assessment of sodium acetate. The production process may require significant water inputs, and proper treatment of wastewater from manufacturing facilities is crucial to prevent water pollution and protect aquatic ecosystems.

In terms of biodiversity, the direct impact of sodium acetate is generally low. However, indirect effects through the food industry's practices and supply chain can influence land use patterns and potentially affect natural habitats.

As the food industry continues to evolve, there is growing interest in sustainable alternatives and green chemistry approaches to food preservation. Research into more environmentally friendly production methods for sodium acetate, as well as exploration of natural preservatives, may help mitigate some of the environmental concerns associated with its use.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!