Sodium Acetate for Optimized Tissue Engineering Processes

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate in TE: Background and Objectives

Sodium acetate has emerged as a promising compound in the field of tissue engineering (TE), offering potential to optimize various processes critical to the development of engineered tissues. The background of sodium acetate in TE traces back to its fundamental role in cellular metabolism and its widespread use in biological research. As a salt formed from acetic acid and sodium hydroxide, sodium acetate has been traditionally utilized in cell culture media and buffer solutions due to its ability to maintain pH balance and provide a source of acetate ions.

The evolution of tissue engineering has led researchers to explore novel approaches for enhancing cell growth, differentiation, and tissue formation. In this context, sodium acetate has gained attention for its multifaceted properties that align with the objectives of optimized tissue engineering processes. One key aspect is its potential to serve as a metabolic substrate, providing an alternative energy source for cells under specific conditions. This property is particularly relevant in scenarios where glucose availability may be limited or where metabolic modulation is desired.

Furthermore, sodium acetate has demonstrated the ability to influence cellular behavior and tissue development through various mechanisms. Studies have shown that it can affect gene expression patterns, potentially guiding cell differentiation and tissue-specific functions. Its role in epigenetic regulation, particularly through its involvement in histone acetylation processes, opens up new avenues for controlling cell fate and tissue organization.

The objectives of researching sodium acetate in tissue engineering are multifaceted and ambitious. Primarily, researchers aim to elucidate the precise mechanisms by which sodium acetate influences cellular processes relevant to tissue engineering. This includes understanding its effects on cell proliferation, migration, and extracellular matrix production – all crucial factors in the development of functional engineered tissues.

Another key objective is to optimize the use of sodium acetate in tissue engineering protocols. This involves determining ideal concentrations, timing of application, and combination with other factors to achieve desired outcomes. Researchers are particularly interested in exploring how sodium acetate can be integrated into advanced biomaterials and scaffolds to enhance their biocompatibility and functionality.

Moreover, the research aims to investigate the potential of sodium acetate in addressing specific challenges in tissue engineering, such as improving vascularization of engineered tissues or enhancing the integration of implants with host tissues. By leveraging the unique properties of sodium acetate, scientists hope to develop more effective strategies for creating complex, functional tissues that can better mimic native tissue architecture and function.

The evolution of tissue engineering has led researchers to explore novel approaches for enhancing cell growth, differentiation, and tissue formation. In this context, sodium acetate has gained attention for its multifaceted properties that align with the objectives of optimized tissue engineering processes. One key aspect is its potential to serve as a metabolic substrate, providing an alternative energy source for cells under specific conditions. This property is particularly relevant in scenarios where glucose availability may be limited or where metabolic modulation is desired.

Furthermore, sodium acetate has demonstrated the ability to influence cellular behavior and tissue development through various mechanisms. Studies have shown that it can affect gene expression patterns, potentially guiding cell differentiation and tissue-specific functions. Its role in epigenetic regulation, particularly through its involvement in histone acetylation processes, opens up new avenues for controlling cell fate and tissue organization.

The objectives of researching sodium acetate in tissue engineering are multifaceted and ambitious. Primarily, researchers aim to elucidate the precise mechanisms by which sodium acetate influences cellular processes relevant to tissue engineering. This includes understanding its effects on cell proliferation, migration, and extracellular matrix production – all crucial factors in the development of functional engineered tissues.

Another key objective is to optimize the use of sodium acetate in tissue engineering protocols. This involves determining ideal concentrations, timing of application, and combination with other factors to achieve desired outcomes. Researchers are particularly interested in exploring how sodium acetate can be integrated into advanced biomaterials and scaffolds to enhance their biocompatibility and functionality.

Moreover, the research aims to investigate the potential of sodium acetate in addressing specific challenges in tissue engineering, such as improving vascularization of engineered tissues or enhancing the integration of implants with host tissues. By leveraging the unique properties of sodium acetate, scientists hope to develop more effective strategies for creating complex, functional tissues that can better mimic native tissue architecture and function.

Market Analysis for Sodium Acetate in TE

The market for sodium acetate in tissue engineering (TE) has been experiencing significant growth in recent years, driven by the increasing demand for advanced biomaterials and the expanding applications of TE in regenerative medicine. Sodium acetate, a versatile compound with unique properties, has found its niche in the TE sector due to its biocompatibility, pH-regulating capabilities, and potential to enhance cell growth and differentiation.

The global tissue engineering market, valued at approximately $9.9 billion in 2019, is projected to reach $28.9 billion by 2027, growing at a CAGR of 14.2% from 2020 to 2027. Within this broader market, the demand for sodium acetate is expected to follow a similar growth trajectory, albeit with some variations specific to its applications in TE processes.

One of the primary drivers for the increased use of sodium acetate in TE is its role in optimizing cell culture media. As research in regenerative medicine advances, there is a growing need for more sophisticated and tailored cell culture environments. Sodium acetate has shown promise in maintaining optimal pH levels and providing a source of acetate ions, which can be metabolized by cells to support growth and function.

The orthopedic and dental segments of the TE market are particularly significant for sodium acetate applications. These sectors require biomaterials that can promote bone and cartilage regeneration, where sodium acetate-based scaffolds have demonstrated potential. The orthopedic TE market alone is expected to grow at a CAGR of 6.2% from 2020 to 2027, indicating a substantial opportunity for sodium acetate-based products.

Geographically, North America and Europe currently dominate the TE market, accounting for over 60% of the global market share. However, the Asia-Pacific region is emerging as the fastest-growing market for TE products, with a projected CAGR of 15.4% from 2020 to 2027. This regional growth is likely to create new opportunities for sodium acetate suppliers and TE product manufacturers.

The increasing focus on personalized medicine and 3D bioprinting is expected to further boost the demand for sodium acetate in TE applications. As these technologies advance, the need for biocompatible materials that can be precisely controlled and manipulated at the molecular level will grow, potentially expanding the market for sodium acetate-based solutions.

However, the market for sodium acetate in TE faces some challenges. Regulatory hurdles and the need for extensive clinical trials can slow down the commercialization of new TE products. Additionally, competition from alternative biomaterials and the ongoing research into novel compounds may impact the market share of sodium acetate-based solutions in the long term.

In conclusion, the market analysis for sodium acetate in tissue engineering reveals a promising outlook, driven by technological advancements, growing healthcare needs, and the expansion of regenerative medicine applications. As research continues to uncover new potential uses for sodium acetate in optimizing TE processes, its market value is expected to grow in tandem with the broader tissue engineering industry.

The global tissue engineering market, valued at approximately $9.9 billion in 2019, is projected to reach $28.9 billion by 2027, growing at a CAGR of 14.2% from 2020 to 2027. Within this broader market, the demand for sodium acetate is expected to follow a similar growth trajectory, albeit with some variations specific to its applications in TE processes.

One of the primary drivers for the increased use of sodium acetate in TE is its role in optimizing cell culture media. As research in regenerative medicine advances, there is a growing need for more sophisticated and tailored cell culture environments. Sodium acetate has shown promise in maintaining optimal pH levels and providing a source of acetate ions, which can be metabolized by cells to support growth and function.

The orthopedic and dental segments of the TE market are particularly significant for sodium acetate applications. These sectors require biomaterials that can promote bone and cartilage regeneration, where sodium acetate-based scaffolds have demonstrated potential. The orthopedic TE market alone is expected to grow at a CAGR of 6.2% from 2020 to 2027, indicating a substantial opportunity for sodium acetate-based products.

Geographically, North America and Europe currently dominate the TE market, accounting for over 60% of the global market share. However, the Asia-Pacific region is emerging as the fastest-growing market for TE products, with a projected CAGR of 15.4% from 2020 to 2027. This regional growth is likely to create new opportunities for sodium acetate suppliers and TE product manufacturers.

The increasing focus on personalized medicine and 3D bioprinting is expected to further boost the demand for sodium acetate in TE applications. As these technologies advance, the need for biocompatible materials that can be precisely controlled and manipulated at the molecular level will grow, potentially expanding the market for sodium acetate-based solutions.

However, the market for sodium acetate in TE faces some challenges. Regulatory hurdles and the need for extensive clinical trials can slow down the commercialization of new TE products. Additionally, competition from alternative biomaterials and the ongoing research into novel compounds may impact the market share of sodium acetate-based solutions in the long term.

In conclusion, the market analysis for sodium acetate in tissue engineering reveals a promising outlook, driven by technological advancements, growing healthcare needs, and the expansion of regenerative medicine applications. As research continues to uncover new potential uses for sodium acetate in optimizing TE processes, its market value is expected to grow in tandem with the broader tissue engineering industry.

Current Challenges in Sodium Acetate TE Applications

Despite the promising potential of sodium acetate in tissue engineering (TE) applications, several challenges persist that hinder its widespread adoption and optimal utilization. One of the primary obstacles is the precise control of sodium acetate concentration within the tissue engineering scaffolds. Maintaining an ideal concentration is crucial for cell viability, proliferation, and differentiation. However, achieving this balance can be difficult due to the dynamic nature of cellular interactions and the varying requirements of different cell types.

Another significant challenge lies in the long-term stability of sodium acetate-based scaffolds. While sodium acetate offers excellent initial properties, its degradation kinetics in physiological conditions can be unpredictable. This uncertainty poses risks for tissue development and may lead to premature scaffold failure or undesired tissue responses. Researchers are actively working on developing methods to fine-tune the degradation rate to match the pace of tissue regeneration.

The biocompatibility of sodium acetate in complex, multi-cellular environments remains a concern. Although generally considered safe, the long-term effects of sodium acetate on various cell types and tissues are not fully understood. This gap in knowledge necessitates extensive in vivo studies to ensure the safety and efficacy of sodium acetate-based TE constructs across different applications.

Furthermore, the scalability of sodium acetate-based TE processes presents a significant hurdle. While promising results have been achieved in laboratory settings, translating these successes to large-scale, clinically relevant tissue constructs remains challenging. Issues such as uniform distribution of sodium acetate throughout larger scaffolds and maintaining consistent cellular responses across the construct need to be addressed.

The integration of sodium acetate with other biomaterials and growth factors in TE applications is another area requiring further research. Optimizing these combinations to enhance tissue regeneration while avoiding potential antagonistic effects is crucial for developing more effective TE solutions. Additionally, the impact of sodium acetate on the mechanical properties of scaffolds over time needs careful consideration, especially for load-bearing tissue applications.

Lastly, the regulatory pathway for sodium acetate-based TE products remains complex and uncertain. As a relatively novel approach in tissue engineering, regulatory bodies are still developing appropriate guidelines and standards for these products. This regulatory ambiguity can slow down the translation of research findings into clinical applications, presenting a significant challenge for researchers and companies working in this field.

Another significant challenge lies in the long-term stability of sodium acetate-based scaffolds. While sodium acetate offers excellent initial properties, its degradation kinetics in physiological conditions can be unpredictable. This uncertainty poses risks for tissue development and may lead to premature scaffold failure or undesired tissue responses. Researchers are actively working on developing methods to fine-tune the degradation rate to match the pace of tissue regeneration.

The biocompatibility of sodium acetate in complex, multi-cellular environments remains a concern. Although generally considered safe, the long-term effects of sodium acetate on various cell types and tissues are not fully understood. This gap in knowledge necessitates extensive in vivo studies to ensure the safety and efficacy of sodium acetate-based TE constructs across different applications.

Furthermore, the scalability of sodium acetate-based TE processes presents a significant hurdle. While promising results have been achieved in laboratory settings, translating these successes to large-scale, clinically relevant tissue constructs remains challenging. Issues such as uniform distribution of sodium acetate throughout larger scaffolds and maintaining consistent cellular responses across the construct need to be addressed.

The integration of sodium acetate with other biomaterials and growth factors in TE applications is another area requiring further research. Optimizing these combinations to enhance tissue regeneration while avoiding potential antagonistic effects is crucial for developing more effective TE solutions. Additionally, the impact of sodium acetate on the mechanical properties of scaffolds over time needs careful consideration, especially for load-bearing tissue applications.

Lastly, the regulatory pathway for sodium acetate-based TE products remains complex and uncertain. As a relatively novel approach in tissue engineering, regulatory bodies are still developing appropriate guidelines and standards for these products. This regulatory ambiguity can slow down the translation of research findings into clinical applications, presenting a significant challenge for researchers and companies working in this field.

Existing Sodium Acetate TE Methodologies

01 Use of sodium acetate in chemical processes

Sodium acetate is widely used in various chemical processes, including as a catalyst, buffer, or reagent. It plays a role in reactions such as esterification, saponification, and neutralization. Its properties make it valuable in industrial applications and laboratory settings.- Use of sodium acetate in heat storage materials: Sodium acetate is utilized in heat storage materials due to its phase change properties. It can absorb and release heat during phase transitions, making it suitable for thermal energy storage applications. These materials can be used in various heating and cooling systems to improve energy efficiency.

- Sodium acetate in food preservation and packaging: Sodium acetate is employed in food preservation and packaging solutions. It acts as a preservative and pH regulator, extending the shelf life of food products. Additionally, it can be incorporated into packaging materials to create active packaging systems that help maintain food quality and safety.

- Production methods for sodium acetate: Various methods are used to produce sodium acetate, including the reaction of acetic acid with sodium hydroxide or sodium carbonate. Some processes involve the use of catalysts or specific reaction conditions to improve yield and purity. These production methods aim to optimize efficiency and reduce costs in industrial-scale manufacturing.

- Sodium acetate in pharmaceutical formulations: Sodium acetate is used in pharmaceutical formulations as a buffering agent and to adjust pH levels. It can be found in various drug preparations, including injectable solutions and oral medications. Its role in maintaining the stability and effectiveness of pharmaceutical products makes it a valuable ingredient in the industry.

- Applications of sodium acetate in industrial processes: Sodium acetate finds applications in various industrial processes, such as textile dyeing, leather tanning, and as a catalyst in chemical reactions. It is also used in the production of certain polymers and as a de-icing agent for roads and runways. Its versatility in industrial applications stems from its chemical properties and relatively low cost.

02 Application in heat storage and phase change materials

Sodium acetate trihydrate is utilized as a phase change material for thermal energy storage. It has a high latent heat of fusion and can store and release heat at a constant temperature, making it suitable for applications in heating and cooling systems, as well as in temperature-regulating textiles and packaging.Expand Specific Solutions03 Use in food and beverage industry

Sodium acetate is employed as a food additive, serving as a preservative, acidity regulator, and flavoring agent. It is used in various food products to enhance taste, extend shelf life, and maintain pH balance. Its application extends to beverages, snacks, and processed foods.Expand Specific Solutions04 Application in pharmaceutical and medical products

Sodium acetate is used in pharmaceutical formulations and medical solutions. It serves as a buffering agent in intravenous fluids, dialysis solutions, and other medical preparations. Its ability to regulate pH and maintain electrolyte balance makes it valuable in healthcare applications.Expand Specific Solutions05 Use in environmental and waste treatment

Sodium acetate finds applications in environmental remediation and waste treatment processes. It can be used in the treatment of industrial effluents, as a deicer for roads and runways, and in the removal of heavy metals from contaminated water. Its biodegradability makes it an environmentally friendly option for certain applications.Expand Specific Solutions

Key Players in Sodium Acetate TE Research

The research on sodium acetate for optimized tissue engineering processes is in a developing stage, with the market showing promising growth potential. The technology's maturity is advancing, as evidenced by involvement from diverse institutions. Key players include academic powerhouses like Northwestern University, University of Michigan, and Drexel University, alongside research-focused entities such as The Charles Stark Draper Laboratory. Commercial interests are represented by companies like Edwards Lifesciences and CartiHeal, indicating growing industry adoption. The competitive landscape spans multiple countries, suggesting a global focus on this technology. As the field progresses, we can expect increased collaboration between academia and industry to drive innovation and market expansion.

Northwestern University

Technical Solution: Northwestern University has developed innovative approaches for using sodium acetate in tissue engineering processes. Their research focuses on incorporating sodium acetate into hydrogel scaffolds to enhance cell viability and tissue formation. The university has created a novel hydrogel system that utilizes sodium acetate as a crosslinking agent, allowing for better control over scaffold properties and degradation rates[1]. This system has shown promising results in promoting cell adhesion, proliferation, and differentiation in various tissue engineering applications, including cartilage and bone regeneration[2]. Additionally, Northwestern researchers have explored the use of sodium acetate as a metabolic substrate to improve cell survival and function in engineered tissues[3].

Strengths: Advanced hydrogel technology, improved cell viability, and enhanced tissue formation. Weaknesses: Potential limitations in scaling up the process for large-scale tissue engineering applications.

The Regents of the University of Michigan

Technical Solution: The University of Michigan has made significant strides in optimizing tissue engineering processes using sodium acetate. Their research team has developed a novel approach that incorporates sodium acetate into biodegradable polymer scaffolds to enhance their mechanical properties and biocompatibility[4]. This method involves the controlled release of sodium acetate from the scaffold, which has been shown to promote cell growth and tissue regeneration. The university has also explored the use of sodium acetate as a pH regulator in tissue engineering applications, demonstrating its ability to maintain optimal conditions for cell culture and tissue development[5]. Furthermore, their studies have revealed that sodium acetate can act as an energy source for cells in engineered tissues, potentially improving their long-term viability and functionality[6].

Strengths: Enhanced scaffold properties, improved pH regulation, and potential for long-term cell viability. Weaknesses: Possible challenges in achieving uniform sodium acetate distribution within complex 3D scaffolds.

Innovative Sodium Acetate TE Techniques

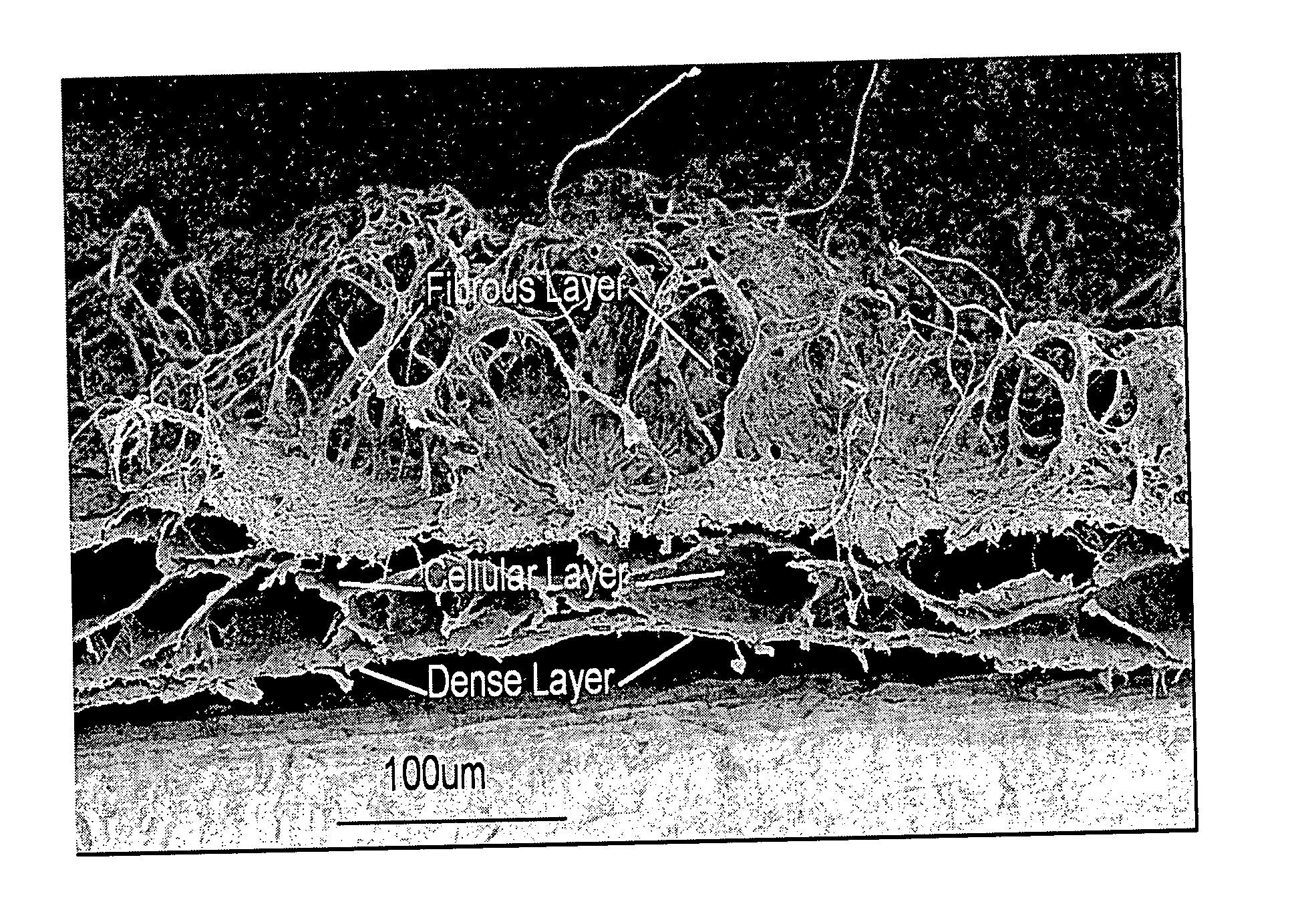

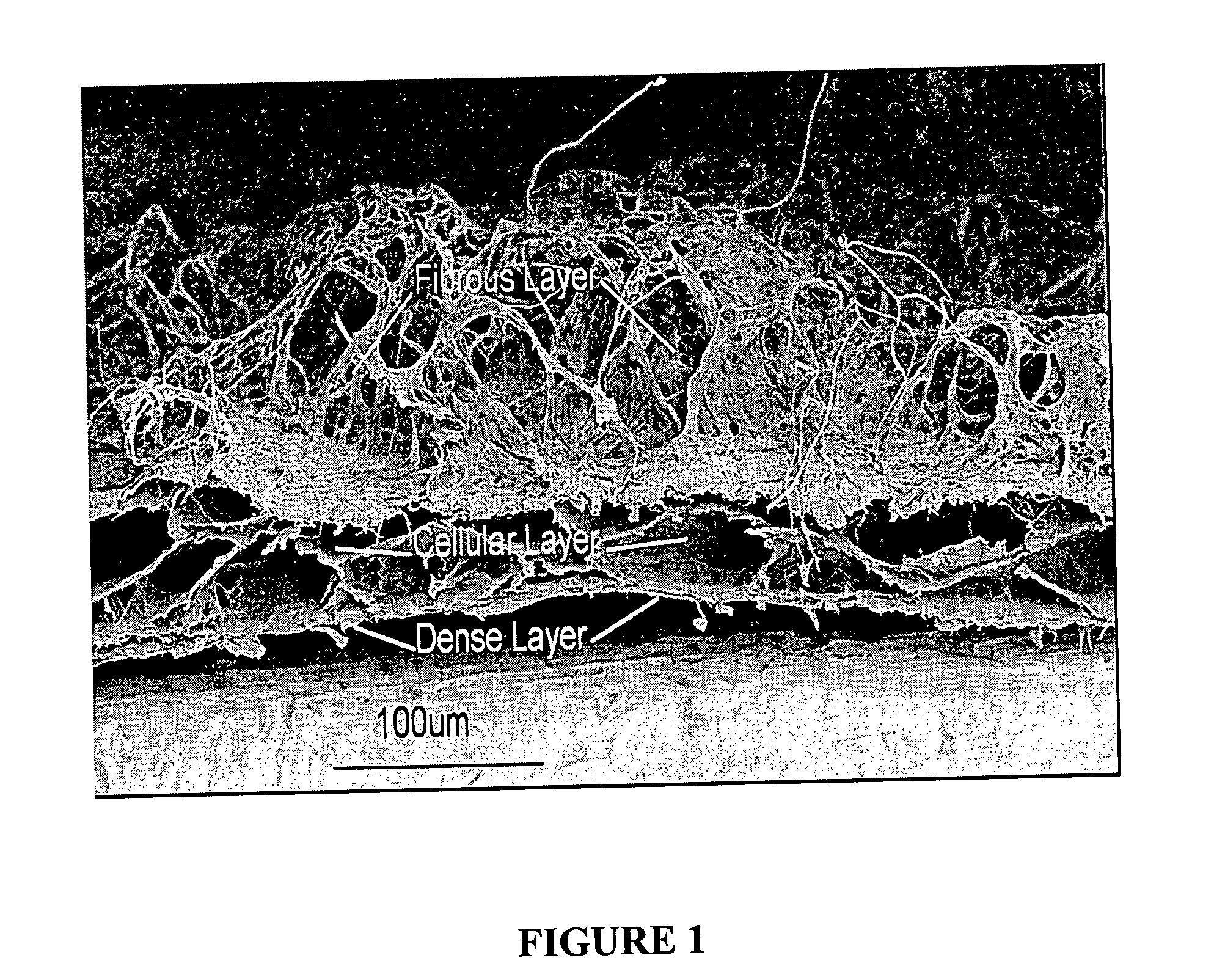

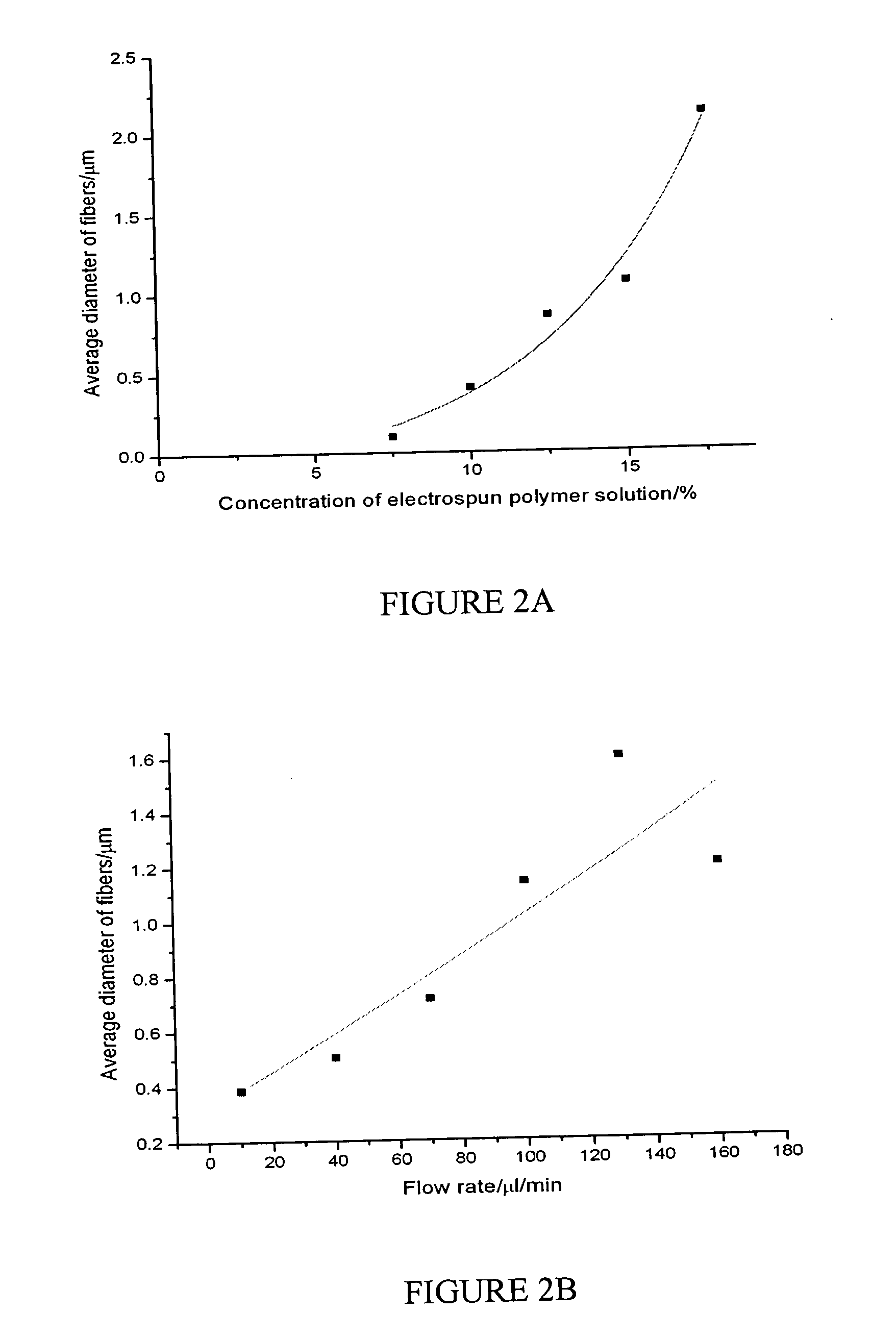

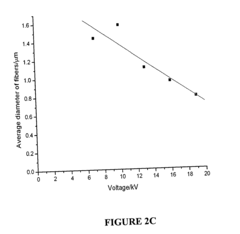

Three dimensional-BIO-mimicking active scaffolds

PatentInactiveUS20070275458A1

Innovation

- The development of a three-dimensional non-woven scaffold produced via electrospinning using cellulose acetate and potentially carbon nanotubes, which mimics the configuration and porosity of natural ECMs, allowing for customized tissue substitutes that can be tailored to match the biomechanical and biochemical needs of target tissues.

bioinks

PatentWO2020094776A1

Innovation

- Development of a hydrogel comprising oxidized alginate with aldehyde groups, crosslinked using imine type crosslinkers, which exhibits excellent viscoelasticity, shear thinning, and self-healing characteristics, allowing for the creation of dynamic covalent gels suitable for 3D printing.

Regulatory Framework for TE Materials

The regulatory framework for tissue engineering (TE) materials plays a crucial role in ensuring the safety, efficacy, and quality of products developed for regenerative medicine applications. In the context of sodium acetate research for optimized tissue engineering processes, understanding and adhering to these regulations is essential for successful product development and commercialization.

In the United States, the Food and Drug Administration (FDA) is the primary regulatory body overseeing TE materials. The FDA classifies these products under the broader category of Human Cells, Tissues, and Cellular and Tissue-Based Products (HCT/Ps). Depending on the specific characteristics and intended use of the TE material, it may be regulated under different pathways, including 361 HCT/Ps, medical devices, biologics, or combination products.

For sodium acetate-based TE materials, the regulatory pathway will likely depend on the level of manipulation and the intended use of the final product. If the sodium acetate is used as a component in a minimally manipulated tissue product, it may fall under the 361 HCT/P category. However, if it involves more extensive processing or is combined with other materials to create a novel product, it may be regulated as a medical device or biologic.

The European Union has established a comprehensive regulatory framework for TE materials through the Advanced Therapy Medicinal Products (ATMP) Regulation. This regulation covers tissue-engineered products, gene therapies, and somatic cell therapies. Sodium acetate-based TE materials would likely be classified as tissue-engineered products under this framework, requiring compliance with Good Manufacturing Practice (GMP) standards and obtaining marketing authorization from the European Medicines Agency (EMA).

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) oversees the regulation of TE materials. The country has implemented a fast-track approval system for regenerative medicine products, which could potentially benefit sodium acetate-based TE materials if they demonstrate promising results in early-stage clinical trials.

Globally, the International Organization for Standardization (ISO) has developed several standards relevant to TE materials, including ISO 13485 for quality management systems and ISO 10993 for biocompatibility testing. These standards provide a framework for ensuring the quality and safety of TE products across different regulatory jurisdictions.

As research on sodium acetate for optimized tissue engineering processes progresses, it is crucial for developers to engage with regulatory authorities early in the development process. This proactive approach can help identify potential regulatory challenges and streamline the path to market approval. Additionally, staying informed about evolving regulations and guidelines in different regions is essential, as the field of tissue engineering continues to advance rapidly, potentially leading to updates in regulatory frameworks.

In the United States, the Food and Drug Administration (FDA) is the primary regulatory body overseeing TE materials. The FDA classifies these products under the broader category of Human Cells, Tissues, and Cellular and Tissue-Based Products (HCT/Ps). Depending on the specific characteristics and intended use of the TE material, it may be regulated under different pathways, including 361 HCT/Ps, medical devices, biologics, or combination products.

For sodium acetate-based TE materials, the regulatory pathway will likely depend on the level of manipulation and the intended use of the final product. If the sodium acetate is used as a component in a minimally manipulated tissue product, it may fall under the 361 HCT/P category. However, if it involves more extensive processing or is combined with other materials to create a novel product, it may be regulated as a medical device or biologic.

The European Union has established a comprehensive regulatory framework for TE materials through the Advanced Therapy Medicinal Products (ATMP) Regulation. This regulation covers tissue-engineered products, gene therapies, and somatic cell therapies. Sodium acetate-based TE materials would likely be classified as tissue-engineered products under this framework, requiring compliance with Good Manufacturing Practice (GMP) standards and obtaining marketing authorization from the European Medicines Agency (EMA).

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) oversees the regulation of TE materials. The country has implemented a fast-track approval system for regenerative medicine products, which could potentially benefit sodium acetate-based TE materials if they demonstrate promising results in early-stage clinical trials.

Globally, the International Organization for Standardization (ISO) has developed several standards relevant to TE materials, including ISO 13485 for quality management systems and ISO 10993 for biocompatibility testing. These standards provide a framework for ensuring the quality and safety of TE products across different regulatory jurisdictions.

As research on sodium acetate for optimized tissue engineering processes progresses, it is crucial for developers to engage with regulatory authorities early in the development process. This proactive approach can help identify potential regulatory challenges and streamline the path to market approval. Additionally, staying informed about evolving regulations and guidelines in different regions is essential, as the field of tissue engineering continues to advance rapidly, potentially leading to updates in regulatory frameworks.

Biocompatibility and Safety Considerations

Biocompatibility and safety considerations are paramount in the research and application of sodium acetate for optimized tissue engineering processes. The use of sodium acetate in tissue engineering scaffolds and culture media necessitates a thorough evaluation of its interactions with biological systems to ensure the safety and efficacy of engineered tissues.

One of the primary concerns in using sodium acetate is its potential impact on cell viability and proliferation. Studies have shown that sodium acetate, at appropriate concentrations, can support cell growth and metabolism without inducing cytotoxicity. However, the optimal concentration range must be carefully determined for each specific cell type and tissue engineering application to avoid any adverse effects on cellular function or tissue development.

The pH-modulating properties of sodium acetate play a crucial role in its biocompatibility. As a weak base, sodium acetate can help maintain a stable pH environment in tissue culture systems, which is essential for cell survival and proper tissue formation. Nevertheless, excessive concentrations of sodium acetate may lead to undesirable pH shifts, potentially disrupting cellular processes and extracellular matrix production.

Another important aspect of biocompatibility is the interaction between sodium acetate and biomaterials used in tissue engineering scaffolds. Research has shown that sodium acetate can influence the mechanical properties and degradation rates of certain biomaterials, such as hydrogels and polymer-based scaffolds. These interactions must be carefully evaluated to ensure that the presence of sodium acetate does not compromise the structural integrity or functionality of the engineered tissues.

The potential for sodium acetate to modulate inflammatory responses is another critical safety consideration. While some studies suggest that sodium acetate may possess anti-inflammatory properties, its effects on immune cell function and tissue integration need to be thoroughly investigated to prevent any unintended immunological reactions in engineered tissues or upon implantation.

Long-term safety assessments are essential when considering the use of sodium acetate in tissue engineering applications intended for clinical use. This includes evaluating the potential for sodium acetate accumulation in tissues, its clearance mechanisms, and any systemic effects that may arise from prolonged exposure. Additionally, the impact of sodium acetate on the differentiation and maturation of stem cells and progenitor cells used in tissue engineering must be carefully examined to ensure that it does not interfere with the desired tissue-specific functions.

In conclusion, while sodium acetate shows promise in optimizing tissue engineering processes, comprehensive biocompatibility and safety studies are crucial to validate its use in various applications. These investigations should encompass in vitro cellular assays, ex vivo tissue models, and in vivo studies to provide a holistic understanding of the safety profile of sodium acetate in tissue engineering contexts.

One of the primary concerns in using sodium acetate is its potential impact on cell viability and proliferation. Studies have shown that sodium acetate, at appropriate concentrations, can support cell growth and metabolism without inducing cytotoxicity. However, the optimal concentration range must be carefully determined for each specific cell type and tissue engineering application to avoid any adverse effects on cellular function or tissue development.

The pH-modulating properties of sodium acetate play a crucial role in its biocompatibility. As a weak base, sodium acetate can help maintain a stable pH environment in tissue culture systems, which is essential for cell survival and proper tissue formation. Nevertheless, excessive concentrations of sodium acetate may lead to undesirable pH shifts, potentially disrupting cellular processes and extracellular matrix production.

Another important aspect of biocompatibility is the interaction between sodium acetate and biomaterials used in tissue engineering scaffolds. Research has shown that sodium acetate can influence the mechanical properties and degradation rates of certain biomaterials, such as hydrogels and polymer-based scaffolds. These interactions must be carefully evaluated to ensure that the presence of sodium acetate does not compromise the structural integrity or functionality of the engineered tissues.

The potential for sodium acetate to modulate inflammatory responses is another critical safety consideration. While some studies suggest that sodium acetate may possess anti-inflammatory properties, its effects on immune cell function and tissue integration need to be thoroughly investigated to prevent any unintended immunological reactions in engineered tissues or upon implantation.

Long-term safety assessments are essential when considering the use of sodium acetate in tissue engineering applications intended for clinical use. This includes evaluating the potential for sodium acetate accumulation in tissues, its clearance mechanisms, and any systemic effects that may arise from prolonged exposure. Additionally, the impact of sodium acetate on the differentiation and maturation of stem cells and progenitor cells used in tissue engineering must be carefully examined to ensure that it does not interfere with the desired tissue-specific functions.

In conclusion, while sodium acetate shows promise in optimizing tissue engineering processes, comprehensive biocompatibility and safety studies are crucial to validate its use in various applications. These investigations should encompass in vitro cellular assays, ex vivo tissue models, and in vivo studies to provide a holistic understanding of the safety profile of sodium acetate in tissue engineering contexts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!