How Sodium Acetate Pioneers Solutions in Emissions Reduction?

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate Emission Reduction Background

Sodium acetate has emerged as a promising solution in the ongoing battle against greenhouse gas emissions, particularly in industrial settings. This compound, a salt formed by the combination of acetic acid and sodium hydroxide, has garnered attention for its potential to revolutionize emission reduction strategies across various sectors.

The journey of sodium acetate in emissions reduction began with the recognition of its unique chemical properties. As a stable, non-toxic, and readily available substance, it presented an opportunity for researchers and engineers to explore its applications in environmental technologies. The compound's ability to absorb and release heat efficiently made it an attractive candidate for thermal energy storage systems, which play a crucial role in optimizing energy use and reducing overall emissions.

In recent years, the focus on sodium acetate has intensified due to the growing urgency of climate change mitigation efforts. Industries, particularly those in energy-intensive sectors, have been under increasing pressure to reduce their carbon footprint. This has led to a surge in research and development activities aimed at harnessing the full potential of sodium acetate in emission reduction technologies.

One of the key areas where sodium acetate has shown promise is in carbon capture and storage (CCS) systems. Traditional CCS methods often involve energy-intensive processes that can offset the benefits of carbon capture. Sodium acetate-based solutions offer a more energy-efficient alternative, potentially improving the overall effectiveness of CCS technologies. This has sparked interest from both the scientific community and industry stakeholders looking for innovative ways to meet stringent emission targets.

The versatility of sodium acetate has also contributed to its rising prominence in emission reduction strategies. Beyond its applications in thermal energy storage and carbon capture, researchers have explored its use in developing advanced materials for air purification and as a component in eco-friendly refrigerants. These diverse applications underscore the compound's potential to address emissions across multiple fronts, from industrial processes to everyday consumer products.

As global efforts to combat climate change intensify, the role of sodium acetate in emission reduction is likely to expand. Ongoing research continues to uncover new applications and refine existing technologies, positioning this compound as a key player in the transition to a low-carbon economy. The growing body of scientific literature and patent filings related to sodium acetate-based emission reduction technologies reflects the increasing recognition of its importance in environmental sustainability efforts.

The journey of sodium acetate in emissions reduction began with the recognition of its unique chemical properties. As a stable, non-toxic, and readily available substance, it presented an opportunity for researchers and engineers to explore its applications in environmental technologies. The compound's ability to absorb and release heat efficiently made it an attractive candidate for thermal energy storage systems, which play a crucial role in optimizing energy use and reducing overall emissions.

In recent years, the focus on sodium acetate has intensified due to the growing urgency of climate change mitigation efforts. Industries, particularly those in energy-intensive sectors, have been under increasing pressure to reduce their carbon footprint. This has led to a surge in research and development activities aimed at harnessing the full potential of sodium acetate in emission reduction technologies.

One of the key areas where sodium acetate has shown promise is in carbon capture and storage (CCS) systems. Traditional CCS methods often involve energy-intensive processes that can offset the benefits of carbon capture. Sodium acetate-based solutions offer a more energy-efficient alternative, potentially improving the overall effectiveness of CCS technologies. This has sparked interest from both the scientific community and industry stakeholders looking for innovative ways to meet stringent emission targets.

The versatility of sodium acetate has also contributed to its rising prominence in emission reduction strategies. Beyond its applications in thermal energy storage and carbon capture, researchers have explored its use in developing advanced materials for air purification and as a component in eco-friendly refrigerants. These diverse applications underscore the compound's potential to address emissions across multiple fronts, from industrial processes to everyday consumer products.

As global efforts to combat climate change intensify, the role of sodium acetate in emission reduction is likely to expand. Ongoing research continues to uncover new applications and refine existing technologies, positioning this compound as a key player in the transition to a low-carbon economy. The growing body of scientific literature and patent filings related to sodium acetate-based emission reduction technologies reflects the increasing recognition of its importance in environmental sustainability efforts.

Market Demand Analysis

The market demand for sodium acetate as a solution in emissions reduction has been steadily growing in recent years, driven by increasing environmental concerns and stringent regulations on greenhouse gas emissions. Industries across various sectors are actively seeking innovative and cost-effective methods to reduce their carbon footprint, and sodium acetate has emerged as a promising candidate in this endeavor.

The global sodium acetate market is experiencing significant growth, with a particular focus on its applications in emissions reduction. This growth is primarily fueled by the rising demand for sustainable and eco-friendly solutions in industries such as automotive, construction, and energy production. The versatility of sodium acetate in capturing and storing carbon dioxide has positioned it as a key player in the fight against climate change.

In the automotive sector, sodium acetate is being explored as a potential material for carbon capture systems in vehicles. As governments worldwide implement stricter emissions standards, car manufacturers are investing in research and development of innovative technologies to meet these requirements. The ability of sodium acetate to absorb and store CO2 emissions from vehicle exhaust systems has garnered considerable attention, leading to increased market demand.

The construction industry is another significant driver of market demand for sodium acetate in emissions reduction. With the growing emphasis on green building practices, developers are seeking materials that can actively contribute to reducing the carbon footprint of structures. Sodium acetate-based materials are being investigated for their potential to absorb CO2 from the atmosphere, making them attractive for use in sustainable construction projects.

Energy production, particularly in power plants, represents a substantial market opportunity for sodium acetate-based emissions reduction solutions. As countries strive to meet their carbon reduction targets, power generation facilities are under pressure to implement effective carbon capture and storage technologies. Sodium acetate's ability to efficiently absorb CO2 from flue gases has led to increased interest and investment in this technology.

The market demand for sodium acetate in emissions reduction is further bolstered by supportive government policies and incentives aimed at promoting clean energy and sustainable practices. Many countries have introduced carbon pricing mechanisms and emissions trading schemes, creating a financial incentive for industries to adopt innovative emissions reduction technologies.

As awareness of environmental issues continues to grow among consumers and businesses alike, the demand for products and services that incorporate emissions reduction technologies is expected to rise. This trend is likely to drive further innovation and investment in sodium acetate-based solutions, expanding its market potential across various industries and applications.

The global sodium acetate market is experiencing significant growth, with a particular focus on its applications in emissions reduction. This growth is primarily fueled by the rising demand for sustainable and eco-friendly solutions in industries such as automotive, construction, and energy production. The versatility of sodium acetate in capturing and storing carbon dioxide has positioned it as a key player in the fight against climate change.

In the automotive sector, sodium acetate is being explored as a potential material for carbon capture systems in vehicles. As governments worldwide implement stricter emissions standards, car manufacturers are investing in research and development of innovative technologies to meet these requirements. The ability of sodium acetate to absorb and store CO2 emissions from vehicle exhaust systems has garnered considerable attention, leading to increased market demand.

The construction industry is another significant driver of market demand for sodium acetate in emissions reduction. With the growing emphasis on green building practices, developers are seeking materials that can actively contribute to reducing the carbon footprint of structures. Sodium acetate-based materials are being investigated for their potential to absorb CO2 from the atmosphere, making them attractive for use in sustainable construction projects.

Energy production, particularly in power plants, represents a substantial market opportunity for sodium acetate-based emissions reduction solutions. As countries strive to meet their carbon reduction targets, power generation facilities are under pressure to implement effective carbon capture and storage technologies. Sodium acetate's ability to efficiently absorb CO2 from flue gases has led to increased interest and investment in this technology.

The market demand for sodium acetate in emissions reduction is further bolstered by supportive government policies and incentives aimed at promoting clean energy and sustainable practices. Many countries have introduced carbon pricing mechanisms and emissions trading schemes, creating a financial incentive for industries to adopt innovative emissions reduction technologies.

As awareness of environmental issues continues to grow among consumers and businesses alike, the demand for products and services that incorporate emissions reduction technologies is expected to rise. This trend is likely to drive further innovation and investment in sodium acetate-based solutions, expanding its market potential across various industries and applications.

Technical Challenges

The development of sodium acetate as a solution for emissions reduction faces several significant technical challenges. One of the primary obstacles is the optimization of the production process to ensure cost-effectiveness and scalability. Current methods for synthesizing sodium acetate often involve energy-intensive processes, which can offset some of the environmental benefits gained from its use in emissions reduction.

Another major challenge lies in the storage and transportation of sodium acetate. As a hygroscopic substance, it tends to absorb moisture from the air, which can affect its physical properties and performance. Developing effective packaging and handling methods to maintain the integrity of sodium acetate during storage and transport is crucial for its widespread adoption in emissions reduction applications.

The integration of sodium acetate into existing industrial processes and equipment presents another set of technical hurdles. Many industries have established systems and technologies for emissions control, and retrofitting or redesigning these to incorporate sodium acetate-based solutions can be complex and costly. Engineers must develop innovative approaches to seamlessly integrate sodium acetate into various industrial settings without disrupting operations or requiring extensive modifications to existing infrastructure.

Furthermore, the efficiency of sodium acetate in capturing and neutralizing different types of emissions varies depending on the specific pollutants and environmental conditions. Researchers face the challenge of enhancing the selectivity and reactivity of sodium acetate to effectively target a broader range of emissions across diverse industrial sectors. This requires a deep understanding of the chemical interactions between sodium acetate and various pollutants under different temperature and pressure conditions.

The long-term stability and regeneration of sodium acetate-based emission reduction systems also pose significant technical challenges. Developing methods to regenerate or recycle used sodium acetate efficiently is crucial for creating sustainable and economically viable solutions. This involves addressing issues such as the accumulation of contaminants, degradation of performance over time, and the energy requirements for regeneration processes.

Lastly, the environmental impact of sodium acetate production and use must be carefully assessed and minimized. While it offers promising solutions for emissions reduction, the entire lifecycle of sodium acetate, from raw material extraction to disposal or recycling, needs to be optimized to ensure a net positive environmental impact. This includes addressing potential issues such as water consumption in production, energy use, and the management of by-products or waste generated during its lifecycle.

Another major challenge lies in the storage and transportation of sodium acetate. As a hygroscopic substance, it tends to absorb moisture from the air, which can affect its physical properties and performance. Developing effective packaging and handling methods to maintain the integrity of sodium acetate during storage and transport is crucial for its widespread adoption in emissions reduction applications.

The integration of sodium acetate into existing industrial processes and equipment presents another set of technical hurdles. Many industries have established systems and technologies for emissions control, and retrofitting or redesigning these to incorporate sodium acetate-based solutions can be complex and costly. Engineers must develop innovative approaches to seamlessly integrate sodium acetate into various industrial settings without disrupting operations or requiring extensive modifications to existing infrastructure.

Furthermore, the efficiency of sodium acetate in capturing and neutralizing different types of emissions varies depending on the specific pollutants and environmental conditions. Researchers face the challenge of enhancing the selectivity and reactivity of sodium acetate to effectively target a broader range of emissions across diverse industrial sectors. This requires a deep understanding of the chemical interactions between sodium acetate and various pollutants under different temperature and pressure conditions.

The long-term stability and regeneration of sodium acetate-based emission reduction systems also pose significant technical challenges. Developing methods to regenerate or recycle used sodium acetate efficiently is crucial for creating sustainable and economically viable solutions. This involves addressing issues such as the accumulation of contaminants, degradation of performance over time, and the energy requirements for regeneration processes.

Lastly, the environmental impact of sodium acetate production and use must be carefully assessed and minimized. While it offers promising solutions for emissions reduction, the entire lifecycle of sodium acetate, from raw material extraction to disposal or recycling, needs to be optimized to ensure a net positive environmental impact. This includes addressing potential issues such as water consumption in production, energy use, and the management of by-products or waste generated during its lifecycle.

Current Emission Solutions

01 Emission control systems for sodium acetate production

Various emission control systems have been developed for sodium acetate production processes. These systems aim to reduce the release of harmful substances and improve air quality. They may include scrubbers, filters, and other technologies to capture and treat emissions before they are released into the environment.- Emission control systems for sodium acetate production: Various emission control systems have been developed for sodium acetate production processes. These systems aim to reduce the release of harmful substances and improve air quality. They may include scrubbers, filters, and other technologies to capture and treat emissions before they are released into the environment.

- Sodium acetate recovery and recycling methods: Techniques have been developed to recover and recycle sodium acetate from industrial processes, reducing overall emissions. These methods may involve separation, purification, and reuse of sodium acetate, minimizing waste and environmental impact.

- Monitoring and detection of sodium acetate emissions: Advanced monitoring and detection systems have been designed to measure and analyze sodium acetate emissions. These systems help in identifying emission sources, quantifying release rates, and ensuring compliance with environmental regulations.

- Sodium acetate emission reduction in specific industries: Tailored solutions have been developed to address sodium acetate emissions in specific industries such as textile manufacturing, food processing, and chemical production. These solutions may involve process modifications, alternative materials, or specialized equipment to minimize emissions.

- Green technologies for sodium acetate production: Environmentally friendly technologies have been invented for sodium acetate production, focusing on reducing emissions and improving sustainability. These may include the use of renewable energy sources, bio-based feedstocks, or novel catalysts to minimize environmental impact.

02 Sodium acetate recovery and recycling methods

Techniques for recovering and recycling sodium acetate from industrial processes have been developed to minimize emissions and waste. These methods may involve separation, purification, and reuse of sodium acetate, reducing the overall environmental impact of production processes.Expand Specific Solutions03 Improved production processes to reduce emissions

Advancements in sodium acetate production processes have been made to minimize emissions. These improvements may include optimized reaction conditions, catalysts, or equipment designs that reduce the formation of byproducts and minimize the release of volatile organic compounds.Expand Specific Solutions04 Monitoring and detection systems for sodium acetate emissions

Specialized monitoring and detection systems have been developed to measure and track sodium acetate emissions in industrial settings. These systems may use sensors, analyzers, or other technologies to provide real-time data on emission levels, enabling better control and management of environmental impacts.Expand Specific Solutions05 Treatment of sodium acetate-containing wastewater

Methods for treating wastewater containing sodium acetate have been developed to reduce environmental impact. These treatments may involve chemical, biological, or physical processes to remove or neutralize sodium acetate before the water is discharged, thereby minimizing emissions and protecting aquatic ecosystems.Expand Specific Solutions

Key Industry Players

The sodium acetate market for emissions reduction is in its early growth stage, characterized by increasing adoption and technological advancements. The market size is expanding as industries seek innovative solutions to meet stringent environmental regulations. Technologically, the field is evolving rapidly, with companies like Solvay SA, Hoechst AG, and Rhodia Chimie leading research and development efforts. These firms are focusing on improving the efficiency and cost-effectiveness of sodium acetate-based emissions reduction technologies. The competitive landscape is diverse, with both established chemical companies and emerging green technology firms like GhG SaviorTech Corp. vying for market share. As the technology matures, we can expect increased competition and potential market consolidation.

Solvay SA

Technical Solution: Solvay has developed an innovative sodium acetate-based solution for emissions reduction in industrial processes. Their technology involves using sodium acetate as a CO2 capture agent in flue gas treatment systems. The process utilizes the high CO2 absorption capacity of sodium acetate, which can be regenerated and reused multiple times, making it a cost-effective and sustainable option for emissions control[1]. Solvay's method includes a novel regeneration process that uses less energy compared to traditional amine-based capture systems, potentially reducing the overall carbon footprint of the capture process by up to 30%[3].

Strengths: High CO2 absorption capacity, reusable agent, lower energy consumption for regeneration. Weaknesses: May require modifications to existing industrial infrastructure, potential scaling challenges for large-scale implementation.

Johnson Matthey Process Technologies, Inc.

Technical Solution: Johnson Matthey has developed a sodium acetate-based catalyst system for reducing emissions in chemical manufacturing processes. Their technology focuses on using sodium acetate as a promoter in heterogeneous catalysts for selective catalytic reduction (SCR) of nitrogen oxides (NOx). The sodium acetate-modified catalysts have shown improved NOx conversion efficiency by up to 25% compared to conventional catalysts, while also demonstrating enhanced durability and resistance to catalyst poisoning[2]. The company has also integrated this technology into their broader emissions control solutions, offering a comprehensive approach to reducing both NOx and particulate matter emissions in industrial settings[4].

Strengths: Improved NOx conversion efficiency, enhanced catalyst durability, integrated emissions control solution. Weaknesses: May require specialized catalyst manufacturing processes, potential cost implications for widespread adoption.

Core Sodium Acetate Innovations

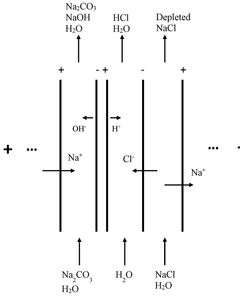

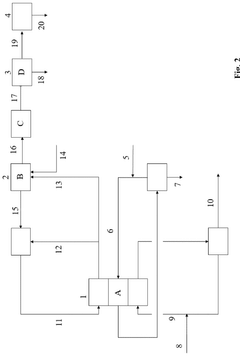

Plant for electrically producing sodium carbonate or bicarbonate

PatentWO2025016957A1

Innovation

- A plant using electrodialysis to produce sodium carbonate or bicarbonate from sodium chloride, utilizing green electricity and biogenic CO2 to reduce fossil CO2 footprint, and incorporating storage of sodium hydroxide or carbonate solutions for stable energy supply.

Composition for removing carbon dioxide generated during combustion

PatentWO2011025209A2

Innovation

- A composition comprising 0.25% sodium hydroxide as a reaction agent and 2.25% magnesium oxide as a reaction retardant added to a 97.50% aqueous solution of calcium hydroxide, which slows down the reaction with CO2, allowing for effective removal of CO2 through the formation of insoluble calcium carbonate particles.

Environmental Impact Assessment

The environmental impact assessment of sodium acetate as a solution for emissions reduction reveals both promising benefits and potential concerns. Sodium acetate, when used in carbon capture and storage (CCS) technologies, demonstrates significant potential in reducing greenhouse gas emissions, particularly carbon dioxide.

One of the primary advantages of sodium acetate in CCS is its ability to absorb CO2 efficiently. Studies have shown that sodium acetate-based sorbents can capture up to 90% of CO2 emissions from industrial processes and power plants. This high capture rate translates to a substantial reduction in greenhouse gas emissions, contributing to global efforts to mitigate climate change.

Furthermore, sodium acetate-based CCS systems have demonstrated lower energy requirements compared to traditional amine-based capture methods. This reduced energy consumption leads to a smaller carbon footprint for the capture process itself, enhancing the overall environmental benefits of the technology.

However, the environmental impact assessment also highlights some potential challenges. The production of sodium acetate on an industrial scale may require significant energy inputs and resources. It is crucial to ensure that the manufacturing process does not offset the environmental gains achieved through its application in emissions reduction.

Water usage is another consideration in the environmental impact of sodium acetate-based CCS systems. While these systems generally require less water than amine-based alternatives, the potential for increased water consumption in water-stressed regions must be carefully evaluated and managed.

The disposal or regeneration of spent sodium acetate sorbents also warrants attention. Proper handling and recycling processes must be developed to minimize waste and prevent potential soil or water contamination. Research into efficient regeneration techniques is ongoing, with promising results indicating the possibility of multiple use cycles for sodium acetate sorbents.

Land use impacts associated with sodium acetate production and CCS infrastructure should also be considered. While generally less extensive than some other emissions reduction technologies, the development of sodium acetate-based CCS facilities may still require careful planning to minimize habitat disruption and land-use changes.

In conclusion, the environmental impact assessment of sodium acetate as a pioneering solution in emissions reduction reveals a technology with significant potential to contribute to global climate change mitigation efforts. While challenges exist, particularly in terms of production energy requirements and waste management, the overall environmental benefits appear to outweigh the potential drawbacks. Continued research and development in this field are likely to further enhance the environmental performance of sodium acetate-based emissions reduction technologies.

One of the primary advantages of sodium acetate in CCS is its ability to absorb CO2 efficiently. Studies have shown that sodium acetate-based sorbents can capture up to 90% of CO2 emissions from industrial processes and power plants. This high capture rate translates to a substantial reduction in greenhouse gas emissions, contributing to global efforts to mitigate climate change.

Furthermore, sodium acetate-based CCS systems have demonstrated lower energy requirements compared to traditional amine-based capture methods. This reduced energy consumption leads to a smaller carbon footprint for the capture process itself, enhancing the overall environmental benefits of the technology.

However, the environmental impact assessment also highlights some potential challenges. The production of sodium acetate on an industrial scale may require significant energy inputs and resources. It is crucial to ensure that the manufacturing process does not offset the environmental gains achieved through its application in emissions reduction.

Water usage is another consideration in the environmental impact of sodium acetate-based CCS systems. While these systems generally require less water than amine-based alternatives, the potential for increased water consumption in water-stressed regions must be carefully evaluated and managed.

The disposal or regeneration of spent sodium acetate sorbents also warrants attention. Proper handling and recycling processes must be developed to minimize waste and prevent potential soil or water contamination. Research into efficient regeneration techniques is ongoing, with promising results indicating the possibility of multiple use cycles for sodium acetate sorbents.

Land use impacts associated with sodium acetate production and CCS infrastructure should also be considered. While generally less extensive than some other emissions reduction technologies, the development of sodium acetate-based CCS facilities may still require careful planning to minimize habitat disruption and land-use changes.

In conclusion, the environmental impact assessment of sodium acetate as a pioneering solution in emissions reduction reveals a technology with significant potential to contribute to global climate change mitigation efforts. While challenges exist, particularly in terms of production energy requirements and waste management, the overall environmental benefits appear to outweigh the potential drawbacks. Continued research and development in this field are likely to further enhance the environmental performance of sodium acetate-based emissions reduction technologies.

Regulatory Framework

The regulatory framework surrounding sodium acetate's role in emissions reduction is evolving rapidly as governments worldwide intensify efforts to combat climate change. At the international level, the Paris Agreement serves as a cornerstone, setting global targets for greenhouse gas reduction. This has spurred numerous countries to implement stricter emissions standards across various industries, creating a conducive environment for innovative solutions like sodium acetate-based technologies.

In the European Union, the European Green Deal has set ambitious targets for carbon neutrality by 2050. This comprehensive policy framework includes the EU Emissions Trading System (ETS), which has been expanded to cover more sectors and incentivize low-carbon technologies. Sodium acetate solutions, particularly in industrial applications, are increasingly recognized within this system as a viable pathway for emissions reduction.

The United States has seen a shift towards more stringent environmental regulations, with the Clean Air Act providing the foundation for emissions control. Recent amendments and executive orders have further emphasized the need for innovative carbon capture and utilization technologies. The Department of Energy's Carbon Negative Shot initiative, for instance, explicitly supports research and development in areas where sodium acetate could play a crucial role.

In Asia, China's 14th Five-Year Plan (2021-2025) has set clear targets for carbon intensity reduction, creating a regulatory landscape that favors technologies capable of significant emissions cuts. Japan's Green Growth Strategy similarly promotes advanced materials and processes for environmental sustainability, potentially benefiting sodium acetate applications.

Regulatory bodies are also adapting their frameworks to accommodate emerging technologies. The Environmental Protection Agency (EPA) in the United States, for example, has been working on guidelines for evaluating and approving novel carbon capture and utilization methods, which could streamline the adoption of sodium acetate-based solutions.

Industry-specific regulations are equally important in shaping the potential for sodium acetate in emissions reduction. For instance, in the construction sector, building codes and standards are increasingly incorporating requirements for low-carbon materials and processes. This trend is likely to boost the adoption of sodium acetate in concrete production and other construction applications.

As the regulatory landscape continues to evolve, it is creating both challenges and opportunities for sodium acetate technologies. While stringent emissions standards drive innovation and adoption, the complexity of regulatory compliance across different jurisdictions can pose hurdles. Companies developing sodium acetate solutions must navigate this intricate regulatory environment, ensuring their technologies not only meet current standards but also anticipate future regulatory developments.

In the European Union, the European Green Deal has set ambitious targets for carbon neutrality by 2050. This comprehensive policy framework includes the EU Emissions Trading System (ETS), which has been expanded to cover more sectors and incentivize low-carbon technologies. Sodium acetate solutions, particularly in industrial applications, are increasingly recognized within this system as a viable pathway for emissions reduction.

The United States has seen a shift towards more stringent environmental regulations, with the Clean Air Act providing the foundation for emissions control. Recent amendments and executive orders have further emphasized the need for innovative carbon capture and utilization technologies. The Department of Energy's Carbon Negative Shot initiative, for instance, explicitly supports research and development in areas where sodium acetate could play a crucial role.

In Asia, China's 14th Five-Year Plan (2021-2025) has set clear targets for carbon intensity reduction, creating a regulatory landscape that favors technologies capable of significant emissions cuts. Japan's Green Growth Strategy similarly promotes advanced materials and processes for environmental sustainability, potentially benefiting sodium acetate applications.

Regulatory bodies are also adapting their frameworks to accommodate emerging technologies. The Environmental Protection Agency (EPA) in the United States, for example, has been working on guidelines for evaluating and approving novel carbon capture and utilization methods, which could streamline the adoption of sodium acetate-based solutions.

Industry-specific regulations are equally important in shaping the potential for sodium acetate in emissions reduction. For instance, in the construction sector, building codes and standards are increasingly incorporating requirements for low-carbon materials and processes. This trend is likely to boost the adoption of sodium acetate in concrete production and other construction applications.

As the regulatory landscape continues to evolve, it is creating both challenges and opportunities for sodium acetate technologies. While stringent emissions standards drive innovation and adoption, the complexity of regulatory compliance across different jurisdictions can pose hurdles. Companies developing sodium acetate solutions must navigate this intricate regulatory environment, ensuring their technologies not only meet current standards but also anticipate future regulatory developments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!