Sodium Acetate’s Value in Prolonged Battery Lifespan

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Acetate Battery Tech Evolution and Objectives

The evolution of sodium acetate in battery technology represents a significant stride towards more sustainable and efficient energy storage solutions. This journey began with the recognition of sodium-ion batteries as a potential alternative to lithium-ion batteries, driven by the abundance and low cost of sodium resources. The initial focus was on developing suitable electrode materials and electrolytes that could accommodate the larger size of sodium ions compared to lithium ions.

As research progressed, scientists discovered the unique properties of sodium acetate, particularly its ability to form a stable solid electrolyte interphase (SEI) layer on the anode surface. This discovery marked a crucial turning point in sodium-ion battery development, as the SEI layer plays a vital role in preventing continuous electrolyte decomposition and ensuring long-term battery stability.

The incorporation of sodium acetate into battery systems has evolved through several key stages. Early experiments focused on using sodium acetate as an electrolyte additive, where it demonstrated promising results in improving the cycling stability of sodium-ion batteries. Subsequent research explored its potential as a primary component in solid electrolytes, leveraging its ionic conductivity and chemical stability.

Recent advancements have centered on optimizing the molecular structure and composition of sodium acetate-based materials to enhance their performance in battery applications. This includes the development of composite materials that combine sodium acetate with other compounds to achieve synergistic effects, such as improved ionic conductivity and mechanical strength.

The primary objective of current research on sodium acetate in battery technology is to significantly extend battery lifespan while maintaining or improving energy density and charging rates. This goal aligns with the broader aim of creating more sustainable and cost-effective energy storage solutions for various applications, from portable electronics to large-scale grid storage.

Researchers are now focusing on several key areas to achieve these objectives. These include understanding the fundamental mechanisms by which sodium acetate contributes to battery longevity, optimizing the integration of sodium acetate-based materials into existing battery architectures, and exploring novel cell designs that can fully capitalize on the unique properties of sodium acetate.

Furthermore, there is a growing emphasis on scalability and manufacturability, with the aim of transitioning sodium acetate-based battery technologies from laboratory prototypes to commercially viable products. This involves addressing challenges related to large-scale production, quality control, and integration with existing manufacturing processes.

As research progressed, scientists discovered the unique properties of sodium acetate, particularly its ability to form a stable solid electrolyte interphase (SEI) layer on the anode surface. This discovery marked a crucial turning point in sodium-ion battery development, as the SEI layer plays a vital role in preventing continuous electrolyte decomposition and ensuring long-term battery stability.

The incorporation of sodium acetate into battery systems has evolved through several key stages. Early experiments focused on using sodium acetate as an electrolyte additive, where it demonstrated promising results in improving the cycling stability of sodium-ion batteries. Subsequent research explored its potential as a primary component in solid electrolytes, leveraging its ionic conductivity and chemical stability.

Recent advancements have centered on optimizing the molecular structure and composition of sodium acetate-based materials to enhance their performance in battery applications. This includes the development of composite materials that combine sodium acetate with other compounds to achieve synergistic effects, such as improved ionic conductivity and mechanical strength.

The primary objective of current research on sodium acetate in battery technology is to significantly extend battery lifespan while maintaining or improving energy density and charging rates. This goal aligns with the broader aim of creating more sustainable and cost-effective energy storage solutions for various applications, from portable electronics to large-scale grid storage.

Researchers are now focusing on several key areas to achieve these objectives. These include understanding the fundamental mechanisms by which sodium acetate contributes to battery longevity, optimizing the integration of sodium acetate-based materials into existing battery architectures, and exploring novel cell designs that can fully capitalize on the unique properties of sodium acetate.

Furthermore, there is a growing emphasis on scalability and manufacturability, with the aim of transitioning sodium acetate-based battery technologies from laboratory prototypes to commercially viable products. This involves addressing challenges related to large-scale production, quality control, and integration with existing manufacturing processes.

Market Demand for Extended Battery Life Solutions

The demand for extended battery life solutions has been steadily increasing across various sectors, driven by the growing reliance on portable electronic devices and the push towards electrification in transportation. Consumers and industries alike are seeking more efficient and longer-lasting power sources, making battery life extension a critical focus for research and development.

In the consumer electronics market, smartphones, laptops, and wearable devices are at the forefront of this demand. Users expect their devices to last longer between charges, with many citing battery life as a key factor in purchasing decisions. This has led to a significant market opportunity for technologies that can extend battery lifespan, with manufacturers competing to offer devices with superior battery performance.

The automotive industry represents another major driver for extended battery life solutions. As electric vehicles (EVs) gain popularity, range anxiety remains a significant barrier to widespread adoption. Consumers are looking for EVs that can travel longer distances on a single charge, making battery life extension technologies crucial for the growth of this sector. The demand extends beyond personal vehicles to commercial fleets, where longer battery life can significantly reduce operational costs and downtime.

In the renewable energy sector, the need for efficient energy storage solutions is paramount. Grid-scale batteries and home energy storage systems require long-lasting, reliable power sources to effectively store and distribute renewable energy. The ability to extend battery lifespan in these applications can lead to more cost-effective and sustainable energy solutions.

The industrial and healthcare sectors also contribute to the growing demand for extended battery life. In industrial settings, longer-lasting batteries can improve the efficiency of equipment and reduce maintenance costs. In healthcare, portable medical devices and implantable technologies benefit greatly from extended battery life, enhancing patient care and reducing the frequency of invasive procedures for battery replacements.

The market for battery life extension technologies is not limited to new battery development. There is also significant interest in solutions that can improve the lifespan of existing batteries, offering a more sustainable approach to battery management. This includes advanced charging technologies, battery management systems, and additives that can enhance battery performance over time.

As environmental concerns grow, the demand for sustainable battery solutions has increased. Technologies that can extend battery life align well with sustainability goals by reducing electronic waste and the need for frequent battery replacements. This environmental aspect adds another layer of market demand, particularly among eco-conscious consumers and businesses committed to reducing their carbon footprint.

In the consumer electronics market, smartphones, laptops, and wearable devices are at the forefront of this demand. Users expect their devices to last longer between charges, with many citing battery life as a key factor in purchasing decisions. This has led to a significant market opportunity for technologies that can extend battery lifespan, with manufacturers competing to offer devices with superior battery performance.

The automotive industry represents another major driver for extended battery life solutions. As electric vehicles (EVs) gain popularity, range anxiety remains a significant barrier to widespread adoption. Consumers are looking for EVs that can travel longer distances on a single charge, making battery life extension technologies crucial for the growth of this sector. The demand extends beyond personal vehicles to commercial fleets, where longer battery life can significantly reduce operational costs and downtime.

In the renewable energy sector, the need for efficient energy storage solutions is paramount. Grid-scale batteries and home energy storage systems require long-lasting, reliable power sources to effectively store and distribute renewable energy. The ability to extend battery lifespan in these applications can lead to more cost-effective and sustainable energy solutions.

The industrial and healthcare sectors also contribute to the growing demand for extended battery life. In industrial settings, longer-lasting batteries can improve the efficiency of equipment and reduce maintenance costs. In healthcare, portable medical devices and implantable technologies benefit greatly from extended battery life, enhancing patient care and reducing the frequency of invasive procedures for battery replacements.

The market for battery life extension technologies is not limited to new battery development. There is also significant interest in solutions that can improve the lifespan of existing batteries, offering a more sustainable approach to battery management. This includes advanced charging technologies, battery management systems, and additives that can enhance battery performance over time.

As environmental concerns grow, the demand for sustainable battery solutions has increased. Technologies that can extend battery life align well with sustainability goals by reducing electronic waste and the need for frequent battery replacements. This environmental aspect adds another layer of market demand, particularly among eco-conscious consumers and businesses committed to reducing their carbon footprint.

Current Challenges in Battery Longevity Enhancement

Despite significant advancements in battery technology, several challenges persist in enhancing battery longevity. One of the primary issues is capacity fade, which occurs due to the gradual degradation of electrode materials over repeated charge-discharge cycles. This results in a reduction of the battery's overall capacity and energy density over time.

Another critical challenge is the formation and growth of solid electrolyte interphase (SEI) layers on electrode surfaces. While SEI formation is essential for battery stability, excessive growth can lead to increased internal resistance and reduced ion transport, ultimately impacting the battery's performance and lifespan.

Thermal management remains a significant hurdle in battery longevity. High temperatures accelerate chemical reactions within the battery, leading to faster degradation of components and potential safety risks. Conversely, low temperatures can significantly reduce battery performance and capacity.

Electrolyte decomposition is another persistent issue affecting battery lifespan. Over time, electrolytes can break down, leading to the formation of gas bubbles and increased internal pressure within the battery. This not only reduces the battery's efficiency but can also pose safety risks.

The challenge of lithium plating, particularly in fast-charging scenarios, continues to be a concern for battery longevity. When lithium ions deposit as metallic lithium on the anode surface instead of intercalating into the graphite structure, it can lead to capacity loss and potential safety hazards.

Mechanical stress on battery components during cycling is another factor limiting battery lifespan. Volume changes in electrode materials during charge and discharge can lead to structural degradation, particle isolation, and loss of electrical contact within the battery.

Addressing these challenges in the context of sodium acetate's potential role in prolonging battery lifespan requires innovative approaches. Research must focus on how sodium acetate might mitigate these issues, potentially by stabilizing electrode-electrolyte interfaces, improving thermal stability, or enhancing the structural integrity of battery components during cycling.

Another critical challenge is the formation and growth of solid electrolyte interphase (SEI) layers on electrode surfaces. While SEI formation is essential for battery stability, excessive growth can lead to increased internal resistance and reduced ion transport, ultimately impacting the battery's performance and lifespan.

Thermal management remains a significant hurdle in battery longevity. High temperatures accelerate chemical reactions within the battery, leading to faster degradation of components and potential safety risks. Conversely, low temperatures can significantly reduce battery performance and capacity.

Electrolyte decomposition is another persistent issue affecting battery lifespan. Over time, electrolytes can break down, leading to the formation of gas bubbles and increased internal pressure within the battery. This not only reduces the battery's efficiency but can also pose safety risks.

The challenge of lithium plating, particularly in fast-charging scenarios, continues to be a concern for battery longevity. When lithium ions deposit as metallic lithium on the anode surface instead of intercalating into the graphite structure, it can lead to capacity loss and potential safety hazards.

Mechanical stress on battery components during cycling is another factor limiting battery lifespan. Volume changes in electrode materials during charge and discharge can lead to structural degradation, particle isolation, and loss of electrical contact within the battery.

Addressing these challenges in the context of sodium acetate's potential role in prolonging battery lifespan requires innovative approaches. Research must focus on how sodium acetate might mitigate these issues, potentially by stabilizing electrode-electrolyte interfaces, improving thermal stability, or enhancing the structural integrity of battery components during cycling.

Existing Sodium Acetate Battery Life Extension Methods

01 Electrolyte composition for improved battery lifespan

The use of sodium acetate as an electrolyte component in batteries can enhance their lifespan. This compound helps to stabilize the electrolyte solution, reduce unwanted side reactions, and improve the overall performance of the battery over time. The inclusion of sodium acetate in the electrolyte formulation can lead to increased cycle life and better long-term stability of the battery.- Electrolyte composition for improved battery lifespan: The use of sodium acetate as an electrolyte component in batteries can enhance their lifespan. This compound helps to stabilize the electrolyte solution, reduce corrosion, and improve the overall performance of the battery over time. The inclusion of sodium acetate in the electrolyte formulation can lead to increased cycle life and better long-term stability of the battery.

- Electrode material optimization for sodium acetate batteries: Developing specialized electrode materials that are compatible with sodium acetate electrolytes can significantly impact battery lifespan. These materials are designed to withstand the specific chemical environment created by sodium acetate, reducing degradation and improving the overall longevity of the battery. Optimized electrode compositions can lead to more efficient charge/discharge cycles and extended battery life.

- Temperature management systems for sodium acetate batteries: Implementing effective temperature control mechanisms in sodium acetate batteries can greatly enhance their lifespan. Proper thermal management helps prevent degradation of the electrolyte and electrode materials, maintaining optimal operating conditions. This can include the use of cooling systems, insulation, or phase change materials to regulate battery temperature during operation and storage.

- Additives for enhancing sodium acetate battery performance: Incorporating specific additives into the sodium acetate electrolyte or electrode materials can improve battery lifespan. These additives may include stabilizers, conductivity enhancers, or compounds that form protective layers on electrode surfaces. By carefully selecting and optimizing these additives, the overall stability and longevity of the battery can be significantly increased.

- Advanced charging and discharging protocols: Developing and implementing sophisticated charging and discharging strategies can extend the lifespan of sodium acetate batteries. These protocols may involve optimized current rates, voltage limits, and rest periods that are specifically tailored to the characteristics of sodium acetate-based systems. By minimizing stress on the battery components during operation, these advanced protocols can significantly enhance the overall lifespan of the battery.

02 Electrode material optimization for sodium acetate batteries

Developing specialized electrode materials that are compatible with sodium acetate electrolytes can significantly impact battery lifespan. These materials are designed to withstand the specific chemical environment created by sodium acetate, reducing degradation and improving the overall longevity of the battery. Optimized electrode compositions can lead to more efficient charge/discharge cycles and extended battery life.Expand Specific Solutions03 Temperature management systems for sodium acetate batteries

Implementing effective temperature control mechanisms can greatly enhance the lifespan of sodium acetate batteries. These systems help maintain optimal operating temperatures, preventing thermal runaway and reducing stress on battery components. Proper thermal management can slow down degradation processes and extend the overall lifespan of the battery.Expand Specific Solutions04 Additives for stabilizing sodium acetate electrolytes

Incorporating specific additives into sodium acetate electrolytes can improve their stability and extend battery lifespan. These additives may include compounds that form protective layers on electrodes, reduce unwanted side reactions, or enhance the ionic conductivity of the electrolyte. The careful selection and combination of additives can lead to significant improvements in battery longevity.Expand Specific Solutions05 Advanced charging protocols for sodium acetate batteries

Developing and implementing specialized charging protocols tailored to sodium acetate batteries can help maximize their lifespan. These protocols may involve optimized charging rates, voltage limits, and rest periods that take into account the unique characteristics of sodium acetate electrolytes. By minimizing stress on the battery during charging, these advanced protocols can significantly extend the overall lifespan of the battery.Expand Specific Solutions

Key Players in Sodium Acetate Battery Research

The research on sodium acetate's value in prolonging battery lifespan is in an early developmental stage, with a growing market potential as the demand for sustainable energy storage solutions increases. The technology's maturity is still evolving, with various players at different stages of development. Companies like LG Energy Solution, Faradion, and Broadbit Batteries are leading the charge in sodium-ion battery technology, which could potentially incorporate sodium acetate. Established firms such as Samsung Electronics and BMW are also investing in this area, indicating its strategic importance. The competitive landscape is diverse, including both specialized startups and major corporations, suggesting a dynamic and rapidly evolving field with significant room for innovation and market growth.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has been exploring the use of sodium acetate in their advanced battery formulations, particularly for electric vehicle applications. Their research focuses on incorporating sodium acetate into the electrolyte solution to enhance the formation of a more stable and uniform SEI layer on the anode surface[4]. This approach aims to mitigate the degradation of the anode material over repeated charge-discharge cycles. LG's studies have shown that batteries with sodium acetate-enhanced electrolytes exhibit improved capacity retention, with some prototypes maintaining over 90% of their initial capacity after 500 cycles at high charge rates[5]. The company is also investigating the synergistic effects of combining sodium acetate with other electrolyte additives to further optimize battery performance and longevity.

Strengths: Extensive manufacturing capabilities and established presence in the EV market, potential for rapid commercialization. Weaknesses: May face challenges in integrating new technology into existing production lines without significant investment.

Faradion Ltd.

Technical Solution: Faradion has developed a proprietary sodium-ion technology that utilizes sodium acetate as a key component in their battery chemistry. Their approach involves using a layered oxide cathode material and a hard carbon anode, with sodium acetate serving as an electrolyte additive. This combination has shown promising results in extending battery lifespan by reducing unwanted side reactions at the electrode-electrolyte interface[1]. The company's research indicates that the addition of sodium acetate helps form a stable Solid Electrolyte Interphase (SEI) layer, which is crucial for long-term cycling stability[2]. Faradion's batteries have demonstrated over 1000 cycles with minimal capacity fade, suggesting a significant improvement in battery longevity compared to conventional lithium-ion batteries[3].

Strengths: Cost-effective and abundant raw materials, improved safety profile due to aqueous electrolytes, and potential for longer cycle life. Weaknesses: Lower energy density compared to lithium-ion batteries, which may limit application in certain high-energy demand scenarios.

Core Innovations in Sodium Acetate Battery Chemistry

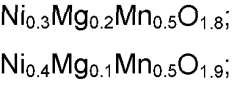

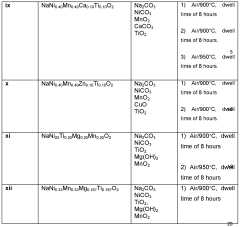

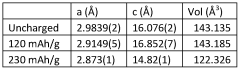

Doped nickelate compounds

PatentWO2014057258A1

Innovation

- Development of electrodes with specific doped nickelate compositions, such as AaM1v M2w M3x M4y M5z O2-c, where A is sodium or a mixed alkali metal, and M1, M2, M3, M4, and M5 are metals in specific oxidation states, allowing for higher charge capacity through overcharging and oxygen deficiency, optimizing the cathode composition for sodium-ion cells.

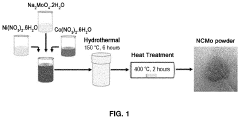

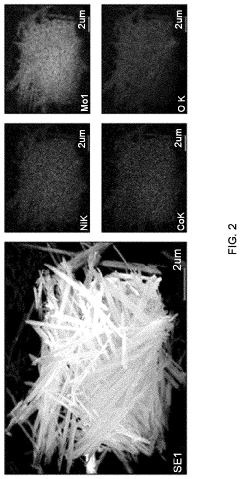

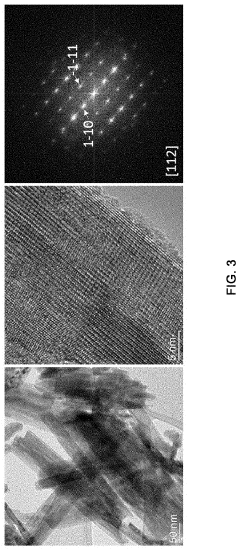

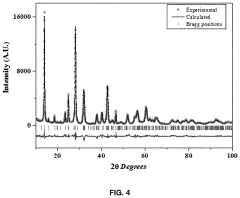

Anode electrode active material for sodium secondary battery comprising nickel cobalt molybdenum oxide, anode electrode for sodium secondary battery comprising same, sodium secondary battery including anode electrode for sodium secondary battery, and method for manufacturing same

PatentActiveUS20230146801A1

Innovation

- A novel anode electrode material composed of nickel cobalt molybdenum oxide (NixCo1-xMoO4) synthesized via a one-pot hydrothermal process, forming a single-phase nanorod structure that enables stable intercalation/deintercalation of sodium ions without significant volume change, reducing electrode damage and enhancing electrochemical characteristics.

Environmental Impact of Sodium Acetate Batteries

The environmental impact of sodium acetate batteries is a crucial consideration in the development and adoption of this technology. These batteries, which utilize sodium acetate as a key component, offer potential advantages in terms of sustainability and reduced environmental footprint compared to traditional lithium-ion batteries.

One of the primary environmental benefits of sodium acetate batteries is the abundance and accessibility of sodium as a raw material. Unlike lithium, which is relatively scarce and often mined in environmentally sensitive areas, sodium is widely available and can be extracted from seawater through less invasive methods. This reduces the environmental impact associated with resource extraction and helps mitigate concerns about resource depletion.

The production process of sodium acetate batteries also tends to be less energy-intensive compared to lithium-ion batteries. This translates to lower carbon emissions during manufacturing, contributing to a reduced overall carbon footprint. Additionally, the materials used in sodium acetate batteries are generally less toxic and more easily recyclable than those found in conventional batteries, further enhancing their environmental credentials.

In terms of end-of-life management, sodium acetate batteries present fewer challenges for recycling and disposal. The components can be more readily separated and recovered, reducing the amount of waste sent to landfills. This aligns with circular economy principles and helps minimize the long-term environmental impact of battery production and usage.

However, it is important to note that the environmental impact of sodium acetate batteries is not entirely negligible. The production of sodium acetate still requires energy and resources, and the large-scale adoption of these batteries would necessitate the development of new supply chains and manufacturing processes. These factors must be carefully managed to ensure that the environmental benefits are maximized.

Furthermore, the long-term ecological effects of increased sodium acetate production and use need to be studied more comprehensively. While sodium is generally considered less harmful than lithium, the potential impacts on soil and water ecosystems from large-scale sodium acetate battery deployment require ongoing research and monitoring.

In conclusion, while sodium acetate batteries show promise in reducing the environmental impact associated with energy storage solutions, a holistic approach to their development and implementation is essential. This includes considering the entire lifecycle of the batteries, from raw material extraction to end-of-life management, to ensure that their adoption truly contributes to a more sustainable energy future.

One of the primary environmental benefits of sodium acetate batteries is the abundance and accessibility of sodium as a raw material. Unlike lithium, which is relatively scarce and often mined in environmentally sensitive areas, sodium is widely available and can be extracted from seawater through less invasive methods. This reduces the environmental impact associated with resource extraction and helps mitigate concerns about resource depletion.

The production process of sodium acetate batteries also tends to be less energy-intensive compared to lithium-ion batteries. This translates to lower carbon emissions during manufacturing, contributing to a reduced overall carbon footprint. Additionally, the materials used in sodium acetate batteries are generally less toxic and more easily recyclable than those found in conventional batteries, further enhancing their environmental credentials.

In terms of end-of-life management, sodium acetate batteries present fewer challenges for recycling and disposal. The components can be more readily separated and recovered, reducing the amount of waste sent to landfills. This aligns with circular economy principles and helps minimize the long-term environmental impact of battery production and usage.

However, it is important to note that the environmental impact of sodium acetate batteries is not entirely negligible. The production of sodium acetate still requires energy and resources, and the large-scale adoption of these batteries would necessitate the development of new supply chains and manufacturing processes. These factors must be carefully managed to ensure that the environmental benefits are maximized.

Furthermore, the long-term ecological effects of increased sodium acetate production and use need to be studied more comprehensively. While sodium is generally considered less harmful than lithium, the potential impacts on soil and water ecosystems from large-scale sodium acetate battery deployment require ongoing research and monitoring.

In conclusion, while sodium acetate batteries show promise in reducing the environmental impact associated with energy storage solutions, a holistic approach to their development and implementation is essential. This includes considering the entire lifecycle of the batteries, from raw material extraction to end-of-life management, to ensure that their adoption truly contributes to a more sustainable energy future.

Cost-Benefit Analysis of Sodium Acetate Battery Tech

The cost-benefit analysis of sodium acetate battery technology reveals a promising avenue for extending battery lifespan, albeit with certain trade-offs to consider. On the cost side, integrating sodium acetate into battery production processes may require initial investments in research, development, and manufacturing infrastructure. These upfront costs could potentially increase the per-unit price of batteries in the short term. Additionally, the sourcing and processing of sodium acetate may introduce new supply chain considerations and potential environmental impacts that need to be carefully evaluated.

However, the benefits of this technology appear to outweigh the costs significantly. The primary advantage lies in the substantial increase in battery lifespan, which could potentially double or even triple the operational life of current lithium-ion batteries. This extended lifespan translates to reduced frequency of battery replacements, leading to long-term cost savings for consumers and businesses alike. Moreover, the improved longevity addresses a critical pain point in the electric vehicle and renewable energy storage sectors, potentially accelerating the adoption of these technologies.

From an environmental perspective, the use of sodium acetate in batteries presents a more sustainable alternative to current technologies. Sodium is abundantly available and less environmentally harmful to extract compared to lithium. The reduced need for battery replacements also means less electronic waste, aligning with global sustainability goals. This eco-friendly aspect could provide a competitive edge in markets with stringent environmental regulations.

In terms of performance, initial studies suggest that sodium acetate-enhanced batteries maintain high energy density and power output comparable to traditional lithium-ion batteries. The improved stability and reduced degradation over time could lead to more consistent performance throughout the battery's lifecycle, a significant advantage in applications requiring reliable long-term energy storage.

The economic implications of this technology extend beyond the battery industry. Industries reliant on long-lasting, high-performance batteries, such as telecommunications, aerospace, and grid energy storage, stand to benefit from reduced operational costs and improved reliability. This could drive innovation and growth in these sectors, potentially creating new market opportunities and job prospects.

However, it's crucial to consider the potential challenges in scaling this technology. The transition from laboratory success to mass production often encounters unforeseen obstacles. Ensuring consistent quality and performance across large-scale manufacturing processes will be critical. Additionally, the integration of this new technology into existing battery production lines and end-user products may require significant adaptation and potentially new safety protocols.

However, the benefits of this technology appear to outweigh the costs significantly. The primary advantage lies in the substantial increase in battery lifespan, which could potentially double or even triple the operational life of current lithium-ion batteries. This extended lifespan translates to reduced frequency of battery replacements, leading to long-term cost savings for consumers and businesses alike. Moreover, the improved longevity addresses a critical pain point in the electric vehicle and renewable energy storage sectors, potentially accelerating the adoption of these technologies.

From an environmental perspective, the use of sodium acetate in batteries presents a more sustainable alternative to current technologies. Sodium is abundantly available and less environmentally harmful to extract compared to lithium. The reduced need for battery replacements also means less electronic waste, aligning with global sustainability goals. This eco-friendly aspect could provide a competitive edge in markets with stringent environmental regulations.

In terms of performance, initial studies suggest that sodium acetate-enhanced batteries maintain high energy density and power output comparable to traditional lithium-ion batteries. The improved stability and reduced degradation over time could lead to more consistent performance throughout the battery's lifecycle, a significant advantage in applications requiring reliable long-term energy storage.

The economic implications of this technology extend beyond the battery industry. Industries reliant on long-lasting, high-performance batteries, such as telecommunications, aerospace, and grid energy storage, stand to benefit from reduced operational costs and improved reliability. This could drive innovation and growth in these sectors, potentially creating new market opportunities and job prospects.

However, it's crucial to consider the potential challenges in scaling this technology. The transition from laboratory success to mass production often encounters unforeseen obstacles. Ensuring consistent quality and performance across large-scale manufacturing processes will be critical. Additionally, the integration of this new technology into existing battery production lines and end-user products may require significant adaptation and potentially new safety protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!