Sulfamic Acid for Semiconductor Cleaning and Surface Preparation

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulfamic Acid in Semiconductors: Background and Objectives

Sulfamic acid has emerged as a crucial component in the semiconductor industry, particularly in the processes of cleaning and surface preparation. The evolution of this technology can be traced back to the early days of semiconductor manufacturing, where the need for ultra-clean surfaces became increasingly apparent as device dimensions shrank and performance requirements escalated.

The primary objective of utilizing sulfamic acid in semiconductor applications is to achieve pristine surfaces free from contaminants, oxides, and other impurities that can adversely affect device performance and reliability. This goal aligns with the industry's relentless pursuit of miniaturization and enhanced functionality in electronic devices.

Over the years, the semiconductor industry has witnessed a significant shift in cleaning technologies, moving from aggressive chemical treatments to more environmentally friendly and selective processes. Sulfamic acid has gained prominence in this transition due to its unique properties that make it particularly suitable for semiconductor applications.

The technology surrounding sulfamic acid in semiconductor cleaning has progressed through several key stages. Initially, it was used as a simple acidic cleaning agent. However, as understanding of its chemical interactions with various semiconductor materials deepened, more sophisticated formulations and application methods were developed. These advancements aimed to optimize the cleaning efficiency while minimizing potential damage to delicate semiconductor structures.

Current research in this field focuses on further refining the use of sulfamic acid, exploring its potential in advanced node technologies, and investigating its compatibility with new materials being introduced in semiconductor manufacturing. The ongoing trend towards three-dimensional device architectures and the integration of novel materials presents new challenges and opportunities for sulfamic acid-based cleaning solutions.

The technological trajectory of sulfamic acid in semiconductor cleaning is closely tied to the broader trends in the industry, including the push for more environmentally sustainable practices, the need for precision cleaning at the atomic scale, and the demand for processes compatible with a wide range of materials and structures.

As we look towards the future, the objectives for sulfamic acid technology in semiconductor applications are multifaceted. These include developing formulations capable of selectively removing contaminants without affecting underlying materials, creating cleaning processes that can be seamlessly integrated into advanced manufacturing flows, and ensuring compatibility with emerging semiconductor materials and architectures.

The primary objective of utilizing sulfamic acid in semiconductor applications is to achieve pristine surfaces free from contaminants, oxides, and other impurities that can adversely affect device performance and reliability. This goal aligns with the industry's relentless pursuit of miniaturization and enhanced functionality in electronic devices.

Over the years, the semiconductor industry has witnessed a significant shift in cleaning technologies, moving from aggressive chemical treatments to more environmentally friendly and selective processes. Sulfamic acid has gained prominence in this transition due to its unique properties that make it particularly suitable for semiconductor applications.

The technology surrounding sulfamic acid in semiconductor cleaning has progressed through several key stages. Initially, it was used as a simple acidic cleaning agent. However, as understanding of its chemical interactions with various semiconductor materials deepened, more sophisticated formulations and application methods were developed. These advancements aimed to optimize the cleaning efficiency while minimizing potential damage to delicate semiconductor structures.

Current research in this field focuses on further refining the use of sulfamic acid, exploring its potential in advanced node technologies, and investigating its compatibility with new materials being introduced in semiconductor manufacturing. The ongoing trend towards three-dimensional device architectures and the integration of novel materials presents new challenges and opportunities for sulfamic acid-based cleaning solutions.

The technological trajectory of sulfamic acid in semiconductor cleaning is closely tied to the broader trends in the industry, including the push for more environmentally sustainable practices, the need for precision cleaning at the atomic scale, and the demand for processes compatible with a wide range of materials and structures.

As we look towards the future, the objectives for sulfamic acid technology in semiconductor applications are multifaceted. These include developing formulations capable of selectively removing contaminants without affecting underlying materials, creating cleaning processes that can be seamlessly integrated into advanced manufacturing flows, and ensuring compatibility with emerging semiconductor materials and architectures.

Market Analysis for Semiconductor Cleaning Solutions

The semiconductor cleaning solutions market has experienced significant growth in recent years, driven by the increasing demand for advanced semiconductor devices across various industries. As the complexity and miniaturization of semiconductor components continue to evolve, the need for effective cleaning solutions becomes paramount to ensure optimal performance and reliability.

The global semiconductor cleaning solutions market is projected to expand at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2026. This growth is primarily attributed to the rising adoption of advanced cleaning technologies in semiconductor manufacturing processes, particularly in the production of high-performance integrated circuits and memory devices.

Key factors contributing to market growth include the increasing demand for consumer electronics, automotive electronics, and the rapid development of 5G technology. The automotive sector, in particular, has emerged as a significant driver for semiconductor cleaning solutions, as modern vehicles incorporate an increasing number of electronic components and advanced driver assistance systems (ADAS).

The Asia-Pacific region dominates the semiconductor cleaning solutions market, accounting for over 60% of the global market share. This dominance is due to the presence of major semiconductor manufacturing hubs in countries such as China, Taiwan, South Korea, and Japan. North America and Europe follow as the second and third-largest markets, respectively, driven by the presence of leading semiconductor companies and research institutions.

In terms of product segments, aqueous cleaning solutions currently hold the largest market share, owing to their effectiveness in removing a wide range of contaminants and their environmentally friendly nature. However, solvent-based cleaning solutions are gaining traction due to their ability to remove stubborn residues and their compatibility with certain sensitive materials.

The market is characterized by intense competition among key players, including DuPont, BASF, Mitsubishi Chemical Corporation, and Avantor Performance Materials. These companies are focusing on developing innovative cleaning solutions that address the evolving needs of the semiconductor industry, such as the removal of sub-10nm particles and the reduction of defectivity rates.

Emerging trends in the semiconductor cleaning solutions market include the development of eco-friendly and biodegradable cleaning agents, the integration of advanced process control systems for optimized cleaning processes, and the adoption of single-wafer cleaning technologies for improved efficiency and reduced chemical consumption.

The global semiconductor cleaning solutions market is projected to expand at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2026. This growth is primarily attributed to the rising adoption of advanced cleaning technologies in semiconductor manufacturing processes, particularly in the production of high-performance integrated circuits and memory devices.

Key factors contributing to market growth include the increasing demand for consumer electronics, automotive electronics, and the rapid development of 5G technology. The automotive sector, in particular, has emerged as a significant driver for semiconductor cleaning solutions, as modern vehicles incorporate an increasing number of electronic components and advanced driver assistance systems (ADAS).

The Asia-Pacific region dominates the semiconductor cleaning solutions market, accounting for over 60% of the global market share. This dominance is due to the presence of major semiconductor manufacturing hubs in countries such as China, Taiwan, South Korea, and Japan. North America and Europe follow as the second and third-largest markets, respectively, driven by the presence of leading semiconductor companies and research institutions.

In terms of product segments, aqueous cleaning solutions currently hold the largest market share, owing to their effectiveness in removing a wide range of contaminants and their environmentally friendly nature. However, solvent-based cleaning solutions are gaining traction due to their ability to remove stubborn residues and their compatibility with certain sensitive materials.

The market is characterized by intense competition among key players, including DuPont, BASF, Mitsubishi Chemical Corporation, and Avantor Performance Materials. These companies are focusing on developing innovative cleaning solutions that address the evolving needs of the semiconductor industry, such as the removal of sub-10nm particles and the reduction of defectivity rates.

Emerging trends in the semiconductor cleaning solutions market include the development of eco-friendly and biodegradable cleaning agents, the integration of advanced process control systems for optimized cleaning processes, and the adoption of single-wafer cleaning technologies for improved efficiency and reduced chemical consumption.

Current Challenges in Semiconductor Surface Preparation

The semiconductor industry faces several critical challenges in surface preparation, particularly as device dimensions continue to shrink and performance requirements become more stringent. One of the primary issues is the removal of increasingly complex and diverse contaminants without damaging delicate structures. Traditional cleaning methods often struggle to effectively clean sub-10nm features without causing physical damage or leaving residues.

Another significant challenge is the need for precise control over surface chemistry. As devices become more sophisticated, even minor variations in surface properties can significantly impact performance. Achieving uniform and reproducible surface conditions across large wafers is becoming increasingly difficult, especially with the industry's transition to 300mm and potentially 450mm wafers.

The environmental impact of cleaning processes is also a growing concern. Many traditional cleaning chemicals are hazardous and require careful handling and disposal. There is a pressing need for more environmentally friendly alternatives that can maintain or improve cleaning efficacy while reducing the ecological footprint of semiconductor manufacturing.

Particle contamination remains a persistent issue, with the detection and removal of ever-smaller particles becoming more challenging. As critical dimensions decrease, particles that were once considered inconsequential can now cause significant yield losses. Developing cleaning techniques that can effectively remove sub-10nm particles without damaging nanostructures is a major focus of research.

The integration of new materials in semiconductor devices, such as high-k dielectrics and metal gates, presents additional cleaning challenges. These materials often require specialized cleaning processes that are compatible with their unique chemical and physical properties. Balancing the need for effective cleaning with the preservation of these sensitive materials is a delicate task.

Energy efficiency in cleaning processes is another area of concern. As the industry strives to reduce its overall energy consumption, there is a need for cleaning technologies that can operate at lower temperatures and with reduced chemical usage without compromising effectiveness.

Lastly, the increasing complexity of 3D structures in advanced semiconductor devices, such as FinFETs and gate-all-around transistors, poses new challenges for surface preparation. Cleaning these intricate structures requires innovative approaches to ensure complete removal of contaminants from high-aspect-ratio features and confined spaces without causing collapse or deformation of the delicate structures.

Another significant challenge is the need for precise control over surface chemistry. As devices become more sophisticated, even minor variations in surface properties can significantly impact performance. Achieving uniform and reproducible surface conditions across large wafers is becoming increasingly difficult, especially with the industry's transition to 300mm and potentially 450mm wafers.

The environmental impact of cleaning processes is also a growing concern. Many traditional cleaning chemicals are hazardous and require careful handling and disposal. There is a pressing need for more environmentally friendly alternatives that can maintain or improve cleaning efficacy while reducing the ecological footprint of semiconductor manufacturing.

Particle contamination remains a persistent issue, with the detection and removal of ever-smaller particles becoming more challenging. As critical dimensions decrease, particles that were once considered inconsequential can now cause significant yield losses. Developing cleaning techniques that can effectively remove sub-10nm particles without damaging nanostructures is a major focus of research.

The integration of new materials in semiconductor devices, such as high-k dielectrics and metal gates, presents additional cleaning challenges. These materials often require specialized cleaning processes that are compatible with their unique chemical and physical properties. Balancing the need for effective cleaning with the preservation of these sensitive materials is a delicate task.

Energy efficiency in cleaning processes is another area of concern. As the industry strives to reduce its overall energy consumption, there is a need for cleaning technologies that can operate at lower temperatures and with reduced chemical usage without compromising effectiveness.

Lastly, the increasing complexity of 3D structures in advanced semiconductor devices, such as FinFETs and gate-all-around transistors, poses new challenges for surface preparation. Cleaning these intricate structures requires innovative approaches to ensure complete removal of contaminants from high-aspect-ratio features and confined spaces without causing collapse or deformation of the delicate structures.

Existing Sulfamic Acid-based Cleaning Solutions

01 Sulfamic acid cleaning compositions

Sulfamic acid is used in cleaning compositions for various surfaces. These compositions often include additional components such as surfactants, corrosion inhibitors, and other acids to enhance cleaning efficiency and protect surfaces. The formulations are effective for removing scale, rust, and other deposits from metal surfaces, particularly in industrial applications.- Sulfamic acid cleaning compositions: Sulfamic acid is used in cleaning compositions for various surfaces. These compositions often include additional components such as surfactants, corrosion inhibitors, and pH adjusters to enhance cleaning efficiency and protect surfaces. The formulations are effective for removing scale, rust, and other deposits from metal surfaces, particularly in industrial applications.

- Surface preparation methods using sulfamic acid: Sulfamic acid is employed in surface preparation techniques, particularly for metal surfaces. These methods involve applying sulfamic acid solutions to remove oxides, scale, and contaminants, preparing the surface for subsequent treatments such as coating or bonding. The process can improve adhesion and corrosion resistance of the treated surfaces.

- Sulfamic acid in specialized cleaning applications: Sulfamic acid is utilized in specialized cleaning applications, such as descaling heat exchangers, cleaning industrial equipment, and removing mineral deposits in pipes and boilers. These applications often require specific concentrations and application methods to ensure effective cleaning without damaging the underlying materials.

- Environmentally friendly sulfamic acid formulations: Development of environmentally friendly sulfamic acid cleaning formulations that reduce environmental impact and improve safety for users. These formulations may include biodegradable additives, lower concentrations of sulfamic acid, or alternative application methods to minimize waste and emissions while maintaining cleaning effectiveness.

- Sulfamic acid in combination with other acids for enhanced cleaning: Combining sulfamic acid with other acids or cleaning agents to create synergistic cleaning effects. These combinations can enhance the overall cleaning performance, broaden the range of contaminants that can be removed, or allow for lower concentrations of individual components while maintaining efficacy.

02 Surface preparation methods using sulfamic acid

Sulfamic acid is employed in surface preparation techniques, particularly for metal surfaces. These methods involve applying sulfamic acid solutions to remove oxides, scale, and contaminants, preparing the surface for further treatment or coating. The process can improve adhesion of subsequent coatings and enhance the overall quality of the treated surface.Expand Specific Solutions03 Sulfamic acid in combination with other acids

Cleaning and surface preparation formulations often combine sulfamic acid with other acids such as hydrochloric acid, phosphoric acid, or organic acids. These combinations can provide synergistic effects, improving the overall cleaning efficiency and expanding the range of contaminants that can be removed from surfaces.Expand Specific Solutions04 Sulfamic acid for specific industrial applications

Sulfamic acid is utilized in specialized cleaning and surface preparation processes for specific industries. These applications include descaling heat exchangers, cleaning boilers, preparing surfaces in the automotive industry, and treating concrete surfaces. The formulations are tailored to meet the unique requirements of each application.Expand Specific Solutions05 Environmental and safety considerations in sulfamic acid use

Formulations and methods involving sulfamic acid are developed with a focus on environmental safety and user protection. This includes the use of biodegradable additives, pH adjusters to minimize corrosion, and the incorporation of safety features in application equipment. These considerations aim to reduce environmental impact and improve worker safety during cleaning and surface preparation processes.Expand Specific Solutions

Key Players in Semiconductor Cleaning Industry

The semiconductor cleaning and surface preparation market using sulfamic acid is in a growth phase, driven by increasing demand for advanced semiconductor devices. The market size is expanding due to the proliferation of electronic devices and the need for more sophisticated cleaning processes. Technologically, the field is advancing rapidly, with companies like FUJIFILM Corp., Semiconductor Manufacturing International (Shanghai) Corp., and Nissan Chemical Corp. leading innovation. These firms, along with others such as JSR Corp. and Mitsubishi Gas Chemical Co., Inc., are developing more efficient and environmentally friendly cleaning solutions. The competitive landscape is characterized by a mix of established chemical companies and specialized semiconductor material suppliers, all vying to meet the industry's evolving requirements for higher purity and performance in chip manufacturing processes.

Kanto Chemical Co., Inc.

Technical Solution: Kanto Chemical has developed advanced sulfamic acid-based cleaning solutions for semiconductor applications. Their proprietary formulation combines sulfamic acid with other chemicals to create a highly effective cleaning agent. This solution is particularly effective in removing metal contaminants and organic residues from silicon wafers[1]. The company has optimized the concentration and pH levels of their sulfamic acid mixture to achieve maximum cleaning efficiency while minimizing surface damage. They have also incorporated additives that enhance the solution's wetting properties, allowing for better penetration into small features and high aspect ratio structures[3]. Kanto Chemical's process involves a multi-step cleaning sequence, including pre-cleaning, main cleaning with the sulfamic acid solution, and post-cleaning rinse steps, all carefully controlled to ensure optimal results[5].

Strengths: Highly effective in removing various contaminants, optimized for minimal surface damage, suitable for advanced node processes. Weaknesses: May require specialized handling and waste treatment due to the acidic nature of the solution.

FUJIFILM Wako Pure Chemical Corp.

Technical Solution: FUJIFILM Wako Pure Chemical has developed a novel sulfamic acid-based cleaning technology for semiconductor applications. Their approach involves using ultra-high purity sulfamic acid in combination with proprietary surfactants to create a cleaning solution that effectively removes both organic and inorganic contaminants from semiconductor surfaces[2]. The company has fine-tuned the composition to achieve a balance between cleaning power and surface preservation. Their process includes a controlled application method that ensures uniform coverage and penetration into complex structures, such as high aspect ratio trenches and vias[4]. FUJIFILM Wako's sulfamic acid solution is particularly effective in removing metal ions and particles without causing damage to sensitive low-k dielectric materials commonly used in advanced semiconductor devices[6]. The company has also developed a specialized rinsing procedure that effectively neutralizes and removes any residual acid, leaving a clean and residue-free surface.

Strengths: Excellent cleaning efficacy for both organic and inorganic contaminants, compatible with advanced materials like low-k dielectrics. Weaknesses: May require specialized equipment for precise application and control of the cleaning process.

Innovations in Sulfamic Acid Application Techniques

Composition for chemical purification of surfaces off adsorbed metal ions and atoms

PatentWO2001031696A1

Innovation

- A composition comprising sulphomaleic anhydride, disulphomaleic anhydride, and water, with a specific ratio, is used for chemical purification, which creates an acid buffer with pH=1, enhancing the dissolution of metal ions and improving the treatment capacity and efficiency.

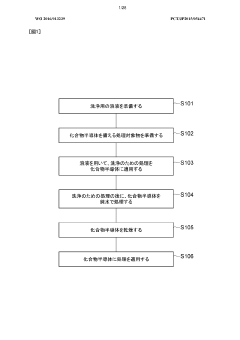

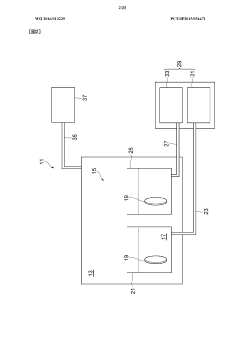

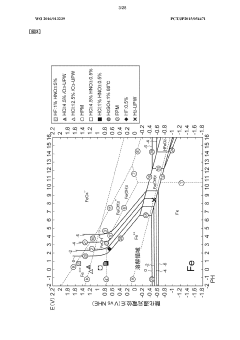

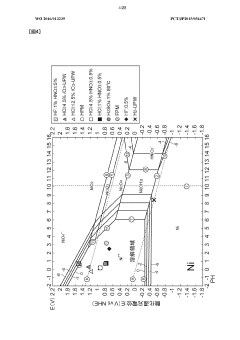

Method for cleaning compound semiconductor and solution for cleaning of compound semiconductor

PatentWO2016013239A1

Innovation

- A cleaning method using a solution with pure water and sulfuric acid at concentrations less than 65 wt%, applied at temperatures of 70°C or higher, which effectively reduces metal impurities like iron, nickel, and copper on the semiconductor surface while minimizing environmental impact by reducing sulfuric acid evaporation and wastewater treatment burdens.

Environmental Impact of Sulfamic Acid Usage

The use of sulfamic acid in semiconductor cleaning and surface preparation processes has significant environmental implications that require careful consideration. While sulfamic acid offers several advantages in terms of cleaning efficiency and effectiveness, its potential environmental impact must be thoroughly assessed and mitigated.

One of the primary environmental concerns associated with sulfamic acid usage is its potential to contribute to water pollution. When discharged into aquatic ecosystems, sulfamic acid can lower the pH of water bodies, potentially harming aquatic life and disrupting ecosystem balance. This acidification effect can be particularly problematic in areas with sensitive aquatic habitats or where water resources are already under stress.

Furthermore, the production and disposal of sulfamic acid can generate hazardous waste streams that require proper management. The manufacturing process of sulfamic acid involves the use of various chemicals, some of which may have their own environmental risks. Improper disposal or accidental release of these waste products can lead to soil and groundwater contamination, posing risks to both human health and the environment.

In terms of air quality, the use of sulfamic acid in semiconductor cleaning processes can potentially release volatile organic compounds (VOCs) and other airborne pollutants. These emissions may contribute to local air pollution and, in some cases, play a role in the formation of smog or other air quality issues. Proper ventilation and emission control systems are crucial to mitigate these potential impacts.

However, it is important to note that sulfamic acid also offers some environmental benefits when compared to alternative cleaning agents. Its biodegradability and lower toxicity profile make it a more environmentally friendly option in many applications. Additionally, the efficient cleaning properties of sulfamic acid can lead to reduced water and energy consumption in semiconductor manufacturing processes, potentially offsetting some of its environmental drawbacks.

To address these environmental concerns, the semiconductor industry has been implementing various strategies. These include the development of closed-loop systems for sulfamic acid recycling, advanced wastewater treatment technologies to neutralize and remove acid residues, and the exploration of even more environmentally benign cleaning alternatives. Research into green chemistry approaches and sustainable manufacturing practices is ongoing, aiming to further reduce the environmental footprint of semiconductor cleaning processes.

In conclusion, while sulfamic acid presents certain environmental challenges, its use in semiconductor cleaning and surface preparation can be managed responsibly through a combination of careful process design, advanced treatment technologies, and ongoing research into more sustainable alternatives. Balancing the technical benefits of sulfamic acid with its environmental impact remains a key consideration for the semiconductor industry as it strives for greater sustainability in its operations.

One of the primary environmental concerns associated with sulfamic acid usage is its potential to contribute to water pollution. When discharged into aquatic ecosystems, sulfamic acid can lower the pH of water bodies, potentially harming aquatic life and disrupting ecosystem balance. This acidification effect can be particularly problematic in areas with sensitive aquatic habitats or where water resources are already under stress.

Furthermore, the production and disposal of sulfamic acid can generate hazardous waste streams that require proper management. The manufacturing process of sulfamic acid involves the use of various chemicals, some of which may have their own environmental risks. Improper disposal or accidental release of these waste products can lead to soil and groundwater contamination, posing risks to both human health and the environment.

In terms of air quality, the use of sulfamic acid in semiconductor cleaning processes can potentially release volatile organic compounds (VOCs) and other airborne pollutants. These emissions may contribute to local air pollution and, in some cases, play a role in the formation of smog or other air quality issues. Proper ventilation and emission control systems are crucial to mitigate these potential impacts.

However, it is important to note that sulfamic acid also offers some environmental benefits when compared to alternative cleaning agents. Its biodegradability and lower toxicity profile make it a more environmentally friendly option in many applications. Additionally, the efficient cleaning properties of sulfamic acid can lead to reduced water and energy consumption in semiconductor manufacturing processes, potentially offsetting some of its environmental drawbacks.

To address these environmental concerns, the semiconductor industry has been implementing various strategies. These include the development of closed-loop systems for sulfamic acid recycling, advanced wastewater treatment technologies to neutralize and remove acid residues, and the exploration of even more environmentally benign cleaning alternatives. Research into green chemistry approaches and sustainable manufacturing practices is ongoing, aiming to further reduce the environmental footprint of semiconductor cleaning processes.

In conclusion, while sulfamic acid presents certain environmental challenges, its use in semiconductor cleaning and surface preparation can be managed responsibly through a combination of careful process design, advanced treatment technologies, and ongoing research into more sustainable alternatives. Balancing the technical benefits of sulfamic acid with its environmental impact remains a key consideration for the semiconductor industry as it strives for greater sustainability in its operations.

Safety Protocols for Handling Sulfamic Acid

Handling sulfamic acid in semiconductor cleaning and surface preparation processes requires strict adherence to safety protocols due to its corrosive and potentially hazardous nature. Personal protective equipment (PPE) is essential when working with sulfamic acid. This includes chemical-resistant gloves, safety goggles or a face shield, and protective clothing such as a lab coat or chemical-resistant apron. Respiratory protection may also be necessary, especially when dealing with powdered forms of sulfamic acid or in poorly ventilated areas.

Proper storage of sulfamic acid is crucial to maintain safety. It should be kept in a cool, dry place, away from direct sunlight and heat sources. The storage area should be well-ventilated and separate from incompatible materials such as strong oxidizing agents, chlorine, and nitric acid. Containers should be tightly sealed and clearly labeled with appropriate hazard warnings.

When preparing solutions of sulfamic acid, it is important to add the acid to water slowly while stirring, never the reverse. This practice helps prevent splashing and excessive heat generation. All mixing and handling should be performed in a fume hood or well-ventilated area to minimize exposure to fumes or dust.

Spill response procedures must be established and communicated to all personnel working with sulfamic acid. In case of a spill, the area should be immediately evacuated, and only trained personnel with proper PPE should handle the cleanup. Neutralization with a weak alkaline solution, such as sodium bicarbonate, can be used for small spills, followed by absorption with an inert material.

Regular safety training and education for all employees handling sulfamic acid is essential. This should include proper handling techniques, emergency procedures, and the use of safety equipment. Material Safety Data Sheets (MSDS) for sulfamic acid should be readily available and reviewed by all personnel involved in its use.

Proper disposal of sulfamic acid and its solutions is critical to environmental safety. It should never be disposed of down drains or in regular waste. Instead, it must be collected and disposed of as hazardous waste according to local regulations and guidelines.

Emergency eyewash stations and safety showers should be installed in areas where sulfamic acid is used or stored. These facilities should be easily accessible and regularly tested to ensure proper function in case of accidental exposure.

Implementing a regular inspection and maintenance program for all equipment and storage facilities used with sulfamic acid is crucial. This helps prevent leaks, spills, or other potential hazards due to equipment failure or deterioration.

By rigorously following these safety protocols, the risks associated with handling sulfamic acid in semiconductor cleaning and surface preparation can be significantly mitigated, ensuring a safer working environment for all personnel involved in these processes.

Proper storage of sulfamic acid is crucial to maintain safety. It should be kept in a cool, dry place, away from direct sunlight and heat sources. The storage area should be well-ventilated and separate from incompatible materials such as strong oxidizing agents, chlorine, and nitric acid. Containers should be tightly sealed and clearly labeled with appropriate hazard warnings.

When preparing solutions of sulfamic acid, it is important to add the acid to water slowly while stirring, never the reverse. This practice helps prevent splashing and excessive heat generation. All mixing and handling should be performed in a fume hood or well-ventilated area to minimize exposure to fumes or dust.

Spill response procedures must be established and communicated to all personnel working with sulfamic acid. In case of a spill, the area should be immediately evacuated, and only trained personnel with proper PPE should handle the cleanup. Neutralization with a weak alkaline solution, such as sodium bicarbonate, can be used for small spills, followed by absorption with an inert material.

Regular safety training and education for all employees handling sulfamic acid is essential. This should include proper handling techniques, emergency procedures, and the use of safety equipment. Material Safety Data Sheets (MSDS) for sulfamic acid should be readily available and reviewed by all personnel involved in its use.

Proper disposal of sulfamic acid and its solutions is critical to environmental safety. It should never be disposed of down drains or in regular waste. Instead, it must be collected and disposed of as hazardous waste according to local regulations and guidelines.

Emergency eyewash stations and safety showers should be installed in areas where sulfamic acid is used or stored. These facilities should be easily accessible and regularly tested to ensure proper function in case of accidental exposure.

Implementing a regular inspection and maintenance program for all equipment and storage facilities used with sulfamic acid is crucial. This helps prevent leaks, spills, or other potential hazards due to equipment failure or deterioration.

By rigorously following these safety protocols, the risks associated with handling sulfamic acid in semiconductor cleaning and surface preparation can be significantly mitigated, ensuring a safer working environment for all personnel involved in these processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!