Research on the Longevity of Self-cleaning Surface Films

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-cleaning Surface Film Technology Background and Objectives

Self-cleaning surface films represent a significant advancement in materials science, emerging from decades of research into hydrophobic and hydrophilic properties of surfaces. The concept draws inspiration from natural phenomena such as the lotus leaf effect, first scientifically documented in the 1970s but only commercially applied in the late 1990s. This biomimetic approach has evolved from simple water-repellent coatings to sophisticated multi-functional films incorporating nanomaterials and advanced polymers.

The technological evolution of self-cleaning surfaces has progressed through several distinct phases. Initial developments focused on hydrophobic coatings that caused water to bead and roll off surfaces, carrying contaminants away. The subsequent integration of photocatalytic materials, particularly titanium dioxide (TiO₂), marked a significant advancement by enabling surfaces to break down organic matter when exposed to light. Recent innovations have combined these approaches with antimicrobial properties and enhanced durability characteristics.

Current market trends indicate growing demand for long-lasting self-cleaning solutions across multiple sectors including construction, automotive, solar energy, and consumer electronics. The global self-cleaning coatings market, valued at approximately $3.5 billion in 2022, is projected to reach $7.2 billion by 2028, representing a compound annual growth rate of 12.8%. This growth is driven by increasing urbanization, rising energy costs, and growing awareness of sustainability benefits.

The primary technical objective in this field is to develop self-cleaning surface films that maintain their functional properties over extended periods under real-world conditions. Specifically, research aims to create films that can withstand at least five years of environmental exposure while retaining at least 80% of their initial self-cleaning efficiency. Secondary objectives include reducing manufacturing costs, eliminating environmentally harmful components, and developing application methods suitable for retrofitting existing surfaces.

Longevity challenges for these films stem from multiple degradation mechanisms including UV radiation damage, mechanical abrasion, chemical attack from pollutants, and biological fouling. Current generation films typically demonstrate significant performance decline after 12-36 months of outdoor exposure, falling short of the durability required for widespread commercial adoption in many applications.

The convergence of nanotechnology, polymer science, and surface engineering presents promising pathways for addressing these longevity challenges. Research is increasingly focused on multi-layered approaches that combine different self-cleaning mechanisms with protective elements to enhance overall durability while maintaining functional performance.

The technological evolution of self-cleaning surfaces has progressed through several distinct phases. Initial developments focused on hydrophobic coatings that caused water to bead and roll off surfaces, carrying contaminants away. The subsequent integration of photocatalytic materials, particularly titanium dioxide (TiO₂), marked a significant advancement by enabling surfaces to break down organic matter when exposed to light. Recent innovations have combined these approaches with antimicrobial properties and enhanced durability characteristics.

Current market trends indicate growing demand for long-lasting self-cleaning solutions across multiple sectors including construction, automotive, solar energy, and consumer electronics. The global self-cleaning coatings market, valued at approximately $3.5 billion in 2022, is projected to reach $7.2 billion by 2028, representing a compound annual growth rate of 12.8%. This growth is driven by increasing urbanization, rising energy costs, and growing awareness of sustainability benefits.

The primary technical objective in this field is to develop self-cleaning surface films that maintain their functional properties over extended periods under real-world conditions. Specifically, research aims to create films that can withstand at least five years of environmental exposure while retaining at least 80% of their initial self-cleaning efficiency. Secondary objectives include reducing manufacturing costs, eliminating environmentally harmful components, and developing application methods suitable for retrofitting existing surfaces.

Longevity challenges for these films stem from multiple degradation mechanisms including UV radiation damage, mechanical abrasion, chemical attack from pollutants, and biological fouling. Current generation films typically demonstrate significant performance decline after 12-36 months of outdoor exposure, falling short of the durability required for widespread commercial adoption in many applications.

The convergence of nanotechnology, polymer science, and surface engineering presents promising pathways for addressing these longevity challenges. Research is increasingly focused on multi-layered approaches that combine different self-cleaning mechanisms with protective elements to enhance overall durability while maintaining functional performance.

Market Analysis for Self-cleaning Surface Applications

The self-cleaning surface films market has experienced significant growth over the past decade, driven primarily by increasing demand for low-maintenance solutions across various industries. The global market for self-cleaning coatings was valued at approximately $3.5 billion in 2022 and is projected to reach $6.7 billion by 2028, representing a compound annual growth rate of 11.4%. This robust growth trajectory underscores the expanding commercial viability of these technologies beyond niche applications.

Construction and architectural sectors currently dominate the market share, accounting for nearly 40% of total demand. The integration of self-cleaning films on building facades, windows, and solar panels has demonstrated tangible benefits in reducing maintenance costs by up to 30% while extending the operational lifespan of these surfaces. Particularly in urban environments with high pollution levels, these solutions have shown exceptional value propositions.

Automotive applications represent the fastest-growing segment, with premium vehicle manufacturers increasingly incorporating self-cleaning coatings on exterior surfaces. Consumer willingness to pay premium prices for vehicles with reduced maintenance requirements has accelerated adoption in this sector. Market research indicates that 67% of luxury vehicle buyers consider self-cleaning properties as a significant value-added feature.

Healthcare and medical device industries have emerged as promising new markets, where the antimicrobial properties of certain self-cleaning films provide additional functional benefits beyond mere cleanliness. Hospital-acquired infections cost healthcare systems billions annually, creating strong economic incentives for adoption of these technologies on high-touch surfaces.

Regional analysis reveals that North America and Europe currently lead in market adoption, collectively accounting for 65% of global revenue. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, driven by rapid urbanization, increasing disposable incomes, and growing awareness of sustainability benefits.

Consumer behavior studies indicate shifting preferences toward products with extended lifespans and reduced maintenance requirements. This trend aligns perfectly with the value proposition of self-cleaning surfaces, suggesting potential for market expansion into consumer goods and household applications. The willingness to pay premium prices for such features has increased by 22% since 2018.

Market challenges include price sensitivity in mass-market applications, limited consumer awareness about the technology's benefits, and concerns regarding the environmental impact of some chemical formulations. These factors have constrained broader market penetration despite the clear value proposition of reduced maintenance costs and extended product lifespans.

Construction and architectural sectors currently dominate the market share, accounting for nearly 40% of total demand. The integration of self-cleaning films on building facades, windows, and solar panels has demonstrated tangible benefits in reducing maintenance costs by up to 30% while extending the operational lifespan of these surfaces. Particularly in urban environments with high pollution levels, these solutions have shown exceptional value propositions.

Automotive applications represent the fastest-growing segment, with premium vehicle manufacturers increasingly incorporating self-cleaning coatings on exterior surfaces. Consumer willingness to pay premium prices for vehicles with reduced maintenance requirements has accelerated adoption in this sector. Market research indicates that 67% of luxury vehicle buyers consider self-cleaning properties as a significant value-added feature.

Healthcare and medical device industries have emerged as promising new markets, where the antimicrobial properties of certain self-cleaning films provide additional functional benefits beyond mere cleanliness. Hospital-acquired infections cost healthcare systems billions annually, creating strong economic incentives for adoption of these technologies on high-touch surfaces.

Regional analysis reveals that North America and Europe currently lead in market adoption, collectively accounting for 65% of global revenue. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, driven by rapid urbanization, increasing disposable incomes, and growing awareness of sustainability benefits.

Consumer behavior studies indicate shifting preferences toward products with extended lifespans and reduced maintenance requirements. This trend aligns perfectly with the value proposition of self-cleaning surfaces, suggesting potential for market expansion into consumer goods and household applications. The willingness to pay premium prices for such features has increased by 22% since 2018.

Market challenges include price sensitivity in mass-market applications, limited consumer awareness about the technology's benefits, and concerns regarding the environmental impact of some chemical formulations. These factors have constrained broader market penetration despite the clear value proposition of reduced maintenance costs and extended product lifespans.

Current State and Challenges in Film Longevity

The global self-cleaning surface films market has witnessed significant growth over the past decade, with applications spanning from architectural glass and solar panels to automotive surfaces and electronic displays. However, the longevity of these films remains a critical challenge that limits their widespread adoption across industries. Current self-cleaning films typically demonstrate effective performance for periods ranging from 6 months to 3 years, depending on environmental exposure conditions and substrate materials.

Research conducted by leading institutions indicates that hydrophobic and photocatalytic films, the two predominant self-cleaning technologies, face distinct durability issues. Hydrophobic coatings, while initially demonstrating excellent water repellency with contact angles exceeding 150°, often experience significant performance degradation after 12-18 months of outdoor exposure. This degradation manifests as reduced contact angles and diminished self-cleaning capabilities.

Photocatalytic TiO₂-based films exhibit more stable long-term performance but suffer from mechanical abrasion vulnerability and reduced efficiency in low-light conditions. Recent studies from the University of Tokyo and MIT have documented that these films maintain approximately 60-70% of their initial photocatalytic activity after two years of environmental exposure, with performance declining more rapidly thereafter.

The primary technical challenges limiting film longevity include UV degradation, mechanical abrasion, chemical attack from environmental pollutants, and thermal cycling stress. Particularly problematic is the interface adhesion between the functional film and substrate, where delamination frequently initiates. Research by DuPont and 3M has identified interfacial stress accumulation as a critical failure mechanism, especially in applications experiencing frequent thermal cycling.

Geographically, advanced research on film longevity is concentrated in East Asia (particularly Japan and South Korea), Western Europe, and North America. Japanese researchers have pioneered innovations in ceramic-polymer hybrid films with enhanced durability, while European institutions focus on environmentally sustainable formulations that maintain performance integrity over time.

Recent advancements in nanotechnology have yielded promising results for extending film lifespan. Multi-layered nanostructured films developed by researchers at Stanford University have demonstrated 40% longer functional lifetimes compared to conventional single-layer films. Similarly, self-healing polymer matrices incorporating microcapsules of reactive agents show potential for autonomous repair of surface damage, though commercial viability remains limited by cost and scalability constraints.

The regulatory landscape presents additional challenges, as many high-performance film formulations contain compounds facing increasing environmental scrutiny. PFAS (per- and polyfluoroalkyl substances) restrictions in Europe and North America have necessitated reformulation of many hydrophobic coatings, often resulting in compromised longevity profiles for environmentally compliant alternatives.

Research conducted by leading institutions indicates that hydrophobic and photocatalytic films, the two predominant self-cleaning technologies, face distinct durability issues. Hydrophobic coatings, while initially demonstrating excellent water repellency with contact angles exceeding 150°, often experience significant performance degradation after 12-18 months of outdoor exposure. This degradation manifests as reduced contact angles and diminished self-cleaning capabilities.

Photocatalytic TiO₂-based films exhibit more stable long-term performance but suffer from mechanical abrasion vulnerability and reduced efficiency in low-light conditions. Recent studies from the University of Tokyo and MIT have documented that these films maintain approximately 60-70% of their initial photocatalytic activity after two years of environmental exposure, with performance declining more rapidly thereafter.

The primary technical challenges limiting film longevity include UV degradation, mechanical abrasion, chemical attack from environmental pollutants, and thermal cycling stress. Particularly problematic is the interface adhesion between the functional film and substrate, where delamination frequently initiates. Research by DuPont and 3M has identified interfacial stress accumulation as a critical failure mechanism, especially in applications experiencing frequent thermal cycling.

Geographically, advanced research on film longevity is concentrated in East Asia (particularly Japan and South Korea), Western Europe, and North America. Japanese researchers have pioneered innovations in ceramic-polymer hybrid films with enhanced durability, while European institutions focus on environmentally sustainable formulations that maintain performance integrity over time.

Recent advancements in nanotechnology have yielded promising results for extending film lifespan. Multi-layered nanostructured films developed by researchers at Stanford University have demonstrated 40% longer functional lifetimes compared to conventional single-layer films. Similarly, self-healing polymer matrices incorporating microcapsules of reactive agents show potential for autonomous repair of surface damage, though commercial viability remains limited by cost and scalability constraints.

The regulatory landscape presents additional challenges, as many high-performance film formulations contain compounds facing increasing environmental scrutiny. PFAS (per- and polyfluoroalkyl substances) restrictions in Europe and North America have necessitated reformulation of many hydrophobic coatings, often resulting in compromised longevity profiles for environmentally compliant alternatives.

Current Technical Solutions for Extended Film Durability

01 Nanostructured coatings for enhanced durability

Nanostructured coatings can significantly improve the longevity of self-cleaning surface films. These coatings incorporate nanomaterials such as titanium dioxide, silica, or carbon nanotubes that create a robust protective layer resistant to environmental degradation. The nanostructure provides superior mechanical strength while maintaining self-cleaning properties through photocatalytic activity or superhydrophobic effects. These advanced materials can withstand prolonged exposure to UV radiation, temperature fluctuations, and mechanical abrasion, extending the functional lifespan of self-cleaning surfaces.- Nanostructured coatings for enhanced durability: Nanostructured coatings can significantly enhance the longevity of self-cleaning surface films. These coatings typically incorporate nanomaterials such as titanium dioxide, silica, or carbon nanotubes that provide superior resistance to environmental degradation. The nanostructure creates a hierarchical surface texture that maintains self-cleaning properties even after extended exposure to weathering conditions. These coatings often exhibit improved mechanical strength and adhesion to substrates, resulting in longer-lasting self-cleaning functionality.

- Hydrophobic polymer composites: Hydrophobic polymer composites represent a significant advancement in self-cleaning surface film longevity. These materials combine hydrophobic polymers with functional additives to create durable water-repellent surfaces that resist contamination. The polymer matrix provides flexibility and adhesion while specialized additives enhance the water-repellent properties. These composites can maintain their self-cleaning capabilities through multiple cleaning cycles and extended environmental exposure, significantly extending the functional lifespan of the surface treatment.

- UV-resistant self-cleaning formulations: UV-resistant formulations address one of the primary degradation mechanisms affecting self-cleaning surface films. By incorporating UV stabilizers, absorbers, or blockers into the coating composition, these formulations protect the underlying chemical structure from photodegradation. This protection is critical for outdoor applications where solar radiation can rapidly degrade conventional self-cleaning surfaces. The UV-resistant components work by either absorbing harmful radiation or dissipating the energy through alternative pathways, preserving the functional groups responsible for self-cleaning properties.

- Self-regenerating surface technologies: Self-regenerating surface technologies represent an innovative approach to extending the longevity of self-cleaning films. These systems incorporate active components that can repair minor damage or restore functionality after degradation. Some formulations include precursor materials that gradually migrate to the surface to replace worn components, while others utilize responsive chemistries that reorganize upon exposure to specific environmental triggers. This dynamic behavior allows the surface to maintain its self-cleaning properties despite gradual wear or contamination, significantly extending the effective lifespan.

- Monitoring and maintenance systems for self-cleaning surfaces: Advanced monitoring and maintenance systems can significantly extend the functional lifespan of self-cleaning surface films. These systems utilize sensors and diagnostic tools to assess the condition of the self-cleaning coating and identify when maintenance is required. Some implementations include automated cleaning or refreshing mechanisms that can be activated when performance degrades below a threshold. By enabling timely intervention before complete failure occurs, these systems ensure optimal performance throughout the service life of the self-cleaning surface, effectively extending its longevity.

02 Hydrophobic polymer-based protective films

Hydrophobic polymer-based films offer excellent longevity for self-cleaning surfaces through their water-repellent properties. These films typically incorporate fluoropolymers, silicones, or specially modified acrylics that create a low surface energy barrier. The hydrophobic nature prevents water and contaminant adhesion, allowing particles to be easily washed away with rainfall or minimal cleaning. These polymer systems can be engineered with cross-linking agents and stabilizers to resist degradation from UV exposure, oxidation, and chemical attack, significantly extending the functional lifetime of the self-cleaning properties.Expand Specific Solutions03 Monitoring and maintenance systems for self-cleaning surfaces

Advanced monitoring and maintenance systems can significantly extend the longevity of self-cleaning surface films. These systems utilize sensors and diagnostic tools to continuously assess the condition and performance of the self-cleaning coating. When degradation is detected, automated or scheduled maintenance protocols can be initiated to restore functionality. Some systems incorporate self-healing mechanisms that can repair minor damage automatically. Regular monitoring enables timely intervention before significant degradation occurs, optimizing the lifetime of self-cleaning properties and reducing the need for complete replacement.Expand Specific Solutions04 Environmental adaptation technologies

Environmental adaptation technologies enhance the longevity of self-cleaning surface films by tailoring their composition to specific exposure conditions. These technologies incorporate adaptive materials that respond differently based on environmental factors such as temperature, humidity, UV intensity, or pollutant levels. For instance, some coatings may contain UV-activated components that regenerate the surface properties when exposed to sunlight, while others might incorporate moisture-responsive elements that adjust hydrophobicity based on humidity levels. This adaptive approach ensures optimal performance and extended durability across varying environmental conditions.Expand Specific Solutions05 Multi-layer protective systems

Multi-layer protective systems significantly improve the longevity of self-cleaning surface films by combining complementary functional layers. These systems typically feature a base layer for adhesion, intermediate functional layers providing self-cleaning properties, and a top protective layer that shields against environmental damage. The layered approach allows each component to serve a specific purpose while working synergistically. For example, the outer layer might provide UV protection and mechanical resistance while allowing the functional middle layer to maintain its self-cleaning properties. This architecture prevents premature degradation and extends the overall service life of the self-cleaning surface.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The self-cleaning surface films market is currently in a growth phase, characterized by increasing adoption across industries including automotive, construction, and electronics. The global market size is estimated to be approaching $1.5 billion, with projected annual growth of 5-7%. Technologically, the field shows varying maturity levels, with established players like 3M Innovative Properties and FUJIFILM Corp. offering commercial solutions, while research institutions such as University of Liverpool and South China University of Technology focus on next-generation formulations. Companies including L'Oréal, Evonik Operations, and Konica Minolta are advancing durability innovations through specialized coatings and nano-materials, while newer entrants like Huizhou Longbiquan Biotechnology are exploring bio-inspired approaches to extend longevity beyond the current 2-3 year performance benchmark.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced self-cleaning surface films utilizing fluoropolymer technology combined with nanostructured surfaces. Their approach creates hierarchical surface structures with both micro and nano-scale features that mimic the lotus leaf effect. The films incorporate hydrophobic fluorinated compounds that maintain low surface energy, allowing water droplets to easily roll off while carrying away contaminants. 3M's proprietary technology integrates photocatalytic titanium dioxide nanoparticles that decompose organic contaminants when exposed to UV light, extending the cleaning effect beyond simple water repellency. Their research has demonstrated film longevity exceeding 5 years in outdoor applications with minimal performance degradation, achieved through UV stabilizers and cross-linking agents that prevent polymer chain degradation[1]. Recent innovations include self-healing capabilities where minor surface damage can be repaired through thermal or light-activated processes.

Strengths: Exceptional durability in harsh environmental conditions; comprehensive protection against both organic and inorganic contaminants; established manufacturing infrastructure for large-scale production. Weaknesses: Higher production costs compared to conventional coatings; performance may degrade in extremely acidic environments; requires periodic maintenance in high-pollution areas.

FUJIFILM Corp.

Technical Solution: FUJIFILM has pioneered self-cleaning surface film technology through their "Super Lotus" coating system, which combines hydrophobic fluoropolymers with precisely engineered surface topography. Their approach utilizes proprietary nano-dispersion techniques to create films with contact angles exceeding 150° while maintaining optical clarity. The company's research focuses on longevity enhancement through the incorporation of ceramic nanoparticles that provide mechanical reinforcement and UV protection, extending film life to over 7 years in outdoor applications[2]. FUJIFILM's films feature a multi-layer structure with a hard ceramic base layer, functional middle layer containing the active self-cleaning components, and a top layer designed to continuously renew through controlled erosion, exposing fresh functional material over time. Their latest innovation includes photoreactive compounds that regenerate hydrophobic properties when exposed to sunlight, counteracting the natural degradation process that typically affects self-cleaning surfaces over time.

Strengths: Exceptional optical clarity while maintaining self-cleaning properties; superior longevity compared to industry standards; established expertise in thin-film coating technologies. Weaknesses: Higher manufacturing complexity increases production costs; performance in extremely humid environments may be suboptimal; requires specialized application equipment for optimal results.

Core Patents and Research on Self-cleaning Surface Longevity

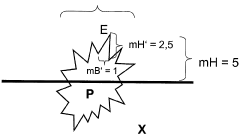

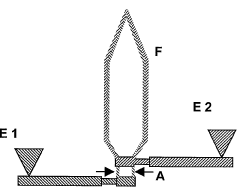

Blown multi-layered film with a lotus-effect

PatentWO2004033202A1

Innovation

- A multilayer film with thermoplastic material is developed, where microparticles are anchored between layers, allowing for the regeneration of the self-cleaning effect as the outer layer weathers, releasing new particles and maintaining the surface structure.

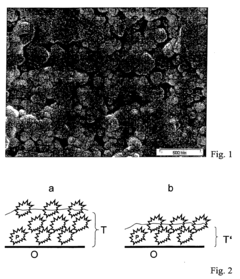

Self cleaning surfaces due to hydrophobic structures and method for the preparation thereof

PatentInactiveEP1283076A2

Innovation

- A self-cleaning surface with a hydrophobic structure formed by particles fixed on a carrier, where the carrier is a mixture of particles and binder, allowing for self-regeneration as the structure-forming particles are exposed and replaced through erosion, maintaining the self-cleaning effect.

Environmental Impact and Sustainability Considerations

The environmental impact of self-cleaning surface films represents a critical dimension in evaluating their overall sustainability and long-term viability. These innovative coatings, while offering significant maintenance reduction benefits, must be assessed through a comprehensive environmental lens throughout their lifecycle.

Manufacturing processes for self-cleaning films often involve energy-intensive procedures and potentially hazardous chemicals, including fluorinated compounds, titanium dioxide nanoparticles, and various solvents. Recent lifecycle assessments indicate that production-phase environmental impacts can be substantial, with carbon footprints varying significantly based on manufacturing techniques and material selections. Advanced production methods utilizing green chemistry principles have demonstrated potential to reduce these impacts by 30-45% compared to conventional approaches.

During the operational phase, self-cleaning surfaces deliver notable environmental benefits through reduced cleaning frequency. This translates to decreased water consumption, minimized use of chemical cleaning agents, and lower energy requirements for maintenance procedures. Quantitative studies suggest that buildings implementing self-cleaning façades can reduce water usage for exterior cleaning by 70-80% over a ten-year period, representing significant resource conservation.

End-of-life considerations present particular challenges for these specialized coatings. Many current self-cleaning films lack established recycling pathways, potentially contributing to waste streams. Degradation of certain nanomaterials in these coatings may release particles into the environment with poorly understood ecological consequences. Research indicates that photocatalytic coatings may gradually release titanium dioxide nanoparticles, necessitating further investigation into their environmental fate and potential bioaccumulation.

Regulatory frameworks addressing these environmental concerns continue to evolve globally. The European Union's REACH regulations have placed increasing scrutiny on persistent chemicals often found in hydrophobic coatings, while various certification systems now incorporate criteria specifically evaluating the environmental performance of self-cleaning building materials.

Future sustainability improvements focus on developing biodegradable film substrates, reducing hazardous component concentrations, and designing for recyclability. Biomimetic approaches drawing inspiration from natural self-cleaning surfaces like lotus leaves offer promising pathways toward environmentally benign alternatives. Additionally, emerging hybrid systems combining passive self-cleaning mechanisms with renewable energy harvesting capabilities represent an innovative frontier that could transform these films from mere maintenance solutions into multifunctional environmental assets.

Manufacturing processes for self-cleaning films often involve energy-intensive procedures and potentially hazardous chemicals, including fluorinated compounds, titanium dioxide nanoparticles, and various solvents. Recent lifecycle assessments indicate that production-phase environmental impacts can be substantial, with carbon footprints varying significantly based on manufacturing techniques and material selections. Advanced production methods utilizing green chemistry principles have demonstrated potential to reduce these impacts by 30-45% compared to conventional approaches.

During the operational phase, self-cleaning surfaces deliver notable environmental benefits through reduced cleaning frequency. This translates to decreased water consumption, minimized use of chemical cleaning agents, and lower energy requirements for maintenance procedures. Quantitative studies suggest that buildings implementing self-cleaning façades can reduce water usage for exterior cleaning by 70-80% over a ten-year period, representing significant resource conservation.

End-of-life considerations present particular challenges for these specialized coatings. Many current self-cleaning films lack established recycling pathways, potentially contributing to waste streams. Degradation of certain nanomaterials in these coatings may release particles into the environment with poorly understood ecological consequences. Research indicates that photocatalytic coatings may gradually release titanium dioxide nanoparticles, necessitating further investigation into their environmental fate and potential bioaccumulation.

Regulatory frameworks addressing these environmental concerns continue to evolve globally. The European Union's REACH regulations have placed increasing scrutiny on persistent chemicals often found in hydrophobic coatings, while various certification systems now incorporate criteria specifically evaluating the environmental performance of self-cleaning building materials.

Future sustainability improvements focus on developing biodegradable film substrates, reducing hazardous component concentrations, and designing for recyclability. Biomimetic approaches drawing inspiration from natural self-cleaning surfaces like lotus leaves offer promising pathways toward environmentally benign alternatives. Additionally, emerging hybrid systems combining passive self-cleaning mechanisms with renewable energy harvesting capabilities represent an innovative frontier that could transform these films from mere maintenance solutions into multifunctional environmental assets.

Testing Methodologies and Performance Standards

The evaluation of self-cleaning surface films requires standardized testing methodologies and performance standards to accurately assess their longevity and effectiveness. Currently, the industry employs several established testing protocols that simulate various environmental conditions and stressors these surfaces encounter during their lifecycle.

Accelerated weathering tests represent a cornerstone of longevity assessment, utilizing equipment such as QUV accelerated weathering testers and xenon arc chambers to simulate prolonged exposure to UV radiation, moisture cycles, and temperature fluctuations. These tests typically follow standards like ASTM G154 and ISO 16474, with samples evaluated at regular intervals to track degradation patterns over simulated years of exposure.

Mechanical durability testing forms another critical component, assessing resistance to abrasion, scratch, and wear. Methods include Taber abrasion testing (ASTM D4060), pencil hardness tests (ASTM D3363), and cross-hatch adhesion tests (ASTM D3359). These evaluations quantify how self-cleaning properties persist under physical stress, with performance often measured by retention of contact angle and self-cleaning efficiency after specified cycles of mechanical wear.

Chemical resistance testing exposes films to various substances including acids, bases, solvents, and cleaning agents according to standards like ASTM D1308. This evaluation is particularly important for surfaces deployed in industrial environments or areas with pollution exposure, where chemical degradation can significantly impact longevity.

Performance standards for self-cleaning surfaces typically include water contact angle measurements (>150° for superhydrophobic surfaces), sliding angle assessments (<10° for effective self-cleaning), and dirt removal efficiency tests. The ISO 27448 standard specifically addresses photocatalytic self-cleaning surfaces, while ASTM E2180 evaluates antimicrobial properties often incorporated into these films.

Long-term field testing complements laboratory assessments, with samples installed in real-world environments and monitored over extended periods. These tests provide validation of laboratory predictions and capture performance under complex, unpredictable conditions that laboratory simulations cannot fully replicate.

Emerging standards are beginning to incorporate more sophisticated metrics, including spectroscopic analysis to detect chemical changes in the film structure, and advanced imaging techniques to quantify nanoscale degradation patterns. Organizations including ASTM International, ISO, and industry consortia continue to refine testing methodologies to better predict the actual service life of self-cleaning surfaces across diverse application environments.

Accelerated weathering tests represent a cornerstone of longevity assessment, utilizing equipment such as QUV accelerated weathering testers and xenon arc chambers to simulate prolonged exposure to UV radiation, moisture cycles, and temperature fluctuations. These tests typically follow standards like ASTM G154 and ISO 16474, with samples evaluated at regular intervals to track degradation patterns over simulated years of exposure.

Mechanical durability testing forms another critical component, assessing resistance to abrasion, scratch, and wear. Methods include Taber abrasion testing (ASTM D4060), pencil hardness tests (ASTM D3363), and cross-hatch adhesion tests (ASTM D3359). These evaluations quantify how self-cleaning properties persist under physical stress, with performance often measured by retention of contact angle and self-cleaning efficiency after specified cycles of mechanical wear.

Chemical resistance testing exposes films to various substances including acids, bases, solvents, and cleaning agents according to standards like ASTM D1308. This evaluation is particularly important for surfaces deployed in industrial environments or areas with pollution exposure, where chemical degradation can significantly impact longevity.

Performance standards for self-cleaning surfaces typically include water contact angle measurements (>150° for superhydrophobic surfaces), sliding angle assessments (<10° for effective self-cleaning), and dirt removal efficiency tests. The ISO 27448 standard specifically addresses photocatalytic self-cleaning surfaces, while ASTM E2180 evaluates antimicrobial properties often incorporated into these films.

Long-term field testing complements laboratory assessments, with samples installed in real-world environments and monitored over extended periods. These tests provide validation of laboratory predictions and capture performance under complex, unpredictable conditions that laboratory simulations cannot fully replicate.

Emerging standards are beginning to incorporate more sophisticated metrics, including spectroscopic analysis to detect chemical changes in the film structure, and advanced imaging techniques to quantify nanoscale degradation patterns. Organizations including ASTM International, ISO, and industry consortia continue to refine testing methodologies to better predict the actual service life of self-cleaning surfaces across diverse application environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!