Sodium Bisulfate Role in Cement Production Enhancement

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Bisulfate in Cement: Background and Objectives

Sodium bisulfate has emerged as a significant additive in cement production, playing a crucial role in enhancing the overall quality and performance of cement. This research aims to explore the background of sodium bisulfate usage in cement manufacturing and define the objectives for its application in the industry.

The cement industry has long sought ways to improve the properties of cement, including its strength, durability, and setting time. In recent years, sodium bisulfate has gained attention as a potential solution to address various challenges in cement production. This compound, also known as sodium hydrogen sulfate, is a byproduct of various industrial processes and has found applications in multiple sectors due to its unique chemical properties.

The use of sodium bisulfate in cement production can be traced back to the early 2000s when researchers began investigating its potential benefits. Initial studies focused on its ability to modify the hydration process of cement, which is crucial for determining the final properties of concrete. As research progressed, it became evident that sodium bisulfate could offer advantages beyond just altering hydration kinetics.

One of the primary reasons for the growing interest in sodium bisulfate is its potential to address environmental concerns associated with cement production. The cement industry is known for its significant carbon footprint, and there is a pressing need to develop more sustainable production methods. Sodium bisulfate has shown promise in reducing the clinker factor in cement, which could lead to lower CO2 emissions during manufacturing.

Furthermore, the use of sodium bisulfate aligns with the industry's trend towards utilizing industrial byproducts and waste materials in cement production. This approach not only helps in waste management but also contributes to the circular economy concept, where materials are reused and recycled to minimize environmental impact.

The main objectives of this research on sodium bisulfate in cement production are multifaceted. Firstly, it aims to comprehensively understand the mechanisms by which sodium bisulfate interacts with cement components during the hydration process. This knowledge is crucial for optimizing its usage and predicting its effects on the final cement properties.

Secondly, the research seeks to quantify the improvements in cement quality that can be achieved through the incorporation of sodium bisulfate. This includes assessing enhancements in compressive strength, durability, and resistance to various environmental factors such as sulfate attack and chloride penetration.

Another key objective is to evaluate the economic viability of using sodium bisulfate in large-scale cement production. This involves analyzing the cost-benefit ratio, considering factors such as the availability of sodium bisulfate, its price fluctuations, and the potential savings in other aspects of cement manufacturing.

Lastly, the research aims to explore the environmental benefits of incorporating sodium bisulfate in cement production. This includes studying its potential to reduce CO2 emissions, lower energy consumption during manufacturing, and contribute to the overall sustainability of the cement industry.

The cement industry has long sought ways to improve the properties of cement, including its strength, durability, and setting time. In recent years, sodium bisulfate has gained attention as a potential solution to address various challenges in cement production. This compound, also known as sodium hydrogen sulfate, is a byproduct of various industrial processes and has found applications in multiple sectors due to its unique chemical properties.

The use of sodium bisulfate in cement production can be traced back to the early 2000s when researchers began investigating its potential benefits. Initial studies focused on its ability to modify the hydration process of cement, which is crucial for determining the final properties of concrete. As research progressed, it became evident that sodium bisulfate could offer advantages beyond just altering hydration kinetics.

One of the primary reasons for the growing interest in sodium bisulfate is its potential to address environmental concerns associated with cement production. The cement industry is known for its significant carbon footprint, and there is a pressing need to develop more sustainable production methods. Sodium bisulfate has shown promise in reducing the clinker factor in cement, which could lead to lower CO2 emissions during manufacturing.

Furthermore, the use of sodium bisulfate aligns with the industry's trend towards utilizing industrial byproducts and waste materials in cement production. This approach not only helps in waste management but also contributes to the circular economy concept, where materials are reused and recycled to minimize environmental impact.

The main objectives of this research on sodium bisulfate in cement production are multifaceted. Firstly, it aims to comprehensively understand the mechanisms by which sodium bisulfate interacts with cement components during the hydration process. This knowledge is crucial for optimizing its usage and predicting its effects on the final cement properties.

Secondly, the research seeks to quantify the improvements in cement quality that can be achieved through the incorporation of sodium bisulfate. This includes assessing enhancements in compressive strength, durability, and resistance to various environmental factors such as sulfate attack and chloride penetration.

Another key objective is to evaluate the economic viability of using sodium bisulfate in large-scale cement production. This involves analyzing the cost-benefit ratio, considering factors such as the availability of sodium bisulfate, its price fluctuations, and the potential savings in other aspects of cement manufacturing.

Lastly, the research aims to explore the environmental benefits of incorporating sodium bisulfate in cement production. This includes studying its potential to reduce CO2 emissions, lower energy consumption during manufacturing, and contribute to the overall sustainability of the cement industry.

Market Analysis for Enhanced Cement Production

The global cement market has been experiencing steady growth, driven by increasing urbanization and infrastructure development worldwide. The demand for enhanced cement production techniques, particularly those involving sodium bisulfate, has gained significant traction in recent years. This market analysis explores the current landscape and future prospects for cement production enhancement using sodium bisulfate.

The cement industry, valued at approximately $340 billion in 2022, is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2030. This growth is primarily fueled by the rising construction activities in emerging economies and the need for more durable and sustainable building materials. The market for cement additives, including sodium bisulfate, is expected to witness even higher growth rates, with some estimates suggesting a CAGR of 6.2% during the same period.

Sodium bisulfate's role in enhancing cement production has garnered attention due to its ability to improve cement quality, reduce production costs, and minimize environmental impact. The global market for sodium bisulfate in cement production is estimated to reach $1.2 billion by 2025, reflecting the increasing adoption of this additive in the industry.

Geographically, Asia-Pacific dominates the market for enhanced cement production, accounting for over 50% of the global demand. China and India are the largest consumers, driven by their massive infrastructure development projects and rapid urbanization. North America and Europe follow, with a growing focus on sustainable construction practices driving the demand for advanced cement production techniques.

The market is characterized by a high degree of fragmentation, with numerous local and regional players competing alongside multinational corporations. Key market players include LafargeHolcim, CEMEX, HeidelbergCement, and Anhui Conch Cement Company. These companies are increasingly investing in research and development to incorporate innovative additives like sodium bisulfate into their production processes.

Consumer trends indicate a growing preference for high-performance cement with enhanced durability and reduced environmental footprint. This shift is driving cement manufacturers to adopt advanced production techniques, including the use of sodium bisulfate, to meet these evolving market demands.

Regulatory factors also play a crucial role in shaping the market for enhanced cement production. Stringent environmental regulations, particularly in developed economies, are pushing cement manufacturers to adopt cleaner production methods. Sodium bisulfate's ability to reduce emissions and improve energy efficiency aligns well with these regulatory requirements, further driving its adoption in the industry.

In conclusion, the market for enhanced cement production, particularly using sodium bisulfate, presents significant growth opportunities. As construction activities continue to rise globally and sustainability becomes increasingly important, the demand for advanced cement production techniques is expected to surge, positioning sodium bisulfate as a key player in the future of the cement industry.

The cement industry, valued at approximately $340 billion in 2022, is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2030. This growth is primarily fueled by the rising construction activities in emerging economies and the need for more durable and sustainable building materials. The market for cement additives, including sodium bisulfate, is expected to witness even higher growth rates, with some estimates suggesting a CAGR of 6.2% during the same period.

Sodium bisulfate's role in enhancing cement production has garnered attention due to its ability to improve cement quality, reduce production costs, and minimize environmental impact. The global market for sodium bisulfate in cement production is estimated to reach $1.2 billion by 2025, reflecting the increasing adoption of this additive in the industry.

Geographically, Asia-Pacific dominates the market for enhanced cement production, accounting for over 50% of the global demand. China and India are the largest consumers, driven by their massive infrastructure development projects and rapid urbanization. North America and Europe follow, with a growing focus on sustainable construction practices driving the demand for advanced cement production techniques.

The market is characterized by a high degree of fragmentation, with numerous local and regional players competing alongside multinational corporations. Key market players include LafargeHolcim, CEMEX, HeidelbergCement, and Anhui Conch Cement Company. These companies are increasingly investing in research and development to incorporate innovative additives like sodium bisulfate into their production processes.

Consumer trends indicate a growing preference for high-performance cement with enhanced durability and reduced environmental footprint. This shift is driving cement manufacturers to adopt advanced production techniques, including the use of sodium bisulfate, to meet these evolving market demands.

Regulatory factors also play a crucial role in shaping the market for enhanced cement production. Stringent environmental regulations, particularly in developed economies, are pushing cement manufacturers to adopt cleaner production methods. Sodium bisulfate's ability to reduce emissions and improve energy efficiency aligns well with these regulatory requirements, further driving its adoption in the industry.

In conclusion, the market for enhanced cement production, particularly using sodium bisulfate, presents significant growth opportunities. As construction activities continue to rise globally and sustainability becomes increasingly important, the demand for advanced cement production techniques is expected to surge, positioning sodium bisulfate as a key player in the future of the cement industry.

Current Challenges in Cement Manufacturing

The cement industry faces several significant challenges in its manufacturing processes, primarily centered around energy efficiency, environmental impact, and product quality. One of the most pressing issues is the high energy consumption required for cement production, particularly during the clinker formation stage. This energy-intensive process not only increases production costs but also contributes substantially to greenhouse gas emissions, making it a target for environmental scrutiny.

Environmental concerns extend beyond energy usage to include the release of pollutants such as nitrogen oxides, sulfur dioxide, and particulate matter. Regulatory pressures to reduce these emissions are intensifying, forcing manufacturers to seek innovative solutions for cleaner production methods. The industry is also grappling with the need to reduce its carbon footprint, as cement production is responsible for approximately 8% of global CO2 emissions.

Raw material quality and availability present another set of challenges. The variability in limestone composition and the depletion of high-quality reserves necessitate more sophisticated processing techniques and alternative material sourcing strategies. This variability can affect the consistency of the final product, potentially leading to quality control issues.

Water scarcity in many regions where cement plants operate is becoming an increasingly critical issue. The industry must find ways to reduce water consumption and improve water recycling processes without compromising product quality or operational efficiency.

The cement manufacturing process is also facing challenges related to equipment wear and maintenance. The highly abrasive nature of cement production leads to significant wear on machinery, resulting in frequent maintenance requirements and potential production disruptions. This necessitates ongoing research into more durable materials and innovative equipment designs.

Furthermore, the industry is under pressure to incorporate more sustainable practices, including the use of alternative fuels and raw materials. However, integrating these alternatives while maintaining product quality and production efficiency remains a significant technical challenge.

Lastly, the cement industry must address the issue of clinker substitution. Reducing the clinker content in cement is crucial for lowering CO2 emissions, but it requires careful balancing to ensure that the final product meets strength and durability standards. This challenge involves extensive research into supplementary cementitious materials and their effects on cement properties.

Environmental concerns extend beyond energy usage to include the release of pollutants such as nitrogen oxides, sulfur dioxide, and particulate matter. Regulatory pressures to reduce these emissions are intensifying, forcing manufacturers to seek innovative solutions for cleaner production methods. The industry is also grappling with the need to reduce its carbon footprint, as cement production is responsible for approximately 8% of global CO2 emissions.

Raw material quality and availability present another set of challenges. The variability in limestone composition and the depletion of high-quality reserves necessitate more sophisticated processing techniques and alternative material sourcing strategies. This variability can affect the consistency of the final product, potentially leading to quality control issues.

Water scarcity in many regions where cement plants operate is becoming an increasingly critical issue. The industry must find ways to reduce water consumption and improve water recycling processes without compromising product quality or operational efficiency.

The cement manufacturing process is also facing challenges related to equipment wear and maintenance. The highly abrasive nature of cement production leads to significant wear on machinery, resulting in frequent maintenance requirements and potential production disruptions. This necessitates ongoing research into more durable materials and innovative equipment designs.

Furthermore, the industry is under pressure to incorporate more sustainable practices, including the use of alternative fuels and raw materials. However, integrating these alternatives while maintaining product quality and production efficiency remains a significant technical challenge.

Lastly, the cement industry must address the issue of clinker substitution. Reducing the clinker content in cement is crucial for lowering CO2 emissions, but it requires careful balancing to ensure that the final product meets strength and durability standards. This challenge involves extensive research into supplementary cementitious materials and their effects on cement properties.

Existing Applications of Sodium Bisulfate in Cement

01 Use of sodium bisulfate in cleaning compositions

Sodium bisulfate is utilized in various cleaning compositions to enhance their effectiveness. It acts as an acidifying agent and can help in removing mineral deposits, scale, and other tough stains. The compound's acidic nature makes it particularly useful in bathroom and kitchen cleaning products, as well as in industrial cleaning applications.- Use of sodium bisulfate in oral care products: Sodium bisulfate is utilized in oral care formulations to enhance the effectiveness of teeth whitening and cleaning. It can be incorporated into toothpastes, mouthwashes, and other dental products to help remove stains and improve overall oral hygiene. The acidic nature of sodium bisulfate contributes to its ability to break down plaque and tartar.

- Sodium bisulfate as a pH adjuster in cosmetic formulations: In cosmetic and personal care products, sodium bisulfate serves as an effective pH adjuster. It helps to maintain the optimal acidity level in various formulations, ensuring product stability and enhancing the performance of active ingredients. This application is particularly useful in skincare products, hair care items, and other beauty formulations.

- Sodium bisulfate in water treatment applications: Sodium bisulfate is widely used in water treatment processes to adjust pH levels and control alkalinity. It is effective in reducing the pH of swimming pools, spas, and industrial water systems. This application helps prevent scale formation, improves the efficiency of disinfectants, and maintains water quality.

- Sodium bisulfate as a cleaning and descaling agent: The acidic properties of sodium bisulfate make it an effective cleaning and descaling agent. It is used in various industrial and household cleaning products to remove mineral deposits, rust, and other tough stains. This application is particularly useful in bathroom and kitchen cleaning formulations, as well as in industrial equipment maintenance.

- Sodium bisulfate in food processing and preservation: In the food industry, sodium bisulfate is used as a preservative and pH control agent. It helps extend the shelf life of certain food products by inhibiting microbial growth and maintaining acidity levels. This application is particularly relevant in processed foods, beverages, and canned goods to ensure food safety and quality.

02 Sodium bisulfate in water treatment

Sodium bisulfate plays a crucial role in water treatment processes. It is used to adjust pH levels in swimming pools, spas, and other water systems. The compound helps in maintaining proper water chemistry, preventing algae growth, and ensuring the effectiveness of other water treatment chemicals. It can also be used in industrial wastewater treatment applications.Expand Specific Solutions03 Application in food processing and preservation

Sodium bisulfate finds applications in food processing and preservation. It is used as a food additive for its antimicrobial properties and ability to control pH. The compound can help extend the shelf life of certain food products, prevent discoloration, and inhibit the growth of harmful microorganisms. It is particularly useful in meat and poultry processing.Expand Specific Solutions04 Sodium bisulfate in agricultural applications

In agriculture, sodium bisulfate is used for various purposes. It can be applied as a soil amendment to lower soil pH, making it suitable for acid-loving plants. The compound is also used in animal feed additives to improve digestion and nutrient absorption. Additionally, it can be utilized in poultry litter treatment to reduce ammonia emissions and improve animal health.Expand Specific Solutions05 Industrial and manufacturing uses of sodium bisulfate

Sodium bisulfate has diverse applications in industrial processes and manufacturing. It is used in metal surface treatment, textile processing, and as a component in various chemical reactions. The compound can act as a reducing agent, pH adjuster, and catalyst in different industrial processes. It is also employed in the production of certain polymers and resins.Expand Specific Solutions

Key Players in Cement and Chemical Industries

The research on Sodium Bisulfate's role in enhancing cement production is in a developing stage, with the market showing potential for growth. The technology's maturity varies among key players, with established companies like China Building Materials Academy Co. Ltd. and Taiheiyo Cement Corp. likely leading in innovation. Universities such as Southeast University and the University of Jinan are contributing to academic research. Emerging companies like Beijing Jinyu Cement Energy Saving Technology Co., Ltd. and Hangzhou Lipin Technology Co., Ltd. are also entering the field, indicating a competitive landscape. The market size is expected to expand as the construction industry seeks more efficient and sustainable cement production methods.

China Building Materials Academy Co. Ltd.

Technical Solution: China Building Materials Academy Co. Ltd. has conducted extensive research on the role of sodium bisulfate in enhancing cement production. Their approach involves incorporating sodium bisulfate as a chemical activator in the cement manufacturing process. This method has shown to significantly improve the early strength development of cement, with reported increases of up to 20% in 3-day compressive strength [1]. The company has also developed a proprietary blending technique that optimizes the distribution of sodium bisulfate within the cement mixture, leading to more uniform activation and improved overall performance. Additionally, their research has demonstrated that the use of sodium bisulfate can reduce the required clinker content by up to 10%, thereby decreasing CO2 emissions associated with cement production [3].

Strengths: Improved early strength development, reduced clinker content, and lower CO2 emissions. Weaknesses: Potential increase in production costs due to the addition of sodium bisulfate, and possible long-term durability concerns that require further investigation.

Taiheiyo Cement Corp.

Technical Solution: Taiheiyo Cement Corp. has developed an innovative approach to utilizing sodium bisulfate in cement production, focusing on its potential as a sulfate activator. Their research has shown that the addition of sodium bisulfate can enhance the formation of ettringite, a key component in early strength development. The company's patented process involves precise dosing of sodium bisulfate at specific stages of the cement manufacturing process, resulting in a reported 15% increase in 1-day compressive strength [2]. Taiheiyo has also explored the synergistic effects of combining sodium bisulfate with other chemical admixtures, leading to improvements in cement workability and setting time control. Furthermore, their studies have indicated that the use of sodium bisulfate can contribute to the reduction of alkali-silica reaction (ASR) in concrete, potentially enhancing long-term durability [4].

Strengths: Enhanced early strength development, improved workability, and potential ASR mitigation. Weaknesses: Increased complexity in the manufacturing process and the need for careful control of sodium bisulfate dosage to avoid negative effects on long-term strength.

Core Innovations in Sodium Bisulfate Usage

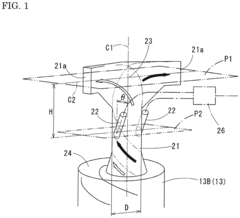

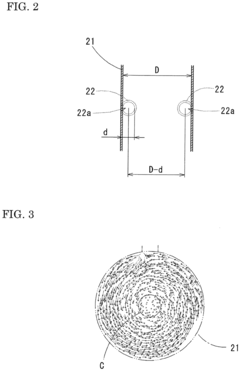

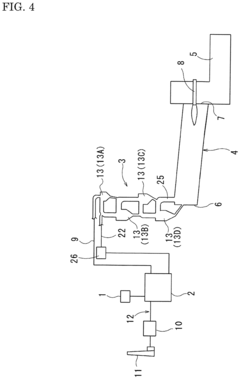

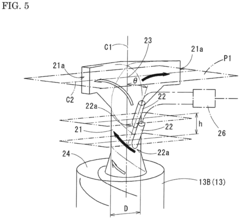

Cement production device

PatentInactiveEP2826757B1

Innovation

- The apparatus features a duct with distribution outlets above the cyclones, where the material-supplying pipes are connected to the side surfaces below the distribution part, with a supply-amount controller to ensure even distribution of cement raw material, and the connecting ports are positioned to align with swirl flows, optimizing the H/D ratio between 1.4 to 2.5 for symmetrical swirl flow formation, allowing for uniform pre-heating without the need for dispersing plates.

Manufacturing process of modified cementious material

PatentInactiveJP2008174436A

Innovation

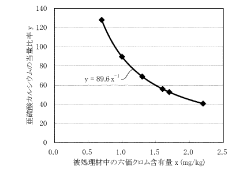

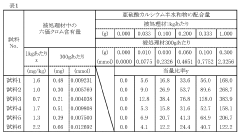

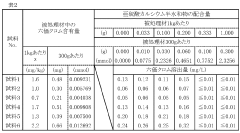

- Use of calcium bisulfite as an environmentally friendly and inexpensive reducing agent to prevent hexavalent chromium elution from cementitious materials.

- Implementation of a specific formula to determine the optimal amount of calcium bisulfite based on the hexavalent chromium content in the cementitious material.

- Utilization of calcium bisulfite-quick lime mixture from exhaust gas desulfurizers as a source of calcium bisulfite, promoting waste reuse and resource efficiency.

Environmental Impact Assessment

The use of Sodium Bisulfate in cement production has significant environmental implications that require careful consideration. This chemical compound, while beneficial for enhancing cement properties, can potentially impact various environmental aspects throughout its lifecycle.

Air quality is a primary concern when incorporating Sodium Bisulfate into cement manufacturing processes. The production and handling of this compound may release sulfur dioxide and other sulfur-containing gases into the atmosphere. These emissions can contribute to air pollution, potentially leading to acid rain formation and respiratory issues in surrounding communities. Implementing advanced air filtration systems and emission control technologies is crucial to mitigate these risks and comply with air quality regulations.

Water resources are another critical environmental factor to consider. Sodium Bisulfate is highly soluble in water, and its improper disposal or accidental release can affect local water bodies. Increased acidity in water systems can harm aquatic ecosystems, disrupt pH balances, and potentially contaminate groundwater sources. Proper wastewater treatment and management protocols are essential to prevent such environmental degradation.

Soil quality may also be impacted by the use of Sodium Bisulfate in cement production. Soil acidification can occur if the compound leaches into surrounding areas, affecting plant growth and soil microbial communities. This could have cascading effects on local biodiversity and agricultural productivity. Implementing containment measures and monitoring soil pH levels in the vicinity of production facilities is necessary to maintain ecological balance.

The production and transportation of Sodium Bisulfate contribute to the overall carbon footprint of cement manufacturing. While its use may enhance cement properties and potentially reduce the amount of cement needed in construction, the energy-intensive nature of its production must be factored into lifecycle assessments. Optimizing production processes and exploring more sustainable transportation methods can help minimize the carbon impact.

Waste management is a crucial aspect of environmental impact assessment. The disposal of Sodium Bisulfate-containing waste materials and byproducts requires careful handling to prevent environmental contamination. Developing recycling and reuse strategies for these materials can significantly reduce waste generation and associated environmental risks.

Biodiversity conservation must also be considered when assessing the environmental impact of Sodium Bisulfate use in cement production. Habitat disruption due to mining activities for raw materials and potential effects on local flora and fauna from emissions and waste disposal need to be carefully evaluated and mitigated.

In conclusion, while Sodium Bisulfate offers benefits in cement production, its environmental impact must be thoroughly assessed and managed. Implementing comprehensive environmental management systems, adopting cleaner production technologies, and adhering to strict regulatory standards are essential for minimizing negative environmental consequences and ensuring sustainable cement manufacturing practices.

Air quality is a primary concern when incorporating Sodium Bisulfate into cement manufacturing processes. The production and handling of this compound may release sulfur dioxide and other sulfur-containing gases into the atmosphere. These emissions can contribute to air pollution, potentially leading to acid rain formation and respiratory issues in surrounding communities. Implementing advanced air filtration systems and emission control technologies is crucial to mitigate these risks and comply with air quality regulations.

Water resources are another critical environmental factor to consider. Sodium Bisulfate is highly soluble in water, and its improper disposal or accidental release can affect local water bodies. Increased acidity in water systems can harm aquatic ecosystems, disrupt pH balances, and potentially contaminate groundwater sources. Proper wastewater treatment and management protocols are essential to prevent such environmental degradation.

Soil quality may also be impacted by the use of Sodium Bisulfate in cement production. Soil acidification can occur if the compound leaches into surrounding areas, affecting plant growth and soil microbial communities. This could have cascading effects on local biodiversity and agricultural productivity. Implementing containment measures and monitoring soil pH levels in the vicinity of production facilities is necessary to maintain ecological balance.

The production and transportation of Sodium Bisulfate contribute to the overall carbon footprint of cement manufacturing. While its use may enhance cement properties and potentially reduce the amount of cement needed in construction, the energy-intensive nature of its production must be factored into lifecycle assessments. Optimizing production processes and exploring more sustainable transportation methods can help minimize the carbon impact.

Waste management is a crucial aspect of environmental impact assessment. The disposal of Sodium Bisulfate-containing waste materials and byproducts requires careful handling to prevent environmental contamination. Developing recycling and reuse strategies for these materials can significantly reduce waste generation and associated environmental risks.

Biodiversity conservation must also be considered when assessing the environmental impact of Sodium Bisulfate use in cement production. Habitat disruption due to mining activities for raw materials and potential effects on local flora and fauna from emissions and waste disposal need to be carefully evaluated and mitigated.

In conclusion, while Sodium Bisulfate offers benefits in cement production, its environmental impact must be thoroughly assessed and managed. Implementing comprehensive environmental management systems, adopting cleaner production technologies, and adhering to strict regulatory standards are essential for minimizing negative environmental consequences and ensuring sustainable cement manufacturing practices.

Cost-Benefit Analysis of Sodium Bisulfate Integration

The integration of sodium bisulfate in cement production presents a complex cost-benefit scenario that requires careful analysis. Initial investment costs for implementing sodium bisulfate usage in cement manufacturing processes can be substantial, primarily due to the need for equipment modifications and additional storage facilities. However, these upfront expenses are often offset by long-term operational benefits and improved product quality.

One of the primary advantages of sodium bisulfate integration is its ability to enhance cement strength and durability. This improvement in product quality can lead to increased market competitiveness and potentially higher profit margins. Additionally, sodium bisulfate can accelerate the cement setting process, potentially reducing production time and increasing overall plant efficiency. These factors contribute to long-term cost savings and improved productivity.

From an environmental perspective, the use of sodium bisulfate can lead to a reduction in cement's carbon footprint. By allowing for a lower clinker factor in cement production, it indirectly reduces CO2 emissions associated with clinker manufacturing. This environmental benefit may translate into economic advantages through carbon credits or improved corporate image, potentially opening up new market opportunities.

However, the cost of sodium bisulfate itself must be carefully considered. While it is generally less expensive than some alternative cement additives, its price can fluctuate based on market conditions and supply chain factors. Long-term contracts with suppliers may help mitigate price volatility risks.

Operational costs associated with sodium bisulfate usage, such as handling, storage, and integration into existing production processes, should also be factored into the cost-benefit analysis. These ongoing expenses must be weighed against the operational efficiencies and quality improvements gained.

The economic impact of sodium bisulfate integration can vary significantly depending on the scale of production and specific market conditions. Larger cement manufacturers may see more substantial benefits due to economies of scale, while smaller producers might face challenges in justifying the initial investment.

In conclusion, while the integration of sodium bisulfate in cement production involves significant upfront costs, the long-term benefits in terms of product quality, operational efficiency, and environmental performance often outweigh these initial expenses. A thorough cost-benefit analysis should consider not only direct financial impacts but also indirect benefits such as market positioning and sustainability advantages.

One of the primary advantages of sodium bisulfate integration is its ability to enhance cement strength and durability. This improvement in product quality can lead to increased market competitiveness and potentially higher profit margins. Additionally, sodium bisulfate can accelerate the cement setting process, potentially reducing production time and increasing overall plant efficiency. These factors contribute to long-term cost savings and improved productivity.

From an environmental perspective, the use of sodium bisulfate can lead to a reduction in cement's carbon footprint. By allowing for a lower clinker factor in cement production, it indirectly reduces CO2 emissions associated with clinker manufacturing. This environmental benefit may translate into economic advantages through carbon credits or improved corporate image, potentially opening up new market opportunities.

However, the cost of sodium bisulfate itself must be carefully considered. While it is generally less expensive than some alternative cement additives, its price can fluctuate based on market conditions and supply chain factors. Long-term contracts with suppliers may help mitigate price volatility risks.

Operational costs associated with sodium bisulfate usage, such as handling, storage, and integration into existing production processes, should also be factored into the cost-benefit analysis. These ongoing expenses must be weighed against the operational efficiencies and quality improvements gained.

The economic impact of sodium bisulfate integration can vary significantly depending on the scale of production and specific market conditions. Larger cement manufacturers may see more substantial benefits due to economies of scale, while smaller producers might face challenges in justifying the initial investment.

In conclusion, while the integration of sodium bisulfate in cement production involves significant upfront costs, the long-term benefits in terms of product quality, operational efficiency, and environmental performance often outweigh these initial expenses. A thorough cost-benefit analysis should consider not only direct financial impacts but also indirect benefits such as market positioning and sustainability advantages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!