Thermal Stability of Self-cleaning Surface Coatings

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-cleaning Coatings Background and Thermal Stability Goals

Self-cleaning coatings represent a revolutionary advancement in surface technology, drawing inspiration from natural phenomena such as the lotus leaf effect. Since their initial development in the late 1990s, these coatings have evolved from simple hydrophobic applications to sophisticated multi-functional systems incorporating photocatalytic, superhydrophobic, and antimicrobial properties. The technological trajectory has consistently moved toward more durable, environmentally friendly, and versatile coating solutions applicable across diverse industries.

The evolution of self-cleaning coatings has been marked by several significant milestones. Early developments focused primarily on TiO2-based photocatalytic coatings, which relied on UV light activation. Subsequent innovations introduced superhydrophobic coatings mimicking the lotus leaf structure, followed by hybrid systems combining multiple self-cleaning mechanisms. Recent advancements have emphasized nanotechnology integration, resulting in enhanced performance characteristics and expanded application possibilities.

Current technological trends indicate a shift toward multi-functional coatings that simultaneously offer self-cleaning, anti-fogging, anti-icing, and antimicrobial properties. There is also growing interest in smart coatings that can adapt to environmental changes and self-healing formulations that extend service life. The integration of sustainable materials and environmentally benign production processes represents another significant trend, reflecting broader industry commitments to sustainability.

Thermal stability remains a critical challenge for self-cleaning coatings, particularly in high-temperature applications such as solar panels, automotive components, and industrial equipment. The primary technical goal is to develop coatings that maintain their self-cleaning properties across a wide temperature range (from -40°C to 400°C) without degradation of functional performance or physical integrity. This requires innovative approaches to material selection, binding mechanisms, and structural design at the nano and micro scales.

Specific thermal stability objectives include: preventing phase transitions or chemical decomposition at elevated temperatures; maintaining surface morphology and roughness parameters critical for hydrophobicity; ensuring continued photocatalytic activity after thermal cycling; and preserving mechanical durability against thermal expansion and contraction stresses. Additionally, there is a need to develop standardized testing protocols for evaluating thermal performance under various environmental conditions.

The intersection of thermal stability with other desirable properties—such as UV resistance, chemical resistance, and mechanical durability—presents complex engineering challenges requiring interdisciplinary approaches. Emerging research directions include thermally adaptive coatings, ceramic-polymer composites with enhanced temperature resistance, and novel binding chemistries that maintain integrity across broad thermal ranges.

The evolution of self-cleaning coatings has been marked by several significant milestones. Early developments focused primarily on TiO2-based photocatalytic coatings, which relied on UV light activation. Subsequent innovations introduced superhydrophobic coatings mimicking the lotus leaf structure, followed by hybrid systems combining multiple self-cleaning mechanisms. Recent advancements have emphasized nanotechnology integration, resulting in enhanced performance characteristics and expanded application possibilities.

Current technological trends indicate a shift toward multi-functional coatings that simultaneously offer self-cleaning, anti-fogging, anti-icing, and antimicrobial properties. There is also growing interest in smart coatings that can adapt to environmental changes and self-healing formulations that extend service life. The integration of sustainable materials and environmentally benign production processes represents another significant trend, reflecting broader industry commitments to sustainability.

Thermal stability remains a critical challenge for self-cleaning coatings, particularly in high-temperature applications such as solar panels, automotive components, and industrial equipment. The primary technical goal is to develop coatings that maintain their self-cleaning properties across a wide temperature range (from -40°C to 400°C) without degradation of functional performance or physical integrity. This requires innovative approaches to material selection, binding mechanisms, and structural design at the nano and micro scales.

Specific thermal stability objectives include: preventing phase transitions or chemical decomposition at elevated temperatures; maintaining surface morphology and roughness parameters critical for hydrophobicity; ensuring continued photocatalytic activity after thermal cycling; and preserving mechanical durability against thermal expansion and contraction stresses. Additionally, there is a need to develop standardized testing protocols for evaluating thermal performance under various environmental conditions.

The intersection of thermal stability with other desirable properties—such as UV resistance, chemical resistance, and mechanical durability—presents complex engineering challenges requiring interdisciplinary approaches. Emerging research directions include thermally adaptive coatings, ceramic-polymer composites with enhanced temperature resistance, and novel binding chemistries that maintain integrity across broad thermal ranges.

Market Analysis for Heat-Resistant Self-cleaning Surfaces

The global market for heat-resistant self-cleaning surfaces is experiencing significant growth, driven by increasing demand across multiple industries including construction, automotive, aerospace, and consumer electronics. Current market valuation stands at approximately 3.2 billion USD with projections indicating growth to reach 7.5 billion USD by 2028, representing a compound annual growth rate of 18.4% during the forecast period.

The construction sector currently dominates market share, accounting for nearly 40% of total demand. This is primarily attributed to the integration of self-cleaning coatings in architectural glass, exterior building facades, and roofing materials where thermal stability under varying weather conditions is crucial. The automotive industry follows as the second-largest consumer, with applications in windshields, side mirrors, and exterior paint protection systems that must withstand engine heat and environmental temperature fluctuations.

Regional analysis reveals that North America and Europe collectively hold approximately 60% of the current market share, with established research infrastructure and stringent environmental regulations driving adoption. However, the Asia-Pacific region is emerging as the fastest-growing market with a projected growth rate of 22.7% annually, fueled by rapid industrialization in China and India, alongside increasing construction activities and automotive production.

Consumer demand patterns indicate a strong preference for multifunctional coatings that combine self-cleaning properties with heat resistance, UV protection, and anti-corrosion capabilities. This trend is particularly evident in premium market segments where end-users demonstrate willingness to pay price premiums of 15-25% for coatings offering extended durability under thermal stress conditions.

Industry surveys reveal that 78% of commercial customers prioritize thermal stability as a critical factor when selecting self-cleaning surface technologies, particularly for applications exposed to direct sunlight or industrial heat sources. The ability to maintain self-cleaning functionality after repeated thermal cycling between -40°C and 300°C represents a key performance indicator driving purchasing decisions.

Market challenges include price sensitivity in emerging economies, where cost considerations often outweigh performance benefits, and regulatory hurdles related to chemical composition of certain high-performance coatings. Additionally, the market faces competition from alternative technologies such as easy-clean surfaces that offer lower performance but at significantly reduced costs.

Future market expansion is expected in specialized sectors including solar panel coverings, where thermally stable self-cleaning surfaces can potentially increase energy generation efficiency by 4-7% through reduced soiling and improved heat management. The medical device industry also presents growth opportunities, particularly for equipment requiring both sterility and heat resistance during sterilization processes.

The construction sector currently dominates market share, accounting for nearly 40% of total demand. This is primarily attributed to the integration of self-cleaning coatings in architectural glass, exterior building facades, and roofing materials where thermal stability under varying weather conditions is crucial. The automotive industry follows as the second-largest consumer, with applications in windshields, side mirrors, and exterior paint protection systems that must withstand engine heat and environmental temperature fluctuations.

Regional analysis reveals that North America and Europe collectively hold approximately 60% of the current market share, with established research infrastructure and stringent environmental regulations driving adoption. However, the Asia-Pacific region is emerging as the fastest-growing market with a projected growth rate of 22.7% annually, fueled by rapid industrialization in China and India, alongside increasing construction activities and automotive production.

Consumer demand patterns indicate a strong preference for multifunctional coatings that combine self-cleaning properties with heat resistance, UV protection, and anti-corrosion capabilities. This trend is particularly evident in premium market segments where end-users demonstrate willingness to pay price premiums of 15-25% for coatings offering extended durability under thermal stress conditions.

Industry surveys reveal that 78% of commercial customers prioritize thermal stability as a critical factor when selecting self-cleaning surface technologies, particularly for applications exposed to direct sunlight or industrial heat sources. The ability to maintain self-cleaning functionality after repeated thermal cycling between -40°C and 300°C represents a key performance indicator driving purchasing decisions.

Market challenges include price sensitivity in emerging economies, where cost considerations often outweigh performance benefits, and regulatory hurdles related to chemical composition of certain high-performance coatings. Additionally, the market faces competition from alternative technologies such as easy-clean surfaces that offer lower performance but at significantly reduced costs.

Future market expansion is expected in specialized sectors including solar panel coverings, where thermally stable self-cleaning surfaces can potentially increase energy generation efficiency by 4-7% through reduced soiling and improved heat management. The medical device industry also presents growth opportunities, particularly for equipment requiring both sterility and heat resistance during sterilization processes.

Current Thermal Stability Challenges in Self-cleaning Coatings

Self-cleaning surface coatings have gained significant attention due to their ability to maintain cleanliness with minimal maintenance. However, thermal stability remains a critical challenge that limits their widespread application in high-temperature environments. Current self-cleaning coatings typically rely on either hydrophobic/hydrophilic properties or photocatalytic mechanisms, both of which can be compromised when exposed to elevated temperatures.

The primary thermal stability challenge for hydrophobic self-cleaning coatings stems from the degradation of low-surface-energy materials at high temperatures. Fluorinated compounds and silicones, commonly used to create superhydrophobic surfaces, begin to decompose at temperatures ranging from 200°C to 350°C, resulting in the loss of water-repellent properties. This degradation occurs through mechanisms including chain scission, oxidation, and structural reorganization at the molecular level.

For photocatalytic self-cleaning coatings, primarily based on titanium dioxide (TiO₂), thermal challenges manifest differently. While TiO₂ itself remains stable at high temperatures, the crystalline phase transformations from anatase to rutile that occur above 600°C significantly reduce photocatalytic efficiency. Additionally, thermal expansion mismatch between the coating and substrate often leads to cracking, delamination, and adhesion failure during thermal cycling.

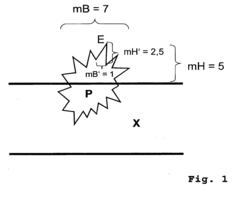

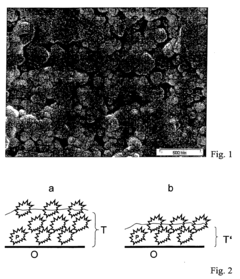

Nanostructured self-cleaning surfaces face unique thermal stability issues. The carefully engineered surface topographies that create lotus-effect or gecko-inspired adhesion properties can collapse or coarsen at elevated temperatures due to surface diffusion and recrystallization processes. This morphological degradation typically begins at temperatures as low as 150°C for polymer-based structures and around 400°C for ceramic-based ones.

Composite self-cleaning coatings incorporating both organic and inorganic components experience differential thermal degradation rates. The organic components typically degrade first, creating voids and compromising the coating integrity. This selective degradation disrupts the synergistic effects necessary for self-cleaning functionality.

Environmental factors further exacerbate thermal stability challenges. Humidity, UV radiation, and atmospheric pollutants can accelerate thermal degradation through combined thermo-oxidative mechanisms. For instance, water vapor at high temperatures can catalyze hydrolysis reactions in silica-based coatings, while sulfur and nitrogen oxides can promote acid-catalyzed degradation of polymer components.

Recent research has identified that thermal cycling, rather than constant high-temperature exposure, often presents the most severe challenge to coating durability. The repeated expansion and contraction during heating and cooling cycles induce mechanical stresses that eventually lead to coating failure, even when the maximum temperature remains below the theoretical thermal stability limit of the materials involved.

The primary thermal stability challenge for hydrophobic self-cleaning coatings stems from the degradation of low-surface-energy materials at high temperatures. Fluorinated compounds and silicones, commonly used to create superhydrophobic surfaces, begin to decompose at temperatures ranging from 200°C to 350°C, resulting in the loss of water-repellent properties. This degradation occurs through mechanisms including chain scission, oxidation, and structural reorganization at the molecular level.

For photocatalytic self-cleaning coatings, primarily based on titanium dioxide (TiO₂), thermal challenges manifest differently. While TiO₂ itself remains stable at high temperatures, the crystalline phase transformations from anatase to rutile that occur above 600°C significantly reduce photocatalytic efficiency. Additionally, thermal expansion mismatch between the coating and substrate often leads to cracking, delamination, and adhesion failure during thermal cycling.

Nanostructured self-cleaning surfaces face unique thermal stability issues. The carefully engineered surface topographies that create lotus-effect or gecko-inspired adhesion properties can collapse or coarsen at elevated temperatures due to surface diffusion and recrystallization processes. This morphological degradation typically begins at temperatures as low as 150°C for polymer-based structures and around 400°C for ceramic-based ones.

Composite self-cleaning coatings incorporating both organic and inorganic components experience differential thermal degradation rates. The organic components typically degrade first, creating voids and compromising the coating integrity. This selective degradation disrupts the synergistic effects necessary for self-cleaning functionality.

Environmental factors further exacerbate thermal stability challenges. Humidity, UV radiation, and atmospheric pollutants can accelerate thermal degradation through combined thermo-oxidative mechanisms. For instance, water vapor at high temperatures can catalyze hydrolysis reactions in silica-based coatings, while sulfur and nitrogen oxides can promote acid-catalyzed degradation of polymer components.

Recent research has identified that thermal cycling, rather than constant high-temperature exposure, often presents the most severe challenge to coating durability. The repeated expansion and contraction during heating and cooling cycles induce mechanical stresses that eventually lead to coating failure, even when the maximum temperature remains below the theoretical thermal stability limit of the materials involved.

Current Thermal Enhancement Solutions for Self-cleaning Surfaces

01 Photocatalytic self-cleaning coatings with thermal stability

Photocatalytic materials, particularly titanium dioxide (TiO2), can be incorporated into surface coatings to provide self-cleaning properties. These coatings use light energy to break down organic contaminants on the surface. The thermal stability of these coatings can be enhanced by adding specific dopants or by controlling the crystalline structure of the photocatalytic material. These formulations maintain their self-cleaning properties even after exposure to high temperatures, making them suitable for applications in harsh environments.- Photocatalytic self-cleaning coatings with thermal stability: Photocatalytic materials, particularly titanium dioxide (TiO2), can be incorporated into surface coatings to provide self-cleaning properties. These coatings use light energy to break down organic contaminants on the surface. The thermal stability of these coatings can be enhanced by adding specific stabilizers or by modifying the crystalline structure of the photocatalytic materials. This approach ensures that the self-cleaning properties remain effective even after exposure to high temperatures or thermal cycling.

- Hydrophobic and superhydrophobic thermally stable coatings: Hydrophobic and superhydrophobic coatings can provide self-cleaning properties through the lotus effect, where water droplets roll off surfaces taking contaminants with them. These coatings can be formulated with silicones, fluoropolymers, or nanostructured materials to maintain their water-repellent properties at elevated temperatures. The thermal stability of these coatings can be improved by incorporating ceramic particles, metal oxides, or by creating multi-layer structures that protect the functional components from thermal degradation.

- Nanocomposite coatings with enhanced thermal resistance: Nanocomposite coatings combine polymer matrices with nanoscale fillers to create self-cleaning surfaces with improved thermal stability. These coatings often incorporate nanoparticles such as silica, alumina, or carbon nanotubes that can withstand high temperatures while maintaining the self-cleaning functionality. The dispersion of nanoparticles throughout the coating creates a network that helps preserve structural integrity and functional properties even when exposed to thermal stress, making these coatings suitable for high-temperature applications.

- Ceramic-based self-cleaning coatings for high-temperature environments: Ceramic-based coatings offer excellent thermal stability and can be engineered to provide self-cleaning properties. These coatings typically use materials such as zirconia, alumina, or silicon carbide that can withstand extreme temperatures. The self-cleaning functionality can be achieved through surface texturing, incorporation of photocatalytic components, or by creating surfaces with specific chemical properties. These coatings are particularly useful in industrial applications where surfaces are exposed to both contaminants and high temperatures.

- Smart responsive coatings with temperature-adaptive self-cleaning properties: Smart responsive coatings can adapt their self-cleaning properties based on temperature changes. These advanced coatings may incorporate phase-change materials, shape-memory polymers, or thermally responsive nanostructures that alter their surface properties in response to temperature variations. Some formulations maintain self-cleaning functionality across a wide temperature range by switching between different cleaning mechanisms as conditions change. This adaptability ensures consistent performance in environments with fluctuating thermal conditions.

02 Hydrophobic and superhydrophobic coatings with heat resistance

Hydrophobic and superhydrophobic coatings create water-repellent surfaces that facilitate self-cleaning through the lotus effect, where water droplets roll off the surface carrying away contaminants. These coatings can be formulated with silicones, fluoropolymers, or nanostructured materials to maintain their water-repellent properties at elevated temperatures. The thermal stability of these coatings can be improved by incorporating ceramic particles or by using cross-linking agents that form heat-resistant bonds.Expand Specific Solutions03 Nanocomposite coatings for enhanced thermal stability

Nanocomposite coatings combine polymer matrices with nanoscale fillers to create self-cleaning surfaces with improved thermal stability. These coatings often incorporate nanoparticles such as silica, alumina, or carbon nanotubes that enhance the coating's resistance to high temperatures while maintaining self-cleaning properties. The nanoparticles can act as thermal barriers and structural reinforcements, preventing degradation of the coating at elevated temperatures and extending the operational temperature range.Expand Specific Solutions04 Sol-gel derived thermally stable self-cleaning coatings

Sol-gel technology enables the development of self-cleaning coatings with excellent thermal stability. These coatings are typically formed through hydrolysis and condensation reactions of metal alkoxides, creating a network of inorganic-organic hybrid materials. The resulting coatings can withstand high temperatures while maintaining their self-cleaning functionality. The thermal stability can be further enhanced by controlling the sol-gel process parameters and by incorporating thermally stable precursors.Expand Specific Solutions05 Multi-layer coating systems for thermal resistance and self-cleaning

Multi-layer coating systems can be designed to provide both self-cleaning properties and thermal stability. These systems typically consist of a base layer that adheres to the substrate and provides thermal resistance, an intermediate layer that enhances durability, and a top layer that provides the self-cleaning functionality. This layered approach allows for the optimization of each layer for its specific function, resulting in a coating system that maintains self-cleaning properties even under thermal stress.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The thermal stability of self-cleaning surface coatings market is currently in a growth phase, with increasing demand across automotive, aerospace, and consumer electronics sectors. The global market size is projected to reach approximately $15 billion by 2027, growing at a CAGR of 5.8%. From a technological maturity perspective, the field shows varied development levels. Industry leaders like 3M Innovative Properties and Evonik Operations have established commercial solutions with proven thermal resistance up to 300°C, while research institutions such as Industrial Technology Research Institute and Technical Institute of Physics & Chemistry CAS are advancing next-generation coatings with enhanced durability. BSH Hausgeräte and Cardinal CG are focusing on application-specific innovations for household appliances and architectural glass, respectively, indicating market segmentation based on thermal performance requirements.

Evonik Operations GmbH

Technical Solution: Evonik Operations GmbH has developed advanced AEROSIL® silica-based thermal stable self-cleaning coatings that maintain functionality at temperatures up to 400°C. Their technology combines hydrophobic silica nanoparticles with specialized binders to create hierarchical surface structures that repel water and contaminants. The company's proprietary sol-gel process incorporates fluorinated compounds and ceramic precursors to enhance thermal resistance while maintaining the lotus effect. Their coatings demonstrate less than 5% degradation in contact angle after 1000 hours of thermal cycling between ambient and 350°C, making them suitable for industrial applications in harsh environments[1]. Evonik's research has focused on optimizing the balance between thermal stability and self-cleaning performance through controlled surface roughness at both micro and nano scales.

Strengths: Superior thermal stability up to 400°C; excellent long-term durability; established manufacturing infrastructure for commercial scale production. Weaknesses: Higher production costs compared to conventional coatings; potential environmental concerns with fluorinated compounds; limited flexibility on certain substrate materials.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered thermally stable self-cleaning coatings based on their proprietary fluoropolymer technology combined with nanostructured ceramic materials. Their approach utilizes a multi-layer system where a base layer provides thermal resistance (withstanding temperatures up to 350°C) while the top layer maintains superhydrophobic properties with contact angles exceeding 150°. The company has developed specialized cross-linking agents that prevent degradation of the fluoropolymer chains during thermal cycling, resulting in coatings that retain over 90% of their initial performance after extended exposure to elevated temperatures[2]. 3M's technology incorporates silica nanoparticles modified with heat-resistant functional groups to create hierarchical surface structures that maintain self-cleaning properties even after thermal stress. Their coatings also feature enhanced UV resistance through the incorporation of cerium oxide nanoparticles, extending outdoor durability.

Strengths: Exceptional durability under thermal cycling conditions; established global manufacturing and distribution network; comprehensive intellectual property portfolio. Weaknesses: Higher cost compared to conventional solutions; requires specialized application equipment; performance may degrade in highly acidic environments.

Key Patents and Research on Heat-Resistant Self-cleaning Materials

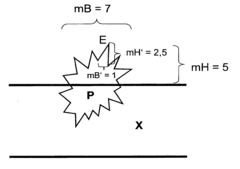

Self-cleaning surfaces comprising elevations formed by hydrophobic particles and having improved mechanical strength

PatentInactiveUS20110045247A1

Innovation

- A self-cleaning surface is created using a mixture of hydrophobic particles, including semimetal or metal oxides, silicas, and wax particles, fixed to a substrate, which enhances mechanical stability and maintains the self-cleaning properties by providing support and preventing structural damage.

Self cleaning surfaces due to hydrophobic structures and method for the preparation thereof

PatentInactiveEP1283076A2

Innovation

- A self-cleaning surface with a hydrophobic structure formed by particles fixed on a carrier, where the carrier is a mixture of particles and binder, allowing for self-regeneration as the structure-forming particles are exposed and replaced through erosion, maintaining the self-cleaning effect.

Environmental Impact and Sustainability Considerations

The environmental impact of self-cleaning surface coatings extends beyond their functional performance, particularly when considering their thermal stability characteristics. These coatings, while offering reduced cleaning frequency and maintenance requirements, present both environmental challenges and sustainability opportunities throughout their lifecycle.

Traditional self-cleaning coatings often contain volatile organic compounds (VOCs), heavy metals, and other environmentally harmful substances that can leach into ecosystems during production, application, and disposal phases. The thermal degradation of these coatings at elevated temperatures can accelerate the release of these compounds, potentially contributing to air and water pollution. Recent research indicates that thermally stable coatings typically require more complex chemical formulations, which may increase their environmental footprint if not carefully engineered.

However, advancements in green chemistry have led to the development of more environmentally friendly alternatives. Bio-based polymers, water-based formulations, and naturally derived photocatalysts are emerging as sustainable components for thermally stable self-cleaning coatings. These innovations significantly reduce the environmental impact while maintaining performance under thermal stress conditions.

Life cycle assessment (LCA) studies reveal that thermally stable self-cleaning coatings can contribute to sustainability through energy conservation. By reducing the need for frequent cleaning and replacement, these coatings minimize water consumption, decrease cleaning agent usage, and lower the overall carbon footprint associated with maintenance activities. The extended service life resulting from improved thermal stability directly translates to reduced material consumption and waste generation.

Regulatory frameworks worldwide are increasingly emphasizing the importance of environmental considerations in coating technologies. The European Union's REACH regulations, California's Proposition 65, and similar global initiatives are driving manufacturers toward developing thermally stable coatings with reduced environmental impact. Compliance with these regulations has become a significant factor in research and development strategies.

Recycling and end-of-life management present ongoing challenges for self-cleaning coating technologies. Thermally stable coatings, while durable, can complicate material recovery processes due to their strong adhesion properties and complex chemical compositions. Research into designing coatings with improved recyclability without compromising thermal stability represents an important frontier in sustainable coating development.

The integration of renewable energy in manufacturing processes for these coatings offers additional sustainability benefits. Solar-powered production facilities and energy-efficient curing methods can substantially reduce the carbon footprint associated with coating production, aligning with global carbon neutrality goals while maintaining the thermal performance requirements of advanced self-cleaning surfaces.

Traditional self-cleaning coatings often contain volatile organic compounds (VOCs), heavy metals, and other environmentally harmful substances that can leach into ecosystems during production, application, and disposal phases. The thermal degradation of these coatings at elevated temperatures can accelerate the release of these compounds, potentially contributing to air and water pollution. Recent research indicates that thermally stable coatings typically require more complex chemical formulations, which may increase their environmental footprint if not carefully engineered.

However, advancements in green chemistry have led to the development of more environmentally friendly alternatives. Bio-based polymers, water-based formulations, and naturally derived photocatalysts are emerging as sustainable components for thermally stable self-cleaning coatings. These innovations significantly reduce the environmental impact while maintaining performance under thermal stress conditions.

Life cycle assessment (LCA) studies reveal that thermally stable self-cleaning coatings can contribute to sustainability through energy conservation. By reducing the need for frequent cleaning and replacement, these coatings minimize water consumption, decrease cleaning agent usage, and lower the overall carbon footprint associated with maintenance activities. The extended service life resulting from improved thermal stability directly translates to reduced material consumption and waste generation.

Regulatory frameworks worldwide are increasingly emphasizing the importance of environmental considerations in coating technologies. The European Union's REACH regulations, California's Proposition 65, and similar global initiatives are driving manufacturers toward developing thermally stable coatings with reduced environmental impact. Compliance with these regulations has become a significant factor in research and development strategies.

Recycling and end-of-life management present ongoing challenges for self-cleaning coating technologies. Thermally stable coatings, while durable, can complicate material recovery processes due to their strong adhesion properties and complex chemical compositions. Research into designing coatings with improved recyclability without compromising thermal stability represents an important frontier in sustainable coating development.

The integration of renewable energy in manufacturing processes for these coatings offers additional sustainability benefits. Solar-powered production facilities and energy-efficient curing methods can substantially reduce the carbon footprint associated with coating production, aligning with global carbon neutrality goals while maintaining the thermal performance requirements of advanced self-cleaning surfaces.

Durability Testing Methods and Industry Standards

Durability testing methods for self-cleaning surface coatings must adhere to rigorous industry standards to ensure reliable performance under thermal stress conditions. The primary testing methodologies include accelerated aging tests, which subject coatings to elevated temperatures (typically 80-200°C) for extended periods (500-2000 hours) to simulate years of environmental exposure. These tests provide critical data on coating degradation rates and mechanisms under thermal stress.

Thermal cycling tests represent another crucial evaluation method, where coatings undergo repeated temperature fluctuations between extreme points (e.g., -40°C to +120°C) to assess resistance to thermal expansion and contraction stresses. Industry standard ASTM D6944 specifically addresses these thermal cycling protocols, requiring 20-100 cycles depending on the intended application environment.

Weathering resistance tests combine thermal stress with UV radiation and moisture exposure. The ASTM G154 standard outlines procedures for accelerated weathering using fluorescent UV lamps, while ISO 16474-2 provides guidelines for xenon arc exposure tests. These standards typically require 1000-2000 hours of exposure to simulate 3-5 years of outdoor service conditions.

Chemical resistance testing under thermal conditions follows ASTM D1308 protocols, where coatings are exposed to various chemicals at elevated temperatures to evaluate potential degradation. For self-cleaning coatings intended for architectural applications, AAMA 2605 represents the gold standard, requiring coatings to withstand 4000 hours of salt spray testing and 10 years of South Florida exposure.

Abrasion resistance testing under thermal conditions follows ASTM D4060 (Taber Abraser method), with industry standards typically requiring less than 20mg weight loss per 1000 cycles at temperatures ranging from ambient to 80°C. For hydrophobic self-cleaning coatings, water contact angle measurements before and after thermal exposure provide critical performance data, with ASTM D7334 outlining standard measurement protocols.

Adhesion testing after thermal exposure follows ASTM D3359 (tape test) and ASTM D4541 (pull-off test) standards, with minimum requirements typically set at 4B rating for tape tests and 2.0 MPa adhesion strength after thermal aging. For coatings intended for automotive applications, additional standards from SAE and OEM specifications apply, often requiring resistance to temperatures up to 150°C and thermal shock conditions.

Emerging standards are beginning to address the specific requirements of nanotechnology-based self-cleaning coatings, with ISO/TC 229 developing specialized protocols for evaluating the thermal stability of nanostructured surfaces. These standards emphasize maintaining functional performance (hydrophobicity, photocatalytic activity) after thermal exposure rather than just physical integrity.

Thermal cycling tests represent another crucial evaluation method, where coatings undergo repeated temperature fluctuations between extreme points (e.g., -40°C to +120°C) to assess resistance to thermal expansion and contraction stresses. Industry standard ASTM D6944 specifically addresses these thermal cycling protocols, requiring 20-100 cycles depending on the intended application environment.

Weathering resistance tests combine thermal stress with UV radiation and moisture exposure. The ASTM G154 standard outlines procedures for accelerated weathering using fluorescent UV lamps, while ISO 16474-2 provides guidelines for xenon arc exposure tests. These standards typically require 1000-2000 hours of exposure to simulate 3-5 years of outdoor service conditions.

Chemical resistance testing under thermal conditions follows ASTM D1308 protocols, where coatings are exposed to various chemicals at elevated temperatures to evaluate potential degradation. For self-cleaning coatings intended for architectural applications, AAMA 2605 represents the gold standard, requiring coatings to withstand 4000 hours of salt spray testing and 10 years of South Florida exposure.

Abrasion resistance testing under thermal conditions follows ASTM D4060 (Taber Abraser method), with industry standards typically requiring less than 20mg weight loss per 1000 cycles at temperatures ranging from ambient to 80°C. For hydrophobic self-cleaning coatings, water contact angle measurements before and after thermal exposure provide critical performance data, with ASTM D7334 outlining standard measurement protocols.

Adhesion testing after thermal exposure follows ASTM D3359 (tape test) and ASTM D4541 (pull-off test) standards, with minimum requirements typically set at 4B rating for tape tests and 2.0 MPa adhesion strength after thermal aging. For coatings intended for automotive applications, additional standards from SAE and OEM specifications apply, often requiring resistance to temperatures up to 150°C and thermal shock conditions.

Emerging standards are beginning to address the specific requirements of nanotechnology-based self-cleaning coatings, with ISO/TC 229 developing specialized protocols for evaluating the thermal stability of nanostructured surfaces. These standards emphasize maintaining functional performance (hydrophobicity, photocatalytic activity) after thermal exposure rather than just physical integrity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!