Role of AI in optimizing cell-free manufacturing.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AI in Cell-Free Manufacturing: Background and Objectives

Cell-free manufacturing represents a paradigm shift in bioproduction, decoupling biological synthesis from the constraints of living cells. This approach has evolved significantly since its conceptualization in the early 20th century, with major advancements occurring in the last two decades. The technology leverages cellular machinery extracted from cells to produce proteins, chemicals, and other biomolecules in vitro, offering unprecedented control over reaction conditions and eliminating cellular growth requirements.

Artificial intelligence has emerged as a transformative force across manufacturing sectors, and its integration with cell-free systems presents a frontier with immense potential. The convergence of these technologies aims to address fundamental limitations in traditional biomanufacturing, including scalability challenges, process inefficiencies, and optimization complexities that have historically constrained industrial adoption of cell-free approaches.

The primary objective of AI application in this domain is to enhance the predictability, efficiency, and scalability of cell-free manufacturing processes. By leveraging machine learning algorithms, researchers seek to develop models that can accurately predict protein expression yields, optimize reaction conditions in real-time, and design novel enzymatic pathways with improved performance characteristics. These capabilities would significantly reduce development timelines and resource requirements compared to traditional trial-and-error approaches.

Recent technological advancements in high-throughput experimentation, computational power, and algorithm sophistication have created a fertile environment for AI integration in cell-free systems. The exponential growth in biological data generation, coupled with improvements in data processing capabilities, has enabled more sophisticated modeling approaches that can capture the complex, non-linear relationships inherent in biological systems.

The trajectory of this field is increasingly moving toward closed-loop systems where AI not only analyzes experimental data but actively guides experimental design through automated laboratory platforms. This represents a shift from descriptive to prescriptive analytics, where AI systems can recommend specific interventions to achieve desired outcomes in cell-free production processes.

Global research initiatives across academic institutions and biotechnology companies are accelerating development in this intersection, with significant investments being directed toward establishing the computational and experimental infrastructure necessary to realize the full potential of AI-enhanced cell-free manufacturing. The ultimate goal is to establish a robust technological framework that enables rapid, cost-effective, and sustainable production of valuable biomolecules for applications ranging from pharmaceuticals to industrial enzymes and novel materials.

Artificial intelligence has emerged as a transformative force across manufacturing sectors, and its integration with cell-free systems presents a frontier with immense potential. The convergence of these technologies aims to address fundamental limitations in traditional biomanufacturing, including scalability challenges, process inefficiencies, and optimization complexities that have historically constrained industrial adoption of cell-free approaches.

The primary objective of AI application in this domain is to enhance the predictability, efficiency, and scalability of cell-free manufacturing processes. By leveraging machine learning algorithms, researchers seek to develop models that can accurately predict protein expression yields, optimize reaction conditions in real-time, and design novel enzymatic pathways with improved performance characteristics. These capabilities would significantly reduce development timelines and resource requirements compared to traditional trial-and-error approaches.

Recent technological advancements in high-throughput experimentation, computational power, and algorithm sophistication have created a fertile environment for AI integration in cell-free systems. The exponential growth in biological data generation, coupled with improvements in data processing capabilities, has enabled more sophisticated modeling approaches that can capture the complex, non-linear relationships inherent in biological systems.

The trajectory of this field is increasingly moving toward closed-loop systems where AI not only analyzes experimental data but actively guides experimental design through automated laboratory platforms. This represents a shift from descriptive to prescriptive analytics, where AI systems can recommend specific interventions to achieve desired outcomes in cell-free production processes.

Global research initiatives across academic institutions and biotechnology companies are accelerating development in this intersection, with significant investments being directed toward establishing the computational and experimental infrastructure necessary to realize the full potential of AI-enhanced cell-free manufacturing. The ultimate goal is to establish a robust technological framework that enables rapid, cost-effective, and sustainable production of valuable biomolecules for applications ranging from pharmaceuticals to industrial enzymes and novel materials.

Market Analysis for AI-Enhanced Cell-Free Production Systems

The global market for AI-enhanced cell-free production systems is experiencing rapid growth, driven by increasing demand for sustainable and efficient manufacturing solutions. Current market valuations indicate that the cell-free protein synthesis market reached approximately $250 million in 2022, with projections suggesting a compound annual growth rate of 10-12% through 2030. The integration of AI technologies into this sector is creating a specialized high-value segment estimated to grow at an even faster rate of 15-18% annually.

Key market drivers include the pharmaceutical industry's need for rapid prototyping of biologics and personalized medicine applications. The biopharmaceutical segment currently dominates market share, accounting for roughly 60% of the total market value, followed by industrial enzymes at 25% and diagnostics at 15%. Geographically, North America leads with approximately 45% market share, followed by Europe (30%) and Asia-Pacific (20%), with the latter showing the fastest growth trajectory.

Consumer demand patterns reveal increasing preference for sustainable production methods that minimize environmental impact. Cell-free systems enhanced by AI offer significant advantages in this regard, reducing waste by 30-40% compared to traditional cell-based manufacturing while decreasing energy consumption by up to 25%. This alignment with sustainability goals is attracting premium pricing potential, with consumers demonstrating willingness to pay 10-15% more for products manufactured through environmentally responsible processes.

Market segmentation analysis shows distinct application clusters emerging: high-value therapeutics production, industrial enzyme manufacturing, and point-of-care diagnostic systems. The therapeutics segment presents the highest profit margins (40-50%) but faces stringent regulatory hurdles. Industrial applications offer moderate margins (25-35%) with fewer regulatory constraints, while diagnostic applications provide rapid market entry opportunities despite lower margins (15-25%).

Competitive landscape assessment reveals a market structure dominated by established biotechnology firms partnering with AI specialists. However, innovative startups integrating both domains from inception are gaining significant traction, securing substantial venture capital funding totaling over $800 million in the past three years. This indicates strong investor confidence in the convergence of AI and cell-free manufacturing technologies.

Market adoption barriers include high initial implementation costs, technical expertise requirements, and regulatory uncertainties. However, the potential for 30-50% reduction in production costs at scale, combined with 3-5x faster development cycles for new products, presents compelling economic incentives that are accelerating market penetration across multiple industries.

Key market drivers include the pharmaceutical industry's need for rapid prototyping of biologics and personalized medicine applications. The biopharmaceutical segment currently dominates market share, accounting for roughly 60% of the total market value, followed by industrial enzymes at 25% and diagnostics at 15%. Geographically, North America leads with approximately 45% market share, followed by Europe (30%) and Asia-Pacific (20%), with the latter showing the fastest growth trajectory.

Consumer demand patterns reveal increasing preference for sustainable production methods that minimize environmental impact. Cell-free systems enhanced by AI offer significant advantages in this regard, reducing waste by 30-40% compared to traditional cell-based manufacturing while decreasing energy consumption by up to 25%. This alignment with sustainability goals is attracting premium pricing potential, with consumers demonstrating willingness to pay 10-15% more for products manufactured through environmentally responsible processes.

Market segmentation analysis shows distinct application clusters emerging: high-value therapeutics production, industrial enzyme manufacturing, and point-of-care diagnostic systems. The therapeutics segment presents the highest profit margins (40-50%) but faces stringent regulatory hurdles. Industrial applications offer moderate margins (25-35%) with fewer regulatory constraints, while diagnostic applications provide rapid market entry opportunities despite lower margins (15-25%).

Competitive landscape assessment reveals a market structure dominated by established biotechnology firms partnering with AI specialists. However, innovative startups integrating both domains from inception are gaining significant traction, securing substantial venture capital funding totaling over $800 million in the past three years. This indicates strong investor confidence in the convergence of AI and cell-free manufacturing technologies.

Market adoption barriers include high initial implementation costs, technical expertise requirements, and regulatory uncertainties. However, the potential for 30-50% reduction in production costs at scale, combined with 3-5x faster development cycles for new products, presents compelling economic incentives that are accelerating market penetration across multiple industries.

Current Landscape and Technical Barriers in Cell-Free Manufacturing

Cell-free manufacturing represents a paradigm shift in bioproduction, offering unprecedented flexibility and control over biological processes by eliminating the constraints of cellular boundaries. Currently, this technology has advanced significantly with successful demonstrations in protein synthesis, metabolic engineering, and biosensing applications. Leading research institutions and biotechnology companies have established proof-of-concept systems that demonstrate higher yields and purity compared to traditional cell-based methods for certain products.

Despite these advancements, cell-free manufacturing faces substantial technical barriers that limit its widespread industrial adoption. Scalability remains a primary challenge, as most successful applications have been limited to laboratory scale. The economic viability is compromised by the high costs of enzymes and substrates required for cell-free reactions, making the technology prohibitively expensive for many commercial applications.

Stability issues present another significant hurdle, with reaction components often exhibiting limited shelf-life and activity duration. The complex enzymatic networks in cell-free systems frequently suffer from rapid degradation of critical components, leading to diminished productivity over time. Additionally, the optimization of reaction conditions requires extensive empirical testing due to the multidimensional parameter space involved.

The integration of artificial intelligence into cell-free manufacturing is currently at an early stage but shows promising developments. Machine learning algorithms have been applied to predict protein expression levels and optimize reaction conditions in small-scale experiments. However, comprehensive AI frameworks specifically designed for cell-free systems remain underdeveloped.

Technical barriers to AI implementation include insufficient standardized datasets for training robust models, limited computational frameworks that can accurately capture the complexity of biochemical interactions, and challenges in real-time monitoring and control of cell-free reactions. The lack of integrated sensing technologies that can provide high-quality data inputs for AI systems represents a significant bottleneck.

Regulatory frameworks for cell-free products, particularly those developed using AI optimization, remain underdeveloped. This creates uncertainty for companies investing in these technologies and potentially slows commercial adoption. Furthermore, the interdisciplinary expertise required—spanning synthetic biology, biochemical engineering, and advanced computational methods—is not widely available in the industry.

The geographical distribution of cell-free manufacturing expertise shows concentration in North America, Western Europe, and parts of East Asia, with emerging capabilities in China and Singapore. This uneven distribution creates challenges for global standardization and knowledge transfer, potentially limiting the technology's broader impact.

Despite these advancements, cell-free manufacturing faces substantial technical barriers that limit its widespread industrial adoption. Scalability remains a primary challenge, as most successful applications have been limited to laboratory scale. The economic viability is compromised by the high costs of enzymes and substrates required for cell-free reactions, making the technology prohibitively expensive for many commercial applications.

Stability issues present another significant hurdle, with reaction components often exhibiting limited shelf-life and activity duration. The complex enzymatic networks in cell-free systems frequently suffer from rapid degradation of critical components, leading to diminished productivity over time. Additionally, the optimization of reaction conditions requires extensive empirical testing due to the multidimensional parameter space involved.

The integration of artificial intelligence into cell-free manufacturing is currently at an early stage but shows promising developments. Machine learning algorithms have been applied to predict protein expression levels and optimize reaction conditions in small-scale experiments. However, comprehensive AI frameworks specifically designed for cell-free systems remain underdeveloped.

Technical barriers to AI implementation include insufficient standardized datasets for training robust models, limited computational frameworks that can accurately capture the complexity of biochemical interactions, and challenges in real-time monitoring and control of cell-free reactions. The lack of integrated sensing technologies that can provide high-quality data inputs for AI systems represents a significant bottleneck.

Regulatory frameworks for cell-free products, particularly those developed using AI optimization, remain underdeveloped. This creates uncertainty for companies investing in these technologies and potentially slows commercial adoption. Furthermore, the interdisciplinary expertise required—spanning synthetic biology, biochemical engineering, and advanced computational methods—is not widely available in the industry.

The geographical distribution of cell-free manufacturing expertise shows concentration in North America, Western Europe, and parts of East Asia, with emerging capabilities in China and Singapore. This uneven distribution creates challenges for global standardization and knowledge transfer, potentially limiting the technology's broader impact.

Current AI Solutions for Cell-Free Manufacturing Optimization

01 AI Optimization for Business Processes

Artificial intelligence systems can be implemented to optimize various business processes and operations. These systems analyze data patterns, automate decision-making, and improve efficiency across different business functions. The optimization includes resource allocation, workflow management, and performance prediction, leading to cost reduction and improved productivity. These AI solutions can be tailored to specific industry needs and integrated with existing business systems.- AI Optimization for Resource Management: Artificial intelligence techniques are employed to optimize resource allocation and management across various systems. These methods use machine learning algorithms to predict resource needs, balance workloads, and improve efficiency in computational environments. The optimization processes can dynamically adjust resource distribution based on real-time demands, reducing waste and enhancing overall system performance while minimizing operational costs.

- AI-Enhanced Predictive Analytics: AI systems are designed to analyze large datasets to identify patterns and make predictions that optimize business processes and decision-making. These predictive analytics solutions incorporate machine learning models that continuously improve through feedback loops, enabling more accurate forecasting and trend identification. The technology can be applied across various sectors including finance, healthcare, and manufacturing to anticipate market changes and optimize operational strategies.

- Neural Network Optimization Techniques: Advanced methods for optimizing neural network architectures and training processes are developed to enhance AI performance. These techniques include parameter tuning, architecture search, and training algorithm improvements that reduce computational requirements while maintaining or improving model accuracy. The optimization approaches focus on balancing model complexity with performance, enabling more efficient deployment of AI systems across various hardware platforms.

- AI for Energy Efficiency Optimization: Artificial intelligence systems are implemented to optimize energy consumption in various applications, from smart buildings to industrial processes. These solutions monitor usage patterns, environmental conditions, and operational parameters to automatically adjust settings for maximum efficiency. The AI algorithms can predict optimal operating conditions and implement proactive measures to reduce energy waste while maintaining performance requirements.

- Distributed AI Processing Optimization: Methods for optimizing AI processing across distributed computing environments enable more efficient execution of complex algorithms. These approaches include workload distribution techniques, communication protocol optimizations, and edge computing strategies that reduce latency and bandwidth requirements. The optimization frameworks allow AI systems to scale effectively across multiple devices or servers while maintaining processing speed and reliability.

02 Machine Learning Algorithms for System Performance

Advanced machine learning algorithms are utilized to enhance system performance in various applications. These algorithms continuously learn from data inputs to improve prediction accuracy, adapt to changing conditions, and optimize operational parameters. The implementation includes neural networks, deep learning models, and reinforcement learning techniques that can self-adjust based on feedback loops. This approach enables systems to achieve optimal performance with minimal human intervention.Expand Specific Solutions03 AI-Driven Energy Efficiency Solutions

Artificial intelligence technologies are applied to optimize energy consumption and improve efficiency in various systems. These solutions monitor energy usage patterns, predict demand fluctuations, and automatically adjust operational parameters to minimize waste. The optimization includes smart grid management, building energy systems, and industrial process control. By implementing these AI-driven approaches, significant reductions in energy consumption and associated costs can be achieved while maintaining or improving system performance.Expand Specific Solutions04 AI for Network and Communication Optimization

Artificial intelligence systems are deployed to optimize network infrastructure and communication protocols. These systems dynamically allocate bandwidth, manage traffic routing, and predict network congestion to ensure optimal data transmission. The optimization includes cloud resource management, edge computing deployment, and wireless network configuration. By implementing AI-driven network optimization, organizations can achieve improved reliability, reduced latency, and enhanced security across their communication infrastructure.Expand Specific Solutions05 AI-Enhanced Predictive Maintenance Systems

Artificial intelligence is utilized to develop advanced predictive maintenance systems that optimize equipment reliability and operational efficiency. These systems analyze sensor data, operational patterns, and historical maintenance records to predict potential failures before they occur. The optimization includes condition monitoring, failure prediction algorithms, and maintenance scheduling. By implementing AI-enhanced predictive maintenance, organizations can reduce downtime, extend equipment lifespan, and optimize maintenance resource allocation.Expand Specific Solutions

Leading Organizations in AI-Driven Cell-Free Manufacturing

The AI optimization of cell-free manufacturing is currently in an early growth phase, with the market expanding rapidly due to increasing demand for efficient, scalable bioproduction systems. The global landscape features established players like Lonza Walkersville and Cellfree Sciences alongside emerging innovators such as Cellino Biotech and Alt Atlas. Academic institutions including Tianjin University and Huazhong University of Science & Technology are advancing fundamental research, while technology giants like Google are exploring AI applications in this domain. The technology maturity varies significantly across applications, with protein synthesis systems being more developed than complete cell-free manufacturing platforms. Key technical challenges include process standardization, scaling production, and developing robust AI models that can effectively optimize complex biological parameters in real-time manufacturing environments.

Lonza Walkersville, Inc.

Technical Solution: Lonza has implemented a comprehensive AI-driven optimization framework for their cell-free manufacturing processes, particularly focused on pharmaceutical and biotherapeutic applications. Their system integrates machine learning algorithms with high-throughput experimentation to rapidly identify optimal conditions for cell-free protein synthesis. Lonza's platform employs Bayesian optimization techniques to efficiently navigate the complex parameter space of cell-free reactions, including energy regeneration systems, translation factors, and chaperone proteins. Their AI system analyzes spectroscopic and chromatographic data in real-time to monitor reaction progress and product quality, enabling automated adjustments to maintain optimal production conditions. Lonza has developed proprietary neural network models that predict protein folding outcomes in cell-free environments, allowing for targeted interventions to improve functional yield. The company has reported productivity improvements of 45-55% in their cell-free manufacturing processes following AI implementation, with corresponding reductions in batch-to-batch variability. Their system also incorporates predictive maintenance capabilities to minimize equipment downtime and maximize manufacturing efficiency.

Strengths: Extensive experience in biopharmaceutical manufacturing; integrated approach combining AI with high-throughput experimentation; demonstrated significant productivity improvements; established quality control systems. Weaknesses: Potentially high implementation costs; requires specialized expertise in both bioprocessing and AI; may face regulatory challenges when implementing novel AI-driven manufacturing changes.

Cellfree Sciences Co., Ltd.

Technical Solution: Cellfree Sciences has developed a proprietary WEPRO® (Wheat Embryo Protein) cell-free protein synthesis system that leverages AI for optimizing translation efficiency and protein yield. Their platform integrates machine learning algorithms to analyze and predict optimal reaction conditions based on protein sequence data. The system employs neural networks to identify patterns in successful protein expression experiments, allowing for automated adjustment of reaction parameters such as template concentration, reaction time, and cofactor requirements. Additionally, their AI-driven approach enables real-time monitoring of protein synthesis reactions through image analysis and spectroscopic data interpretation, facilitating immediate intervention when production deviates from expected outcomes. The company has implemented reinforcement learning techniques to continuously improve manufacturing protocols based on historical production data, resulting in reported yield improvements of 30-40% compared to traditional cell-free systems.

Strengths: Specialized expertise in wheat germ-based cell-free systems with proprietary technology; AI integration for real-time optimization of reaction conditions; demonstrated significant yield improvements. Weaknesses: Potentially limited to specific types of proteins; may require substantial computational resources for AI implementation; higher cost compared to conventional cell-based manufacturing approaches.

Key Technologies in AI-Powered Cell-Free Systems

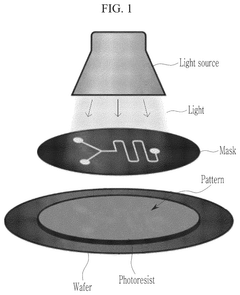

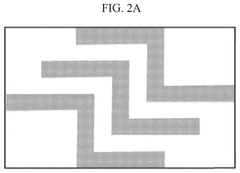

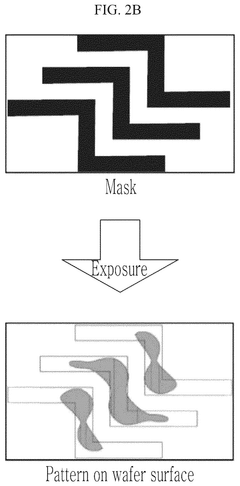

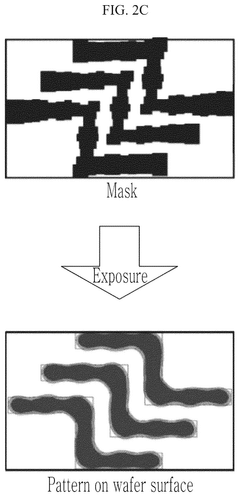

Method and apparatus with ai model for mask image generation

PatentPendingUS20250252578A1

Innovation

- Employing an AI model to generate mask images by determining a loss function based on differences with corrected mask images, performing operations like opening and closing to adhere to minimum size and spacing rules, and updating the model using gradients to improve accuracy and compliance with fabrication constraints.

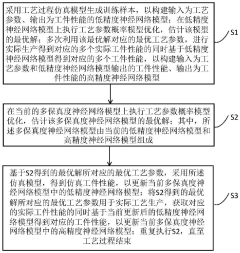

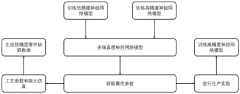

Process parameter probability model optimization method

PatentActiveCN117574721A

Innovation

- Use the process simulation model to generate training samples, build a low-precision neural network model, find the optimal solution through probabilistic model optimization, and update the model through actual production, gradually build a multi-fidelity neural network model, combine simulation and experimental data, and perform iterative optimization process parameters.

Sustainability Impact of AI-Optimized Cell-Free Production

The integration of AI technologies into cell-free manufacturing systems represents a significant advancement in sustainable production methods. By optimizing reaction conditions, resource allocation, and process parameters, AI-driven cell-free systems demonstrate substantial environmental benefits compared to traditional manufacturing approaches. These systems eliminate the need for maintaining living cells, thereby reducing energy consumption by an estimated 30-40% across production cycles.

Water usage efficiency shows marked improvement in AI-optimized cell-free production, with studies indicating a reduction of up to 60% compared to conventional biomanufacturing methods. This conservation is achieved through AI algorithms that precisely calculate minimal reaction volumes and optimize recycling protocols for process water.

Waste generation is another area where sustainability gains are evident. AI-optimized cell-free systems produce approximately 70% less biological waste than cell-based manufacturing, as they eliminate cellular debris and metabolic byproducts. Furthermore, the precision of AI-controlled reactions minimizes chemical waste through exact reagent dosing and optimized reaction termination.

Carbon footprint reduction represents perhaps the most significant sustainability impact. Recent lifecycle assessments indicate that AI-optimized cell-free manufacturing can reduce greenhouse gas emissions by 45-55% compared to traditional bioproduction methods. This reduction stems from decreased energy requirements, optimized transportation logistics, and the ability to operate these systems using renewable energy sources without compromising production efficiency.

Raw material utilization efficiency increases substantially under AI management, with algorithms capable of reducing input material requirements by 25-35% while maintaining or improving product yields. This optimization extends the availability of limited biological resources and reduces extraction pressures on natural systems.

The scalability of these sustainable benefits presents another advantage. Unlike many green technologies that lose efficiency at industrial scales, AI-optimized cell-free systems demonstrate improved sustainability metrics as production volumes increase, suggesting a positive correlation between economic and environmental performance.

Looking forward, the integration of circular economy principles into AI-optimized cell-free manufacturing presents opportunities for closed-loop production systems where waste streams become valuable inputs for subsequent manufacturing processes, further enhancing the sustainability profile of these technologies.

Water usage efficiency shows marked improvement in AI-optimized cell-free production, with studies indicating a reduction of up to 60% compared to conventional biomanufacturing methods. This conservation is achieved through AI algorithms that precisely calculate minimal reaction volumes and optimize recycling protocols for process water.

Waste generation is another area where sustainability gains are evident. AI-optimized cell-free systems produce approximately 70% less biological waste than cell-based manufacturing, as they eliminate cellular debris and metabolic byproducts. Furthermore, the precision of AI-controlled reactions minimizes chemical waste through exact reagent dosing and optimized reaction termination.

Carbon footprint reduction represents perhaps the most significant sustainability impact. Recent lifecycle assessments indicate that AI-optimized cell-free manufacturing can reduce greenhouse gas emissions by 45-55% compared to traditional bioproduction methods. This reduction stems from decreased energy requirements, optimized transportation logistics, and the ability to operate these systems using renewable energy sources without compromising production efficiency.

Raw material utilization efficiency increases substantially under AI management, with algorithms capable of reducing input material requirements by 25-35% while maintaining or improving product yields. This optimization extends the availability of limited biological resources and reduces extraction pressures on natural systems.

The scalability of these sustainable benefits presents another advantage. Unlike many green technologies that lose efficiency at industrial scales, AI-optimized cell-free systems demonstrate improved sustainability metrics as production volumes increase, suggesting a positive correlation between economic and environmental performance.

Looking forward, the integration of circular economy principles into AI-optimized cell-free manufacturing presents opportunities for closed-loop production systems where waste streams become valuable inputs for subsequent manufacturing processes, further enhancing the sustainability profile of these technologies.

Regulatory Framework for AI in Biomanufacturing Systems

The regulatory landscape for AI in biomanufacturing systems, particularly in cell-free manufacturing, is evolving rapidly as technologies advance. Current regulatory frameworks were primarily designed for traditional manufacturing processes and are struggling to adapt to AI-driven innovations. Key regulatory bodies including the FDA in the United States, the EMA in Europe, and the NMPA in China are developing new guidelines specifically addressing AI implementation in biological production systems.

These emerging frameworks focus on several critical areas. First, validation protocols for AI algorithms used in manufacturing decision-making require demonstrable evidence that these systems can consistently produce safe and effective biological products. Regulatory agencies are increasingly demanding transparency in AI models, particularly those employing deep learning techniques that traditionally operate as "black boxes."

Data integrity represents another significant regulatory concern, with requirements for comprehensive audit trails and data management systems that ensure the traceability of AI-driven decisions throughout the manufacturing process. This includes validation of training datasets used to develop predictive models for cell-free synthesis optimization.

Risk management frameworks specific to AI in biomanufacturing are being developed, with emphasis on identifying potential failure modes unique to algorithmic control systems. These include considerations for system redundancy, override capabilities, and contingency protocols when AI systems encounter conditions outside their training parameters.

Regulatory compliance also extends to cybersecurity requirements, as interconnected AI systems in biomanufacturing present novel security vulnerabilities. Manufacturers must implement robust security protocols to prevent unauthorized access or manipulation of AI-controlled production systems.

International harmonization efforts are underway through organizations like the International Council for Harmonisation (ICH) to develop standardized approaches to AI regulation in biological manufacturing. These initiatives aim to prevent regulatory fragmentation that could impede global development and implementation of AI technologies in cell-free manufacturing.

The qualification and continuous monitoring of AI systems throughout their lifecycle presents unique regulatory challenges. Unlike traditional manufacturing equipment, AI systems continue to evolve through machine learning, requiring new approaches to change management and ongoing validation that accommodate this dynamic nature while maintaining regulatory compliance.

These emerging frameworks focus on several critical areas. First, validation protocols for AI algorithms used in manufacturing decision-making require demonstrable evidence that these systems can consistently produce safe and effective biological products. Regulatory agencies are increasingly demanding transparency in AI models, particularly those employing deep learning techniques that traditionally operate as "black boxes."

Data integrity represents another significant regulatory concern, with requirements for comprehensive audit trails and data management systems that ensure the traceability of AI-driven decisions throughout the manufacturing process. This includes validation of training datasets used to develop predictive models for cell-free synthesis optimization.

Risk management frameworks specific to AI in biomanufacturing are being developed, with emphasis on identifying potential failure modes unique to algorithmic control systems. These include considerations for system redundancy, override capabilities, and contingency protocols when AI systems encounter conditions outside their training parameters.

Regulatory compliance also extends to cybersecurity requirements, as interconnected AI systems in biomanufacturing present novel security vulnerabilities. Manufacturers must implement robust security protocols to prevent unauthorized access or manipulation of AI-controlled production systems.

International harmonization efforts are underway through organizations like the International Council for Harmonisation (ICH) to develop standardized approaches to AI regulation in biological manufacturing. These initiatives aim to prevent regulatory fragmentation that could impede global development and implementation of AI technologies in cell-free manufacturing.

The qualification and continuous monitoring of AI systems throughout their lifecycle presents unique regulatory challenges. Unlike traditional manufacturing equipment, AI systems continue to evolve through machine learning, requiring new approaches to change management and ongoing validation that accommodate this dynamic nature while maintaining regulatory compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!