Cell-free synthesis for nucleic acid therapeutics.

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cell-free Synthesis Background and Objectives

Cell-free synthesis represents a revolutionary approach in the field of biotechnology, emerging from the convergence of synthetic biology, molecular biology, and biochemical engineering. This technology has evolved significantly since the pioneering work on cell-free protein synthesis in the 1960s, with recent advancements enabling the production of complex biomolecules outside living cells. The trajectory of development has accelerated dramatically in the past decade, driven by innovations in enzyme engineering, reaction optimization, and analytical techniques.

The application of cell-free synthesis specifically to nucleic acid therapeutics marks a significant technological frontier with transformative potential for modern medicine. Nucleic acid therapeutics, including mRNA vaccines, antisense oligonucleotides, and gene therapy vectors, have demonstrated remarkable clinical efficacy but face persistent manufacturing challenges. Cell-free synthesis offers a promising alternative to traditional cell-based production methods, potentially addressing limitations in scalability, purity, and cost-effectiveness.

The primary objective of cell-free synthesis for nucleic acid therapeutics is to establish robust, scalable, and economically viable production platforms that can meet growing global demand. This includes developing systems capable of producing pharmaceutical-grade RNA and DNA constructs with precise sequence control, minimal contamination, and high functional integrity. Additionally, the technology aims to reduce production timelines and enhance flexibility in manufacturing different nucleic acid modalities.

Technical goals encompass optimizing enzymatic reactions for improved yield and fidelity, developing novel purification strategies specific to cell-free products, and creating standardized quality control protocols. There is also significant focus on designing modular, automated systems that can facilitate rapid production adjustments in response to emerging therapeutic needs or pandemic scenarios.

From a broader perspective, cell-free synthesis aims to democratize access to nucleic acid therapeutics by simplifying production requirements and reducing capital investment barriers. This aligns with global health objectives of ensuring equitable distribution of advanced medical technologies across diverse geographic and economic contexts.

The evolution of this technology is increasingly guided by principles of sustainability, with research efforts directed toward developing renewable feedstocks, minimizing waste generation, and optimizing energy efficiency throughout the production process. These environmental considerations represent an important dimension of the technology's long-term viability and societal acceptance.

As we examine the trajectory of cell-free synthesis for nucleic acid therapeutics, it becomes evident that the field is positioned at an inflection point, with technical capabilities expanding rapidly and applications diversifying across therapeutic areas. The convergence of computational design tools, high-throughput screening methods, and mechanistic understanding is accelerating innovation and creating new possibilities for addressing previously intractable medical challenges.

The application of cell-free synthesis specifically to nucleic acid therapeutics marks a significant technological frontier with transformative potential for modern medicine. Nucleic acid therapeutics, including mRNA vaccines, antisense oligonucleotides, and gene therapy vectors, have demonstrated remarkable clinical efficacy but face persistent manufacturing challenges. Cell-free synthesis offers a promising alternative to traditional cell-based production methods, potentially addressing limitations in scalability, purity, and cost-effectiveness.

The primary objective of cell-free synthesis for nucleic acid therapeutics is to establish robust, scalable, and economically viable production platforms that can meet growing global demand. This includes developing systems capable of producing pharmaceutical-grade RNA and DNA constructs with precise sequence control, minimal contamination, and high functional integrity. Additionally, the technology aims to reduce production timelines and enhance flexibility in manufacturing different nucleic acid modalities.

Technical goals encompass optimizing enzymatic reactions for improved yield and fidelity, developing novel purification strategies specific to cell-free products, and creating standardized quality control protocols. There is also significant focus on designing modular, automated systems that can facilitate rapid production adjustments in response to emerging therapeutic needs or pandemic scenarios.

From a broader perspective, cell-free synthesis aims to democratize access to nucleic acid therapeutics by simplifying production requirements and reducing capital investment barriers. This aligns with global health objectives of ensuring equitable distribution of advanced medical technologies across diverse geographic and economic contexts.

The evolution of this technology is increasingly guided by principles of sustainability, with research efforts directed toward developing renewable feedstocks, minimizing waste generation, and optimizing energy efficiency throughout the production process. These environmental considerations represent an important dimension of the technology's long-term viability and societal acceptance.

As we examine the trajectory of cell-free synthesis for nucleic acid therapeutics, it becomes evident that the field is positioned at an inflection point, with technical capabilities expanding rapidly and applications diversifying across therapeutic areas. The convergence of computational design tools, high-throughput screening methods, and mechanistic understanding is accelerating innovation and creating new possibilities for addressing previously intractable medical challenges.

Market Analysis for Nucleic Acid Therapeutics

The global market for nucleic acid therapeutics has experienced remarkable growth in recent years, driven by advancements in cell-free synthesis technologies and expanding applications in treating previously undruggable targets. As of 2023, the market size has reached approximately $15 billion, with projections indicating a compound annual growth rate (CAGR) of 12-15% over the next five years.

RNA-based therapeutics, particularly mRNA vaccines and therapies, represent the fastest-growing segment within this market. The unprecedented success of mRNA COVID-19 vaccines has dramatically accelerated investment and interest in this field, creating a ripple effect across the entire nucleic acid therapeutics landscape. This segment alone is expected to reach $25 billion by 2028.

Cell-free synthesis systems have emerged as a critical enabling technology for nucleic acid therapeutics manufacturing, offering significant advantages in production speed, scalability, and cost-effectiveness compared to traditional cell-based methods. The market for cell-free synthesis platforms and reagents is growing at 18% annually, reflecting their increasing adoption in both research and commercial production settings.

Geographically, North America dominates the market with approximately 45% share, followed by Europe at 30% and Asia-Pacific at 20%. However, the Asia-Pacific region is witnessing the fastest growth rate due to increasing investments in biotechnology infrastructure and favorable regulatory environments in countries like China, Japan, and South Korea.

From an application perspective, oncology remains the largest therapeutic area for nucleic acid therapeutics, accounting for 35% of the market. However, treatments for rare genetic disorders, infectious diseases, and cardiovascular conditions are rapidly expanding application areas, collectively representing over 50% of the pipeline candidates.

Key market challenges include high manufacturing costs, complex regulatory pathways, and delivery system limitations. The average cost of goods for nucleic acid therapeutics remains 3-5 times higher than conventional small molecule drugs, though cell-free synthesis technologies are helping to narrow this gap.

Customer segments for nucleic acid therapeutics include pharmaceutical companies, biotechnology firms, academic research institutions, and contract manufacturing organizations. Large pharmaceutical companies have significantly increased their investment in this space, with over $10 billion in licensing deals and acquisitions reported in the past two years alone.

The competitive landscape is characterized by a mix of established pharmaceutical giants and specialized biotechnology companies. Recent market consolidation trends suggest that companies with proprietary cell-free synthesis platforms are particularly attractive acquisition targets, highlighting the strategic importance of this technology in the broader nucleic acid therapeutics value chain.

RNA-based therapeutics, particularly mRNA vaccines and therapies, represent the fastest-growing segment within this market. The unprecedented success of mRNA COVID-19 vaccines has dramatically accelerated investment and interest in this field, creating a ripple effect across the entire nucleic acid therapeutics landscape. This segment alone is expected to reach $25 billion by 2028.

Cell-free synthesis systems have emerged as a critical enabling technology for nucleic acid therapeutics manufacturing, offering significant advantages in production speed, scalability, and cost-effectiveness compared to traditional cell-based methods. The market for cell-free synthesis platforms and reagents is growing at 18% annually, reflecting their increasing adoption in both research and commercial production settings.

Geographically, North America dominates the market with approximately 45% share, followed by Europe at 30% and Asia-Pacific at 20%. However, the Asia-Pacific region is witnessing the fastest growth rate due to increasing investments in biotechnology infrastructure and favorable regulatory environments in countries like China, Japan, and South Korea.

From an application perspective, oncology remains the largest therapeutic area for nucleic acid therapeutics, accounting for 35% of the market. However, treatments for rare genetic disorders, infectious diseases, and cardiovascular conditions are rapidly expanding application areas, collectively representing over 50% of the pipeline candidates.

Key market challenges include high manufacturing costs, complex regulatory pathways, and delivery system limitations. The average cost of goods for nucleic acid therapeutics remains 3-5 times higher than conventional small molecule drugs, though cell-free synthesis technologies are helping to narrow this gap.

Customer segments for nucleic acid therapeutics include pharmaceutical companies, biotechnology firms, academic research institutions, and contract manufacturing organizations. Large pharmaceutical companies have significantly increased their investment in this space, with over $10 billion in licensing deals and acquisitions reported in the past two years alone.

The competitive landscape is characterized by a mix of established pharmaceutical giants and specialized biotechnology companies. Recent market consolidation trends suggest that companies with proprietary cell-free synthesis platforms are particularly attractive acquisition targets, highlighting the strategic importance of this technology in the broader nucleic acid therapeutics value chain.

Technical Landscape and Barriers in Cell-free Systems

Cell-free synthesis systems have emerged as a powerful platform for the production of nucleic acid therapeutics, offering advantages over traditional cell-based methods. These systems utilize cellular machinery extracted from cells to perform transcription and translation processes in vitro, eliminating constraints associated with maintaining cell viability and growth.

The current technical landscape of cell-free systems spans several methodological approaches, including extract-based systems derived from E. coli, wheat germ, insect cells, and mammalian cells. Each source provides distinct advantages: E. coli extracts offer high yields and cost-effectiveness, while mammalian extracts provide superior post-translational modifications essential for therapeutic applications. PURE (Protein synthesis Using Recombinant Elements) systems represent another significant advancement, utilizing purified components rather than crude extracts for enhanced reproducibility.

Despite remarkable progress, cell-free systems face substantial technical barriers. Extract preparation remains inconsistent across laboratories, with batch-to-batch variability significantly impacting yield and product quality. This inconsistency poses challenges for regulatory approval of therapeutics produced using these systems. Scalability represents another critical limitation, as most cell-free reactions operate optimally at microliter to milliliter scales, whereas industrial production requires liter-scale operations.

Energy supply constitutes a fundamental challenge in cell-free systems. The absence of cellular metabolic pathways necessitates external energy sources, typically ATP and GTP, which are rapidly depleted during synthesis. Various energy regeneration systems have been developed, but maintaining sustained energy levels for extended production periods remains problematic.

Post-translational modifications present particular difficulties for nucleic acid therapeutics requiring complex folding or chemical modifications. While mammalian extracts partially address this issue, they introduce additional complexities regarding extract preparation and standardization.

Nuclease contamination poses a significant barrier specifically for nucleic acid therapeutic production. Residual nucleases in cell extracts can degrade both template DNA/RNA and the synthesized therapeutic products, necessitating additional purification steps or nuclease inhibition strategies.

The regulatory pathway for cell-free produced therapeutics remains largely uncharted territory. Concerns regarding product consistency, purity, and potential contaminants from the cell-free system itself create uncertainty in the approval process, potentially extending development timelines for novel therapeutics.

The current technical landscape of cell-free systems spans several methodological approaches, including extract-based systems derived from E. coli, wheat germ, insect cells, and mammalian cells. Each source provides distinct advantages: E. coli extracts offer high yields and cost-effectiveness, while mammalian extracts provide superior post-translational modifications essential for therapeutic applications. PURE (Protein synthesis Using Recombinant Elements) systems represent another significant advancement, utilizing purified components rather than crude extracts for enhanced reproducibility.

Despite remarkable progress, cell-free systems face substantial technical barriers. Extract preparation remains inconsistent across laboratories, with batch-to-batch variability significantly impacting yield and product quality. This inconsistency poses challenges for regulatory approval of therapeutics produced using these systems. Scalability represents another critical limitation, as most cell-free reactions operate optimally at microliter to milliliter scales, whereas industrial production requires liter-scale operations.

Energy supply constitutes a fundamental challenge in cell-free systems. The absence of cellular metabolic pathways necessitates external energy sources, typically ATP and GTP, which are rapidly depleted during synthesis. Various energy regeneration systems have been developed, but maintaining sustained energy levels for extended production periods remains problematic.

Post-translational modifications present particular difficulties for nucleic acid therapeutics requiring complex folding or chemical modifications. While mammalian extracts partially address this issue, they introduce additional complexities regarding extract preparation and standardization.

Nuclease contamination poses a significant barrier specifically for nucleic acid therapeutic production. Residual nucleases in cell extracts can degrade both template DNA/RNA and the synthesized therapeutic products, necessitating additional purification steps or nuclease inhibition strategies.

The regulatory pathway for cell-free produced therapeutics remains largely uncharted territory. Concerns regarding product consistency, purity, and potential contaminants from the cell-free system itself create uncertainty in the approval process, potentially extending development timelines for novel therapeutics.

Current Cell-free Synthesis Methodologies

01 Cell-free protein synthesis systems

Cell-free protein synthesis systems allow for the production of proteins outside of living cells. These systems typically contain all the necessary components for transcription and translation, including ribosomes, enzymes, and nucleic acids. They offer advantages such as rapid protein production, the ability to produce toxic proteins, and simplified purification processes. These systems can be derived from various organisms including bacteria, yeast, and mammalian cells.- Cell-free protein synthesis systems: Cell-free protein synthesis systems allow for the production of proteins outside of living cells. These systems typically contain all the necessary components for transcription and translation, including ribosomes, enzymes, nucleotides, and amino acids. They offer advantages such as rapid protein production, the ability to produce toxic proteins, and simplified purification processes. These systems can be derived from various organisms including bacteria, yeast, and mammalian cells.

- Cell-free synthesis for therapeutic applications: Cell-free synthesis technologies are increasingly being applied to produce therapeutic proteins and vaccines. This approach enables the production of complex biomolecules with proper folding and post-translational modifications. The cell-free environment allows for the synthesis of proteins that might be toxic to living cells, expanding the range of potential therapeutic candidates. These systems can be optimized for high-yield production of pharmaceutically relevant proteins with reduced contamination risks.

- Optimization of cell-free synthesis reactions: Various methods have been developed to optimize cell-free synthesis reactions for improved yield and functionality. These include the development of specialized reaction mixtures, energy regeneration systems, and stabilizing agents. Continuous-exchange cell-free systems allow for prolonged protein synthesis by continuously supplying substrates and removing inhibitory byproducts. Temperature control, pH optimization, and codon optimization strategies further enhance the efficiency of cell-free protein production.

- Cell-free synthesis for diagnostic applications: Cell-free synthesis platforms are being utilized for diagnostic applications, enabling rapid detection of pathogens and biomarkers. These systems can be integrated into portable devices for point-of-care testing, allowing for quick analysis without sophisticated laboratory equipment. The ability to produce detection reagents on-demand makes these systems particularly valuable for responding to emerging infectious diseases and for use in resource-limited settings.

- Novel cell-free synthesis technologies: Emerging technologies in cell-free synthesis include microfluidic platforms, immobilized template systems, and cell-mimetic environments. These innovations aim to enhance protein yield, reduce reaction volumes, and enable the synthesis of complex multi-domain proteins. Some approaches incorporate artificial cellular compartments or synthetic membranes to mimic the cellular environment. Advanced cell-free systems also integrate non-canonical amino acids for producing proteins with novel functionalities.

02 Cell-free synthesis for therapeutic applications

Cell-free synthesis technologies are increasingly being applied to produce therapeutic proteins and vaccines. This approach allows for rapid production of pharmaceuticals without the constraints of cell viability. It enables the synthesis of complex proteins with post-translational modifications and can be scaled for industrial production. The technology is particularly valuable for personalized medicine and rapid response to emerging diseases.Expand Specific Solutions03 Optimization of cell-free synthesis reactions

Various methods have been developed to optimize cell-free synthesis reactions for improved yield and functionality. These include engineering of the reaction environment, addition of stabilizing agents, development of continuous-exchange systems, and optimization of energy regeneration pathways. Advanced techniques involve the use of microfluidics, nanomaterials, and computational modeling to enhance the efficiency and productivity of cell-free systems.Expand Specific Solutions04 Cell-free diagnostic and biosensing applications

Cell-free synthesis platforms are being utilized for diagnostic applications and biosensing. These systems can be freeze-dried for storage and rapidly activated when needed, making them suitable for point-of-care diagnostics. They can be engineered to produce reporter proteins in response to specific analytes, enabling detection of pathogens, toxins, or biomarkers. The technology allows for rapid, sensitive, and specific detection without the need for complex laboratory equipment.Expand Specific Solutions05 Novel cell-free synthesis components and extracts

Research has focused on developing novel components and extracts for cell-free synthesis systems. This includes engineered ribosomes, modified tRNAs, optimized cell extracts, and synthetic genetic elements. These innovations aim to expand the capabilities of cell-free systems, such as incorporating non-standard amino acids, producing complex proteins with correct folding, and increasing overall system efficiency. Advanced extract preparation methods have been developed to enhance protein yield and reduce resource requirements.Expand Specific Solutions

Leading Companies in Cell-free Nucleic Acid Production

Cell-free synthesis for nucleic acid therapeutics is currently in an early growth phase, with market size expanding rapidly due to increasing applications in personalized medicine and vaccine development. The technology is transitioning from research to commercial applications, though still requires significant refinement. Leading players demonstrate varying levels of technical maturity: DNA Script and Molecular Assemblies are pioneering enzymatic DNA synthesis approaches, while established institutions like Tsinghua University and Swiss Federal Institute of Technology contribute fundamental research. Companies like Aldevron and Guardant Health are applying cell-free technologies to therapeutic development, while startups such as Nunabio and Camena Bioscience focus on improving synthesis accuracy and scalability. The competitive landscape features both specialized biotechnology firms and diversified pharmaceutical companies like Dr. Reddy's Laboratories exploring this promising frontier.

DNA Script SAS

Technical Solution: DNA Script has developed an innovative enzymatic DNA synthesis technology called SYNTAX, which operates in a cell-free environment to produce high-quality nucleic acids for therapeutic applications. Their platform leverages naturally derived enzymes that mimic cellular DNA replication processes but function in a controlled cell-free setting. The SYNTAX system enables the synthesis of DNA sequences with significantly reduced error rates compared to traditional phosphoramidite chemistry, making it particularly valuable for therapeutic applications where sequence accuracy is critical. DNA Script's technology operates without the harsh chemicals required in conventional methods, eliminating toxic waste streams and enabling the incorporation of sensitive modifications that would be damaged by traditional approaches. Their benchtop DNA printer system automates the entire synthesis process, allowing researchers to produce custom DNA sequences on-demand within hours rather than days or weeks required by outsourced services.

Strengths: The enzymatic approach provides superior sequence accuracy and enables incorporation of modifications that are challenging with chemical methods. The automated benchtop system democratizes access to custom DNA synthesis. Weaknesses: Current limitations in maximum sequence length compared to some biological methods, and potentially higher costs per base for short production runs compared to established chemical synthesis at industrial scale.

Aldevron LLC

Technical Solution: Aldevron has developed a proprietary cell-free synthesis platform specifically optimized for nucleic acid therapeutics production. Their system utilizes highly purified enzymes and optimized reaction conditions to achieve high-yield, large-scale production of mRNA, DNA, and other nucleic acid therapeutics. The platform incorporates advanced purification techniques that eliminate cellular contaminants, resulting in pharmaceutical-grade nucleic acids with consistently high purity profiles. Aldevron's cell-free synthesis technology employs a continuous-flow bioreactor system that allows for scalable production from milligram to gram quantities while maintaining product quality. Their process includes proprietary nucleotide modifications that enhance stability and reduce immunogenicity of the synthesized nucleic acids, making them more suitable for therapeutic applications.

Strengths: Highly scalable production capacity, pharmaceutical-grade purity, and established regulatory compliance. Their continuous-flow system enables cost-effective large-scale manufacturing. Weaknesses: The technology may require specialized equipment and expertise, potentially limiting accessibility for smaller organizations. The process optimization for novel nucleic acid constructs may require significant development time.

Key Patents and Innovations in Cell-free Systems

Cell Free Biosynthesis of High-Quality Nucleic Acid and Uses Thereof

PatentInactiveUS20080305142A1

Innovation

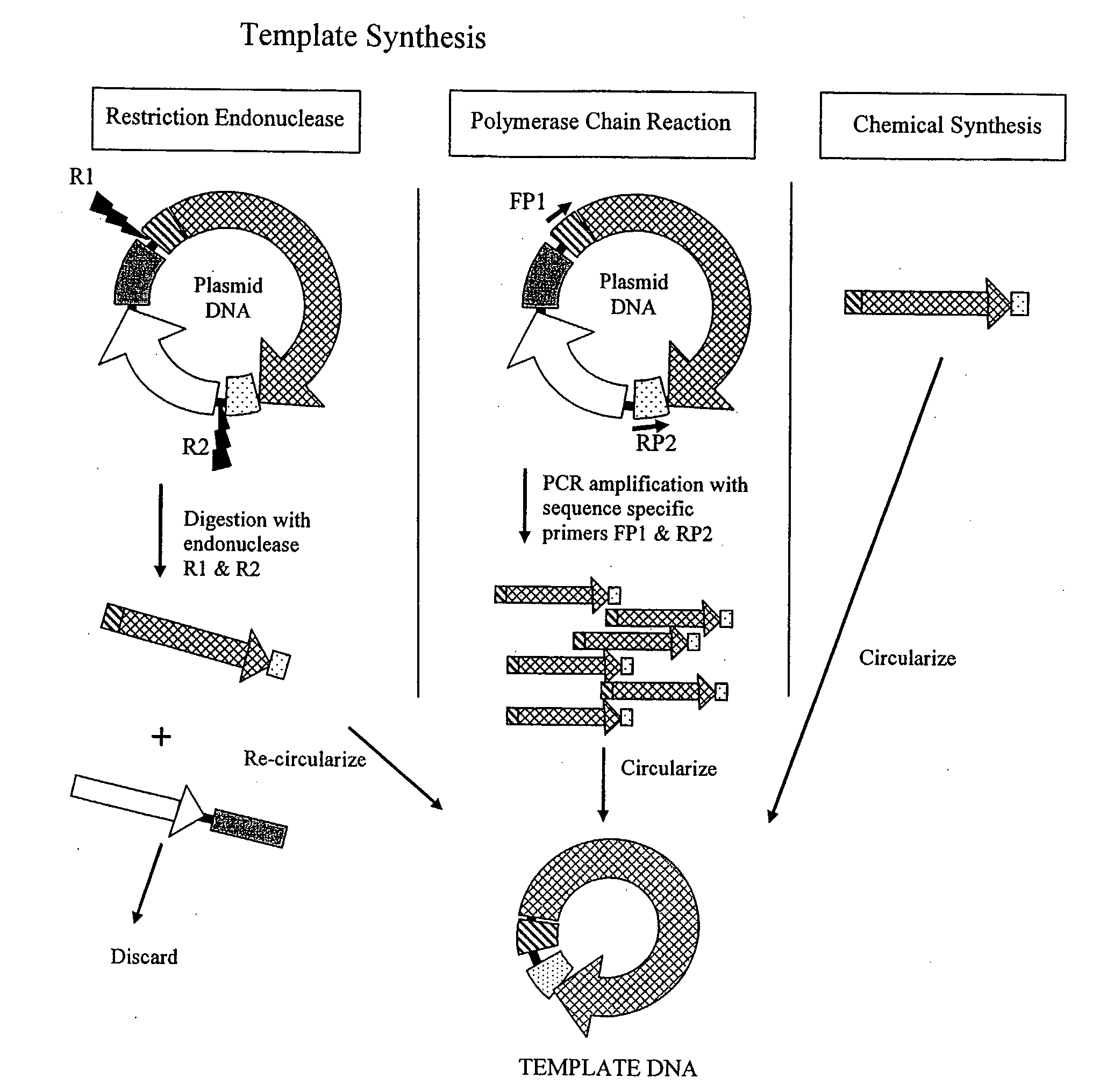

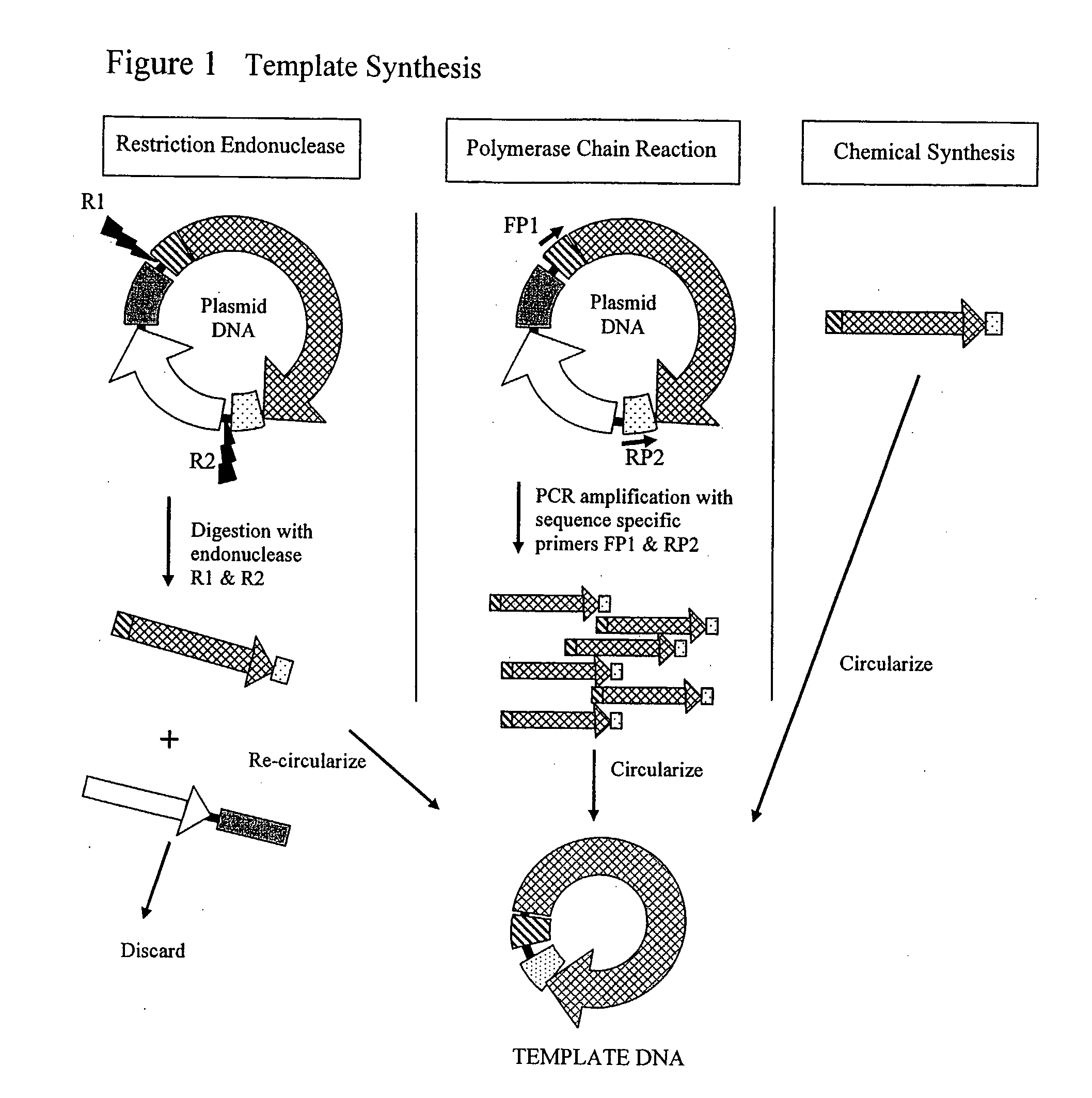

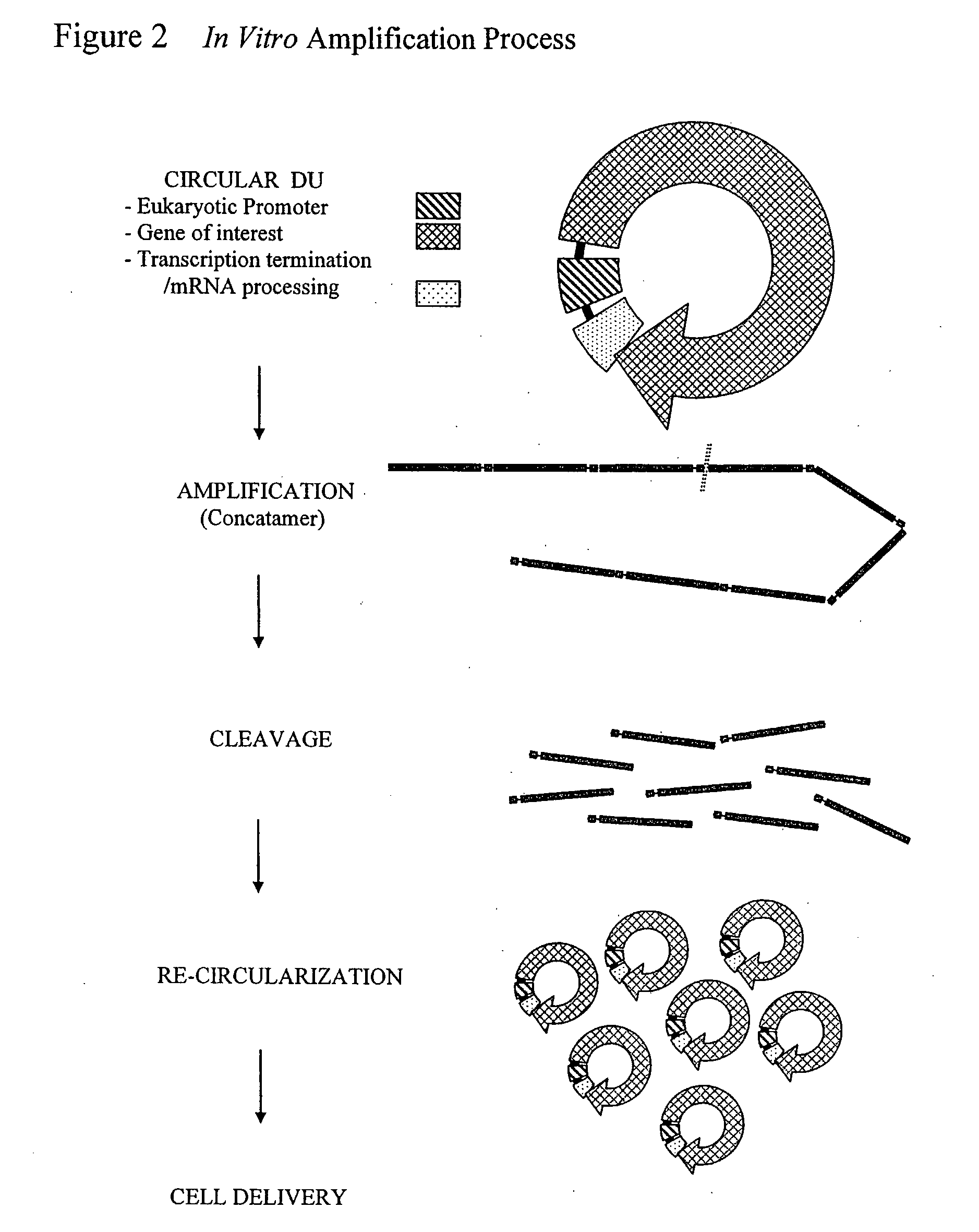

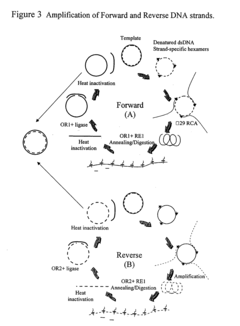

- A cell-free rolling circle amplification (RCA) system is optimized for large-scale production of high-quality nucleic acids using streamlined expression cassette templates, high-fidelity polymerases, and minimalistic buffer systems, reducing the need for expensive purification procedures and minimizing bacterial contaminants.

Cell-free biosynthesis of nucleic acid

PatentWO2007018744A2

Innovation

- A cell-free system for nucleic acid production using high-fidelity polymerases and streamlined expression cassettes, which minimizes bacterial contaminants and toxins, allowing for efficient and affordable large-scale production of high-quality nucleic acids with reduced purification needs.

Regulatory Framework for Nucleic Acid Therapeutics

The regulatory landscape for nucleic acid therapeutics is complex and evolving rapidly as these innovative treatments gain traction in clinical applications. Regulatory bodies worldwide, including the FDA, EMA, and PMDA, have established specialized frameworks to address the unique characteristics and challenges of nucleic acid-based products manufactured through cell-free synthesis methods.

The FDA's approach to regulating nucleic acid therapeutics primarily falls under the Center for Biologics Evaluation and Research (CBER) and the Center for Drug Evaluation and Research (CDER), depending on the specific mechanism of action. In 2018, the FDA released guidance specifically addressing development considerations for oligonucleotide-based therapeutics, acknowledging the unique manufacturing processes including cell-free synthesis systems.

European regulations, managed by the EMA, classify most nucleic acid therapeutics as Advanced Therapy Medicinal Products (ATMPs), subject to centralized authorization procedures. The EMA has established the Committee for Advanced Therapies (CAT) to evaluate quality, safety, and efficacy of these products, with specific considerations for cell-free manufacturing processes.

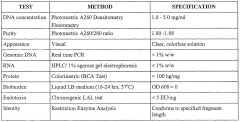

Quality control requirements present significant regulatory challenges for cell-free synthesized nucleic acid therapeutics. Regulatory agencies demand comprehensive characterization of impurity profiles, sequence verification, and structural integrity. The absence of cellular components in cell-free synthesis creates distinct regulatory considerations compared to cell-based production methods.

Safety assessment frameworks for these therapeutics focus on immunogenicity potential, off-target effects, and toxicity profiles. Regulatory bodies typically require extensive non-clinical studies addressing biodistribution, pharmacokinetics, and potential genotoxicity before advancing to clinical trials.

Accelerated approval pathways have emerged for nucleic acid therapeutics targeting rare diseases or unmet medical needs. The FDA's Breakthrough Therapy designation and the EMA's PRIME (PRIority MEdicines) scheme have facilitated expedited development of several nucleic acid therapeutics, including those manufactured via cell-free synthesis.

International harmonization efforts through the International Council for Harmonisation (ICH) are working to standardize regulatory requirements across regions, though significant regional differences persist. Japan's PMDA has developed specific guidelines for oligonucleotide therapeutics that acknowledge cell-free synthesis approaches, while China's NMPA continues to evolve its regulatory framework for these novel modalities.

As the field advances, regulatory frameworks are expected to further adapt to address emerging challenges in cell-free synthesis, including scaled manufacturing processes, novel delivery systems, and increasingly complex nucleic acid structures designed for therapeutic applications.

The FDA's approach to regulating nucleic acid therapeutics primarily falls under the Center for Biologics Evaluation and Research (CBER) and the Center for Drug Evaluation and Research (CDER), depending on the specific mechanism of action. In 2018, the FDA released guidance specifically addressing development considerations for oligonucleotide-based therapeutics, acknowledging the unique manufacturing processes including cell-free synthesis systems.

European regulations, managed by the EMA, classify most nucleic acid therapeutics as Advanced Therapy Medicinal Products (ATMPs), subject to centralized authorization procedures. The EMA has established the Committee for Advanced Therapies (CAT) to evaluate quality, safety, and efficacy of these products, with specific considerations for cell-free manufacturing processes.

Quality control requirements present significant regulatory challenges for cell-free synthesized nucleic acid therapeutics. Regulatory agencies demand comprehensive characterization of impurity profiles, sequence verification, and structural integrity. The absence of cellular components in cell-free synthesis creates distinct regulatory considerations compared to cell-based production methods.

Safety assessment frameworks for these therapeutics focus on immunogenicity potential, off-target effects, and toxicity profiles. Regulatory bodies typically require extensive non-clinical studies addressing biodistribution, pharmacokinetics, and potential genotoxicity before advancing to clinical trials.

Accelerated approval pathways have emerged for nucleic acid therapeutics targeting rare diseases or unmet medical needs. The FDA's Breakthrough Therapy designation and the EMA's PRIME (PRIority MEdicines) scheme have facilitated expedited development of several nucleic acid therapeutics, including those manufactured via cell-free synthesis.

International harmonization efforts through the International Council for Harmonisation (ICH) are working to standardize regulatory requirements across regions, though significant regional differences persist. Japan's PMDA has developed specific guidelines for oligonucleotide therapeutics that acknowledge cell-free synthesis approaches, while China's NMPA continues to evolve its regulatory framework for these novel modalities.

As the field advances, regulatory frameworks are expected to further adapt to address emerging challenges in cell-free synthesis, including scaled manufacturing processes, novel delivery systems, and increasingly complex nucleic acid structures designed for therapeutic applications.

Scalability and Manufacturing Considerations

Scaling up cell-free synthesis systems for nucleic acid therapeutics presents unique challenges compared to traditional biopharmaceutical manufacturing. Current laboratory-scale cell-free synthesis methods typically operate at volumes ranging from microliters to milliliters, which is insufficient for commercial production of nucleic acid therapeutics that require kilogram-scale outputs. The transition from bench to industrial scale demands significant engineering solutions to maintain reaction efficiency, product quality, and economic viability.

A critical consideration in scaling cell-free systems is the maintenance of optimal reaction conditions across larger volumes. As reaction vessels increase in size, challenges emerge in temperature control, mixing efficiency, and oxygen transfer rates. These parameters directly impact enzyme activity and stability, which are fundamental to the success of cell-free synthesis. Engineering solutions such as specialized bioreactors with enhanced mixing capabilities and precise temperature control systems are being developed to address these challenges.

Raw material supply chains represent another significant hurdle for large-scale cell-free manufacturing. The process requires high-quality enzymes, nucleotides, and other biochemical components that must be consistently available at industrial quantities. Currently, the market for these specialized reagents is limited, resulting in high costs and potential supply constraints. Establishing robust supply chains and developing more cost-effective production methods for these critical components will be essential for commercial viability.

Quality control and regulatory compliance become increasingly complex at larger scales. Cell-free synthesis systems must demonstrate consistent product quality, with minimal batch-to-batch variation. This necessitates the development of in-process monitoring technologies capable of real-time assessment of reaction parameters and product formation. Advanced analytical methods, including high-throughput sequencing and mass spectrometry, are being adapted for continuous monitoring of nucleic acid synthesis to ensure product integrity.

Economic considerations also play a crucial role in scaling decisions. The cost structure of cell-free manufacturing differs significantly from traditional bioproduction methods. While cell-free systems eliminate expenses related to cell culture and downstream processing of cellular debris, they introduce higher costs for enzymatic components and nucleotides. Comprehensive techno-economic analyses suggest that economies of scale can be achieved through process intensification, continuous manufacturing approaches, and recycling of expensive components.

Emerging technologies are addressing these scalability challenges. Microfluidic and continuous flow systems offer promising alternatives to batch processing, potentially enabling more efficient use of reagents and improved control over reaction conditions. Additionally, advances in enzyme engineering are producing more stable and efficient protein components that can withstand industrial manufacturing conditions while maintaining high catalytic activity.

A critical consideration in scaling cell-free systems is the maintenance of optimal reaction conditions across larger volumes. As reaction vessels increase in size, challenges emerge in temperature control, mixing efficiency, and oxygen transfer rates. These parameters directly impact enzyme activity and stability, which are fundamental to the success of cell-free synthesis. Engineering solutions such as specialized bioreactors with enhanced mixing capabilities and precise temperature control systems are being developed to address these challenges.

Raw material supply chains represent another significant hurdle for large-scale cell-free manufacturing. The process requires high-quality enzymes, nucleotides, and other biochemical components that must be consistently available at industrial quantities. Currently, the market for these specialized reagents is limited, resulting in high costs and potential supply constraints. Establishing robust supply chains and developing more cost-effective production methods for these critical components will be essential for commercial viability.

Quality control and regulatory compliance become increasingly complex at larger scales. Cell-free synthesis systems must demonstrate consistent product quality, with minimal batch-to-batch variation. This necessitates the development of in-process monitoring technologies capable of real-time assessment of reaction parameters and product formation. Advanced analytical methods, including high-throughput sequencing and mass spectrometry, are being adapted for continuous monitoring of nucleic acid synthesis to ensure product integrity.

Economic considerations also play a crucial role in scaling decisions. The cost structure of cell-free manufacturing differs significantly from traditional bioproduction methods. While cell-free systems eliminate expenses related to cell culture and downstream processing of cellular debris, they introduce higher costs for enzymatic components and nucleotides. Comprehensive techno-economic analyses suggest that economies of scale can be achieved through process intensification, continuous manufacturing approaches, and recycling of expensive components.

Emerging technologies are addressing these scalability challenges. Microfluidic and continuous flow systems offer promising alternatives to batch processing, potentially enabling more efficient use of reagents and improved control over reaction conditions. Additionally, advances in enzyme engineering are producing more stable and efficient protein components that can withstand industrial manufacturing conditions while maintaining high catalytic activity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!