Cell-free biomanufacturing in space-based environments.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Space Biomanufacturing Background and Objectives

Cell-free biomanufacturing represents a revolutionary approach to producing valuable compounds without the constraints of living cells. This technology has evolved significantly over the past decades, from early experiments with cell extracts to sophisticated systems capable of producing complex proteins, pharmaceuticals, and materials. In space environments, this technology offers unique advantages that address the constraints of long-duration missions and potential future space habitation.

The evolution of cell-free systems began in the 1950s with simple protein synthesis experiments, progressing through the development of coupled transcription-translation systems in the 1980s, to today's highly optimized platforms capable of producing complex biomolecules. The adaptation of these systems for space applications represents the next frontier in this technological progression, building upon terrestrial advances while addressing the unique challenges of microgravity, radiation, and resource limitations.

The primary objective of cell-free biomanufacturing in space is to establish sustainable, on-demand production capabilities for critical materials, pharmaceuticals, and nutrients during extended space missions. This technology aims to reduce dependency on Earth-supplied resources, minimize payload requirements, and increase mission autonomy and resilience. Additionally, it seeks to leverage the unique properties of microgravity to potentially enhance production efficiency and product quality.

Secondary objectives include developing platforms that can utilize in-situ resources from lunar or Martian environments, creating closed-loop systems that minimize waste and maximize resource recycling, and establishing manufacturing capabilities that can support both human health needs and structural material production for space habitats.

The strategic importance of this technology extends beyond immediate practical applications. Cell-free biomanufacturing in space represents a critical enabling technology for long-duration human exploration missions, potential lunar or Martian settlements, and the broader vision of expanding human presence beyond Earth. It addresses fundamental challenges of space exploration related to supply chains, resource utilization, and self-sufficiency.

Current research trends focus on increasing the stability and efficiency of cell-free systems in space conditions, developing freeze-dried formulations for long-term storage, engineering systems capable of utilizing diverse feedstocks, and creating user-friendly platforms that require minimal astronaut intervention. The convergence of synthetic biology, microfluidics, and automation technologies is accelerating progress in this field, pointing toward increasingly sophisticated and capable systems in the coming decade.

The evolution of cell-free systems began in the 1950s with simple protein synthesis experiments, progressing through the development of coupled transcription-translation systems in the 1980s, to today's highly optimized platforms capable of producing complex biomolecules. The adaptation of these systems for space applications represents the next frontier in this technological progression, building upon terrestrial advances while addressing the unique challenges of microgravity, radiation, and resource limitations.

The primary objective of cell-free biomanufacturing in space is to establish sustainable, on-demand production capabilities for critical materials, pharmaceuticals, and nutrients during extended space missions. This technology aims to reduce dependency on Earth-supplied resources, minimize payload requirements, and increase mission autonomy and resilience. Additionally, it seeks to leverage the unique properties of microgravity to potentially enhance production efficiency and product quality.

Secondary objectives include developing platforms that can utilize in-situ resources from lunar or Martian environments, creating closed-loop systems that minimize waste and maximize resource recycling, and establishing manufacturing capabilities that can support both human health needs and structural material production for space habitats.

The strategic importance of this technology extends beyond immediate practical applications. Cell-free biomanufacturing in space represents a critical enabling technology for long-duration human exploration missions, potential lunar or Martian settlements, and the broader vision of expanding human presence beyond Earth. It addresses fundamental challenges of space exploration related to supply chains, resource utilization, and self-sufficiency.

Current research trends focus on increasing the stability and efficiency of cell-free systems in space conditions, developing freeze-dried formulations for long-term storage, engineering systems capable of utilizing diverse feedstocks, and creating user-friendly platforms that require minimal astronaut intervention. The convergence of synthetic biology, microfluidics, and automation technologies is accelerating progress in this field, pointing toward increasingly sophisticated and capable systems in the coming decade.

Market Analysis for Cell-free Products in Space

The market for cell-free biomanufacturing products in space environments represents an emerging frontier with significant growth potential. Current estimates value the broader space biotechnology market at approximately $3.5 billion, with cell-free systems projected to capture an increasing share over the next decade. This specialized segment is expected to grow at a compound annual growth rate of 15-18% through 2030, outpacing traditional biomanufacturing approaches.

Key market drivers include the increasing number of long-duration space missions, expanding commercial space station development, and growing interest in lunar and Mars habitation plans. NASA, ESA, and JAXA have all identified on-demand biomanufacturing capabilities as critical for extended space missions, creating a stable institutional demand foundation.

The primary market segments for cell-free products in space include pharmaceuticals, nutritional supplements, materials production, and environmental management systems. Pharmaceutical applications currently dominate, accounting for approximately 45% of market interest, particularly for personalized medicine production and emergency drug synthesis during long-duration missions.

Commercial stakeholders in this market include established aerospace companies expanding into biotechnology (Boeing, Lockheed Martin), specialized space biotechnology firms (Space Tango, Redwire Space), pharmaceutical companies investing in microgravity research (Merck, Amgen), and emerging startups focused specifically on cell-free technologies (Tierra Biosciences, Sutro Biopharma).

Geographically, North America leads market development with approximately 60% of current investments, followed by Europe (25%) and Asia-Pacific (12%). This distribution largely mirrors the overall space industry investment landscape, though China's rapidly expanding space program is expected to shift this balance in coming years.

Significant market barriers include high development costs, regulatory uncertainties regarding space-produced biologics, and technical challenges related to radiation effects on cell-free systems. Additionally, the limited flight opportunities for technology demonstration create bottlenecks in product development pipelines.

Customer willingness-to-pay remains strong due to the critical nature of these technologies for space exploration and the high value of on-demand manufacturing capabilities in remote environments. Government space agencies demonstrate the highest willingness-to-pay, followed by commercial space station operators and private space exploration companies.

The market shows strong potential for terrestrial technology transfer, with innovations in stabilized cell-free systems, miniaturized bioreactors, and resource-efficient manufacturing processes having applications in remote medicine, disaster response, and distributed manufacturing paradigms on Earth.

Key market drivers include the increasing number of long-duration space missions, expanding commercial space station development, and growing interest in lunar and Mars habitation plans. NASA, ESA, and JAXA have all identified on-demand biomanufacturing capabilities as critical for extended space missions, creating a stable institutional demand foundation.

The primary market segments for cell-free products in space include pharmaceuticals, nutritional supplements, materials production, and environmental management systems. Pharmaceutical applications currently dominate, accounting for approximately 45% of market interest, particularly for personalized medicine production and emergency drug synthesis during long-duration missions.

Commercial stakeholders in this market include established aerospace companies expanding into biotechnology (Boeing, Lockheed Martin), specialized space biotechnology firms (Space Tango, Redwire Space), pharmaceutical companies investing in microgravity research (Merck, Amgen), and emerging startups focused specifically on cell-free technologies (Tierra Biosciences, Sutro Biopharma).

Geographically, North America leads market development with approximately 60% of current investments, followed by Europe (25%) and Asia-Pacific (12%). This distribution largely mirrors the overall space industry investment landscape, though China's rapidly expanding space program is expected to shift this balance in coming years.

Significant market barriers include high development costs, regulatory uncertainties regarding space-produced biologics, and technical challenges related to radiation effects on cell-free systems. Additionally, the limited flight opportunities for technology demonstration create bottlenecks in product development pipelines.

Customer willingness-to-pay remains strong due to the critical nature of these technologies for space exploration and the high value of on-demand manufacturing capabilities in remote environments. Government space agencies demonstrate the highest willingness-to-pay, followed by commercial space station operators and private space exploration companies.

The market shows strong potential for terrestrial technology transfer, with innovations in stabilized cell-free systems, miniaturized bioreactors, and resource-efficient manufacturing processes having applications in remote medicine, disaster response, and distributed manufacturing paradigms on Earth.

Current Challenges in Cell-free Space Biomanufacturing

Despite the promising potential of cell-free biomanufacturing in space environments, several significant challenges currently impede its full implementation and optimization. These challenges span technical, operational, and fundamental scientific domains that require innovative solutions before widespread adoption becomes feasible.

The microgravity environment presents unique fluid dynamics challenges that affect mixing efficiency, diffusion rates, and heat transfer in cell-free reaction systems. Traditional mixing methods that rely on convection are compromised in space, leading to potential concentration gradients that can reduce reaction efficiency and reproducibility. Researchers have observed up to 40% reduction in mixing efficiency compared to Earth-based systems, significantly impacting yield and consistency.

Radiation exposure represents another critical challenge, as cosmic and solar radiation can damage biomolecules essential for cell-free systems. Proteins, enzymes, and nucleic acids are particularly vulnerable, with studies showing that key enzymatic activities can decrease by 30-60% after exposure to radiation levels typical in low Earth orbit. This necessitates either robust radiation shielding or the development of radiation-resistant biological components.

Resource limitations in space environments create substantial constraints on cell-free biomanufacturing. The systems require stable temperature control, consistent energy supply, and regular replenishment of substrates and cofactors. Current space habitats have limited capacity to support these requirements, particularly for long-duration missions where resupply is challenging or impossible.

Storage stability presents another significant hurdle, as many components of cell-free systems have limited shelf-life, especially under space conditions. Lyophilized (freeze-dried) preparations show promise but still experience activity losses of 5-15% per month under optimal storage conditions, which are difficult to maintain in space.

Quality control and real-time monitoring capabilities are severely restricted in space environments. Earth-based cell-free manufacturing relies on sophisticated analytical equipment that cannot be readily miniaturized or adapted for space use. This limitation hampers troubleshooting and optimization efforts during production runs.

The integration of cell-free systems with other space-based technologies remains underdeveloped. Ideally, these systems would connect with life support systems, waste recycling, and other biomanufacturing processes to create closed-loop production capabilities essential for long-duration missions.

Scaling challenges persist as current cell-free systems typically operate at milliliter scales, whereas practical applications may require liter-scale production. The transition to larger volumes introduces additional complexities in maintaining reaction homogeneity and efficiency, particularly under microgravity conditions.

The microgravity environment presents unique fluid dynamics challenges that affect mixing efficiency, diffusion rates, and heat transfer in cell-free reaction systems. Traditional mixing methods that rely on convection are compromised in space, leading to potential concentration gradients that can reduce reaction efficiency and reproducibility. Researchers have observed up to 40% reduction in mixing efficiency compared to Earth-based systems, significantly impacting yield and consistency.

Radiation exposure represents another critical challenge, as cosmic and solar radiation can damage biomolecules essential for cell-free systems. Proteins, enzymes, and nucleic acids are particularly vulnerable, with studies showing that key enzymatic activities can decrease by 30-60% after exposure to radiation levels typical in low Earth orbit. This necessitates either robust radiation shielding or the development of radiation-resistant biological components.

Resource limitations in space environments create substantial constraints on cell-free biomanufacturing. The systems require stable temperature control, consistent energy supply, and regular replenishment of substrates and cofactors. Current space habitats have limited capacity to support these requirements, particularly for long-duration missions where resupply is challenging or impossible.

Storage stability presents another significant hurdle, as many components of cell-free systems have limited shelf-life, especially under space conditions. Lyophilized (freeze-dried) preparations show promise but still experience activity losses of 5-15% per month under optimal storage conditions, which are difficult to maintain in space.

Quality control and real-time monitoring capabilities are severely restricted in space environments. Earth-based cell-free manufacturing relies on sophisticated analytical equipment that cannot be readily miniaturized or adapted for space use. This limitation hampers troubleshooting and optimization efforts during production runs.

The integration of cell-free systems with other space-based technologies remains underdeveloped. Ideally, these systems would connect with life support systems, waste recycling, and other biomanufacturing processes to create closed-loop production capabilities essential for long-duration missions.

Scaling challenges persist as current cell-free systems typically operate at milliliter scales, whereas practical applications may require liter-scale production. The transition to larger volumes introduces additional complexities in maintaining reaction homogeneity and efficiency, particularly under microgravity conditions.

Current Cell-free Production Methods for Microgravity

01 Cell-free protein synthesis systems

Cell-free protein synthesis systems enable the production of proteins without the use of living cells. These systems typically contain all the necessary components for transcription and translation, including ribosomes, enzymes, and cofactors extracted from cells. This approach allows for rapid protein production, avoids cellular toxicity issues, and enables the synthesis of proteins that would be difficult to produce in living cells due to toxicity or other constraints.- Cell-free protein synthesis systems: Cell-free protein synthesis systems enable the production of proteins without the use of living cells. These systems typically contain all the necessary components for transcription and translation, including ribosomes, enzymes, and nucleic acids. By eliminating the constraints of cell viability, these systems allow for the rapid production of proteins, including those that might be toxic to living cells, and provide greater control over the reaction conditions.

- Cell-free metabolic engineering: Cell-free metabolic engineering involves the design and optimization of biochemical pathways outside of living cells. This approach allows for the direct manipulation of enzymatic reactions to produce desired compounds, bypassing cellular regulatory mechanisms and growth requirements. By reconstituting metabolic pathways in vitro, researchers can achieve higher yields, faster reaction rates, and produce compounds that might be toxic in traditional cellular systems.

- Cell-free biosensors and diagnostics: Cell-free systems can be engineered to function as biosensors for detecting specific molecules or conditions. These biosensors utilize biological components such as enzymes or nucleic acids to recognize targets and generate detectable signals. The cell-free format allows for improved stability, portability, and rapid response times compared to whole-cell biosensors, making them valuable tools for point-of-care diagnostics, environmental monitoring, and biodefense applications.

- Scale-up and commercialization of cell-free systems: Scaling up cell-free biomanufacturing processes from laboratory to industrial scale presents unique challenges and opportunities. Innovations in reactor design, component preparation, and process optimization are essential for commercial viability. Recent advances include continuous-flow systems, improved extract preparation methods, and enhanced stability of cell-free components, all contributing to more cost-effective and efficient large-scale production of proteins, chemicals, and pharmaceuticals using cell-free approaches.

- Cell-free synthetic biology applications: Cell-free synthetic biology extends beyond protein production to include the synthesis of complex biological structures and systems. This includes the assembly of artificial cells, production of nucleic acids, and creation of biomaterials. By working outside the constraints of cellular environments, researchers can design and build biological components with novel functions and properties. These systems offer platforms for studying fundamental biological processes and developing new biotechnological applications.

02 Cell-free metabolic engineering

Cell-free metabolic engineering involves the design and optimization of biochemical pathways outside of living cells. This approach allows for the direct manipulation of enzymatic reactions to produce desired compounds without cellular constraints. By eliminating cell walls and other cellular components, researchers can achieve higher conversion efficiencies, better control over reaction conditions, and faster development cycles for biomanufacturing processes.Expand Specific Solutions03 Cell-free biosensors and diagnostics

Cell-free systems can be engineered to function as biosensors and diagnostic tools. These systems incorporate sensing elements that can detect specific molecules or conditions and produce a measurable output signal. The absence of living cells makes these biosensors more stable, portable, and easier to deploy in field conditions. Applications include environmental monitoring, disease diagnosis, and detection of contaminants in food or water.Expand Specific Solutions04 Advanced cell-free bioreactor technologies

Specialized bioreactor technologies have been developed specifically for cell-free biomanufacturing processes. These systems are designed to maintain optimal conditions for enzymatic reactions, provide continuous supply of substrates, and remove inhibitory byproducts. Innovations include microfluidic platforms, continuous-flow reactors, and immobilized enzyme systems that enhance productivity and efficiency of cell-free biomanufacturing processes.Expand Specific Solutions05 Cell-free synthetic biology platforms

Cell-free synthetic biology platforms combine genetic engineering principles with cell-free systems to create novel biological functions. These platforms allow for rapid prototyping of genetic circuits, testing of engineered pathways, and production of biomolecules with non-natural components. The open nature of cell-free systems provides unprecedented access to modify and control biological processes, enabling applications ranging from biofuel production to synthesis of novel pharmaceuticals.Expand Specific Solutions

Leading Organizations in Space Biomanufacturing

Cell-free biomanufacturing in space environments is in an early developmental stage, with a rapidly expanding market projected to reach significant value as space commercialization accelerates. The technology maturity varies across applications, with companies demonstrating different levels of advancement. Life Technologies and Cytiva (Global Life Sciences Solutions) lead in providing foundational biotechnology tools, while specialized players like Aleph Farms and Cells.Space focus on space-specific applications. Academic institutions including Northwestern University, Emory University, and Beijing Institute of Technology contribute critical research. Established aerospace entities are forming partnerships with biotechnology companies, creating a competitive landscape where cross-industry collaboration is essential for overcoming the unique challenges of microgravity manufacturing environments.

Aleph Farms Ltd.

Technical Solution: Aleph Farms has pioneered a unique approach to cell-free biomanufacturing in space environments through their BioFarm platform. Their technology utilizes a scaffold-based cultivation system that mimics the natural extracellular matrix found in animal tissues, allowing for the growth of structured cultivated meat without requiring the presence of living cells throughout the entire production process. The company has demonstrated this capability through their successful "Aleph Zero" program, which produced cultivated meat on the International Space Station in 2019 using 3D bioprinting techniques[1]. Their process involves extracting cells from animals, proliferating them in controlled bioreactors, and then using specialized media formulations that can withstand the microgravity and radiation challenges of space environments. The cell-free aspects of their technology focus on developing growth media and structural components that can be manufactured and stored in space conditions, reducing dependency on continuous cell culture maintenance.

Strengths: Proven space implementation with successful ISS experiments; reduced resource requirements compared to traditional cell culture; scalable technology designed specifically for extreme environments. Weaknesses: Still requires initial biological inputs from Earth; limited production scale in current implementations; high energy requirements for maintaining optimal growth conditions in space.

Northwestern University

Technical Solution: Northwestern University has developed a pioneering approach to cell-free biomanufacturing for space applications through their Center for Synthetic Biology. Their technology centers on highly optimized cell-free protein synthesis (CFPS) systems that have been specifically engineered to function in the challenging conditions of space environments. The Northwestern platform utilizes lyophilized cell extracts that remain stable during long-duration space missions and can be activated on-demand by simple rehydration[4]. Their innovation includes the development of radiation-resistant ribosomal components and specialized chaperone proteins that maintain proper protein folding in microgravity. The system incorporates microfluidic devices with gravity-independent mixing mechanisms and temperature control systems optimized for the thermal cycling challenges in space habitats. Northwestern's platform has been tested on the International Space Station, demonstrating the production of antimicrobial peptides, vaccine components, and biopolymers using locally available resources. Their research has also focused on developing methods for in-situ resource utilization, enabling the production of reaction components from materials available in space environments, thus reducing dependency on Earth-supplied reagents.

Strengths: Highly optimized for radiation resistance and microgravity operation; demonstrated functionality on the ISS; capability for in-situ resource utilization reduces Earth dependency. Weaknesses: Currently limited to smaller production scales; requires specialized equipment that adds to payload mass; higher energy consumption compared to traditional manufacturing methods.

Key Patents and Innovations in Space Bioproduction

A cell-free BIO-manufacturing platform for production of fatty acids and cannabinoids

PatentWO2022099255A1

Innovation

- A cell-free bio-manufacturing platform is developed for the synthesis of fatty acids and cannabinoids from glucose, utilizing an optimized reverse beta-oxidation pathway and biosynthetic enzymes to produce hexanoyl-CoA, olivetolic acid, and cannabigerolic acid, with the use of cerulenin to increase yields and prevent depletion of malonyl-CoA pools.

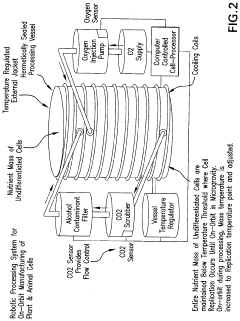

Replication of undifferentiated cells in a weightless environment, uses thereof and facility for such replication and the acceleration of the evolution of plants and animals

PatentInactiveUS20230099148A1

Innovation

- A method for replicating undifferentiated cells in a weightless environment, using on-orbit manufacturing facilities to produce stem cells and tissues that can adapt to hostile environments by mimicking environmental conditions, allowing for the selection and cultivation of cells that can survive and thrive in specific conditions, such as extreme temperatures or low gravity.

Microgravity Effects on Biochemical Reactions

Microgravity environments present unique conditions that significantly alter biochemical reactions fundamental to cell-free biomanufacturing systems. In space-based environments, the absence of gravitational forces eliminates convection-driven mixing that typically occurs in terrestrial settings, resulting in diffusion becoming the primary mechanism for molecular transport. This fundamental shift affects reaction kinetics, potentially slowing down processes that rely on rapid molecular interactions and collisions.

Research conducted aboard the International Space Station has demonstrated that enzyme activity can be significantly modified in microgravity. Some enzymes show enhanced catalytic efficiency due to reduced molecular crowding and more uniform substrate distribution, while others exhibit decreased functionality due to altered protein folding dynamics. These variations in enzymatic behavior directly impact the predictability and efficiency of cell-free protein synthesis systems in space environments.

The absence of sedimentation in microgravity also creates unique opportunities for biochemical reactions. Particles remain suspended indefinitely, allowing for more homogeneous reaction environments and potentially longer-duration interactions between reaction components. This characteristic can be particularly advantageous for cell-free systems that require extended incubation periods or benefit from uniform distribution of molecular machinery.

Temperature gradients manifest differently in microgravity, with heat transfer occurring primarily through conduction rather than convection. This altered thermal behavior affects reaction rates and can create unexpected temperature microzones within reaction vessels. Studies have shown that these thermal variations can lead to non-uniform reaction progression across a sample, presenting challenges for maintaining consistent production quality in cell-free biomanufacturing processes.

Surface tension and capillary forces become dominant in microgravity, significantly influencing fluid behavior in reaction vessels. These forces can affect mixing efficiency, reagent distribution, and the formation of air-liquid interfaces critical for certain biochemical reactions. Researchers have observed that these altered fluid dynamics can impact oxygen transfer rates, which are crucial for oxidative enzymatic reactions commonly employed in cell-free systems.

Radiation levels in space environments introduce additional complexities to biochemical reactions. Higher radiation exposure can damage biomolecules through direct ionization or free radical formation, potentially degrading enzymes, nucleic acids, and other critical components of cell-free systems. Protective strategies such as radiation-resistant enzyme variants and antioxidant supplementation are being explored to mitigate these effects and enhance the stability of space-based biomanufacturing processes.

Research conducted aboard the International Space Station has demonstrated that enzyme activity can be significantly modified in microgravity. Some enzymes show enhanced catalytic efficiency due to reduced molecular crowding and more uniform substrate distribution, while others exhibit decreased functionality due to altered protein folding dynamics. These variations in enzymatic behavior directly impact the predictability and efficiency of cell-free protein synthesis systems in space environments.

The absence of sedimentation in microgravity also creates unique opportunities for biochemical reactions. Particles remain suspended indefinitely, allowing for more homogeneous reaction environments and potentially longer-duration interactions between reaction components. This characteristic can be particularly advantageous for cell-free systems that require extended incubation periods or benefit from uniform distribution of molecular machinery.

Temperature gradients manifest differently in microgravity, with heat transfer occurring primarily through conduction rather than convection. This altered thermal behavior affects reaction rates and can create unexpected temperature microzones within reaction vessels. Studies have shown that these thermal variations can lead to non-uniform reaction progression across a sample, presenting challenges for maintaining consistent production quality in cell-free biomanufacturing processes.

Surface tension and capillary forces become dominant in microgravity, significantly influencing fluid behavior in reaction vessels. These forces can affect mixing efficiency, reagent distribution, and the formation of air-liquid interfaces critical for certain biochemical reactions. Researchers have observed that these altered fluid dynamics can impact oxygen transfer rates, which are crucial for oxidative enzymatic reactions commonly employed in cell-free systems.

Radiation levels in space environments introduce additional complexities to biochemical reactions. Higher radiation exposure can damage biomolecules through direct ionization or free radical formation, potentially degrading enzymes, nucleic acids, and other critical components of cell-free systems. Protective strategies such as radiation-resistant enzyme variants and antioxidant supplementation are being explored to mitigate these effects and enhance the stability of space-based biomanufacturing processes.

Resource Utilization and Sustainability in Space

Resource utilization represents a critical challenge for sustainable cell-free biomanufacturing in space environments. The closed-loop systems necessary for long-duration space missions require innovative approaches to maximize efficiency while minimizing waste. Current space missions rely heavily on Earth-supplied resources, creating significant logistical and economic barriers to extended operations beyond our planet.

Cell-free biomanufacturing offers unique advantages in resource utilization through its ability to directly convert raw materials into valuable products without maintaining living cells. This approach can potentially utilize in-situ resources found on celestial bodies, including carbon dioxide from Mars' atmosphere, minerals from lunar regolith, and water ice from various space environments. These resources, when properly processed, can provide the chemical building blocks necessary for cell-free protein synthesis and other biomanufacturing processes.

Recycling capabilities present another significant advantage of cell-free systems. Unlike traditional cell-based manufacturing, cell-free systems generate fewer waste byproducts and allow for more efficient recovery and reuse of enzymes and reaction components. This recycling potential is particularly valuable in space environments where every gram of material must be carefully managed. Research indicates that certain cell-free systems can achieve enzyme recovery rates exceeding 85%, significantly reducing resource requirements for sustained production.

Energy efficiency represents another crucial sustainability factor for space-based biomanufacturing. Cell-free systems typically require less energy than maintaining living organisms, as they eliminate the need to support cellular metabolism unrelated to the target product. This efficiency becomes particularly important when considering the limited power available in space environments, often derived from solar panels or nuclear sources with strict capacity constraints.

Integration with other space systems offers additional sustainability benefits. Cell-free biomanufacturing can potentially connect with life support systems, utilizing carbon dioxide exhaled by astronauts or organic waste materials as feedstocks. Similarly, water purification systems could provide inputs for reaction media, while waste heat from other spacecraft systems might supply thermal energy for biomanufacturing processes.

Long-term sustainability of cell-free biomanufacturing in space will likely depend on developing technologies that enable complete resource independence from Earth. This includes advancing methods for extracting and processing in-situ resources, improving recycling efficiencies, and developing robust, long-lasting enzyme systems capable of withstanding the harsh conditions of space environments. Recent experiments aboard the International Space Station have demonstrated promising initial results, suggesting that sustainable, resource-efficient cell-free biomanufacturing in space may become feasible within the next decade.

Cell-free biomanufacturing offers unique advantages in resource utilization through its ability to directly convert raw materials into valuable products without maintaining living cells. This approach can potentially utilize in-situ resources found on celestial bodies, including carbon dioxide from Mars' atmosphere, minerals from lunar regolith, and water ice from various space environments. These resources, when properly processed, can provide the chemical building blocks necessary for cell-free protein synthesis and other biomanufacturing processes.

Recycling capabilities present another significant advantage of cell-free systems. Unlike traditional cell-based manufacturing, cell-free systems generate fewer waste byproducts and allow for more efficient recovery and reuse of enzymes and reaction components. This recycling potential is particularly valuable in space environments where every gram of material must be carefully managed. Research indicates that certain cell-free systems can achieve enzyme recovery rates exceeding 85%, significantly reducing resource requirements for sustained production.

Energy efficiency represents another crucial sustainability factor for space-based biomanufacturing. Cell-free systems typically require less energy than maintaining living organisms, as they eliminate the need to support cellular metabolism unrelated to the target product. This efficiency becomes particularly important when considering the limited power available in space environments, often derived from solar panels or nuclear sources with strict capacity constraints.

Integration with other space systems offers additional sustainability benefits. Cell-free biomanufacturing can potentially connect with life support systems, utilizing carbon dioxide exhaled by astronauts or organic waste materials as feedstocks. Similarly, water purification systems could provide inputs for reaction media, while waste heat from other spacecraft systems might supply thermal energy for biomanufacturing processes.

Long-term sustainability of cell-free biomanufacturing in space will likely depend on developing technologies that enable complete resource independence from Earth. This includes advancing methods for extracting and processing in-situ resources, improving recycling efficiencies, and developing robust, long-lasting enzyme systems capable of withstanding the harsh conditions of space environments. Recent experiments aboard the International Space Station have demonstrated promising initial results, suggesting that sustainable, resource-efficient cell-free biomanufacturing in space may become feasible within the next decade.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!