The influence of microfluidics on cell-free biomanufacturing.

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidics in Cell-Free Biomanufacturing: Background and Objectives

Microfluidics represents a transformative technology that has evolved significantly over the past two decades, integrating principles from engineering, physics, chemistry, and biology. The field emerged in the early 1990s as an extension of microelectromechanical systems (MEMS) technology, with pioneering work by researchers like George Whitesides and Stephen Quake establishing fundamental fabrication techniques and applications. Since then, microfluidics has progressed from simple channel designs to sophisticated lab-on-a-chip platforms capable of performing complex biological processes.

In the context of cell-free biomanufacturing, microfluidics offers unprecedented control over reaction conditions at microscale volumes. Cell-free systems, which utilize cellular machinery extracted from cells to produce proteins and other biomolecules without the constraints of cellular viability, have been studied since the mid-20th century. However, their integration with microfluidic technologies represents a relatively recent advancement that addresses many limitations of traditional batch reactions.

The convergence of these technologies has been driven by increasing demands for sustainable bioproduction methods, personalized medicine applications, and point-of-care diagnostics. Market analyses indicate that the global cell-free protein expression market is expected to reach $3.8 billion by 2027, with microfluidic applications representing a significant growth segment within this space.

The technical evolution trajectory shows clear progression from simple proof-of-concept demonstrations to increasingly sophisticated implementations. Early work focused primarily on demonstrating basic protein expression in microchannels, while recent advances have achieved continuous-flow production systems, multiplexed reactions, and integration with downstream processing steps.

The primary objective of current research in microfluidics for cell-free biomanufacturing is to develop scalable, efficient, and economically viable production platforms that can compete with traditional cell-based manufacturing approaches. Specific technical goals include enhancing reaction yields through improved mass transfer, extending reaction lifetimes through continuous reagent exchange, reducing reagent consumption, and enabling real-time monitoring and control of production processes.

Additional objectives include developing standardized microfluidic interfaces for cell-free systems, improving the stability and activity of cell-free extracts in microfluidic environments, and creating modular designs that can be rapidly reconfigured for different production targets. The field also aims to bridge the gap between laboratory demonstrations and industrial implementation by addressing challenges related to throughput, robustness, and integration with existing biomanufacturing infrastructure.

As this technology continues to mature, it promises to enable distributed biomanufacturing capabilities, rapid prototyping of biological products, and on-demand production of therapeutics and other high-value biomolecules, potentially revolutionizing how biological products are developed, manufactured, and delivered.

In the context of cell-free biomanufacturing, microfluidics offers unprecedented control over reaction conditions at microscale volumes. Cell-free systems, which utilize cellular machinery extracted from cells to produce proteins and other biomolecules without the constraints of cellular viability, have been studied since the mid-20th century. However, their integration with microfluidic technologies represents a relatively recent advancement that addresses many limitations of traditional batch reactions.

The convergence of these technologies has been driven by increasing demands for sustainable bioproduction methods, personalized medicine applications, and point-of-care diagnostics. Market analyses indicate that the global cell-free protein expression market is expected to reach $3.8 billion by 2027, with microfluidic applications representing a significant growth segment within this space.

The technical evolution trajectory shows clear progression from simple proof-of-concept demonstrations to increasingly sophisticated implementations. Early work focused primarily on demonstrating basic protein expression in microchannels, while recent advances have achieved continuous-flow production systems, multiplexed reactions, and integration with downstream processing steps.

The primary objective of current research in microfluidics for cell-free biomanufacturing is to develop scalable, efficient, and economically viable production platforms that can compete with traditional cell-based manufacturing approaches. Specific technical goals include enhancing reaction yields through improved mass transfer, extending reaction lifetimes through continuous reagent exchange, reducing reagent consumption, and enabling real-time monitoring and control of production processes.

Additional objectives include developing standardized microfluidic interfaces for cell-free systems, improving the stability and activity of cell-free extracts in microfluidic environments, and creating modular designs that can be rapidly reconfigured for different production targets. The field also aims to bridge the gap between laboratory demonstrations and industrial implementation by addressing challenges related to throughput, robustness, and integration with existing biomanufacturing infrastructure.

As this technology continues to mature, it promises to enable distributed biomanufacturing capabilities, rapid prototyping of biological products, and on-demand production of therapeutics and other high-value biomolecules, potentially revolutionizing how biological products are developed, manufactured, and delivered.

Market Analysis for Cell-Free Biomanufacturing Solutions

The cell-free biomanufacturing market is experiencing significant growth, driven by increasing demand for sustainable and efficient production methods across pharmaceutical, biotechnology, and chemical industries. Current market valuations indicate that the global cell-free protein synthesis market reached approximately 250 million USD in 2022 and is projected to grow at a compound annual growth rate of 8-10% through 2030.

Microfluidics technology has emerged as a transformative force in this sector, enabling precise control over reaction conditions and dramatically reducing reagent consumption. This integration has created a specialized market segment estimated to be growing at 12-15% annually, outpacing the broader cell-free market.

Demand analysis reveals three primary market segments: pharmaceutical companies seeking rapid prototyping of therapeutic proteins, diagnostic manufacturers requiring point-of-care testing solutions, and academic research institutions exploring fundamental biological processes. The pharmaceutical segment currently represents the largest market share at approximately 45%, followed by diagnostics at 30% and research at 25%.

Geographic distribution of market demand shows North America leading with 40% market share, followed by Europe (30%), Asia-Pacific (20%), and rest of the world (10%). However, the Asia-Pacific region demonstrates the fastest growth rate, particularly in China, South Korea, and Singapore where government initiatives are actively promoting biotechnology innovation.

Customer needs assessment indicates five key requirements driving market adoption: reduced production costs (cited by 78% of potential customers), increased production speed (65%), improved product quality (60%), enhanced scalability (55%), and reduced environmental impact (40%). Microfluidics-enabled cell-free systems address all these needs to varying degrees, with particularly strong performance in cost reduction and production speed.

Market barriers include high initial investment costs, technical complexity requiring specialized expertise, regulatory uncertainties, and competition from traditional manufacturing methods. Despite these challenges, the market demonstrates strong growth potential as technological advancements continue to address these limitations.

Pricing analysis reveals that microfluidics-enhanced cell-free biomanufacturing solutions command a premium of 15-20% over conventional cell-free systems, justified by their superior performance metrics. This premium is expected to decrease as technology matures and competition increases, potentially expanding market accessibility.

Future market projections suggest that microfluidics integration will become standard in cell-free biomanufacturing within 5-7 years, with particular growth in point-of-care diagnostic applications and personalized medicine production.

Microfluidics technology has emerged as a transformative force in this sector, enabling precise control over reaction conditions and dramatically reducing reagent consumption. This integration has created a specialized market segment estimated to be growing at 12-15% annually, outpacing the broader cell-free market.

Demand analysis reveals three primary market segments: pharmaceutical companies seeking rapid prototyping of therapeutic proteins, diagnostic manufacturers requiring point-of-care testing solutions, and academic research institutions exploring fundamental biological processes. The pharmaceutical segment currently represents the largest market share at approximately 45%, followed by diagnostics at 30% and research at 25%.

Geographic distribution of market demand shows North America leading with 40% market share, followed by Europe (30%), Asia-Pacific (20%), and rest of the world (10%). However, the Asia-Pacific region demonstrates the fastest growth rate, particularly in China, South Korea, and Singapore where government initiatives are actively promoting biotechnology innovation.

Customer needs assessment indicates five key requirements driving market adoption: reduced production costs (cited by 78% of potential customers), increased production speed (65%), improved product quality (60%), enhanced scalability (55%), and reduced environmental impact (40%). Microfluidics-enabled cell-free systems address all these needs to varying degrees, with particularly strong performance in cost reduction and production speed.

Market barriers include high initial investment costs, technical complexity requiring specialized expertise, regulatory uncertainties, and competition from traditional manufacturing methods. Despite these challenges, the market demonstrates strong growth potential as technological advancements continue to address these limitations.

Pricing analysis reveals that microfluidics-enhanced cell-free biomanufacturing solutions command a premium of 15-20% over conventional cell-free systems, justified by their superior performance metrics. This premium is expected to decrease as technology matures and competition increases, potentially expanding market accessibility.

Future market projections suggest that microfluidics integration will become standard in cell-free biomanufacturing within 5-7 years, with particular growth in point-of-care diagnostic applications and personalized medicine production.

Current Microfluidic Technologies and Implementation Barriers

Microfluidic technologies have evolved significantly over the past decade, offering unprecedented control over fluid manipulation at microscale dimensions. Current microfluidic platforms for cell-free biomanufacturing can be categorized into several major types: droplet-based systems, continuous flow microreactors, digital microfluidics, and paper-based microfluidics. Each system presents unique advantages for specific cell-free applications.

Droplet-based microfluidic systems enable high-throughput operations by generating discrete aqueous droplets in an immiscible carrier fluid. These systems excel at compartmentalization of cell-free reactions, allowing for parallelization and miniaturization. Recent advances have achieved droplet generation rates exceeding 10,000 droplets per second with highly uniform size distributions (coefficient of variation <3%).

Continuous flow microreactors provide stable environments for sustained cell-free protein synthesis, with residence times precisely controlled through channel geometry and flow rates. These systems have demonstrated protein production yields up to 2.3 g/L in optimized configurations, significantly higher than conventional batch reactions.

Digital microfluidics, utilizing electrowetting-on-dielectric (EWOD) principles, offers programmable manipulation of discrete droplets without physical channels. This technology provides exceptional flexibility for multistep protocols but faces challenges in scaling beyond laboratory demonstrations.

Despite these technological advances, several implementation barriers limit widespread adoption of microfluidics in cell-free biomanufacturing. Material compatibility represents a significant challenge, as many polymers used in microfluidic fabrication can adsorb proteins or inhibit enzymatic reactions. Surface passivation techniques using bovine serum albumin or polyethylene glycol coatings provide partial solutions but add complexity to manufacturing processes.

Scaling limitations present another major barrier. While microfluidic devices excel at small-scale operations, translating these advantages to industrial production volumes remains challenging. Current parallelization approaches face issues with flow distribution uniformity and system complexity that grow exponentially with scale.

Integration with existing bioprocess infrastructure poses additional challenges. Most industrial biomanufacturing relies on established reactor technologies, and retrofitting microfluidic components requires significant process reengineering and validation efforts.

Economic considerations further complicate implementation. The capital investment for specialized microfluidic equipment and the operational expertise required for maintenance create significant barriers to entry. Current cost analyses suggest that microfluidic approaches become economically viable only for high-value products or when conventional methods fail to deliver required performance metrics.

Regulatory uncertainty represents the final major barrier, as novel microfluidic manufacturing platforms must navigate complex approval pathways with limited precedent. The lack of standardized validation protocols specifically designed for microfluidic production systems further complicates regulatory compliance.

Droplet-based microfluidic systems enable high-throughput operations by generating discrete aqueous droplets in an immiscible carrier fluid. These systems excel at compartmentalization of cell-free reactions, allowing for parallelization and miniaturization. Recent advances have achieved droplet generation rates exceeding 10,000 droplets per second with highly uniform size distributions (coefficient of variation <3%).

Continuous flow microreactors provide stable environments for sustained cell-free protein synthesis, with residence times precisely controlled through channel geometry and flow rates. These systems have demonstrated protein production yields up to 2.3 g/L in optimized configurations, significantly higher than conventional batch reactions.

Digital microfluidics, utilizing electrowetting-on-dielectric (EWOD) principles, offers programmable manipulation of discrete droplets without physical channels. This technology provides exceptional flexibility for multistep protocols but faces challenges in scaling beyond laboratory demonstrations.

Despite these technological advances, several implementation barriers limit widespread adoption of microfluidics in cell-free biomanufacturing. Material compatibility represents a significant challenge, as many polymers used in microfluidic fabrication can adsorb proteins or inhibit enzymatic reactions. Surface passivation techniques using bovine serum albumin or polyethylene glycol coatings provide partial solutions but add complexity to manufacturing processes.

Scaling limitations present another major barrier. While microfluidic devices excel at small-scale operations, translating these advantages to industrial production volumes remains challenging. Current parallelization approaches face issues with flow distribution uniformity and system complexity that grow exponentially with scale.

Integration with existing bioprocess infrastructure poses additional challenges. Most industrial biomanufacturing relies on established reactor technologies, and retrofitting microfluidic components requires significant process reengineering and validation efforts.

Economic considerations further complicate implementation. The capital investment for specialized microfluidic equipment and the operational expertise required for maintenance create significant barriers to entry. Current cost analyses suggest that microfluidic approaches become economically viable only for high-value products or when conventional methods fail to deliver required performance metrics.

Regulatory uncertainty represents the final major barrier, as novel microfluidic manufacturing platforms must navigate complex approval pathways with limited precedent. The lack of standardized validation protocols specifically designed for microfluidic production systems further complicates regulatory compliance.

Existing Microfluidic Platforms for Cell-Free Applications

01 Microfluidic device design and fabrication

Microfluidic devices are designed and fabricated using various materials and techniques to create channels, chambers, and other structures at the microscale. These devices enable precise control of fluid flow, mixing, and manipulation for applications in chemistry, biology, and medicine. Advanced fabrication methods include soft lithography, etching, and 3D printing to create complex microfluidic architectures with specific functionalities.- Microfluidic device design and fabrication: Microfluidic devices are designed and fabricated using various techniques to create channels, chambers, and other structures at the microscale. These devices enable precise control of fluid flow and manipulation of small volumes of liquids for applications in chemistry, biology, and medicine. The fabrication methods include soft lithography, etching, and 3D printing, which allow for the creation of complex microfluidic architectures with specific functionalities.

- Droplet generation and manipulation in microfluidics: Microfluidic systems can generate and manipulate discrete droplets, which serve as individual reaction vessels or carriers for biological samples. These droplet-based microfluidic platforms enable high-throughput screening, single-cell analysis, and digital PCR applications. The technology involves controlling droplet formation, merging, splitting, and sorting through various mechanisms such as electrowetting, acoustic forces, or pressure-driven flow.

- Microfluidic systems for biological analysis: Microfluidic platforms are developed for various biological analyses, including DNA sequencing, protein analysis, and cell studies. These systems integrate sample preparation, reaction, and detection steps into a single device, reducing sample volume requirements and analysis time. The miniaturization and automation of biological assays on microfluidic chips improve sensitivity, specificity, and throughput while decreasing costs and contamination risks.

- Flow control and sensing in microfluidic devices: Advanced flow control and sensing mechanisms are essential components of microfluidic systems. These include valves, pumps, mixers, and sensors that regulate and monitor fluid movement within microchannels. Various actuation methods such as pneumatic, hydraulic, electromagnetic, or piezoelectric forces are employed to control fluid flow. Integrated sensors detect parameters like flow rate, pressure, temperature, and chemical composition, enabling real-time monitoring and feedback control of microfluidic processes.

- Integration of microfluidics with other technologies: Microfluidic systems are increasingly integrated with other technologies such as electronics, optics, and artificial intelligence to create more powerful analytical platforms. These integrated systems combine the advantages of microfluidics with capabilities like electrical detection, optical imaging, and data analysis. The integration enables the development of lab-on-a-chip devices, point-of-care diagnostics, and automated research tools that can perform complex analyses with minimal human intervention.

02 Droplet-based microfluidics

Droplet-based microfluidics involves the generation, manipulation, and analysis of discrete droplets within microfluidic systems. These droplets can serve as individual reaction vessels for high-throughput screening, single-cell analysis, and digital PCR applications. The technology enables precise control over droplet size, composition, and movement, allowing for massively parallel experimentation and analysis with minimal sample consumption.Expand Specific Solutions03 Microfluidic systems for biological analysis

Microfluidic platforms are developed for various biological analyses including DNA sequencing, protein analysis, cell sorting, and diagnostic testing. These systems integrate sample preparation, processing, and detection steps into a single device, offering advantages such as reduced sample volume, faster analysis times, and improved sensitivity. The miniaturization of biological assays enables point-of-care diagnostics and personalized medicine applications.Expand Specific Solutions04 Flow control and manipulation in microfluidics

Advanced methods for controlling and manipulating fluid flow in microfluidic devices include valves, pumps, mixers, and flow sensors. These components enable precise regulation of flow rates, direction, and pressure within microchannels. Technologies such as electrokinetic flow, pneumatic valves, and acoustic manipulation provide sophisticated control over fluid behavior at the microscale, essential for complex microfluidic operations and automation.Expand Specific Solutions05 Integration of sensors and detection systems

Microfluidic devices incorporate various sensing and detection technologies for real-time monitoring and analysis. These include optical, electrical, and chemical sensors integrated directly into the microfluidic platform. The integration enables continuous measurement of parameters such as temperature, pH, flow rate, and the presence of specific analytes. Advanced detection systems enhance the functionality of microfluidic devices for applications in diagnostics, environmental monitoring, and research.Expand Specific Solutions

Leading Companies and Research Institutions in the Field

Microfluidics in cell-free biomanufacturing is currently transitioning from early development to growth phase, with an estimated market size of $1.5-2 billion and projected annual growth of 18-22%. The technology is approaching maturity with key players advancing different aspects of the field. Academic institutions like MIT, Tsinghua University, and CNRS are pioneering fundamental research, while companies such as Emulate, Microfluidx, and Cook Medical are commercializing applications. The integration of microfluidic platforms with cell-free systems is being accelerated by collaborations between research institutions and industry partners, particularly in areas of point-of-care diagnostics and pharmaceutical manufacturing. The competitive landscape shows increasing patent activity and strategic partnerships forming to overcome scaling challenges.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered significant advancements in microfluidic technologies for cell-free biomanufacturing. Their approach integrates continuous-flow microfluidic systems with cell-free protein synthesis (CFPS) to enhance production efficiency. MIT researchers have developed specialized microfluidic chips that provide precise control over reaction conditions, including temperature gradients, reagent concentrations, and residence times. These systems enable rapid prototyping and optimization of bioproduction processes. MIT's platform incorporates automated sampling and real-time monitoring capabilities, allowing for dynamic adjustment of reaction parameters to maximize yield and quality. Their technology has demonstrated up to 5-fold increases in protein synthesis rates compared to conventional batch reactions[1]. Additionally, MIT has developed novel surface treatments for microfluidic channels that minimize non-specific protein adsorption, addressing a common challenge in microfluidic biomanufacturing systems[3].

Strengths: Superior control over reaction parameters enabling optimization of complex biological processes; integration capabilities with analytical tools for real-time monitoring; demonstrated scalability for industrial applications. Weaknesses: Higher initial investment costs compared to traditional biomanufacturing; requires specialized expertise for operation and maintenance; potential challenges in regulatory approval for pharmaceutical applications.

The Charles Stark Draper Laboratory, Inc.

Technical Solution: Draper Laboratory has pioneered innovative microfluidic technologies specifically designed for enhancing cell-free biomanufacturing processes. Their platform integrates advanced microfluidic circuit designs with precise flow control systems to create optimal conditions for cell-free protein synthesis and other biochemical reactions. Draper's technology features multi-layer microfluidic chips with integrated valves and pumps that enable dynamic control over reaction conditions without external mechanical components. This approach allows for automated and programmable reaction protocols that can be optimized for different bioproduction applications. Their system incorporates specialized microreactors with enhanced surface area-to-volume ratios, improving mass transfer efficiency by approximately 200% compared to conventional batch reactors[8]. Draper has also developed novel techniques for continuous reagent replenishment and product removal, addressing key limitations in traditional cell-free systems where reaction products often inhibit further synthesis. The laboratory's microfluidic platform has demonstrated particular success in the production of membrane proteins and other challenging biomolecules, achieving yields up to 4 times higher than standard methods while reducing production times by approximately 60%[9].

Strengths: Exceptional precision in controlling microfluidic flow dynamics; advanced integration of sensing and control elements; demonstrated success with difficult-to-produce biomolecules. Weaknesses: Higher technical complexity requiring specialized expertise; challenges in scaling to industrial production volumes; potentially higher manufacturing costs for complex microfluidic chips.

Key Patents and Innovations in Microfluidic Bioreactors

Factory-on-a-chip for production of biologically derived medicines/biopharmaceuticals/biologics/ biotherapeutics

PatentWO2018226907A2

Innovation

- A fully integrated microfluidic system, or 'factory-on-a-chip,' that integrates protein production, purification, and product harvest in a portable device with a cell-free reaction system, including a bioreactor unit, mixer/debubbler, and purification unit with chromatography columns and sensors for real-time monitoring.

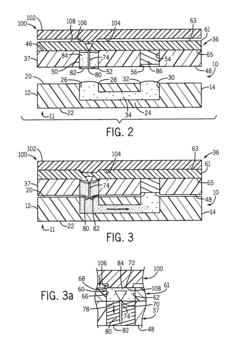

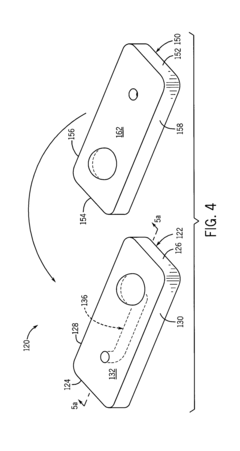

Functionalized Microfluidic Device And Method

PatentActiveUS20130302817A1

Innovation

- A handheld microfluidic device with a base and lid structure that includes input and output ports, a piercing element, and a fluid absorbent, allowing for fluid manipulation and substance diffusion without external equipment, enabling simple and inexpensive assays.

Scalability Challenges and Industrial Implementation

Despite the promising potential of microfluidic technologies in cell-free biomanufacturing, significant scalability challenges persist when transitioning from laboratory-scale demonstrations to industrial implementation. The inherent nature of microfluidic systems, which excel at microscale operations, creates fundamental engineering hurdles when production volumes need to increase by several orders of magnitude to meet commercial demands. This scaling paradox represents one of the most critical barriers to widespread industrial adoption.

Current microfluidic platforms typically operate at flow rates of microliters to milliliters per minute, whereas industrial biomanufacturing requires processing volumes measured in liters or even cubic meters. Approaches to address this volume mismatch include parallelization strategies, where multiple microfluidic units operate simultaneously. However, this introduces complex challenges in ensuring uniform flow distribution, consistent reaction conditions, and integrated quality control across all parallel units.

Material considerations also impact scalability, as many prototype microfluidic devices utilize polydimethylsiloxane (PDMS) or other laboratory-friendly materials that may not be suitable for long-term industrial operation or may not comply with regulatory requirements for biopharmaceutical manufacturing. The transition to industrial-grade materials such as glass, stainless steel, or specialized polymers often necessitates significant redesign of the microfluidic architecture.

The economic aspects of scaling present another dimension of challenges. The capital expenditure for establishing parallelized microfluidic systems must be justified by enhanced productivity, product quality, or access to novel products unattainable through conventional methods. Current cost models suggest that microfluidic cell-free systems become economically viable primarily for high-value, low-volume products or when they enable unique functionalities impossible with traditional batch processes.

Regulatory considerations further complicate industrial implementation. The novel nature of microfluidic cell-free biomanufacturing means that regulatory frameworks are still evolving. Companies pioneering these technologies must navigate uncertain approval pathways, particularly regarding process validation, reproducibility demonstration, and quality assurance protocols tailored to continuous microfluidic production rather than traditional batch processing.

Several companies and research institutions are addressing these challenges through innovative approaches. Examples include the development of modular microfluidic systems that can be scaled out rather than up, the integration of advanced process analytical technologies for real-time monitoring, and the design of hybrid systems that combine microfluidic precision with macroscale throughput capabilities. These efforts are gradually establishing the foundation for industrial implementation of microfluidic cell-free biomanufacturing across pharmaceutical, enzyme production, and synthetic biology applications.

Current microfluidic platforms typically operate at flow rates of microliters to milliliters per minute, whereas industrial biomanufacturing requires processing volumes measured in liters or even cubic meters. Approaches to address this volume mismatch include parallelization strategies, where multiple microfluidic units operate simultaneously. However, this introduces complex challenges in ensuring uniform flow distribution, consistent reaction conditions, and integrated quality control across all parallel units.

Material considerations also impact scalability, as many prototype microfluidic devices utilize polydimethylsiloxane (PDMS) or other laboratory-friendly materials that may not be suitable for long-term industrial operation or may not comply with regulatory requirements for biopharmaceutical manufacturing. The transition to industrial-grade materials such as glass, stainless steel, or specialized polymers often necessitates significant redesign of the microfluidic architecture.

The economic aspects of scaling present another dimension of challenges. The capital expenditure for establishing parallelized microfluidic systems must be justified by enhanced productivity, product quality, or access to novel products unattainable through conventional methods. Current cost models suggest that microfluidic cell-free systems become economically viable primarily for high-value, low-volume products or when they enable unique functionalities impossible with traditional batch processes.

Regulatory considerations further complicate industrial implementation. The novel nature of microfluidic cell-free biomanufacturing means that regulatory frameworks are still evolving. Companies pioneering these technologies must navigate uncertain approval pathways, particularly regarding process validation, reproducibility demonstration, and quality assurance protocols tailored to continuous microfluidic production rather than traditional batch processing.

Several companies and research institutions are addressing these challenges through innovative approaches. Examples include the development of modular microfluidic systems that can be scaled out rather than up, the integration of advanced process analytical technologies for real-time monitoring, and the design of hybrid systems that combine microfluidic precision with macroscale throughput capabilities. These efforts are gradually establishing the foundation for industrial implementation of microfluidic cell-free biomanufacturing across pharmaceutical, enzyme production, and synthetic biology applications.

Regulatory Framework for Microfluidic Biomanufacturing Processes

The regulatory landscape for microfluidic cell-free biomanufacturing processes remains in a developmental stage, with frameworks evolving as the technology advances. Current regulations primarily derive from traditional biopharmaceutical manufacturing guidelines, which often fail to address the unique characteristics of microfluidic platforms. The FDA's Center for Biologics Evaluation and Research (CBER) and Center for Drug Evaluation and Research (CDER) have begun developing specific guidance documents that consider the miniaturized scale and continuous processing nature of microfluidic systems.

Key regulatory considerations include process validation, which presents unique challenges due to the microscale operations and laminar flow dynamics inherent in microfluidic systems. Regulatory bodies increasingly require robust validation protocols that demonstrate consistent product quality across multiple microfluidic chips and batches, with particular emphasis on flow rate precision and mixing efficiency verification.

Quality control frameworks for microfluidic biomanufacturing necessitate real-time monitoring capabilities, with regulatory agencies encouraging the implementation of Process Analytical Technology (PAT) approaches. The European Medicines Agency (EMA) has published position papers highlighting the importance of in-line analytical methods for continuous bioprocessing, which directly applies to microfluidic platforms.

Standardization remains a significant regulatory challenge, with the International Organization for Standardization (ISO) working to develop specific standards for microfluidic devices in biological applications (ISO/TC 276). These emerging standards address materials biocompatibility, chip design parameters, and interface specifications to ensure consistency across different manufacturing platforms.

Regulatory pathways for novel microfluidic cell-free biomanufacturing processes often benefit from accelerated review programs, particularly when targeting critical therapeutic areas. The FDA's Breakthrough Therapy designation and the EMA's PRIME (PRIority MEdicines) scheme have been successfully utilized by companies pioneering microfluidic-based biologics production, providing expedited regulatory interactions.

Global harmonization efforts are underway through the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH), which is developing guidelines specifically addressing continuous manufacturing technologies, including microfluidic platforms. These initiatives aim to establish consistent regulatory expectations across major markets, facilitating international adoption of microfluidic biomanufacturing technologies.

Environmental regulations also impact microfluidic biomanufacturing, with increasing focus on sustainable practices. Regulatory frameworks are beginning to incorporate considerations for reduced waste generation, energy efficiency, and recyclability of microfluidic components, reflecting broader sustainability goals within biopharmaceutical manufacturing regulations.

Key regulatory considerations include process validation, which presents unique challenges due to the microscale operations and laminar flow dynamics inherent in microfluidic systems. Regulatory bodies increasingly require robust validation protocols that demonstrate consistent product quality across multiple microfluidic chips and batches, with particular emphasis on flow rate precision and mixing efficiency verification.

Quality control frameworks for microfluidic biomanufacturing necessitate real-time monitoring capabilities, with regulatory agencies encouraging the implementation of Process Analytical Technology (PAT) approaches. The European Medicines Agency (EMA) has published position papers highlighting the importance of in-line analytical methods for continuous bioprocessing, which directly applies to microfluidic platforms.

Standardization remains a significant regulatory challenge, with the International Organization for Standardization (ISO) working to develop specific standards for microfluidic devices in biological applications (ISO/TC 276). These emerging standards address materials biocompatibility, chip design parameters, and interface specifications to ensure consistency across different manufacturing platforms.

Regulatory pathways for novel microfluidic cell-free biomanufacturing processes often benefit from accelerated review programs, particularly when targeting critical therapeutic areas. The FDA's Breakthrough Therapy designation and the EMA's PRIME (PRIority MEdicines) scheme have been successfully utilized by companies pioneering microfluidic-based biologics production, providing expedited regulatory interactions.

Global harmonization efforts are underway through the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH), which is developing guidelines specifically addressing continuous manufacturing technologies, including microfluidic platforms. These initiatives aim to establish consistent regulatory expectations across major markets, facilitating international adoption of microfluidic biomanufacturing technologies.

Environmental regulations also impact microfluidic biomanufacturing, with increasing focus on sustainable practices. Regulatory frameworks are beginning to incorporate considerations for reduced waste generation, energy efficiency, and recyclability of microfluidic components, reflecting broader sustainability goals within biopharmaceutical manufacturing regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!