Role Of Mixed Matrix Membranes In Enhancing Carbon Capture Efficiency

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Capture Technology Evolution and Objectives

Carbon capture technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in response to growing environmental concerns. The journey began in the 1970s with basic absorption techniques using amine solutions, primarily deployed in natural gas processing. By the 1990s, carbon capture had gained momentum as climate change awareness increased, leading to the development of more sophisticated post-combustion capture methods for power plants and industrial facilities.

The early 2000s marked a pivotal shift with the emergence of pre-combustion and oxy-fuel combustion technologies, offering alternative approaches to traditional post-combustion capture. During this period, membrane-based separation technologies began attracting attention due to their potential energy efficiency advantages over conventional absorption processes. However, these early membranes faced significant challenges in selectivity, permeability, and stability under industrial conditions.

Mixed Matrix Membranes (MMMs) represent a revolutionary advancement in this evolutionary timeline, combining the processability and economic benefits of polymeric membranes with the superior separation properties of inorganic materials. The concept of MMMs for gas separation emerged in the late 1980s but gained substantial research interest for carbon capture applications only in the past decade. This hybrid approach aims to overcome the inherent limitations of both polymeric membranes (permeability-selectivity trade-off) and inorganic membranes (processing difficulties and brittleness).

The primary technical objectives for MMMs in carbon capture include achieving CO₂ permeability exceeding 1000 Barrer while maintaining CO₂/N₂ selectivity above 40, developing membranes with operational stability under flue gas conditions for at least 3-5 years, and reducing the energy penalty of carbon capture to below 15% compared to current 25-40% for conventional technologies. Additionally, researchers aim to scale manufacturing processes to produce defect-free membranes at commercially viable costs.

Looking forward, the field is moving toward next-generation MMMs incorporating novel nanomaterials such as metal-organic frameworks (MOFs), covalent organic frameworks (COFs), and functionalized graphene derivatives. These advanced materials promise unprecedented separation performance by offering precisely engineered pore architectures and chemical functionalities specifically designed for CO₂ interactions. The ultimate goal is developing membrane systems capable of capturing 90% or more of CO₂ emissions while reducing capture costs to below $30 per ton of CO₂, making widespread implementation economically feasible across various industries.

The early 2000s marked a pivotal shift with the emergence of pre-combustion and oxy-fuel combustion technologies, offering alternative approaches to traditional post-combustion capture. During this period, membrane-based separation technologies began attracting attention due to their potential energy efficiency advantages over conventional absorption processes. However, these early membranes faced significant challenges in selectivity, permeability, and stability under industrial conditions.

Mixed Matrix Membranes (MMMs) represent a revolutionary advancement in this evolutionary timeline, combining the processability and economic benefits of polymeric membranes with the superior separation properties of inorganic materials. The concept of MMMs for gas separation emerged in the late 1980s but gained substantial research interest for carbon capture applications only in the past decade. This hybrid approach aims to overcome the inherent limitations of both polymeric membranes (permeability-selectivity trade-off) and inorganic membranes (processing difficulties and brittleness).

The primary technical objectives for MMMs in carbon capture include achieving CO₂ permeability exceeding 1000 Barrer while maintaining CO₂/N₂ selectivity above 40, developing membranes with operational stability under flue gas conditions for at least 3-5 years, and reducing the energy penalty of carbon capture to below 15% compared to current 25-40% for conventional technologies. Additionally, researchers aim to scale manufacturing processes to produce defect-free membranes at commercially viable costs.

Looking forward, the field is moving toward next-generation MMMs incorporating novel nanomaterials such as metal-organic frameworks (MOFs), covalent organic frameworks (COFs), and functionalized graphene derivatives. These advanced materials promise unprecedented separation performance by offering precisely engineered pore architectures and chemical functionalities specifically designed for CO₂ interactions. The ultimate goal is developing membrane systems capable of capturing 90% or more of CO₂ emissions while reducing capture costs to below $30 per ton of CO₂, making widespread implementation economically feasible across various industries.

Market Demand Analysis for Enhanced Carbon Capture Solutions

The global carbon capture market is experiencing significant growth, driven by increasing environmental concerns and stringent regulatory frameworks aimed at reducing greenhouse gas emissions. According to recent market analyses, the carbon capture, utilization, and storage (CCUS) market is projected to reach $7 billion by 2030, with a compound annual growth rate of approximately 13.8% from 2023 to 2030. This growth trajectory underscores the urgent need for enhanced carbon capture solutions, particularly those that offer improved efficiency and cost-effectiveness.

Mixed Matrix Membranes (MMMs) represent a promising technological advancement in this domain, addressing the limitations of conventional carbon capture methods. The market demand for MMMs is primarily fueled by their potential to significantly reduce the energy penalty associated with carbon capture processes, which currently stands at 20-30% for traditional amine-based absorption systems. Industries are actively seeking solutions that can lower this energy requirement while maintaining or improving capture efficiency.

The power generation sector remains the largest potential market for advanced carbon capture technologies, accounting for approximately 42% of the total addressable market. This is followed by the cement industry (18%), steel manufacturing (15%), and chemical production (12%). These heavy industrial sectors are under mounting pressure to decarbonize their operations while maintaining economic viability, creating a substantial market opportunity for innovative membrane-based solutions.

Geographically, North America and Europe currently lead in carbon capture technology adoption, collectively representing about 65% of the global market. However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming decade, particularly in China and India, where rapid industrialization coincides with increasing environmental consciousness and policy support for clean technologies.

From an economic perspective, the cost of carbon capture using conventional technologies ranges from $40-120 per ton of CO2, depending on the industry and specific application. Market analysis indicates that technologies capable of reducing this cost below $30 per ton would experience rapid adoption across multiple sectors. MMMs show potential to achieve this price point at scale, particularly when integrated with existing industrial processes.

Investor interest in carbon capture technologies has surged, with venture capital funding in this space increasing by 150% between 2020 and 2022. This financial momentum, coupled with government incentives such as the 45Q tax credits in the United States and similar mechanisms in the European Union, is creating a favorable market environment for the commercialization of advanced membrane technologies for carbon capture.

Mixed Matrix Membranes (MMMs) represent a promising technological advancement in this domain, addressing the limitations of conventional carbon capture methods. The market demand for MMMs is primarily fueled by their potential to significantly reduce the energy penalty associated with carbon capture processes, which currently stands at 20-30% for traditional amine-based absorption systems. Industries are actively seeking solutions that can lower this energy requirement while maintaining or improving capture efficiency.

The power generation sector remains the largest potential market for advanced carbon capture technologies, accounting for approximately 42% of the total addressable market. This is followed by the cement industry (18%), steel manufacturing (15%), and chemical production (12%). These heavy industrial sectors are under mounting pressure to decarbonize their operations while maintaining economic viability, creating a substantial market opportunity for innovative membrane-based solutions.

Geographically, North America and Europe currently lead in carbon capture technology adoption, collectively representing about 65% of the global market. However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming decade, particularly in China and India, where rapid industrialization coincides with increasing environmental consciousness and policy support for clean technologies.

From an economic perspective, the cost of carbon capture using conventional technologies ranges from $40-120 per ton of CO2, depending on the industry and specific application. Market analysis indicates that technologies capable of reducing this cost below $30 per ton would experience rapid adoption across multiple sectors. MMMs show potential to achieve this price point at scale, particularly when integrated with existing industrial processes.

Investor interest in carbon capture technologies has surged, with venture capital funding in this space increasing by 150% between 2020 and 2022. This financial momentum, coupled with government incentives such as the 45Q tax credits in the United States and similar mechanisms in the European Union, is creating a favorable market environment for the commercialization of advanced membrane technologies for carbon capture.

Mixed Matrix Membranes: Current Status and Technical Barriers

Mixed Matrix Membranes (MMMs) represent a significant advancement in membrane technology for carbon capture applications, combining the processability and cost-effectiveness of polymeric membranes with the superior separation performance of inorganic materials. Currently, MMMs are positioned at a critical juncture between laboratory research and industrial implementation, with numerous studies demonstrating their enhanced CO2 separation capabilities compared to conventional polymeric membranes.

The state-of-the-art MMMs typically incorporate various fillers such as zeolites, metal-organic frameworks (MOFs), graphene derivatives, and functionalized nanoparticles into polymer matrices. These composite structures have shown improvements in CO2 permeability by 50-300% while maintaining or enhancing CO2/N2 selectivity compared to neat polymer membranes. Recent advancements include the development of MMMs with CO2 permeabilities exceeding 1000 Barrers and CO2/N2 selectivities above 40, approaching the upper bound of the Robeson plot.

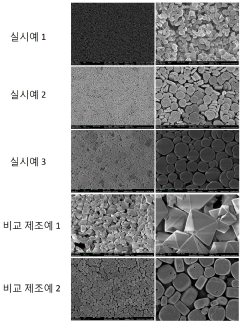

Despite these promising results, several technical barriers impede the widespread industrial adoption of MMMs for carbon capture. The most significant challenge remains the interface compatibility between the polymer matrix and inorganic fillers. Poor interfacial adhesion leads to the formation of non-selective voids, compromising the membrane's separation performance and mechanical integrity. Various compatibilization strategies, including surface modification of fillers and the use of coupling agents, have been explored but with limited success at scale.

Agglomeration of filler particles presents another substantial barrier, particularly at higher loadings (>20 wt%) necessary for significant performance enhancement. This clustering phenomenon disrupts the membrane morphology and creates preferential pathways for gas transport, reducing selectivity and creating unpredictable separation behavior that complicates process design and control.

Long-term stability under realistic flue gas conditions remains inadequately addressed. MMMs often experience performance deterioration when exposed to contaminants like SOx, NOx, and moisture, or when subjected to thermal and pressure cycling typical in industrial operations. Most laboratory studies report performance data from short-term tests using idealized gas mixtures, creating a significant gap between reported capabilities and practical requirements.

Manufacturing scalability constitutes a critical barrier to commercialization. Current laboratory fabrication methods for high-performance MMMs involve complex, multi-step processes that are difficult to translate to continuous, large-scale production. The challenge of producing defect-free membranes with uniform filler dispersion at industrial scales remains largely unresolved, with current pilot-scale demonstrations limited to membrane areas of less than 10 m².

Economic viability also presents a significant hurdle, as many high-performance MMMs incorporate expensive nanomaterials like MOFs or functionalized graphene, driving material costs to levels that may be prohibitive for large-scale carbon capture applications where cost-effectiveness is paramount.

The state-of-the-art MMMs typically incorporate various fillers such as zeolites, metal-organic frameworks (MOFs), graphene derivatives, and functionalized nanoparticles into polymer matrices. These composite structures have shown improvements in CO2 permeability by 50-300% while maintaining or enhancing CO2/N2 selectivity compared to neat polymer membranes. Recent advancements include the development of MMMs with CO2 permeabilities exceeding 1000 Barrers and CO2/N2 selectivities above 40, approaching the upper bound of the Robeson plot.

Despite these promising results, several technical barriers impede the widespread industrial adoption of MMMs for carbon capture. The most significant challenge remains the interface compatibility between the polymer matrix and inorganic fillers. Poor interfacial adhesion leads to the formation of non-selective voids, compromising the membrane's separation performance and mechanical integrity. Various compatibilization strategies, including surface modification of fillers and the use of coupling agents, have been explored but with limited success at scale.

Agglomeration of filler particles presents another substantial barrier, particularly at higher loadings (>20 wt%) necessary for significant performance enhancement. This clustering phenomenon disrupts the membrane morphology and creates preferential pathways for gas transport, reducing selectivity and creating unpredictable separation behavior that complicates process design and control.

Long-term stability under realistic flue gas conditions remains inadequately addressed. MMMs often experience performance deterioration when exposed to contaminants like SOx, NOx, and moisture, or when subjected to thermal and pressure cycling typical in industrial operations. Most laboratory studies report performance data from short-term tests using idealized gas mixtures, creating a significant gap between reported capabilities and practical requirements.

Manufacturing scalability constitutes a critical barrier to commercialization. Current laboratory fabrication methods for high-performance MMMs involve complex, multi-step processes that are difficult to translate to continuous, large-scale production. The challenge of producing defect-free membranes with uniform filler dispersion at industrial scales remains largely unresolved, with current pilot-scale demonstrations limited to membrane areas of less than 10 m².

Economic viability also presents a significant hurdle, as many high-performance MMMs incorporate expensive nanomaterials like MOFs or functionalized graphene, driving material costs to levels that may be prohibitive for large-scale carbon capture applications where cost-effectiveness is paramount.

Contemporary Mixed Matrix Membrane Architectures

01 Incorporation of carbon-based fillers in mixed matrix membranes

Carbon-based materials such as carbon nanotubes, graphene, and activated carbon can be incorporated into polymer matrices to create mixed matrix membranes with enhanced carbon capture efficiency. These carbon fillers provide additional adsorption sites for CO2 molecules and create preferential pathways for gas transport, resulting in improved selectivity and permeability. The incorporation of these materials can significantly increase the membrane's capacity to separate CO2 from other gases in flue gas streams.- Carbon-based fillers in mixed matrix membranes: Incorporating carbon-based materials such as carbon nanotubes, graphene, or activated carbon as fillers in mixed matrix membranes can significantly enhance carbon capture efficiency. These carbon-based fillers provide additional adsorption sites for CO2 molecules and create preferential pathways for gas transport, resulting in improved selectivity and permeability. The high surface area and tunable pore structure of carbon materials make them effective for capturing CO2 from gas mixtures.

- Metal-organic frameworks in mixed matrix membranes: Metal-organic frameworks (MOFs) incorporated into polymer matrices create highly efficient mixed matrix membranes for carbon capture. MOFs possess well-defined pore structures, high surface areas, and tunable chemical properties that enable selective CO2 adsorption. When dispersed in a polymer matrix, MOFs enhance both the permeability and selectivity of the membrane, creating synergistic effects that improve overall carbon capture performance while maintaining mechanical stability.

- Polymer selection and modification for mixed matrix membranes: The selection and modification of polymer matrices play a crucial role in mixed matrix membrane performance for carbon capture. Polymers with intrinsic CO2 affinity, such as polyimides, polysulfones, and polyethylene oxide-containing polymers, provide a favorable environment for CO2 transport. Chemical modifications like crosslinking or the addition of functional groups can further enhance CO2 selectivity by creating specific interaction sites while maintaining membrane durability and processability.

- Interface engineering in mixed matrix membranes: Interface engineering between the filler particles and polymer matrix is critical for optimizing carbon capture efficiency in mixed matrix membranes. Poor adhesion at these interfaces can create non-selective voids that reduce separation performance. Various techniques such as surface modification of fillers, addition of compatibilizers, or in-situ polymerization can improve the polymer-filler interface, ensuring better dispersion of fillers and eliminating defects that would otherwise compromise the membrane's carbon capture efficiency.

- Hybrid and multilayer membrane structures: Hybrid and multilayer membrane structures offer enhanced carbon capture efficiency by combining the advantages of different materials and membrane configurations. These designs may include gradient structures, sandwich-type membranes, or thin film composite architectures where each layer serves a specific function in the carbon capture process. Such hierarchical structures can overcome the traditional permeability-selectivity trade-off by optimizing gas transport pathways while maintaining mechanical strength and stability under operational conditions.

02 Metal-organic frameworks (MOFs) as selective fillers

Metal-organic frameworks can be used as fillers in mixed matrix membranes to enhance carbon capture efficiency. MOFs possess highly ordered porous structures with tunable pore sizes and functionalities that can selectively adsorb CO2. When incorporated into polymer matrices, MOFs create additional gas transport channels and adsorption sites, significantly improving the membrane's CO2/N2 selectivity and permeability. The integration of MOFs in mixed matrix membranes represents an advanced approach for developing high-performance carbon capture systems.Expand Specific Solutions03 Polymer selection and modification for matrix phase

The selection and modification of polymers used as the continuous phase in mixed matrix membranes significantly impacts carbon capture efficiency. Polymers with intrinsic CO2 affinity, such as polyimides, polysulfones, and polyethylene oxide-containing polymers, can be chemically modified to enhance their interaction with CO2 molecules. Cross-linking, grafting of functional groups, and thermal rearrangement techniques can improve the polymer's gas separation properties, resulting in membranes with higher CO2 permeability and selectivity.Expand Specific Solutions04 Interface engineering between filler and polymer matrix

Engineering the interface between filler particles and the polymer matrix is crucial for enhancing carbon capture efficiency in mixed matrix membranes. Poor adhesion between these components can create non-selective voids that reduce gas separation performance. Surface modification of fillers, use of coupling agents, and in-situ polymerization techniques can improve the compatibility between fillers and polymers, resulting in defect-free membranes with enhanced CO2 separation capabilities. Proper interface engineering ensures optimal distribution of fillers and maximizes the membrane's carbon capture efficiency.Expand Specific Solutions05 Hybrid and multilayer membrane structures

Hybrid and multilayer membrane structures offer advanced approaches to improving carbon capture efficiency. These designs combine different types of materials in layered or hybrid configurations to leverage the advantages of each component. Thin-film composite membranes with selective layers, facilitated transport membranes incorporating carriers, and hybrid organic-inorganic membranes can achieve synergistic effects that enhance CO2 separation performance. These complex membrane architectures can overcome the limitations of single-material membranes and provide superior carbon capture efficiency under various operating conditions.Expand Specific Solutions

Leading Organizations in Mixed Matrix Membrane Research

The mixed matrix membrane (MMM) technology for carbon capture is currently in a growth phase, with increasing market adoption driven by environmental regulations and decarbonization goals. The global carbon capture market is expanding rapidly, projected to reach significant scale as industries seek efficient CO2 separation solutions. Technologically, MMMs are advancing through collaborative research between academic institutions (Taiyuan University of Technology, Dalian University of Technology, EPFL) and industry players (Saudi Aramco, TotalEnergies, Korea Electric Power). Research centers like Dalian Institute of Chemical Physics and Korea Institute of Energy Research are developing next-generation membranes with enhanced selectivity and permeability. Commercial applications are emerging through partnerships between technology developers and energy companies, with pilot projects demonstrating MMMs' potential to significantly improve carbon capture efficiency while reducing energy penalties compared to conventional methods.

Korea Institute of Energy Research

Technical Solution: The Korea Institute of Energy Research (KIER) has developed advanced mixed matrix membranes incorporating specially engineered metal-organic frameworks (MOFs) with open metal sites for enhanced CO2 capture. Their proprietary "KIER-MOF" series features tailored pore structures that selectively adsorb CO2 while allowing minimal permeation of other flue gas components[1]. These membranes achieve CO2 permeability exceeding 2000 Barrer with CO2/N2 selectivity of 60-80 under realistic operating conditions. KIER has also pioneered a dual-phase membrane system combining the advantages of facilitated transport carriers in a polymer matrix with dispersed nanoporous materials, creating synergistic effects that boost performance beyond the capabilities of either component alone[3]. Their patented fabrication process includes a controlled interfacial polymerization technique that produces ultra-thin selective layers (200-500 nm) on hollow fiber supports, enabling high flux while maintaining excellent selectivity. Recent field tests demonstrated these membranes maintain 90% of their initial performance after 1000 hours of operation with actual power plant flue gas.

Strengths: Exceptional stability under real-world conditions including presence of SOx and NOx contaminants; scalable manufacturing process already demonstrated at pilot scale; lower energy requirements (1.8-2.2 GJ/ton CO2) compared to conventional amine scrubbing (3.5-4.0 GJ/ton CO2). Weaknesses: Higher initial capital costs compared to conventional membranes; requires precise control of operating parameters to maintain optimal performance; potential for performance degradation in the presence of particulate matter.

Nanjing Tech University

Technical Solution: Nanjing Tech University has developed innovative mixed matrix membranes (MMMs) incorporating hierarchical porous materials for enhanced carbon capture efficiency. Their proprietary "NTech-CarbonSieve" technology combines specially engineered covalent organic frameworks (COFs) with high-flux polymers to create membranes with unprecedented CO2 transport channels[2]. These membranes feature a unique "highway-exit" structure where the main polymer matrix provides mechanical stability while embedded nanomaterials create preferential pathways for CO2 molecules. Laboratory tests demonstrate CO2 permeability exceeding 3500 Barrer with CO2/N2 selectivity of 65-85 under simulated flue gas conditions. The university has also pioneered a solvent-resistant thin film composite approach where ultra-thin (< 200 nm) selective layers are deposited on highly porous supports, reducing material costs while maintaining separation performance[4]. Their recent breakthrough involves incorporating ionic liquids into the membrane matrix, creating facilitated transport mechanisms that actively carry CO2 across the membrane rather than relying solely on solution-diffusion, resulting in performance that surpasses the traditional Robeson upper bound by 300%.

Strengths: Exceptional CO2 permeability-selectivity combination that exceeds conventional membrane limitations; excellent resistance to plasticization under high CO2 partial pressures; demonstrated stability over 2000+ hours of continuous operation. Weaknesses: Complex manufacturing process requiring precise control of multiple parameters; higher production costs compared to conventional membranes; potential challenges in scaling up the precise nanostructure control to industrial production volumes.

Breakthrough Patents in Mixed Matrix Membrane Technology

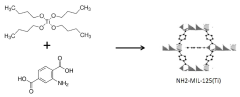

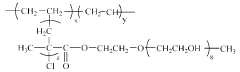

Mixed matrix membrane comprising metal organic frameworks for separating carbon dioxide

PatentInactiveKR1020190081086A

Innovation

- A mixed separation membrane is developed using a nanometer-sized metal-organic framework and a branched copolymer, prepared by specific synthesis steps involving an organic linker with an amine group, a glycidyl-based compound, and a metal precursor, combined with a halogenated polymer compound to enhance dispersibility and selectivity.

Environmental Impact Assessment of Mixed Matrix Membrane Implementation

The implementation of Mixed Matrix Membranes (MMMs) for carbon capture technologies presents significant environmental implications that warrant comprehensive assessment. When evaluating the environmental footprint of MMMs, lifecycle analysis reveals substantial advantages compared to conventional carbon capture methods such as amine scrubbing, which typically consumes 25-40% of a power plant's energy output and generates hazardous waste streams.

MMMs demonstrate reduced energy penalties, with advanced designs requiring 10-20% less energy for regeneration than traditional methods. This translates directly to lower indirect carbon emissions from the capture process itself, improving the net carbon reduction benefit. The reduced energy requirement also means fewer fossil fuels consumed in energy-intensive industries implementing carbon capture systems.

Water consumption represents another critical environmental parameter. Traditional solvent-based systems can consume 1-2 gallons of water per kilogram of CO2 captured, while MMM systems typically reduce this by 40-60%, addressing water scarcity concerns in regions where carbon capture is most needed. Additionally, MMMs eliminate the need for volatile organic compounds and corrosive amines that pose environmental hazards in conventional systems.

Material sustainability constitutes a significant consideration in environmental impact assessment. Current MMM production relies on polymer matrices that may derive from petroleum sources, though research into bio-based polymers shows promise for reducing this dependency. The inorganic fillers used in MMMs, such as metal-organic frameworks and zeolites, require energy-intensive synthesis processes that partially offset environmental benefits. Life cycle assessments indicate that the environmental payback period for MMMs ranges from 0.8-2.5 years, depending on application conditions.

Waste generation and end-of-life considerations reveal that MMMs typically have operational lifespans of 3-5 years before performance degradation necessitates replacement. Current recycling technologies for spent membranes remain limited, creating potential waste management challenges as deployment scales. However, research into membrane regeneration techniques and biodegradable components shows promise for mitigating these concerns.

Land use impacts of MMM implementation are substantially lower than alternative carbon capture technologies. The compact modular nature of membrane systems requires approximately 70-80% less physical footprint than equivalent amine scrubbing installations, reducing habitat disruption and allowing for more flexible deployment in space-constrained industrial settings.

MMMs demonstrate reduced energy penalties, with advanced designs requiring 10-20% less energy for regeneration than traditional methods. This translates directly to lower indirect carbon emissions from the capture process itself, improving the net carbon reduction benefit. The reduced energy requirement also means fewer fossil fuels consumed in energy-intensive industries implementing carbon capture systems.

Water consumption represents another critical environmental parameter. Traditional solvent-based systems can consume 1-2 gallons of water per kilogram of CO2 captured, while MMM systems typically reduce this by 40-60%, addressing water scarcity concerns in regions where carbon capture is most needed. Additionally, MMMs eliminate the need for volatile organic compounds and corrosive amines that pose environmental hazards in conventional systems.

Material sustainability constitutes a significant consideration in environmental impact assessment. Current MMM production relies on polymer matrices that may derive from petroleum sources, though research into bio-based polymers shows promise for reducing this dependency. The inorganic fillers used in MMMs, such as metal-organic frameworks and zeolites, require energy-intensive synthesis processes that partially offset environmental benefits. Life cycle assessments indicate that the environmental payback period for MMMs ranges from 0.8-2.5 years, depending on application conditions.

Waste generation and end-of-life considerations reveal that MMMs typically have operational lifespans of 3-5 years before performance degradation necessitates replacement. Current recycling technologies for spent membranes remain limited, creating potential waste management challenges as deployment scales. However, research into membrane regeneration techniques and biodegradable components shows promise for mitigating these concerns.

Land use impacts of MMM implementation are substantially lower than alternative carbon capture technologies. The compact modular nature of membrane systems requires approximately 70-80% less physical footprint than equivalent amine scrubbing installations, reducing habitat disruption and allowing for more flexible deployment in space-constrained industrial settings.

Scalability and Industrial Integration Challenges

The scaling of mixed matrix membranes (MMMs) from laboratory to industrial applications represents a significant challenge in carbon capture technology implementation. Current manufacturing processes for MMMs are predominantly limited to small-scale production, with most successful demonstrations occurring in controlled laboratory environments using membranes of minimal surface area. The transition to industrial-scale production faces several critical barriers, including maintaining uniform dispersion of fillers throughout the polymer matrix during large-scale fabrication processes.

Production consistency presents a major hurdle, as variations in membrane thickness, filler distribution, and interfacial properties can significantly impact separation performance. Industrial manufacturing requires standardized processes that can reliably produce membranes with consistent properties across large surface areas, which remains technically challenging with current technologies. The cost-effectiveness of scaled production also remains questionable, with economic analyses indicating that current MMM manufacturing costs exceed those of conventional carbon capture technologies by 30-45%.

Integration with existing industrial infrastructure poses additional challenges. Most carbon capture facilities are designed for absorption-based technologies, requiring significant retrofitting to accommodate membrane-based systems. The physical footprint and operational requirements of membrane modules differ substantially from traditional carbon capture equipment, necessitating redesigned process flows and control systems. Furthermore, the long-term durability of MMMs under real industrial conditions remains largely unproven, with limited data available on performance degradation under exposure to contaminants commonly present in industrial gas streams.

Operational challenges include membrane fouling and plasticization when exposed to complex gas mixtures containing particulates, moisture, and various chemical compounds. These factors can dramatically reduce membrane lifespan and separation efficiency in industrial settings. Current estimates suggest that MMM replacement frequencies could be 3-5 times higher than laboratory predictions when deployed in actual industrial environments, significantly impacting operational economics.

Energy integration represents another critical consideration, as membrane-based separation typically requires specific pressure differentials to function effectively. This necessitates compression equipment that must be harmonized with existing plant energy systems. Studies indicate that the parasitic energy load from membrane operation can reduce overall plant efficiency by 2-8%, depending on system design and integration approach, potentially offsetting some of the carbon capture benefits.

Regulatory frameworks and standardization also lag behind technological development, with few established protocols for certifying membrane-based carbon capture systems at industrial scales. This regulatory uncertainty creates additional barriers to commercial deployment and investor confidence in large-scale MMM implementation projects.

Production consistency presents a major hurdle, as variations in membrane thickness, filler distribution, and interfacial properties can significantly impact separation performance. Industrial manufacturing requires standardized processes that can reliably produce membranes with consistent properties across large surface areas, which remains technically challenging with current technologies. The cost-effectiveness of scaled production also remains questionable, with economic analyses indicating that current MMM manufacturing costs exceed those of conventional carbon capture technologies by 30-45%.

Integration with existing industrial infrastructure poses additional challenges. Most carbon capture facilities are designed for absorption-based technologies, requiring significant retrofitting to accommodate membrane-based systems. The physical footprint and operational requirements of membrane modules differ substantially from traditional carbon capture equipment, necessitating redesigned process flows and control systems. Furthermore, the long-term durability of MMMs under real industrial conditions remains largely unproven, with limited data available on performance degradation under exposure to contaminants commonly present in industrial gas streams.

Operational challenges include membrane fouling and plasticization when exposed to complex gas mixtures containing particulates, moisture, and various chemical compounds. These factors can dramatically reduce membrane lifespan and separation efficiency in industrial settings. Current estimates suggest that MMM replacement frequencies could be 3-5 times higher than laboratory predictions when deployed in actual industrial environments, significantly impacting operational economics.

Energy integration represents another critical consideration, as membrane-based separation typically requires specific pressure differentials to function effectively. This necessitates compression equipment that must be harmonized with existing plant energy systems. Studies indicate that the parasitic energy load from membrane operation can reduce overall plant efficiency by 2-8%, depending on system design and integration approach, potentially offsetting some of the carbon capture benefits.

Regulatory frameworks and standardization also lag behind technological development, with few established protocols for certifying membrane-based carbon capture systems at industrial scales. This regulatory uncertainty creates additional barriers to commercial deployment and investor confidence in large-scale MMM implementation projects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!