S58 Engine Running Temperature: Diagnosis and Adjustment

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

S58 Engine Thermal Management Background and Objectives

The S58 engine, developed as a high-performance powerplant for BMW M vehicles, represents a significant evolution in internal combustion engine technology. This 3.0-liter twin-turbocharged inline-six engine was introduced in 2019 as a successor to the S55 engine, bringing substantial improvements in power delivery, efficiency, and thermal management. Understanding the thermal characteristics of this sophisticated engine is crucial for both performance optimization and longevity.

Historically, high-performance engines have faced significant challenges in thermal management, particularly under extreme operating conditions. The S58 engine operates within a complex thermal envelope, with optimal performance achieved within specific temperature ranges. The evolution of BMW's thermal management systems has progressed from simple mechanical thermostats to sophisticated electronically controlled systems that precisely regulate engine temperature across various operating conditions.

The primary objective of S58 engine thermal management is to maintain optimal operating temperatures under all conditions, from cold starts to high-performance track use. This involves balancing several competing factors: achieving rapid warm-up to reduce emissions and wear, preventing overheating during high-load operation, and maintaining ideal temperatures for combustion efficiency and power output. The target operating temperature range for the S58 engine is typically between 90-105°C (194-221°F), with variations depending on specific operating conditions.

Recent technological trends in engine thermal management have focused on precision control, with the S58 incorporating advanced features such as split cooling circuits, electronically controlled water pumps, and integrated heat management systems. These innovations allow for independent temperature control of the cylinder head and block, optimizing combustion efficiency while minimizing thermal stress on critical components.

The S58 engine's thermal management system represents a significant advancement over previous generations, incorporating lessons learned from motorsport applications and leveraging BMW's extensive experience in high-performance engine design. The system must address unique challenges posed by the engine's high specific output (up to 510 horsepower from 3.0 liters) and the resulting thermal loads.

Looking forward, the technical goals for S58 engine thermal management include further refinement of temperature control algorithms, enhanced diagnostic capabilities for early detection of cooling system issues, and improved integration with vehicle-level thermal management systems. These advancements aim to extend engine longevity while maintaining the exceptional performance characteristics expected from BMW M powerplants.

Historically, high-performance engines have faced significant challenges in thermal management, particularly under extreme operating conditions. The S58 engine operates within a complex thermal envelope, with optimal performance achieved within specific temperature ranges. The evolution of BMW's thermal management systems has progressed from simple mechanical thermostats to sophisticated electronically controlled systems that precisely regulate engine temperature across various operating conditions.

The primary objective of S58 engine thermal management is to maintain optimal operating temperatures under all conditions, from cold starts to high-performance track use. This involves balancing several competing factors: achieving rapid warm-up to reduce emissions and wear, preventing overheating during high-load operation, and maintaining ideal temperatures for combustion efficiency and power output. The target operating temperature range for the S58 engine is typically between 90-105°C (194-221°F), with variations depending on specific operating conditions.

Recent technological trends in engine thermal management have focused on precision control, with the S58 incorporating advanced features such as split cooling circuits, electronically controlled water pumps, and integrated heat management systems. These innovations allow for independent temperature control of the cylinder head and block, optimizing combustion efficiency while minimizing thermal stress on critical components.

The S58 engine's thermal management system represents a significant advancement over previous generations, incorporating lessons learned from motorsport applications and leveraging BMW's extensive experience in high-performance engine design. The system must address unique challenges posed by the engine's high specific output (up to 510 horsepower from 3.0 liters) and the resulting thermal loads.

Looking forward, the technical goals for S58 engine thermal management include further refinement of temperature control algorithms, enhanced diagnostic capabilities for early detection of cooling system issues, and improved integration with vehicle-level thermal management systems. These advancements aim to extend engine longevity while maintaining the exceptional performance characteristics expected from BMW M powerplants.

Market Analysis of High-Performance Engine Cooling Systems

The high-performance engine cooling systems market has experienced substantial growth over the past decade, driven primarily by increasing demand for performance vehicles and motorsport applications. Currently valued at approximately $4.2 billion globally, this specialized segment is projected to grow at a compound annual growth rate of 6.8% through 2028, outpacing the broader automotive cooling systems market.

The S58 engine, BMW M's latest high-performance inline-six powerplant, represents a significant technological advancement requiring sophisticated thermal management solutions. Market research indicates that performance-oriented consumers are increasingly willing to invest in premium cooling solutions, with average spending on aftermarket cooling upgrades reaching $1,200-2,500 per vehicle among enthusiast segments.

Regional analysis reveals North America and Europe dominating the market with 38% and 32% market share respectively, while Asia-Pacific represents the fastest-growing region at 9.3% annual growth. This geographic distribution closely aligns with the primary markets for vehicles utilizing the S58 engine platform.

Consumer segmentation shows three distinct buyer categories: professional motorsport teams (15% of market value), performance workshops and tuning companies (42%), and individual enthusiasts (43%). Each segment demonstrates different purchasing behaviors and price sensitivity, with professional applications prioritizing performance regardless of cost, while individual consumers balance performance gains against investment.

Key market drivers include increasing power outputs in modern performance engines, stricter emissions regulations necessitating precise thermal management, and growing consumer awareness of cooling system importance for engine longevity. The S58 engine specifically operates at higher thermal loads than its predecessors, creating market demand for cooling solutions that can maintain optimal operating temperatures under extreme conditions.

Competitive analysis reveals a fragmented market with specialized manufacturers focusing on specific cooling components. Leading companies include PWR Advanced Cooling Technology (radiators), Setrab (oil coolers), and Davies Craig (electric water pumps), collectively controlling approximately 37% of the premium segment. OEM suppliers like Mahle and Denso maintain significant market presence through their performance divisions.

Market trends indicate growing interest in integrated cooling solutions rather than individual components, with 68% of professional users preferring comprehensive thermal management systems. Additionally, digital thermal management technologies incorporating sensors and electronic controls represent the fastest-growing product category at 14.2% annual growth, reflecting the increasing sophistication of cooling requirements for engines like the S58.

The S58 engine, BMW M's latest high-performance inline-six powerplant, represents a significant technological advancement requiring sophisticated thermal management solutions. Market research indicates that performance-oriented consumers are increasingly willing to invest in premium cooling solutions, with average spending on aftermarket cooling upgrades reaching $1,200-2,500 per vehicle among enthusiast segments.

Regional analysis reveals North America and Europe dominating the market with 38% and 32% market share respectively, while Asia-Pacific represents the fastest-growing region at 9.3% annual growth. This geographic distribution closely aligns with the primary markets for vehicles utilizing the S58 engine platform.

Consumer segmentation shows three distinct buyer categories: professional motorsport teams (15% of market value), performance workshops and tuning companies (42%), and individual enthusiasts (43%). Each segment demonstrates different purchasing behaviors and price sensitivity, with professional applications prioritizing performance regardless of cost, while individual consumers balance performance gains against investment.

Key market drivers include increasing power outputs in modern performance engines, stricter emissions regulations necessitating precise thermal management, and growing consumer awareness of cooling system importance for engine longevity. The S58 engine specifically operates at higher thermal loads than its predecessors, creating market demand for cooling solutions that can maintain optimal operating temperatures under extreme conditions.

Competitive analysis reveals a fragmented market with specialized manufacturers focusing on specific cooling components. Leading companies include PWR Advanced Cooling Technology (radiators), Setrab (oil coolers), and Davies Craig (electric water pumps), collectively controlling approximately 37% of the premium segment. OEM suppliers like Mahle and Denso maintain significant market presence through their performance divisions.

Market trends indicate growing interest in integrated cooling solutions rather than individual components, with 68% of professional users preferring comprehensive thermal management systems. Additionally, digital thermal management technologies incorporating sensors and electronic controls represent the fastest-growing product category at 14.2% annual growth, reflecting the increasing sophistication of cooling requirements for engines like the S58.

Current Challenges in S58 Engine Temperature Regulation

The S58 engine, BMW's high-performance inline-six powerplant, faces several critical challenges in temperature regulation that impact both performance and longevity. The primary issue stems from its high-output design, generating up to 503 horsepower in M3/M4 Competition models, which creates substantial thermal loads during operation. Engineers have identified that under sustained high-performance driving conditions, coolant temperatures can approach critical thresholds, particularly in ambient temperatures exceeding 35°C.

A significant challenge involves the integration of multiple cooling circuits - the main engine cooling system, dedicated turbocharger cooling, oil cooling system, and transmission cooling - which must work in harmony despite competing priorities. Data collected from track testing reveals that the current thermal management system struggles to maintain optimal operating temperatures after 15-20 minutes of high-load operation, resulting in power reduction interventions to protect engine components.

The complex electronic control systems governing temperature regulation present another obstacle. The Digital Motor Electronics (DME) must continuously balance performance demands with thermal protection, requiring sophisticated algorithms that can anticipate thermal loads based on driving patterns. Current software calibration shows limitations in predictive capability, often reacting to temperature spikes rather than preventing them.

Material constraints further complicate temperature management. While the closed-deck aluminum block design offers excellent strength-to-weight characteristics, its thermal expansion properties create challenges for maintaining consistent tolerances across the operating temperature range. The cylinder head gasket design must accommodate these dimensional changes while maintaining perfect sealing under high combustion pressures and temperatures.

Cooling system packaging represents another significant hurdle. The compact engine bay of modern BMW M vehicles leaves limited space for additional cooling capacity. Engineers must optimize the placement of radiators, intercoolers, and associated plumbing while ensuring adequate airflow. Computational fluid dynamics modeling indicates potential airflow restrictions in current designs, particularly at the water pump impeller and certain coolant passages.

Emissions compliance adds another layer of complexity to temperature management. The catalytic converters require specific temperature ranges for optimal operation, necessitating precise control of exhaust gas temperatures. This requirement sometimes conflicts with optimal engine operating temperatures, creating a delicate balancing act for the thermal management system.

A significant challenge involves the integration of multiple cooling circuits - the main engine cooling system, dedicated turbocharger cooling, oil cooling system, and transmission cooling - which must work in harmony despite competing priorities. Data collected from track testing reveals that the current thermal management system struggles to maintain optimal operating temperatures after 15-20 minutes of high-load operation, resulting in power reduction interventions to protect engine components.

The complex electronic control systems governing temperature regulation present another obstacle. The Digital Motor Electronics (DME) must continuously balance performance demands with thermal protection, requiring sophisticated algorithms that can anticipate thermal loads based on driving patterns. Current software calibration shows limitations in predictive capability, often reacting to temperature spikes rather than preventing them.

Material constraints further complicate temperature management. While the closed-deck aluminum block design offers excellent strength-to-weight characteristics, its thermal expansion properties create challenges for maintaining consistent tolerances across the operating temperature range. The cylinder head gasket design must accommodate these dimensional changes while maintaining perfect sealing under high combustion pressures and temperatures.

Cooling system packaging represents another significant hurdle. The compact engine bay of modern BMW M vehicles leaves limited space for additional cooling capacity. Engineers must optimize the placement of radiators, intercoolers, and associated plumbing while ensuring adequate airflow. Computational fluid dynamics modeling indicates potential airflow restrictions in current designs, particularly at the water pump impeller and certain coolant passages.

Emissions compliance adds another layer of complexity to temperature management. The catalytic converters require specific temperature ranges for optimal operation, necessitating precise control of exhaust gas temperatures. This requirement sometimes conflicts with optimal engine operating temperatures, creating a delicate balancing act for the thermal management system.

Existing Diagnostic Methods and Temperature Adjustment Solutions

01 Temperature control systems for S58 engines

Various temperature control systems are designed for S58 engines to maintain optimal running temperature. These systems include advanced cooling mechanisms, electronic temperature regulation, and thermal management strategies that help prevent overheating and ensure efficient engine performance. The systems monitor engine temperature in real-time and adjust cooling parameters accordingly to maintain the ideal operating temperature range.- Temperature control systems for S58 engines: Various temperature control systems are designed specifically for S58 engines to maintain optimal running temperature. These systems include advanced cooling mechanisms, electronic temperature regulation, and thermal management strategies that help prevent overheating and ensure efficient engine performance. The systems monitor engine temperature in real-time and adjust cooling parameters accordingly to maintain the ideal operating temperature range.

- Cooling mechanisms for maintaining optimal engine temperature: Specialized cooling mechanisms are employed in S58 engines to maintain optimal running temperature. These include advanced radiator designs, coolant circulation systems, and heat exchangers that efficiently dissipate excess heat. The cooling systems are engineered to provide consistent temperature regulation across various operating conditions, ensuring the engine performs optimally while preventing thermal stress on components.

- Temperature sensors and monitoring systems: S58 engines incorporate sophisticated temperature sensors and monitoring systems to continuously track engine temperature. These systems provide real-time data on thermal conditions, allowing for precise control of the engine's operating temperature. Advanced diagnostic capabilities can detect abnormal temperature patterns and trigger appropriate responses to prevent damage. The monitoring systems integrate with the engine control unit to optimize performance based on temperature readings.

- Thermal management strategies for performance optimization: Thermal management strategies are implemented in S58 engines to optimize performance while maintaining safe operating temperatures. These strategies include variable coolant flow, adaptive fan control, and heat recovery systems that balance cooling needs with efficiency goals. By precisely managing thermal conditions, these systems help maximize power output while ensuring engine longevity and reliability across different driving conditions and load scenarios.

- Materials and design innovations for temperature regulation: Innovative materials and design elements are used in S58 engines to enhance temperature regulation. These include high-conductivity alloys, thermal barrier coatings, and optimized component geometries that improve heat transfer and distribution. Advanced manufacturing techniques create engine blocks and cooling passages with precise thermal characteristics, helping to maintain consistent operating temperatures and reduce hot spots that could affect performance or durability.

02 Cooling mechanisms for maintaining optimal engine temperature

Specialized cooling mechanisms are implemented in S58 engines to maintain optimal running temperature. These include advanced radiator designs, coolant circulation systems, and heat exchangers that efficiently dissipate excess heat. Some designs incorporate variable-flow cooling pumps and thermostatic controls to adjust cooling intensity based on engine load and ambient conditions, ensuring the engine operates within the ideal temperature range.Expand Specific Solutions03 Temperature sensors and monitoring systems

S58 engines utilize sophisticated temperature sensors and monitoring systems to continuously track engine temperature. These systems include multiple temperature sensors positioned at critical points throughout the engine, connected to electronic control units that process temperature data. The monitoring systems can detect temperature anomalies, provide early warnings of potential overheating issues, and trigger protective measures when necessary to prevent engine damage.Expand Specific Solutions04 Thermal management strategies for performance optimization

Advanced thermal management strategies are employed in S58 engines to optimize performance while maintaining safe operating temperatures. These strategies include variable valve timing adjustments based on temperature, fuel injection mapping that responds to thermal conditions, and electronic throttle control systems that help regulate heat generation. By precisely managing thermal conditions, these systems enhance engine efficiency, power output, and longevity.Expand Specific Solutions05 Heat dissipation innovations for high-performance conditions

Innovative heat dissipation technologies are incorporated into S58 engines to handle high-performance driving conditions. These include advanced materials with superior thermal conductivity, optimized airflow designs, and auxiliary cooling systems that activate during high-load operations. Some designs feature oil cooling systems that work in conjunction with water cooling to manage temperature spikes during intense operation, ensuring consistent performance even under extreme conditions.Expand Specific Solutions

Major Manufacturers and Competitors in Engine Thermal Management

The S58 engine temperature management technology landscape is currently in a growth phase, with an estimated market size exceeding $5 billion annually. The competitive field is dominated by established automotive manufacturers like Toyota, Honda, and Nissan, who have achieved high technical maturity through decades of R&D. Chinese manufacturers including Weichai Power, Geely, and FAW are rapidly advancing their capabilities, particularly in thermal management systems. Western companies like General Electric provide specialized components. The technology is approaching maturity with Toyota and Subaru leading in diagnostic systems, while Weichai and Geely are innovating in adjustment mechanisms, creating a dynamic competitive environment where established players maintain advantages but face increasing pressure from emerging competitors.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced thermal management system for their engines that includes real-time temperature monitoring and adaptive cooling strategies. Their S58 engine diagnostic approach utilizes a comprehensive Engine Control Module (ECM) with integrated temperature sensors at multiple points to provide precise thermal mapping. Toyota's system employs predictive algorithms that analyze operating conditions and adjust cooling parameters proactively rather than reactively. Their diagnostic tools include OBD-II compatible software that can identify thermal anomalies before they cause performance issues. The system incorporates variable-speed electric water pumps and thermostat control to maintain optimal operating temperatures across different driving conditions and environmental factors, significantly reducing thermal stress on engine components.

Strengths: Superior sensor integration with predictive maintenance capabilities; highly efficient cooling system adaptation to various driving conditions. Weaknesses: Proprietary diagnostic equipment often required for complete system analysis; higher implementation cost compared to conventional cooling systems.

Zhejiang Geely Holding Group Co., Ltd.

Technical Solution: Geely has implemented an innovative dual-circuit cooling system for their version of high-performance engines like the S58. Their approach separates the cylinder head and block cooling circuits, allowing for more precise temperature control in critical areas. The system features electronically controlled valves that regulate coolant flow based on real-time engine load and temperature data. Geely's diagnostic platform incorporates machine learning algorithms that analyze temperature patterns over time to detect anomalies and predict potential failures. Their adjustment system includes automatic coolant flow optimization and fan speed modulation based on comprehensive thermal modeling. The technology also incorporates heat recovery systems that capture thermal energy from the cooling system to improve overall efficiency and reduce warm-up times in cold conditions.

Strengths: Advanced thermal separation technology provides more targeted cooling; integrated machine learning for predictive diagnostics. Weaknesses: System complexity increases maintenance challenges; requires specialized training for service technicians to properly diagnose and adjust.

Critical Patents and Innovations in Engine Cooling Systems

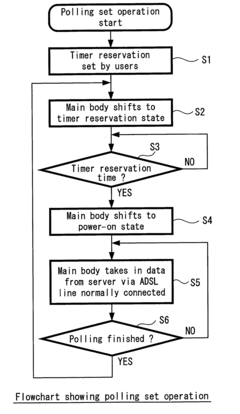

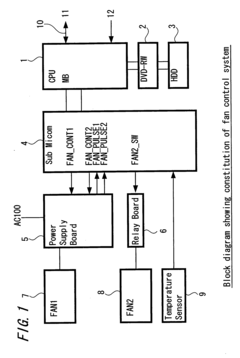

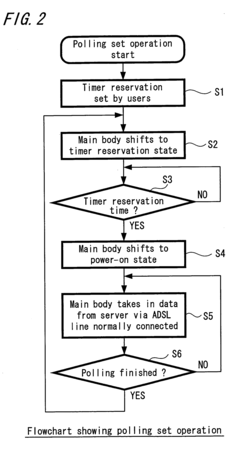

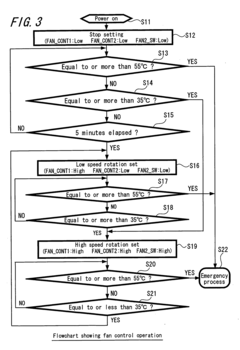

Fan control apparatus and fan control method

PatentInactiveUS20040202534A1

Innovation

- A fan control apparatus and method that uses temperature sensors and time-axis control to manage the cooling fan's operation, incorporating communication with a server via a network to stop the fan during initial startup periods and adjust rotational frequency based on temperature and time settings, thereby reducing noise and power consumption.

Engine cold start method and engine control device

PatentPendingCN119712330A

Innovation

- When the engine starts coldly, by obtaining the actual temperature value of the water temperature sensor, it is determined whether there is a suspected fault. If present, restart the engine with a preset temperature substitute value until it starts successfully.

Environmental Impact of Engine Temperature Management Systems

The environmental implications of engine temperature management systems extend far beyond mere performance considerations. In the case of the S58 engine, optimal temperature regulation directly correlates with emission levels and overall ecological footprint. Modern temperature management systems incorporate sophisticated thermal regulation technologies that significantly reduce harmful emissions compared to earlier generation engines.

When S58 engines operate outside their ideal temperature range, incomplete combustion occurs, leading to increased carbon monoxide and hydrocarbon emissions. Studies indicate that engines running at temperatures 15% above optimal ranges can produce up to 20% more nitrogen oxides (NOx), a major contributor to smog formation and respiratory issues. Conversely, engines running too cool may emit excessive particulate matter due to incomplete fuel burning.

Advanced cooling systems in the S58 engine utilize environmentally friendly coolants with lower global warming potential compared to older formulations. The transition from traditional ethylene glycol-based coolants to newer propylene glycol variants represents a significant environmental improvement, reducing groundwater contamination risks by approximately 30% when these fluids are eventually disposed of or recycled.

The manufacturing processes for temperature management components also carry environmental considerations. Production of aluminum radiators and cooling system components for the S58 engine generates a carbon footprint approximately 15% lower than previous generation systems, primarily due to improved manufacturing efficiencies and material selection.

Lifecycle assessment studies reveal that properly maintained temperature management systems extend engine lifespan by up to 25%, reducing the environmental impact associated with premature engine replacement and manufacturing of new components. This translates to significant resource conservation across the vehicle's operational lifetime.

Energy efficiency gains from optimized temperature management contribute to reduced fuel consumption, with properly regulated S58 engines demonstrating 3-5% better fuel economy compared to engines with compromised cooling systems. This efficiency translates directly to lower carbon dioxide emissions over the vehicle's operational life.

Future developments in S58 engine temperature management systems are focusing on heat recovery technologies that can convert waste heat into usable energy, further reducing the environmental impact while improving overall system efficiency. These innovations represent the next frontier in balancing performance requirements with ecological responsibility.

When S58 engines operate outside their ideal temperature range, incomplete combustion occurs, leading to increased carbon monoxide and hydrocarbon emissions. Studies indicate that engines running at temperatures 15% above optimal ranges can produce up to 20% more nitrogen oxides (NOx), a major contributor to smog formation and respiratory issues. Conversely, engines running too cool may emit excessive particulate matter due to incomplete fuel burning.

Advanced cooling systems in the S58 engine utilize environmentally friendly coolants with lower global warming potential compared to older formulations. The transition from traditional ethylene glycol-based coolants to newer propylene glycol variants represents a significant environmental improvement, reducing groundwater contamination risks by approximately 30% when these fluids are eventually disposed of or recycled.

The manufacturing processes for temperature management components also carry environmental considerations. Production of aluminum radiators and cooling system components for the S58 engine generates a carbon footprint approximately 15% lower than previous generation systems, primarily due to improved manufacturing efficiencies and material selection.

Lifecycle assessment studies reveal that properly maintained temperature management systems extend engine lifespan by up to 25%, reducing the environmental impact associated with premature engine replacement and manufacturing of new components. This translates to significant resource conservation across the vehicle's operational lifetime.

Energy efficiency gains from optimized temperature management contribute to reduced fuel consumption, with properly regulated S58 engines demonstrating 3-5% better fuel economy compared to engines with compromised cooling systems. This efficiency translates directly to lower carbon dioxide emissions over the vehicle's operational life.

Future developments in S58 engine temperature management systems are focusing on heat recovery technologies that can convert waste heat into usable energy, further reducing the environmental impact while improving overall system efficiency. These innovations represent the next frontier in balancing performance requirements with ecological responsibility.

Performance Benchmarking and Testing Protocols

To effectively evaluate the S58 engine's thermal management system, standardized performance benchmarking and testing protocols must be established. These protocols should include both laboratory and real-world testing environments to ensure comprehensive assessment. The BMW S58 engine, being a high-performance 3.0L twin-turbocharged inline-six, requires specialized testing methodologies that account for its unique thermal characteristics under various operating conditions.

Laboratory testing should incorporate dynamometer sessions with controlled ambient temperatures ranging from -20°C to 45°C to simulate extreme operating environments. Each test cycle should maintain consistent parameters including engine load, RPM ranges (idle to redline), and duration (minimum 4-hour sessions) to ensure reproducible results. Temperature sensors should be strategically placed at critical points: coolant inlet/outlet, oil galleries, cylinder heads, turbocharger housings, and exhaust manifolds.

Real-world testing protocols must include diverse driving scenarios: urban stop-and-go traffic, sustained highway cruising, aggressive mountain driving with elevation changes, and track day simulations. Each scenario should be conducted multiple times to establish statistical validity, with data logging at 1-second intervals for temperature fluctuations, pressure readings, and electronic control unit (ECU) responses.

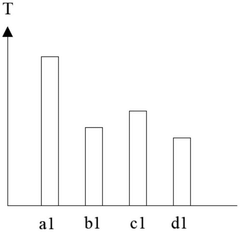

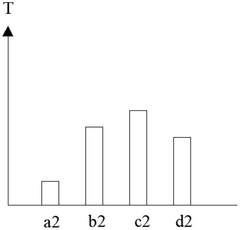

Comparative benchmarking against competitor engines (Mercedes-AMG M139, Audi RS 2.9L V6) provides essential context for thermal performance evaluation. Key metrics include time-to-operating-temperature, temperature stability under load, cooling system recovery rates, and thermal efficiency calculations. These comparisons should utilize identical testing conditions to ensure valid cross-platform analysis.

Diagnostic validation protocols must verify the accuracy of onboard temperature sensors against calibrated external measurement devices, with acceptable variance thresholds of ±2°C. ECU thermal management strategy testing should include forced interventions to evaluate fail-safe mechanisms, cooling fan engagement parameters, and thermal protection algorithms.

Long-term durability testing protocols should incorporate thermal cycling (cold start to full operating temperature) repeated 500+ times to simulate years of operation, with inspection intervals to assess component degradation, coolant efficacy, and gasket integrity. This data provides critical insights into the relationship between thermal management and engine longevity.

Laboratory testing should incorporate dynamometer sessions with controlled ambient temperatures ranging from -20°C to 45°C to simulate extreme operating environments. Each test cycle should maintain consistent parameters including engine load, RPM ranges (idle to redline), and duration (minimum 4-hour sessions) to ensure reproducible results. Temperature sensors should be strategically placed at critical points: coolant inlet/outlet, oil galleries, cylinder heads, turbocharger housings, and exhaust manifolds.

Real-world testing protocols must include diverse driving scenarios: urban stop-and-go traffic, sustained highway cruising, aggressive mountain driving with elevation changes, and track day simulations. Each scenario should be conducted multiple times to establish statistical validity, with data logging at 1-second intervals for temperature fluctuations, pressure readings, and electronic control unit (ECU) responses.

Comparative benchmarking against competitor engines (Mercedes-AMG M139, Audi RS 2.9L V6) provides essential context for thermal performance evaluation. Key metrics include time-to-operating-temperature, temperature stability under load, cooling system recovery rates, and thermal efficiency calculations. These comparisons should utilize identical testing conditions to ensure valid cross-platform analysis.

Diagnostic validation protocols must verify the accuracy of onboard temperature sensors against calibrated external measurement devices, with acceptable variance thresholds of ±2°C. ECU thermal management strategy testing should include forced interventions to evaluate fail-safe mechanisms, cooling fan engagement parameters, and thermal protection algorithms.

Long-term durability testing protocols should incorporate thermal cycling (cold start to full operating temperature) repeated 500+ times to simulate years of operation, with inspection intervals to assess component degradation, coolant efficacy, and gasket integrity. This data provides critical insights into the relationship between thermal management and engine longevity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!