Safety and Deactivation Mechanisms for Blade Battery Leakage

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Blade Battery Safety Background and Objectives

Blade batteries have emerged as a promising technology in the electric vehicle (EV) industry, offering advantages in energy density, safety, and cost-effectiveness. However, as with any energy storage system, safety concerns remain paramount. The background of blade battery safety is rooted in the broader context of lithium-ion battery development and the ongoing quest for safer, more efficient energy storage solutions for EVs.

The evolution of blade batteries can be traced back to the early 2020s when BYD, a leading Chinese automotive manufacturer, introduced this innovative cell-to-pack (CTP) technology. The primary objective behind the development of blade batteries was to address the safety issues associated with traditional lithium-ion batteries, particularly the risk of thermal runaway and fire incidents that had plagued the EV industry.

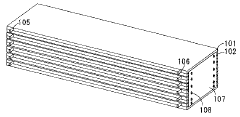

Blade batteries are designed with a unique form factor, resembling long, thin blades that can be arranged in a compact, space-efficient manner within the battery pack. This design not only improves energy density but also enhances structural integrity and heat dissipation capabilities. The core technology utilizes lithium iron phosphate (LFP) chemistry, known for its inherent stability and safety advantages over other lithium-ion chemistries.

The primary safety objectives for blade batteries include preventing thermal runaway, minimizing the risk of fire or explosion, and containing any potential leakage of electrolytes or harmful substances. These objectives are crucial not only for protecting vehicle occupants but also for ensuring public safety and building consumer confidence in EV technology.

To achieve these safety goals, researchers and engineers have focused on developing advanced battery management systems, implementing robust thermal management strategies, and designing fail-safe mechanisms to isolate and deactivate faulty cells. Additionally, efforts have been directed towards improving the structural integrity of the battery pack to withstand severe impacts and prevent punctures that could lead to leakage or short circuits.

The development of safety and deactivation mechanisms for blade battery leakage is a critical aspect of this ongoing research. These mechanisms aim to detect potential leaks at an early stage, prevent the spread of electrolytes or gases, and safely shut down affected cells or modules to maintain overall system integrity. This focus on leak prevention and mitigation is essential, as even small leaks can potentially escalate into more severe safety incidents if left unchecked.

As the EV market continues to grow and blade battery technology gains wider adoption, the importance of robust safety measures becomes increasingly apparent. The industry's objectives extend beyond mere compliance with safety standards to proactively addressing potential risks and enhancing overall battery performance and longevity. This holistic approach to blade battery safety sets the stage for continued innovation and improvement in EV energy storage systems.

The evolution of blade batteries can be traced back to the early 2020s when BYD, a leading Chinese automotive manufacturer, introduced this innovative cell-to-pack (CTP) technology. The primary objective behind the development of blade batteries was to address the safety issues associated with traditional lithium-ion batteries, particularly the risk of thermal runaway and fire incidents that had plagued the EV industry.

Blade batteries are designed with a unique form factor, resembling long, thin blades that can be arranged in a compact, space-efficient manner within the battery pack. This design not only improves energy density but also enhances structural integrity and heat dissipation capabilities. The core technology utilizes lithium iron phosphate (LFP) chemistry, known for its inherent stability and safety advantages over other lithium-ion chemistries.

The primary safety objectives for blade batteries include preventing thermal runaway, minimizing the risk of fire or explosion, and containing any potential leakage of electrolytes or harmful substances. These objectives are crucial not only for protecting vehicle occupants but also for ensuring public safety and building consumer confidence in EV technology.

To achieve these safety goals, researchers and engineers have focused on developing advanced battery management systems, implementing robust thermal management strategies, and designing fail-safe mechanisms to isolate and deactivate faulty cells. Additionally, efforts have been directed towards improving the structural integrity of the battery pack to withstand severe impacts and prevent punctures that could lead to leakage or short circuits.

The development of safety and deactivation mechanisms for blade battery leakage is a critical aspect of this ongoing research. These mechanisms aim to detect potential leaks at an early stage, prevent the spread of electrolytes or gases, and safely shut down affected cells or modules to maintain overall system integrity. This focus on leak prevention and mitigation is essential, as even small leaks can potentially escalate into more severe safety incidents if left unchecked.

As the EV market continues to grow and blade battery technology gains wider adoption, the importance of robust safety measures becomes increasingly apparent. The industry's objectives extend beyond mere compliance with safety standards to proactively addressing potential risks and enhancing overall battery performance and longevity. This holistic approach to blade battery safety sets the stage for continued innovation and improvement in EV energy storage systems.

Market Analysis for Safer EV Batteries

The electric vehicle (EV) battery market is experiencing rapid growth, driven by increasing demand for safer and more efficient energy storage solutions. As concerns about battery safety continue to rise, particularly regarding the potential risks associated with blade battery leakage, there is a growing market opportunity for advanced safety and deactivation mechanisms.

The global EV battery market is projected to expand significantly in the coming years, with a strong emphasis on safety features. This growth is fueled by stringent government regulations, consumer awareness, and the automotive industry's commitment to enhancing EV safety. Major automotive manufacturers and battery suppliers are investing heavily in research and development to address safety concerns, creating a competitive landscape for innovative solutions.

Consumer demand for safer EV batteries is a key driver in this market. High-profile incidents involving battery fires and leakages have heightened public awareness, leading to increased scrutiny of battery safety features. This has resulted in a shift in consumer preferences towards EVs with advanced safety mechanisms, creating a market pull for technologies that can effectively prevent or mitigate battery leakage risks.

The market for blade batteries, known for their high energy density and improved safety features, is gaining traction. However, the potential for leakage remains a concern, opening up opportunities for specialized safety and deactivation mechanisms. This niche market segment is attracting attention from both established players and startups, fostering innovation in areas such as smart battery management systems, advanced thermal management, and rapid deactivation technologies.

Geographically, the market for safer EV batteries is seeing strong growth in regions with high EV adoption rates, such as China, Europe, and North America. These markets are characterized by supportive government policies, well-developed charging infrastructure, and a strong focus on environmental sustainability. Emerging markets in Asia and South America are also showing increasing interest in safer EV battery technologies, driven by urbanization and growing environmental concerns.

The aftermarket segment for EV battery safety solutions is also expanding, as owners of older EV models seek to upgrade their vehicles with the latest safety features. This creates opportunities for retrofit solutions and aftermarket safety devices designed to enhance the safety of existing battery systems.

In conclusion, the market analysis for safer EV batteries, particularly focusing on safety and deactivation mechanisms for blade battery leakage, reveals a robust and growing demand. This trend is supported by regulatory pressures, consumer expectations, and industry-wide commitments to enhancing EV safety. As the EV market continues to mature, the development and implementation of advanced safety technologies will play a crucial role in shaping consumer confidence and driving wider EV adoption.

The global EV battery market is projected to expand significantly in the coming years, with a strong emphasis on safety features. This growth is fueled by stringent government regulations, consumer awareness, and the automotive industry's commitment to enhancing EV safety. Major automotive manufacturers and battery suppliers are investing heavily in research and development to address safety concerns, creating a competitive landscape for innovative solutions.

Consumer demand for safer EV batteries is a key driver in this market. High-profile incidents involving battery fires and leakages have heightened public awareness, leading to increased scrutiny of battery safety features. This has resulted in a shift in consumer preferences towards EVs with advanced safety mechanisms, creating a market pull for technologies that can effectively prevent or mitigate battery leakage risks.

The market for blade batteries, known for their high energy density and improved safety features, is gaining traction. However, the potential for leakage remains a concern, opening up opportunities for specialized safety and deactivation mechanisms. This niche market segment is attracting attention from both established players and startups, fostering innovation in areas such as smart battery management systems, advanced thermal management, and rapid deactivation technologies.

Geographically, the market for safer EV batteries is seeing strong growth in regions with high EV adoption rates, such as China, Europe, and North America. These markets are characterized by supportive government policies, well-developed charging infrastructure, and a strong focus on environmental sustainability. Emerging markets in Asia and South America are also showing increasing interest in safer EV battery technologies, driven by urbanization and growing environmental concerns.

The aftermarket segment for EV battery safety solutions is also expanding, as owners of older EV models seek to upgrade their vehicles with the latest safety features. This creates opportunities for retrofit solutions and aftermarket safety devices designed to enhance the safety of existing battery systems.

In conclusion, the market analysis for safer EV batteries, particularly focusing on safety and deactivation mechanisms for blade battery leakage, reveals a robust and growing demand. This trend is supported by regulatory pressures, consumer expectations, and industry-wide commitments to enhancing EV safety. As the EV market continues to mature, the development and implementation of advanced safety technologies will play a crucial role in shaping consumer confidence and driving wider EV adoption.

Current Challenges in Blade Battery Leakage Prevention

Despite significant advancements in blade battery technology, several critical challenges persist in preventing and mitigating battery leakage. One of the primary concerns is the structural integrity of the battery casing. The thin, elongated design of blade batteries, while advantageous for energy density and packaging, creates vulnerabilities along the edges and seams. These areas are prone to stress concentrations and potential failure points, especially under extreme conditions or impact scenarios.

Another major challenge lies in the thermal management of blade batteries. The compact design limits heat dissipation capabilities, potentially leading to thermal runaway situations. When internal temperatures rise excessively, it can cause electrolyte decomposition and gas generation, increasing internal pressure and the risk of leakage. Developing effective cooling systems that can operate within the confined spaces of blade batteries remains a significant engineering hurdle.

The electrolyte composition itself presents additional challenges. While efforts have been made to develop more stable and less volatile electrolytes, finding the perfect balance between performance and safety continues to be a complex task. Electrolytes that offer high ionic conductivity often come with increased flammability and reactivity, exacerbating the consequences of potential leakage.

Material degradation over time is another critical issue. The repeated charge-discharge cycles and exposure to various environmental conditions can lead to the gradual breakdown of separator materials and electrode structures. This degradation can create microscopic pathways for electrolyte seepage, which may not be immediately detectable but can escalate into more severe leakage problems over time.

The manufacturing process also poses significant challenges in ensuring consistent quality and preventing defects that could lead to leakage. The precision required in assembling blade batteries, particularly in sealing techniques and electrode alignment, leaves little room for error. Even minor imperfections during production can translate into weak points susceptible to leakage under operational stresses.

Lastly, the development of reliable early detection systems for battery leakage remains an ongoing challenge. Current sensing technologies often struggle to differentiate between normal operational fluctuations and early signs of leakage, particularly in the compact environment of blade batteries. This limitation hampers the implementation of proactive safety measures and timely deactivation mechanisms.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, thermal engineering, manufacturing processes, and sensor technologies. The industry continues to invest heavily in research and development to overcome these hurdles, recognizing that solving these issues is crucial for the widespread adoption and safety of blade battery technology in various applications, particularly in the automotive sector.

Another major challenge lies in the thermal management of blade batteries. The compact design limits heat dissipation capabilities, potentially leading to thermal runaway situations. When internal temperatures rise excessively, it can cause electrolyte decomposition and gas generation, increasing internal pressure and the risk of leakage. Developing effective cooling systems that can operate within the confined spaces of blade batteries remains a significant engineering hurdle.

The electrolyte composition itself presents additional challenges. While efforts have been made to develop more stable and less volatile electrolytes, finding the perfect balance between performance and safety continues to be a complex task. Electrolytes that offer high ionic conductivity often come with increased flammability and reactivity, exacerbating the consequences of potential leakage.

Material degradation over time is another critical issue. The repeated charge-discharge cycles and exposure to various environmental conditions can lead to the gradual breakdown of separator materials and electrode structures. This degradation can create microscopic pathways for electrolyte seepage, which may not be immediately detectable but can escalate into more severe leakage problems over time.

The manufacturing process also poses significant challenges in ensuring consistent quality and preventing defects that could lead to leakage. The precision required in assembling blade batteries, particularly in sealing techniques and electrode alignment, leaves little room for error. Even minor imperfections during production can translate into weak points susceptible to leakage under operational stresses.

Lastly, the development of reliable early detection systems for battery leakage remains an ongoing challenge. Current sensing technologies often struggle to differentiate between normal operational fluctuations and early signs of leakage, particularly in the compact environment of blade batteries. This limitation hampers the implementation of proactive safety measures and timely deactivation mechanisms.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, thermal engineering, manufacturing processes, and sensor technologies. The industry continues to invest heavily in research and development to overcome these hurdles, recognizing that solving these issues is crucial for the widespread adoption and safety of blade battery technology in various applications, particularly in the automotive sector.

Existing Leakage Detection and Deactivation Methods

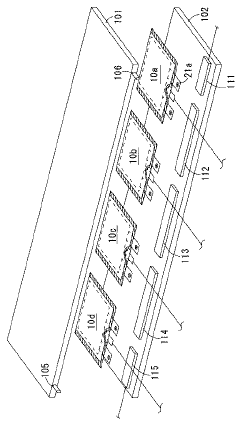

01 Battery cell structure and design

Blade batteries employ a unique structural design to enhance safety. This includes optimized cell arrangement, improved heat dissipation mechanisms, and reinforced casing materials. The design aims to prevent thermal runaway and minimize the risk of fire or explosion in case of damage or malfunction.- Battery cell structure and design: Blade batteries employ a unique structural design to enhance safety. This includes optimized cell arrangement, improved heat dissipation mechanisms, and reinforced casing materials. The design aims to prevent thermal runaway and minimize the risk of fire or explosion in case of damage or malfunction.

- Safety mechanisms and protective features: Various safety mechanisms are incorporated into blade batteries to prevent accidents and ensure user safety. These may include pressure relief valves, temperature sensors, short-circuit protection, and advanced battery management systems that monitor and control the battery's performance and safety parameters.

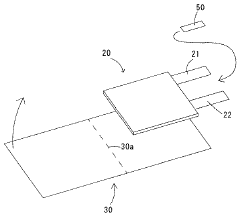

- Manufacturing processes and quality control: Specialized manufacturing processes and stringent quality control measures are implemented to ensure the safety and reliability of blade batteries. This includes advanced electrode coating techniques, precise assembly methods, and comprehensive testing procedures to identify and eliminate potential defects or weaknesses in the battery cells.

- Materials selection and composition: The choice of materials used in blade batteries plays a crucial role in their safety profile. Advanced electrode materials, electrolyte formulations, and separator technologies are employed to enhance stability, reduce the risk of internal short circuits, and improve overall battery performance and safety.

- Safety testing and certification: Rigorous safety testing protocols and certification processes are established for blade batteries to ensure compliance with industry standards and regulations. These tests evaluate the battery's performance under various conditions, including mechanical stress, thermal abuse, and electrical overload, to verify their safety and reliability in real-world applications.

02 Safety monitoring and control systems

Advanced monitoring and control systems are integrated into blade batteries to ensure safety. These systems continuously monitor temperature, voltage, and current, and can quickly detect and respond to abnormal conditions. They may include features such as automatic shut-off mechanisms and intelligent battery management systems.Expand Specific Solutions03 Thermal management techniques

Effective thermal management is crucial for blade battery safety. This involves innovative cooling systems, heat-resistant materials, and thermal insulation techniques. These measures help maintain optimal operating temperatures, prevent overheating, and reduce the risk of thermal runaway incidents.Expand Specific Solutions04 Protective coatings and materials

Blade batteries utilize advanced protective coatings and materials to enhance safety. This includes fire-resistant coatings, impact-resistant casings, and specialized electrolyte formulations. These materials help prevent short circuits, contain potential fires, and improve overall battery durability.Expand Specific Solutions05 Manufacturing and quality control processes

Stringent manufacturing and quality control processes are implemented to ensure blade battery safety. This includes precision assembly techniques, rigorous testing protocols, and advanced inspection methods. These processes aim to minimize defects, ensure consistency, and validate the safety features of each battery produced.Expand Specific Solutions

Key Players in EV Battery Safety Solutions

The safety and deactivation mechanisms for blade battery leakage represent a critical area in the evolving electric vehicle (EV) battery market. This sector is in a growth phase, with the global EV battery market expected to reach $133.46 billion by 2027. The technology is advancing rapidly, with companies like Contemporary Amperex Technology Co., Ltd. (CATL) and LG Energy Solution leading the way in blade battery innovation. These firms, along with others such as Samsung Electronics and SK On, are investing heavily in research and development to enhance safety features and performance. The competitive landscape is intensifying as both established players and new entrants strive to develop more efficient, safer, and cost-effective battery solutions.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL's blade battery technology incorporates advanced safety mechanisms to prevent leakage and thermal runaway. The company utilizes a novel cell-to-pack (CTP) design that eliminates the need for module housings, improving energy density by 50% compared to conventional lithium-ion batteries[1]. The blade-shaped cells are arranged in a array and secured with structural adhesive, creating a more stable and impact-resistant pack. CATL has implemented a multi-layer protection system, including a flame-retardant electrolyte, a thermal propagation prevention interlayer, and an intelligent battery management system (BMS) that continuously monitors cell health and can initiate emergency shutdown procedures if anomalies are detected[2][3].

Strengths: High energy density, improved structural integrity, and advanced safety features. Weaknesses: Potential complexity in manufacturing and higher initial costs compared to traditional battery designs.

LG Chem Ltd.

Technical Solution: LG Chem has developed a comprehensive safety approach for their battery systems, focusing on preventing leakage and thermal runaway. Their solution includes a multi-layered safety system with physical, chemical, and electronic safeguards. The company utilizes a ceramic-coated separator that acts as a thermal fuse, shutting down ion flow if temperatures exceed safe levels[4]. LG Chem has also implemented an advanced cooling system that efficiently dissipates heat, reducing the risk of thermal runaway. Their batteries feature a robust mechanical design with reinforced casings to prevent physical damage and leakage. Additionally, LG Chem's smart BMS employs machine learning algorithms to predict and prevent potential safety issues before they occur[5].

Strengths: Comprehensive multi-layered safety approach and advanced BMS. Weaknesses: Potential for higher manufacturing costs due to complex safety features.

Innovative Approaches to Blade Battery Safety

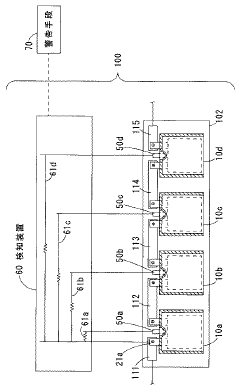

Battery module equipped with liquid leak detection mechanism

PatentInactiveJP2007265760A

Innovation

- A battery module design with a retractable seal portion having a weaker seal strength than others, creating an isolation area where a conductive member detects electrolyte leakage by generating a potential difference, allowing early warning and isolation of the leaking battery.

Battery module

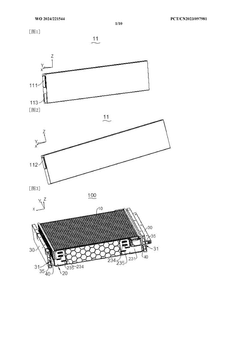

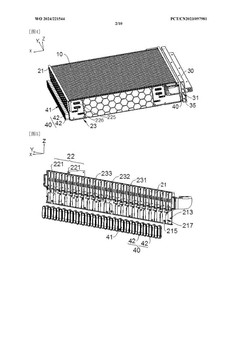

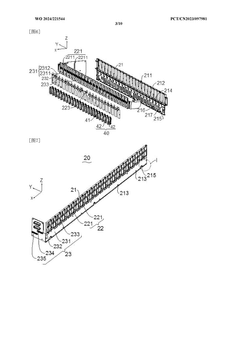

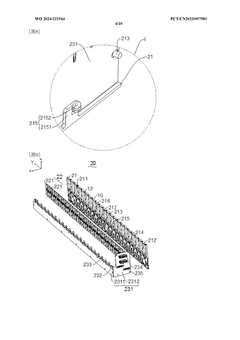

PatentWO2024221544A1

Innovation

- Design the diversion structure, including multiple diversion channels. One diversion channel corresponds to the explosion-proof valve of a battery. The diversion channel is connected with the pressure relief channel. The diversion channel is guided into the beam body to avoid high-temperature gas and liquid splashing.

Regulatory Framework for EV Battery Safety

The regulatory framework for electric vehicle (EV) battery safety is a critical aspect of ensuring the safe deployment and operation of EVs worldwide. As the adoption of EVs continues to grow, governments and regulatory bodies have been developing and refining safety standards and regulations to address the unique challenges posed by high-capacity lithium-ion batteries used in these vehicles.

In the United States, the National Highway Traffic Safety Administration (NHTSA) plays a crucial role in establishing and enforcing safety standards for EVs and their batteries. The Federal Motor Vehicle Safety Standards (FMVSS) include specific requirements for EV battery safety, such as crash protection and thermal management. Additionally, the Society of Automotive Engineers (SAE) has developed standards like J2929, which outlines safety requirements for EV batteries.

The European Union has implemented comprehensive regulations for EV battery safety through the United Nations Economic Commission for Europe (UNECE) Regulation No. 100. This regulation covers various aspects of EV safety, including battery system design, thermal management, and crash protection. The EU has also introduced the General Safety Regulation (GSR), which includes provisions for EV battery safety and fire prevention.

In China, the world's largest EV market, the government has implemented stringent safety standards for EV batteries. The GB/T 31467 standard series covers various aspects of EV battery safety, including performance requirements, testing methods, and safety management. The Chinese authorities have also introduced regulations for battery recycling and disposal to address environmental concerns.

International organizations, such as the International Electrotechnical Commission (IEC), have developed global standards for EV battery safety. The IEC 62660 series provides guidelines for performance and reliability testing of lithium-ion batteries used in EVs. These standards help ensure consistency in safety measures across different regions and manufacturers.

As the technology evolves, regulatory frameworks are continuously updated to address emerging safety concerns. For instance, recent focus has been placed on developing regulations for solid-state batteries, which promise higher energy density and improved safety compared to traditional lithium-ion batteries. Regulatory bodies are also working on standardizing safety protocols for battery swapping stations and fast-charging infrastructure.

The regulatory landscape for EV battery safety is complex and dynamic, requiring ongoing collaboration between governments, industry stakeholders, and research institutions. As new technologies and safety challenges emerge, regulatory frameworks will continue to evolve to ensure the safe and sustainable growth of the EV industry.

In the United States, the National Highway Traffic Safety Administration (NHTSA) plays a crucial role in establishing and enforcing safety standards for EVs and their batteries. The Federal Motor Vehicle Safety Standards (FMVSS) include specific requirements for EV battery safety, such as crash protection and thermal management. Additionally, the Society of Automotive Engineers (SAE) has developed standards like J2929, which outlines safety requirements for EV batteries.

The European Union has implemented comprehensive regulations for EV battery safety through the United Nations Economic Commission for Europe (UNECE) Regulation No. 100. This regulation covers various aspects of EV safety, including battery system design, thermal management, and crash protection. The EU has also introduced the General Safety Regulation (GSR), which includes provisions for EV battery safety and fire prevention.

In China, the world's largest EV market, the government has implemented stringent safety standards for EV batteries. The GB/T 31467 standard series covers various aspects of EV battery safety, including performance requirements, testing methods, and safety management. The Chinese authorities have also introduced regulations for battery recycling and disposal to address environmental concerns.

International organizations, such as the International Electrotechnical Commission (IEC), have developed global standards for EV battery safety. The IEC 62660 series provides guidelines for performance and reliability testing of lithium-ion batteries used in EVs. These standards help ensure consistency in safety measures across different regions and manufacturers.

As the technology evolves, regulatory frameworks are continuously updated to address emerging safety concerns. For instance, recent focus has been placed on developing regulations for solid-state batteries, which promise higher energy density and improved safety compared to traditional lithium-ion batteries. Regulatory bodies are also working on standardizing safety protocols for battery swapping stations and fast-charging infrastructure.

The regulatory landscape for EV battery safety is complex and dynamic, requiring ongoing collaboration between governments, industry stakeholders, and research institutions. As new technologies and safety challenges emerge, regulatory frameworks will continue to evolve to ensure the safe and sustainable growth of the EV industry.

Environmental Impact of Battery Safety Measures

The implementation of safety and deactivation mechanisms for blade battery leakage has significant environmental implications that must be carefully considered. These measures, while crucial for protecting human health and safety, can potentially impact the environment throughout the battery lifecycle.

During the manufacturing process, the production of safety components and materials used in deactivation mechanisms may require additional resources and energy. This could lead to increased carbon emissions and resource depletion if not managed sustainably. However, advancements in eco-friendly manufacturing techniques and materials science are helping to mitigate these impacts.

In the operational phase, the presence of safety mechanisms may slightly increase the overall weight and complexity of battery systems. This could marginally reduce the energy efficiency of electric vehicles, potentially leading to increased energy consumption. Nevertheless, the long-term benefits of enhanced safety often outweigh these minor drawbacks.

End-of-life considerations are particularly important when assessing the environmental impact of battery safety measures. The additional components and materials used in safety systems may complicate the recycling process, potentially reducing the overall recyclability of the battery. However, innovative recycling technologies are being developed to address these challenges and maximize material recovery.

It is worth noting that effective safety measures can indirectly benefit the environment by preventing catastrophic battery failures. Such incidents could result in the release of hazardous materials and chemicals into ecosystems, causing significant environmental damage. By minimizing the risk of leakage and thermal runaway, these safety mechanisms help protect both human health and the environment.

The development of more environmentally friendly safety solutions is an active area of research. Bio-based materials, smart sensors, and self-healing technologies are being explored as potential alternatives to traditional safety components. These innovations aim to enhance battery safety while minimizing environmental impact throughout the product lifecycle.

In conclusion, while the implementation of safety and deactivation mechanisms for blade battery leakage does have some environmental implications, the overall impact is generally positive when considering the potential consequences of battery failures. Continued research and development in this field are essential to further optimize the balance between safety and environmental sustainability in battery technology.

During the manufacturing process, the production of safety components and materials used in deactivation mechanisms may require additional resources and energy. This could lead to increased carbon emissions and resource depletion if not managed sustainably. However, advancements in eco-friendly manufacturing techniques and materials science are helping to mitigate these impacts.

In the operational phase, the presence of safety mechanisms may slightly increase the overall weight and complexity of battery systems. This could marginally reduce the energy efficiency of electric vehicles, potentially leading to increased energy consumption. Nevertheless, the long-term benefits of enhanced safety often outweigh these minor drawbacks.

End-of-life considerations are particularly important when assessing the environmental impact of battery safety measures. The additional components and materials used in safety systems may complicate the recycling process, potentially reducing the overall recyclability of the battery. However, innovative recycling technologies are being developed to address these challenges and maximize material recovery.

It is worth noting that effective safety measures can indirectly benefit the environment by preventing catastrophic battery failures. Such incidents could result in the release of hazardous materials and chemicals into ecosystems, causing significant environmental damage. By minimizing the risk of leakage and thermal runaway, these safety mechanisms help protect both human health and the environment.

The development of more environmentally friendly safety solutions is an active area of research. Bio-based materials, smart sensors, and self-healing technologies are being explored as potential alternatives to traditional safety components. These innovations aim to enhance battery safety while minimizing environmental impact throughout the product lifecycle.

In conclusion, while the implementation of safety and deactivation mechanisms for blade battery leakage does have some environmental implications, the overall impact is generally positive when considering the potential consequences of battery failures. Continued research and development in this field are essential to further optimize the balance between safety and environmental sustainability in battery technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!