Safety and Risk Assessment in Glacial Acetic Acid Production

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glacial Acetic Acid Production Overview and Safety Goals

Glacial acetic acid production is a critical process in the chemical industry, with applications spanning various sectors including pharmaceuticals, textiles, and food processing. This highly corrosive and flammable substance demands rigorous safety measures throughout its production lifecycle. The primary goal of safety in glacial acetic acid production is to protect workers, the environment, and surrounding communities from potential hazards associated with its manufacture, storage, and transportation.

The production of glacial acetic acid typically involves either methanol carbonylation or acetaldehyde oxidation processes. Each method presents unique safety challenges that must be addressed through comprehensive risk assessment and management strategies. The methanol carbonylation process, for instance, operates under high pressure and temperature conditions, necessitating robust equipment design and stringent operational protocols to prevent leaks or equipment failures.

Safety goals in glacial acetic acid production encompass several key areas. Firstly, process safety management aims to identify and mitigate risks associated with the production process itself. This includes implementing inherently safer designs, conducting regular hazard and operability studies (HAZOP), and establishing effective process control systems to maintain optimal operating conditions.

Secondly, containment and handling procedures are crucial to prevent exposure to this highly corrosive substance. This involves the use of appropriate materials for storage tanks, piping, and transfer equipment, as well as the implementation of robust maintenance schedules to ensure the integrity of these systems over time.

Emergency preparedness forms another critical component of safety goals. This includes developing comprehensive emergency response plans, conducting regular drills, and ensuring that all personnel are adequately trained in emergency procedures. Additionally, the installation of safety systems such as fire suppression equipment, gas detection systems, and emergency shutdown mechanisms is essential to minimize the impact of potential incidents.

Environmental protection is also a key safety objective in glacial acetic acid production. This involves implementing effective waste management strategies, monitoring and controlling emissions, and establishing spill prevention and response protocols to safeguard surrounding ecosystems and water resources.

Occupational health and safety measures are paramount, focusing on protecting workers from exposure through the use of personal protective equipment, implementing proper ventilation systems, and establishing strict operational procedures. Regular health monitoring and safety training programs are essential components of this aspect of safety management.

In conclusion, the overarching safety goals in glacial acetic acid production aim to create a comprehensive framework that addresses all potential risks associated with the production process. By integrating process safety, containment strategies, emergency preparedness, environmental protection, and occupational safety measures, manufacturers can strive to achieve a robust safety culture that prioritizes the well-being of workers, the community, and the environment.

The production of glacial acetic acid typically involves either methanol carbonylation or acetaldehyde oxidation processes. Each method presents unique safety challenges that must be addressed through comprehensive risk assessment and management strategies. The methanol carbonylation process, for instance, operates under high pressure and temperature conditions, necessitating robust equipment design and stringent operational protocols to prevent leaks or equipment failures.

Safety goals in glacial acetic acid production encompass several key areas. Firstly, process safety management aims to identify and mitigate risks associated with the production process itself. This includes implementing inherently safer designs, conducting regular hazard and operability studies (HAZOP), and establishing effective process control systems to maintain optimal operating conditions.

Secondly, containment and handling procedures are crucial to prevent exposure to this highly corrosive substance. This involves the use of appropriate materials for storage tanks, piping, and transfer equipment, as well as the implementation of robust maintenance schedules to ensure the integrity of these systems over time.

Emergency preparedness forms another critical component of safety goals. This includes developing comprehensive emergency response plans, conducting regular drills, and ensuring that all personnel are adequately trained in emergency procedures. Additionally, the installation of safety systems such as fire suppression equipment, gas detection systems, and emergency shutdown mechanisms is essential to minimize the impact of potential incidents.

Environmental protection is also a key safety objective in glacial acetic acid production. This involves implementing effective waste management strategies, monitoring and controlling emissions, and establishing spill prevention and response protocols to safeguard surrounding ecosystems and water resources.

Occupational health and safety measures are paramount, focusing on protecting workers from exposure through the use of personal protective equipment, implementing proper ventilation systems, and establishing strict operational procedures. Regular health monitoring and safety training programs are essential components of this aspect of safety management.

In conclusion, the overarching safety goals in glacial acetic acid production aim to create a comprehensive framework that addresses all potential risks associated with the production process. By integrating process safety, containment strategies, emergency preparedness, environmental protection, and occupational safety measures, manufacturers can strive to achieve a robust safety culture that prioritizes the well-being of workers, the community, and the environment.

Market Demand Analysis for Glacial Acetic Acid

The global market for glacial acetic acid has been experiencing steady growth, driven by its versatile applications across various industries. The chemical sector remains the largest consumer, utilizing glacial acetic acid as a key raw material in the production of vinyl acetate monomer (VAM), purified terephthalic acid (PTA), and acetic anhydride. These derivatives find extensive use in manufacturing adhesives, paints, textiles, and plastics.

In recent years, the pharmaceutical industry has emerged as a significant driver of demand for glacial acetic acid. Its use as a solvent and reagent in drug synthesis, as well as its role in producing aspirin and other medications, has contributed to increased consumption. The food industry also continues to be a stable market, with glacial acetic acid being used as a food additive and preservative.

The Asia-Pacific region, particularly China and India, has been the fastest-growing market for glacial acetic acid. Rapid industrialization, expanding manufacturing sectors, and increasing disposable incomes have fueled demand in these countries. North America and Europe maintain steady consumption levels, primarily driven by established chemical and pharmaceutical industries.

Environmental concerns and sustainability initiatives have begun to influence market dynamics. There is a growing interest in bio-based acetic acid production methods, which could potentially reshape the market landscape in the coming years. However, traditional petrochemical-based production still dominates due to cost-effectiveness and established infrastructure.

The COVID-19 pandemic initially disrupted supply chains and temporarily reduced demand in certain sectors. However, the increased focus on hygiene and sanitation has led to a surge in demand for acetic acid-based disinfectants and cleaning products. This unexpected shift has partially offset losses in other application areas.

Looking ahead, the market for glacial acetic acid is expected to continue its growth trajectory. Emerging applications in biodegradable plastics and green solvents present new opportunities for market expansion. Additionally, the ongoing development of more efficient and environmentally friendly production processes is likely to enhance the overall market attractiveness of glacial acetic acid.

As safety and risk assessment in glacial acetic acid production become increasingly important, manufacturers are investing in advanced technologies and processes to ensure worker safety and environmental protection. This focus on safety is expected to drive innovation in production methods and potentially lead to the development of safer alternatives, which could further influence market dynamics in the coming years.

In recent years, the pharmaceutical industry has emerged as a significant driver of demand for glacial acetic acid. Its use as a solvent and reagent in drug synthesis, as well as its role in producing aspirin and other medications, has contributed to increased consumption. The food industry also continues to be a stable market, with glacial acetic acid being used as a food additive and preservative.

The Asia-Pacific region, particularly China and India, has been the fastest-growing market for glacial acetic acid. Rapid industrialization, expanding manufacturing sectors, and increasing disposable incomes have fueled demand in these countries. North America and Europe maintain steady consumption levels, primarily driven by established chemical and pharmaceutical industries.

Environmental concerns and sustainability initiatives have begun to influence market dynamics. There is a growing interest in bio-based acetic acid production methods, which could potentially reshape the market landscape in the coming years. However, traditional petrochemical-based production still dominates due to cost-effectiveness and established infrastructure.

The COVID-19 pandemic initially disrupted supply chains and temporarily reduced demand in certain sectors. However, the increased focus on hygiene and sanitation has led to a surge in demand for acetic acid-based disinfectants and cleaning products. This unexpected shift has partially offset losses in other application areas.

Looking ahead, the market for glacial acetic acid is expected to continue its growth trajectory. Emerging applications in biodegradable plastics and green solvents present new opportunities for market expansion. Additionally, the ongoing development of more efficient and environmentally friendly production processes is likely to enhance the overall market attractiveness of glacial acetic acid.

As safety and risk assessment in glacial acetic acid production become increasingly important, manufacturers are investing in advanced technologies and processes to ensure worker safety and environmental protection. This focus on safety is expected to drive innovation in production methods and potentially lead to the development of safer alternatives, which could further influence market dynamics in the coming years.

Current Safety Challenges in Production Process

The production of glacial acetic acid presents several significant safety challenges that require careful assessment and management. One of the primary concerns is the highly corrosive nature of acetic acid, which can cause severe burns and damage to equipment. This necessitates the use of specialized materials for storage tanks, piping, and handling equipment, as well as rigorous maintenance protocols to prevent leaks and spills.

Another critical safety issue is the flammability of acetic acid vapors. The production process often involves high temperatures, increasing the risk of fire and explosion. This danger is compounded by the fact that acetic acid has a relatively low flash point, making it susceptible to ignition from various sources, including static electricity. Implementing robust fire prevention systems and maintaining proper ventilation are essential to mitigate these risks.

The potential for worker exposure to acetic acid vapors and liquid poses a significant health hazard. Inhalation of vapors can cause respiratory irritation, while skin contact with the liquid can result in severe chemical burns. Ensuring proper personal protective equipment (PPE) and implementing stringent safety protocols for handling and emergency response are crucial to protect workers.

Process safety management is another key challenge in glacial acetic acid production. The complexity of the production process, which often involves multiple stages and high-pressure systems, requires careful monitoring and control. Any deviation from optimal operating conditions can lead to runaway reactions or equipment failure, potentially resulting in catastrophic incidents.

Environmental concerns also play a significant role in the safety challenges of acetic acid production. Accidental releases can have severe impacts on local ecosystems and water sources. Implementing effective containment systems and developing comprehensive spill response plans are essential for environmental protection and regulatory compliance.

The transportation and storage of glacial acetic acid present additional safety challenges. The corrosive nature of the product requires specialized containers and handling procedures. Ensuring proper labeling, packaging, and transportation protocols is critical to prevent accidents during transit and storage.

Addressing these safety challenges requires a multifaceted approach, including engineering controls, administrative measures, and ongoing training programs. Regular risk assessments, safety audits, and continuous improvement initiatives are necessary to identify and mitigate potential hazards in the production process. Additionally, staying abreast of evolving safety standards and best practices in the industry is crucial for maintaining a robust safety culture in glacial acetic acid production facilities.

Another critical safety issue is the flammability of acetic acid vapors. The production process often involves high temperatures, increasing the risk of fire and explosion. This danger is compounded by the fact that acetic acid has a relatively low flash point, making it susceptible to ignition from various sources, including static electricity. Implementing robust fire prevention systems and maintaining proper ventilation are essential to mitigate these risks.

The potential for worker exposure to acetic acid vapors and liquid poses a significant health hazard. Inhalation of vapors can cause respiratory irritation, while skin contact with the liquid can result in severe chemical burns. Ensuring proper personal protective equipment (PPE) and implementing stringent safety protocols for handling and emergency response are crucial to protect workers.

Process safety management is another key challenge in glacial acetic acid production. The complexity of the production process, which often involves multiple stages and high-pressure systems, requires careful monitoring and control. Any deviation from optimal operating conditions can lead to runaway reactions or equipment failure, potentially resulting in catastrophic incidents.

Environmental concerns also play a significant role in the safety challenges of acetic acid production. Accidental releases can have severe impacts on local ecosystems and water sources. Implementing effective containment systems and developing comprehensive spill response plans are essential for environmental protection and regulatory compliance.

The transportation and storage of glacial acetic acid present additional safety challenges. The corrosive nature of the product requires specialized containers and handling procedures. Ensuring proper labeling, packaging, and transportation protocols is critical to prevent accidents during transit and storage.

Addressing these safety challenges requires a multifaceted approach, including engineering controls, administrative measures, and ongoing training programs. Regular risk assessments, safety audits, and continuous improvement initiatives are necessary to identify and mitigate potential hazards in the production process. Additionally, staying abreast of evolving safety standards and best practices in the industry is crucial for maintaining a robust safety culture in glacial acetic acid production facilities.

Existing Risk Assessment Methodologies

01 Safety measures for handling glacial acetic acid

Proper safety measures are crucial when handling glacial acetic acid due to its corrosive nature. This includes using appropriate personal protective equipment (PPE) such as chemical-resistant gloves, safety goggles, and protective clothing. Adequate ventilation in the workspace is essential to prevent the accumulation of vapors. Emergency eyewash stations and safety showers should be readily available in case of accidental exposure.- Safety measures in handling and storage: Proper safety measures are crucial when handling and storing glacial acetic acid. This includes using appropriate personal protective equipment, ensuring adequate ventilation, and implementing spill containment systems. Storage facilities should be designed to prevent leaks and maintain stable temperatures. Regular safety inspections and employee training are essential to minimize risks associated with this corrosive substance.

- Risk assessment and mitigation strategies: Comprehensive risk assessments should be conducted to identify potential hazards associated with glacial acetic acid use. This includes evaluating exposure routes, potential chemical reactions, and environmental impacts. Based on these assessments, mitigation strategies can be developed, such as implementing engineering controls, establishing emergency response procedures, and optimizing process designs to reduce the likelihood of accidents.

- Transportation and packaging safety: Safe transportation and packaging of glacial acetic acid are critical to prevent accidents during transit. This involves using appropriate containers made of compatible materials, proper labeling and documentation, and adhering to transportation regulations. Specialized equipment for loading and unloading, as well as secure fixation methods during transport, should be employed to minimize the risk of spills or leaks.

- Environmental and health impact management: Managing the environmental and health impacts of glacial acetic acid is essential for sustainable use. This includes implementing waste treatment systems, monitoring air and water quality, and establishing protocols for safe disposal. Occupational health monitoring programs should be in place to detect and prevent potential health issues among workers exposed to the substance. Additionally, developing less hazardous alternatives or process modifications can help reduce overall environmental and health risks.

- Emergency response and containment procedures: Effective emergency response and containment procedures are crucial for managing incidents involving glacial acetic acid. This includes developing detailed emergency action plans, installing appropriate fire suppression systems, and providing specialized equipment for spill containment and neutralization. Regular drills and training exercises should be conducted to ensure personnel are prepared to respond quickly and effectively in case of accidents or spills.

02 Storage and transportation precautions

Glacial acetic acid requires specific storage and transportation conditions to minimize risks. It should be stored in tightly sealed containers made of compatible materials, away from heat sources and direct sunlight. During transportation, proper labeling and packaging are essential. Specialized containers with pressure-relief valves may be used to prevent pressure buildup. Segregation from incompatible materials is necessary to avoid potential reactions.Expand Specific Solutions03 Environmental and health risks

Glacial acetic acid poses environmental and health risks if not handled properly. It can cause severe burns to skin and eyes upon contact, and inhalation of vapors can irritate the respiratory system. In case of spills, it can contaminate soil and water sources, potentially harming aquatic life. Proper disposal methods and spill containment procedures are crucial to mitigate these risks.Expand Specific Solutions04 Risk assessment and mitigation strategies

Conducting thorough risk assessments is essential for facilities handling glacial acetic acid. This involves identifying potential hazards, evaluating exposure scenarios, and implementing appropriate control measures. Mitigation strategies may include engineering controls like closed systems and local exhaust ventilation, administrative controls such as standard operating procedures, and emergency response planning.Expand Specific Solutions05 Safe handling in industrial processes

In industrial settings, specific safety measures are required for processes involving glacial acetic acid. This includes using corrosion-resistant equipment, implementing proper transfer and handling procedures, and ensuring adequate process controls. Regular maintenance and inspection of equipment are crucial to prevent leaks or failures. Training programs for personnel on safe handling practices and emergency procedures are essential to minimize risks in industrial applications.Expand Specific Solutions

Key Players in Glacial Acetic Acid Industry

The safety and risk assessment in glacial acetic acid production is a critical concern in the chemical industry, currently in a mature stage with established players. The global market for acetic acid is substantial, valued at over $8 billion, with steady growth projected. Technologically, the process is well-developed, with companies like Celanese, LyondellBasell, and BP Chemicals leading in production capabilities. Emerging players such as Daicel Corp. and Evonik Operations are also making significant contributions, focusing on innovative production methods and safety enhancements. The industry is characterized by ongoing efforts to improve process efficiency and safety protocols, with a growing emphasis on sustainable production techniques and risk mitigation strategies.

Daicel Corp.

Technical Solution: Daicel Corp. has developed an advanced safety management system for glacial acetic acid production, incorporating real-time monitoring and predictive analytics. Their approach includes a multi-layered risk assessment framework that combines process hazard analysis (PHA) with quantitative risk assessment (QRA) techniques[1]. The system utilizes IoT sensors and machine learning algorithms to continuously monitor critical process parameters, such as temperature, pressure, and flow rates, enabling early detection of potential safety issues[3]. Daicel has also implemented a comprehensive emergency response plan, including regular safety drills and training programs for operators, to ensure rapid and effective responses to any incidents[5].

Strengths: Cutting-edge technology integration, proactive risk management, and comprehensive safety culture. Weaknesses: High initial implementation costs and potential over-reliance on automated systems.

Celanese International Corp.

Technical Solution: Celanese has pioneered a holistic approach to safety and risk assessment in glacial acetic acid production, focusing on inherently safer design principles. Their methodology incorporates advanced process simulation tools to identify and mitigate potential hazards at the design stage[2]. The company has developed proprietary catalysts and reactor designs that enhance process stability and reduce the likelihood of runaway reactions[4]. Celanese's risk assessment protocol includes detailed fault tree analysis and event tree analysis, providing a comprehensive understanding of potential failure modes and their consequences[6]. Additionally, they have implemented a state-of-the-art process control system with built-in safety interlocks and redundancies to prevent and contain potential incidents[8].

Strengths: Inherently safer design approach, advanced process control, and comprehensive risk analysis. Weaknesses: Potentially higher production costs due to extensive safety measures and proprietary technology dependence.

Innovative Safety Technologies for Acetic Acid Production

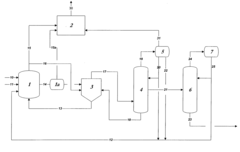

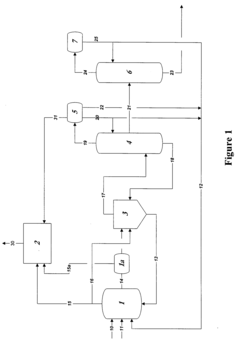

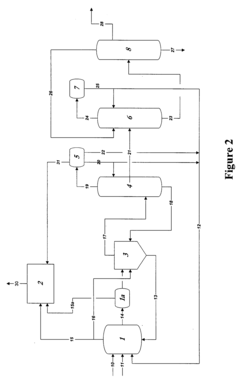

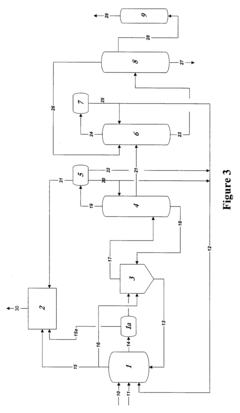

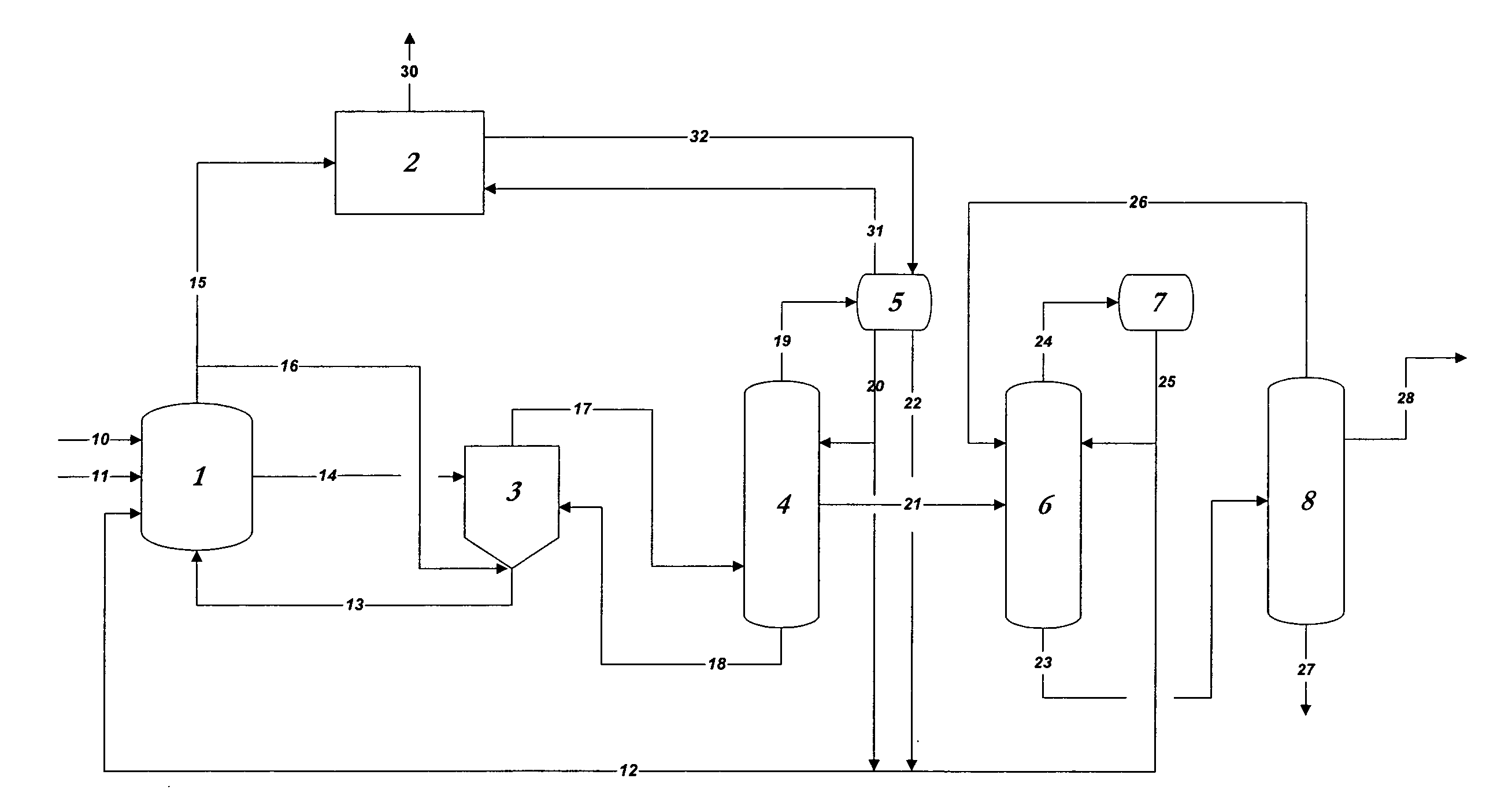

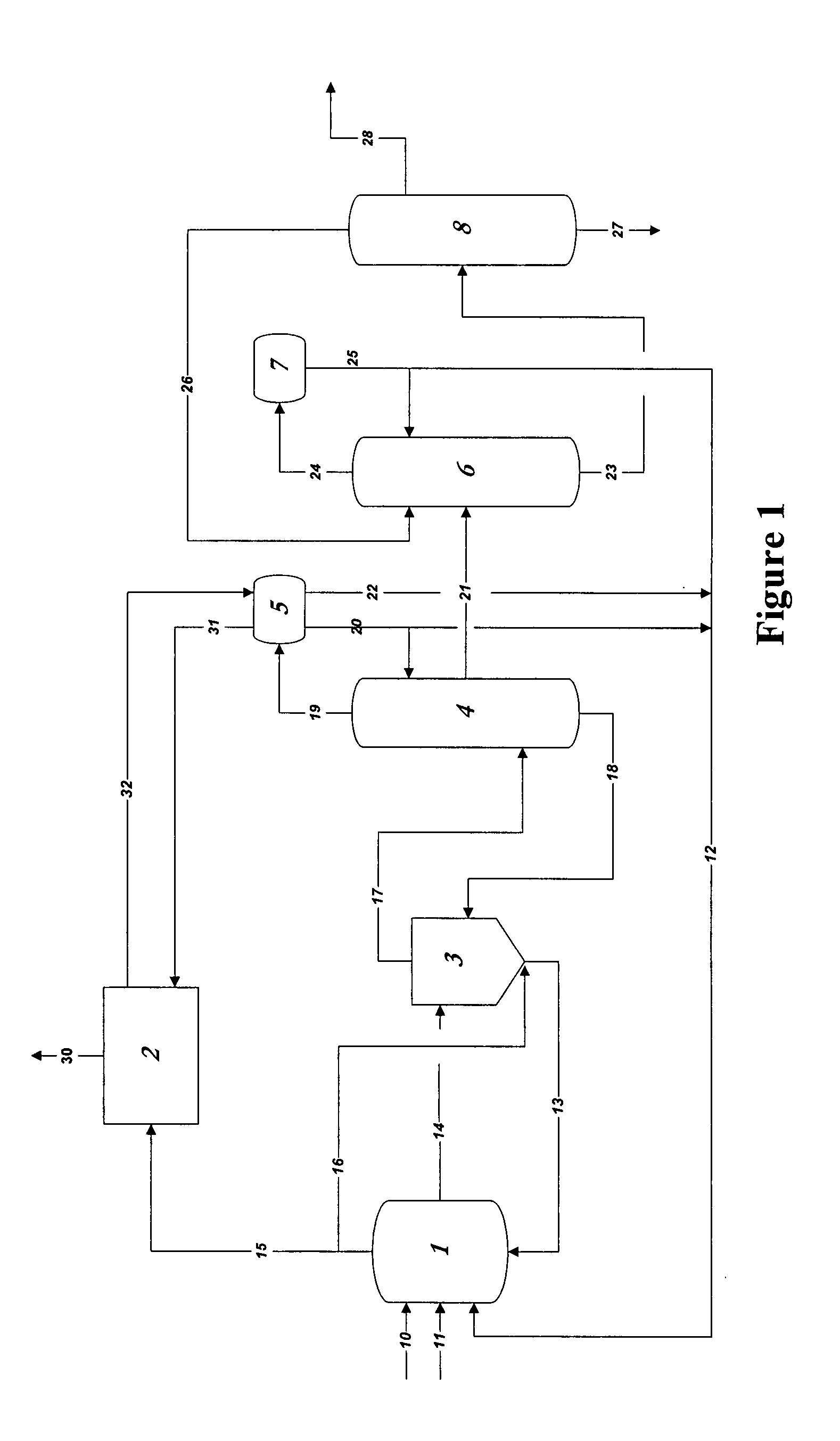

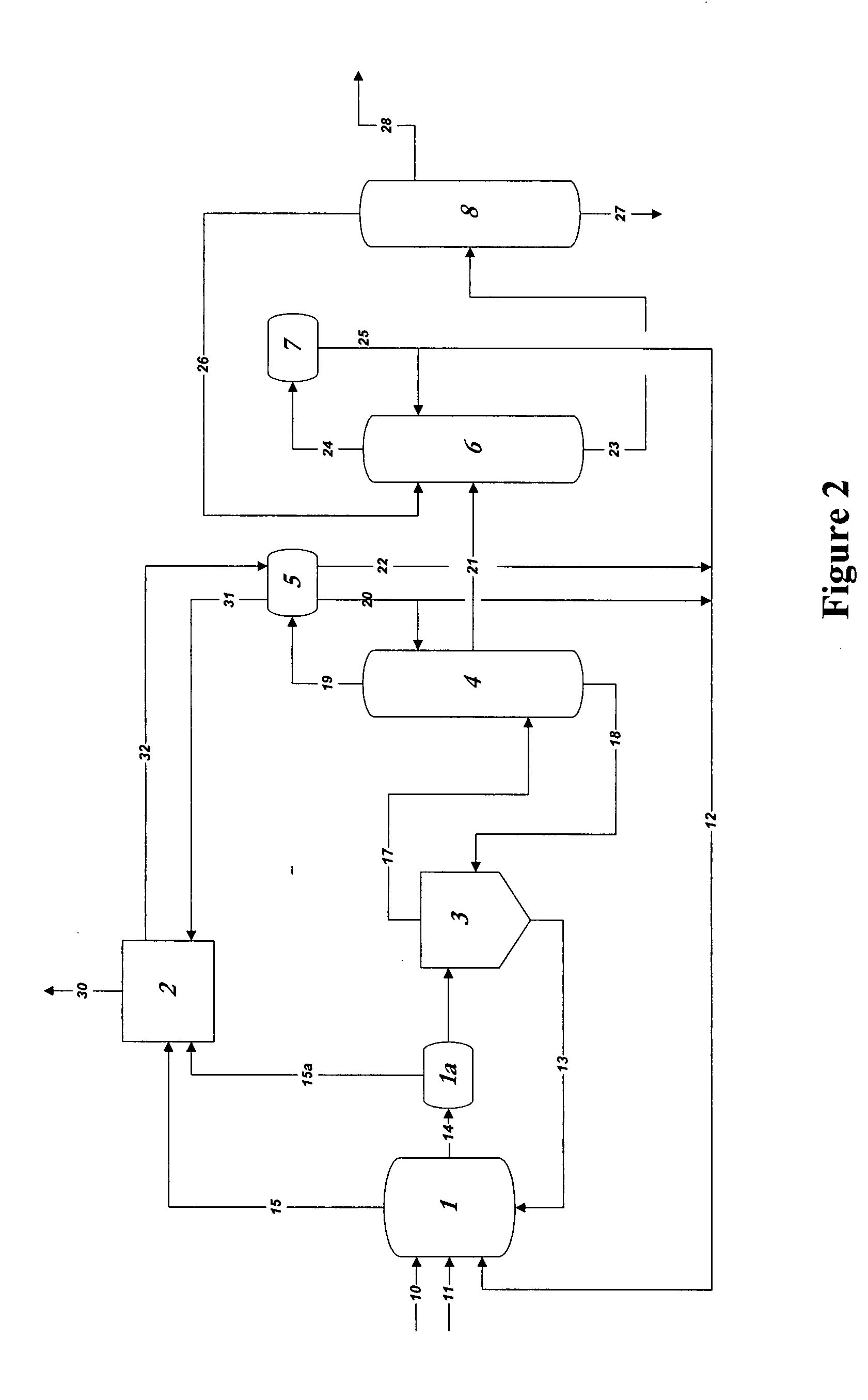

Control of impurities in product glacial acetic acid of rhodium-catalyzed methanol carbonylation

PatentInactiveUS20090187043A1

Innovation

- A method involving a rhodium-catalyzed carbonylation process with controlled water and iodide concentrations, combined with the use of a macroreticular strong-acid cation exchange resin and silver or mercury exchanged cation exchange substrates to manage impurities, ensuring high purity glacial acetic acid production.

Control of impurities in reaction product of rhodium-catalyzed methanol carbonylation

PatentInactiveUS20080293966A1

Innovation

- A method involving the reaction of methanol, methyl acetate, or dimethyl ether with carbon monoxide in the presence of a rhodium catalyst, maintaining a water concentration of 0.5 to 14 weight percent to control formic acid content in the product acetic acid to 15-160 ppm, and using a silver exchanged cationic ion exchange resin to reduce sulfur levels below 1 ppm.

Regulatory Framework for Chemical Safety

The regulatory framework for chemical safety in glacial acetic acid production encompasses a complex network of international, national, and industry-specific standards and guidelines. At the international level, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a foundation for hazard communication and risk management. This system has been widely adopted and adapted by various countries, including the United States, European Union members, and many Asian nations.

In the United States, the Occupational Safety and Health Administration (OSHA) plays a crucial role in enforcing safety standards for acetic acid production. OSHA's Process Safety Management (PSM) standard (29 CFR 1910.119) is particularly relevant, as it addresses the management of highly hazardous chemicals. The Environmental Protection Agency (EPA) also contributes to the regulatory landscape through its Risk Management Program (RMP) under the Clean Air Act.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation and the CLP (Classification, Labelling, and Packaging) regulation form the cornerstone of chemical safety in Europe. These regulations mandate thorough risk assessments, safety data sheets, and proper labeling for hazardous substances like glacial acetic acid.

Industry-specific guidelines, such as those provided by the American Chemistry Council and the European Chemical Industry Council (CEFIC), offer detailed best practices for the safe production, handling, and transportation of acetic acid. These guidelines often go beyond regulatory requirements, addressing specific operational challenges and promoting continuous improvement in safety practices.

Safety standards for equipment and processes in acetic acid production are governed by organizations like the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO). These standards cover aspects such as pressure vessel design, piping systems, and process control mechanisms, all critical for maintaining safety in acetic acid facilities.

Regulatory bodies also emphasize the importance of regular safety audits, incident reporting, and continuous training programs. Many jurisdictions require companies to develop and maintain comprehensive safety management systems that integrate risk assessment, emergency response planning, and ongoing performance evaluation.

As the chemical industry evolves, so do the regulatory frameworks. Recent trends include an increased focus on sustainability and environmental protection, leading to more stringent emissions controls and waste management regulations. Additionally, there is a growing emphasis on the integration of digital technologies for real-time monitoring and predictive maintenance, which is beginning to influence regulatory approaches to chemical safety.

In the United States, the Occupational Safety and Health Administration (OSHA) plays a crucial role in enforcing safety standards for acetic acid production. OSHA's Process Safety Management (PSM) standard (29 CFR 1910.119) is particularly relevant, as it addresses the management of highly hazardous chemicals. The Environmental Protection Agency (EPA) also contributes to the regulatory landscape through its Risk Management Program (RMP) under the Clean Air Act.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation and the CLP (Classification, Labelling, and Packaging) regulation form the cornerstone of chemical safety in Europe. These regulations mandate thorough risk assessments, safety data sheets, and proper labeling for hazardous substances like glacial acetic acid.

Industry-specific guidelines, such as those provided by the American Chemistry Council and the European Chemical Industry Council (CEFIC), offer detailed best practices for the safe production, handling, and transportation of acetic acid. These guidelines often go beyond regulatory requirements, addressing specific operational challenges and promoting continuous improvement in safety practices.

Safety standards for equipment and processes in acetic acid production are governed by organizations like the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO). These standards cover aspects such as pressure vessel design, piping systems, and process control mechanisms, all critical for maintaining safety in acetic acid facilities.

Regulatory bodies also emphasize the importance of regular safety audits, incident reporting, and continuous training programs. Many jurisdictions require companies to develop and maintain comprehensive safety management systems that integrate risk assessment, emergency response planning, and ongoing performance evaluation.

As the chemical industry evolves, so do the regulatory frameworks. Recent trends include an increased focus on sustainability and environmental protection, leading to more stringent emissions controls and waste management regulations. Additionally, there is a growing emphasis on the integration of digital technologies for real-time monitoring and predictive maintenance, which is beginning to influence regulatory approaches to chemical safety.

Environmental Impact Assessment

The environmental impact assessment of glacial acetic acid production is a critical component in evaluating the overall safety and risk profile of the manufacturing process. This assessment encompasses various aspects of environmental concern, including air emissions, water pollution, soil contamination, and waste management.

Air emissions from glacial acetic acid production primarily consist of volatile organic compounds (VOCs) and acetic acid vapors. These emissions can contribute to the formation of ground-level ozone and photochemical smog, potentially impacting local air quality and human health. Proper ventilation systems and emission control technologies, such as scrubbers and thermal oxidizers, are essential to mitigate these impacts.

Water pollution is another significant concern in the production of glacial acetic acid. Wastewater from the manufacturing process may contain high levels of acidity and organic compounds. If not properly treated, this effluent can harm aquatic ecosystems and contaminate groundwater resources. Implementing advanced wastewater treatment systems, including neutralization and biological treatment processes, is crucial to minimize the environmental impact on water bodies.

Soil contamination risks arise from potential spills or leaks during production, storage, and transportation of glacial acetic acid. The highly corrosive nature of the acid can lead to soil acidification and damage to vegetation. Proper containment measures, such as impermeable flooring and secondary containment systems, are necessary to prevent soil contamination and protect surrounding ecosystems.

Waste management is an integral part of the environmental impact assessment. The production process generates various waste streams, including spent catalysts, byproducts, and packaging materials. Implementing a comprehensive waste management plan that prioritizes reduction, reuse, and recycling can significantly minimize the environmental footprint of glacial acetic acid production.

Energy consumption and greenhouse gas emissions associated with the production process also contribute to the overall environmental impact. Conducting energy audits and implementing energy-efficient technologies can help reduce the carbon footprint of the manufacturing facility. Additionally, exploring renewable energy sources for powering the production process can further mitigate the environmental impact.

Biodiversity and ecosystem impacts should be considered, especially if the production facility is located near sensitive habitats or protected areas. A thorough assessment of the potential effects on local flora and fauna, including any endangered species, is essential to develop appropriate mitigation strategies and ensure compliance with environmental regulations.

In conclusion, a comprehensive environmental impact assessment for glacial acetic acid production should address air emissions, water pollution, soil contamination, waste management, energy consumption, and biodiversity impacts. By identifying and mitigating these environmental risks, manufacturers can enhance the overall safety profile of their operations and contribute to sustainable industrial practices.

Air emissions from glacial acetic acid production primarily consist of volatile organic compounds (VOCs) and acetic acid vapors. These emissions can contribute to the formation of ground-level ozone and photochemical smog, potentially impacting local air quality and human health. Proper ventilation systems and emission control technologies, such as scrubbers and thermal oxidizers, are essential to mitigate these impacts.

Water pollution is another significant concern in the production of glacial acetic acid. Wastewater from the manufacturing process may contain high levels of acidity and organic compounds. If not properly treated, this effluent can harm aquatic ecosystems and contaminate groundwater resources. Implementing advanced wastewater treatment systems, including neutralization and biological treatment processes, is crucial to minimize the environmental impact on water bodies.

Soil contamination risks arise from potential spills or leaks during production, storage, and transportation of glacial acetic acid. The highly corrosive nature of the acid can lead to soil acidification and damage to vegetation. Proper containment measures, such as impermeable flooring and secondary containment systems, are necessary to prevent soil contamination and protect surrounding ecosystems.

Waste management is an integral part of the environmental impact assessment. The production process generates various waste streams, including spent catalysts, byproducts, and packaging materials. Implementing a comprehensive waste management plan that prioritizes reduction, reuse, and recycling can significantly minimize the environmental footprint of glacial acetic acid production.

Energy consumption and greenhouse gas emissions associated with the production process also contribute to the overall environmental impact. Conducting energy audits and implementing energy-efficient technologies can help reduce the carbon footprint of the manufacturing facility. Additionally, exploring renewable energy sources for powering the production process can further mitigate the environmental impact.

Biodiversity and ecosystem impacts should be considered, especially if the production facility is located near sensitive habitats or protected areas. A thorough assessment of the potential effects on local flora and fauna, including any endangered species, is essential to develop appropriate mitigation strategies and ensure compliance with environmental regulations.

In conclusion, a comprehensive environmental impact assessment for glacial acetic acid production should address air emissions, water pollution, soil contamination, waste management, energy consumption, and biodiversity impacts. By identifying and mitigating these environmental risks, manufacturers can enhance the overall safety profile of their operations and contribute to sustainable industrial practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!