Safety Mechanisms for Blade Battery Fire Prevention

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Safety Evolution

Battery safety has evolved significantly over the past few decades, driven by the increasing demand for high-performance energy storage solutions across various industries. The journey of battery safety evolution can be traced back to the early days of lead-acid batteries, which were prone to acid leaks and hydrogen gas emissions.

As lithium-ion batteries emerged in the 1990s, they brought new safety challenges, including thermal runaway and electrolyte flammability. These issues led to several high-profile incidents, such as laptop battery fires and electric vehicle (EV) battery explosions, prompting intense research and development efforts to enhance battery safety.

The early 2000s saw the introduction of improved battery management systems (BMS) and thermal management techniques. These advancements helped monitor battery health, regulate charging and discharging processes, and prevent overheating. Simultaneously, manufacturers began incorporating physical safety features like pressure relief valves and thermal fuses to mitigate risks associated with battery failure.

By the mid-2010s, the focus shifted towards developing inherently safer battery chemistries. This led to the emergence of lithium iron phosphate (LFP) batteries, known for their enhanced thermal stability and reduced fire risk compared to traditional lithium-ion batteries. The automotive industry, in particular, embraced LFP technology for its safety benefits in electric vehicles.

Recent years have witnessed the advent of solid-state batteries, which promise to eliminate many of the safety concerns associated with liquid electrolytes. These batteries use solid electrolytes, significantly reducing the risk of leakage and flammability. Although still in the early stages of commercialization, solid-state batteries represent a major leap forward in battery safety technology.

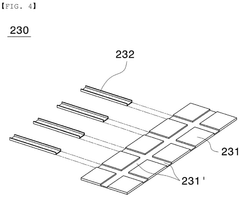

The development of blade batteries marks another milestone in battery safety evolution. Introduced by BYD in 2020, blade batteries are a type of LFP battery designed with a unique long and thin form factor. This design not only improves energy density but also enhances structural integrity and heat dissipation, further reducing the risk of thermal runaway and fire.

As the demand for safer and more efficient energy storage solutions continues to grow, ongoing research focuses on advanced materials, novel cell designs, and intelligent safety systems. These efforts aim to address the evolving safety challenges posed by increasingly powerful and compact battery technologies, particularly in applications such as electric vehicles and grid-scale energy storage.

As lithium-ion batteries emerged in the 1990s, they brought new safety challenges, including thermal runaway and electrolyte flammability. These issues led to several high-profile incidents, such as laptop battery fires and electric vehicle (EV) battery explosions, prompting intense research and development efforts to enhance battery safety.

The early 2000s saw the introduction of improved battery management systems (BMS) and thermal management techniques. These advancements helped monitor battery health, regulate charging and discharging processes, and prevent overheating. Simultaneously, manufacturers began incorporating physical safety features like pressure relief valves and thermal fuses to mitigate risks associated with battery failure.

By the mid-2010s, the focus shifted towards developing inherently safer battery chemistries. This led to the emergence of lithium iron phosphate (LFP) batteries, known for their enhanced thermal stability and reduced fire risk compared to traditional lithium-ion batteries. The automotive industry, in particular, embraced LFP technology for its safety benefits in electric vehicles.

Recent years have witnessed the advent of solid-state batteries, which promise to eliminate many of the safety concerns associated with liquid electrolytes. These batteries use solid electrolytes, significantly reducing the risk of leakage and flammability. Although still in the early stages of commercialization, solid-state batteries represent a major leap forward in battery safety technology.

The development of blade batteries marks another milestone in battery safety evolution. Introduced by BYD in 2020, blade batteries are a type of LFP battery designed with a unique long and thin form factor. This design not only improves energy density but also enhances structural integrity and heat dissipation, further reducing the risk of thermal runaway and fire.

As the demand for safer and more efficient energy storage solutions continues to grow, ongoing research focuses on advanced materials, novel cell designs, and intelligent safety systems. These efforts aim to address the evolving safety challenges posed by increasingly powerful and compact battery technologies, particularly in applications such as electric vehicles and grid-scale energy storage.

Market Demand Analysis

The market demand for safety mechanisms in blade batteries has seen a significant surge in recent years, driven by the rapid growth of the electric vehicle (EV) industry and increasing concerns about battery safety. As EVs become more mainstream, consumers and regulators alike are placing a higher emphasis on the safety aspects of battery technology, particularly in preventing fire incidents.

The global EV market has been experiencing exponential growth, with sales projected to reach 10.5 million units in 2022, up from 6.6 million in 2021. This growth trajectory is expected to continue, with some analysts predicting that EVs could account for up to 60% of new car sales by 2030. As the EV market expands, so does the demand for safer and more reliable battery technologies.

Blade batteries, known for their high energy density and improved safety features, have gained traction in the EV industry. However, the risk of thermal runaway and potential fire hazards remains a critical concern. This has created a substantial market demand for advanced safety mechanisms specifically designed for blade batteries.

The automotive industry has been the primary driver of this demand, with major car manufacturers investing heavily in battery safety research and development. Additionally, there is growing interest from other sectors such as energy storage systems for renewable energy and portable electronic devices, further expanding the market for blade battery safety mechanisms.

Consumer awareness and expectations regarding battery safety have also risen dramatically following high-profile incidents of EV battery fires. This has put pressure on manufacturers to implement more robust safety features, creating a market pull for innovative fire prevention technologies.

Regulatory bodies worldwide are tightening safety standards for EV batteries, which is expected to further boost the demand for advanced safety mechanisms. For instance, the United Nations Economic Commission for Europe (UNECE) has introduced new regulations for EV battery safety, which are likely to be adopted by many countries.

The market for blade battery safety mechanisms is not limited to new EV production. There is also a growing aftermarket segment for retrofitting existing EVs with improved safety systems, presenting additional opportunities for technology providers.

In terms of geographical distribution, the demand is particularly strong in regions with high EV adoption rates, such as China, Europe, and North America. However, as EV markets mature in other parts of the world, the demand for safety mechanisms is expected to grow globally.

The global EV market has been experiencing exponential growth, with sales projected to reach 10.5 million units in 2022, up from 6.6 million in 2021. This growth trajectory is expected to continue, with some analysts predicting that EVs could account for up to 60% of new car sales by 2030. As the EV market expands, so does the demand for safer and more reliable battery technologies.

Blade batteries, known for their high energy density and improved safety features, have gained traction in the EV industry. However, the risk of thermal runaway and potential fire hazards remains a critical concern. This has created a substantial market demand for advanced safety mechanisms specifically designed for blade batteries.

The automotive industry has been the primary driver of this demand, with major car manufacturers investing heavily in battery safety research and development. Additionally, there is growing interest from other sectors such as energy storage systems for renewable energy and portable electronic devices, further expanding the market for blade battery safety mechanisms.

Consumer awareness and expectations regarding battery safety have also risen dramatically following high-profile incidents of EV battery fires. This has put pressure on manufacturers to implement more robust safety features, creating a market pull for innovative fire prevention technologies.

Regulatory bodies worldwide are tightening safety standards for EV batteries, which is expected to further boost the demand for advanced safety mechanisms. For instance, the United Nations Economic Commission for Europe (UNECE) has introduced new regulations for EV battery safety, which are likely to be adopted by many countries.

The market for blade battery safety mechanisms is not limited to new EV production. There is also a growing aftermarket segment for retrofitting existing EVs with improved safety systems, presenting additional opportunities for technology providers.

In terms of geographical distribution, the demand is particularly strong in regions with high EV adoption rates, such as China, Europe, and North America. However, as EV markets mature in other parts of the world, the demand for safety mechanisms is expected to grow globally.

Blade Battery Challenges

Blade batteries, while offering significant advantages in energy density and safety compared to traditional lithium-ion batteries, still face several challenges that need to be addressed for widespread adoption and optimal performance. One of the primary concerns is thermal runaway, which can lead to catastrophic battery failure and potential fire hazards.

The unique structure of blade batteries, characterized by long, thin cells, presents specific thermal management challenges. Heat dissipation becomes more complex due to the increased surface area and reduced thickness of the cells. This can lead to uneven temperature distribution and potential hotspots, which may trigger thermal runaway if not properly managed.

Another significant challenge is the mechanical stress on the battery cells. The elongated shape of blade batteries makes them more susceptible to bending and twisting forces, especially when integrated into electric vehicle designs. This mechanical stress can potentially lead to internal short circuits or damage to the battery's protective layers, compromising its safety and performance.

The manufacturing process for blade batteries also presents unique challenges. Ensuring consistent quality and uniformity across the length of each cell is crucial but technically demanding. Any imperfections or inconsistencies in the manufacturing process can lead to weak points in the battery, increasing the risk of failure or reduced performance over time.

Balancing the trade-off between energy density and safety remains an ongoing challenge for blade battery technology. While the design allows for higher energy density compared to traditional lithium-ion batteries, pushing the limits of energy storage capacity must be carefully balanced against potential safety risks.

The integration of blade batteries into existing battery management systems (BMS) and vehicle architectures presents another set of challenges. BMS algorithms and hardware may need to be adapted to effectively monitor and manage the unique characteristics of blade batteries, including their thermal behavior and voltage distribution along the length of the cells.

Lastly, the long-term durability and aging characteristics of blade batteries are still not fully understood. As this technology is relatively new, there is limited real-world data on how these batteries perform over extended periods and numerous charge-discharge cycles. Understanding and mitigating potential degradation mechanisms specific to blade batteries is crucial for ensuring their long-term reliability and safety in various applications.

The unique structure of blade batteries, characterized by long, thin cells, presents specific thermal management challenges. Heat dissipation becomes more complex due to the increased surface area and reduced thickness of the cells. This can lead to uneven temperature distribution and potential hotspots, which may trigger thermal runaway if not properly managed.

Another significant challenge is the mechanical stress on the battery cells. The elongated shape of blade batteries makes them more susceptible to bending and twisting forces, especially when integrated into electric vehicle designs. This mechanical stress can potentially lead to internal short circuits or damage to the battery's protective layers, compromising its safety and performance.

The manufacturing process for blade batteries also presents unique challenges. Ensuring consistent quality and uniformity across the length of each cell is crucial but technically demanding. Any imperfections or inconsistencies in the manufacturing process can lead to weak points in the battery, increasing the risk of failure or reduced performance over time.

Balancing the trade-off between energy density and safety remains an ongoing challenge for blade battery technology. While the design allows for higher energy density compared to traditional lithium-ion batteries, pushing the limits of energy storage capacity must be carefully balanced against potential safety risks.

The integration of blade batteries into existing battery management systems (BMS) and vehicle architectures presents another set of challenges. BMS algorithms and hardware may need to be adapted to effectively monitor and manage the unique characteristics of blade batteries, including their thermal behavior and voltage distribution along the length of the cells.

Lastly, the long-term durability and aging characteristics of blade batteries are still not fully understood. As this technology is relatively new, there is limited real-world data on how these batteries perform over extended periods and numerous charge-discharge cycles. Understanding and mitigating potential degradation mechanisms specific to blade batteries is crucial for ensuring their long-term reliability and safety in various applications.

Current Safety Solutions

01 Thermal management systems

Implementing advanced thermal management systems in blade batteries to prevent overheating and potential fire hazards. These systems may include cooling mechanisms, heat dissipation structures, and temperature monitoring devices to maintain optimal operating conditions and reduce the risk of thermal runaway.- Thermal management systems: Implementing advanced thermal management systems in blade batteries to prevent overheating and potential fire hazards. These systems may include cooling mechanisms, heat dissipation structures, and temperature monitoring devices to maintain optimal operating conditions and reduce the risk of thermal runaway.

- Safety mechanisms and protective structures: Incorporating various safety mechanisms and protective structures within the blade battery design to enhance fire prevention. This may include pressure relief valves, isolation layers, fire-resistant materials, and compartmentalization techniques to contain and mitigate potential fire incidents.

- Battery management systems (BMS): Developing sophisticated battery management systems that continuously monitor and control various parameters such as voltage, current, and temperature. These systems can detect abnormalities, implement protective measures, and optimize battery performance to prevent conditions that may lead to fires.

- Electrolyte and separator improvements: Enhancing the safety of blade batteries through advancements in electrolyte formulations and separator materials. This includes developing flame-retardant electrolytes, using ceramic-coated separators, and implementing other material innovations to reduce the risk of internal short circuits and thermal runaway.

- Early detection and warning systems: Integrating advanced sensors and diagnostic tools to enable early detection of potential fire hazards in blade batteries. These systems can identify precursors to thermal events, such as gas emissions or subtle temperature changes, allowing for timely intervention and preventive measures to be taken before a fire occurs.

02 Safety mechanisms and protective structures

Incorporating various safety mechanisms and protective structures within the blade battery design to enhance fire prevention. This may include pressure relief valves, isolation layers, fire-resistant materials, and compartmentalization techniques to contain and mitigate potential fire incidents.Expand Specific Solutions03 Advanced battery management systems

Developing and implementing sophisticated battery management systems (BMS) that continuously monitor and control various parameters such as voltage, current, and temperature. These systems can detect abnormalities, prevent overcharging or over-discharging, and initiate safety protocols to prevent fire incidents.Expand Specific Solutions04 Fire-resistant materials and coatings

Utilizing fire-resistant materials and coatings in the construction of blade batteries to enhance their overall fire prevention capabilities. This may include the use of flame-retardant separators, electrolytes, and external coatings that can withstand high temperatures and prevent the spread of fire.Expand Specific Solutions05 Early detection and warning systems

Integrating early detection and warning systems into blade batteries to identify potential fire risks before they escalate. This may involve the use of sensors, gas detectors, and artificial intelligence algorithms to analyze battery behavior and provide timely alerts for preventive actions.Expand Specific Solutions

Key Industry Players

The safety mechanisms for blade battery fire prevention market is in its growth stage, driven by increasing adoption of electric vehicles and energy storage systems. The global market size is projected to expand significantly in the coming years, fueled by stringent safety regulations and growing awareness of battery fire risks. Technologically, the field is rapidly evolving, with companies like LG Energy Solution, SVOLT, and Contemporary Amperex Technology leading innovation. These firms are developing advanced safety features such as thermal management systems, fire-resistant materials, and intelligent battery management systems. Collaboration between automotive manufacturers like Geely and battery suppliers is accelerating the development and implementation of safer battery technologies.

Toshiba Battery Co., Ltd.

Technical Solution: Toshiba Battery Co., Ltd. has developed innovative safety mechanisms for their SCiB™ (Super Charge ion Battery) technology. This lithium-titanium oxide battery design inherently reduces the risk of thermal runaway and fire[1]. Toshiba's approach includes the use of a proprietary separator technology that maintains stability at high temperatures, reducing the risk of internal short circuits[2]. The company has implemented advanced manufacturing processes to ensure high-quality and consistent production of battery cells, minimizing defects that could lead to safety issues[3]. Toshiba's Battery Management System (BMS) incorporates sophisticated algorithms for real-time monitoring and predictive diagnostics, enabling early detection of potential safety concerns[4]. Additionally, the SCiB™ technology features rapid charging capabilities without compromising safety, due to its unique anode material that resists lithium metal deposition during fast charging[5].

Strengths: Inherently safer lithium-titanium oxide chemistry, advanced separator technology, and robust BMS. Fast charging capability without compromising safety. Weaknesses: Potentially lower energy density compared to some other lithium-ion chemistries.

Huawei Digital Power Technologies Co Ltd

Technical Solution: Huawei Digital Power has developed an innovative approach to battery safety, particularly focusing on their energy storage systems. Their safety mechanisms include a multi-level protection strategy, starting from the cell level up to the system level. At the cell level, Huawei employs advanced materials and designs to enhance intrinsic safety, including the use of flame-retardant separators and electrolytes[1]. The company has implemented a sophisticated Battery Management System (BMS) that utilizes AI algorithms for real-time monitoring and predictive maintenance[2]. Huawei's energy storage systems incorporate active and passive cooling technologies to manage thermal risks effectively[3]. Additionally, they have developed a unique modular design that allows for better isolation of potential fire incidents and easier maintenance[4]. The company also employs advanced diagnostic tools and remote monitoring capabilities to ensure early detection of any safety anomalies[5].

Strengths: Comprehensive multi-level safety approach, advanced AI-driven BMS, and modular design for improved safety management. Weaknesses: Potential complexity in system integration and higher initial costs due to advanced technologies.

Core Safety Innovations

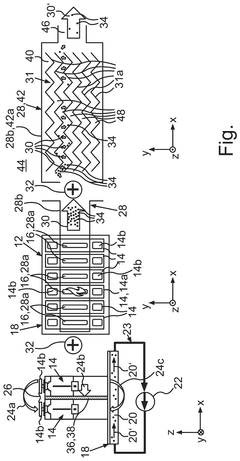

Battery fire prevention system, and method for preventing a battery fire resulting from thermal runaway of a battery cell

PatentPendingUS20240347853A1

Innovation

- A battery fire prevention system comprising a cell degassing channel with a gas flow influencing structure for controlled gas discharge and filtration, combined with a cooling device that activates coolant flow upon thermal runaway, to prevent heat propagation and spontaneous ignition, utilizing a synergistic interaction of controlled gas guidance, gas treatment, and defined heat conduction paths.

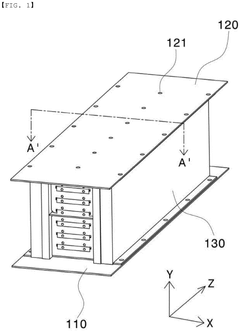

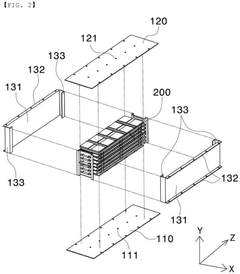

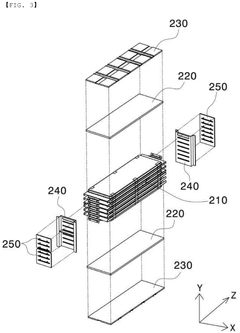

Battery module having pocket capable of capturing flare and spark ejected during swelling

PatentPendingEP4553979A2

Innovation

- A battery module design that includes a protective case with side covers featuring vertical plates and bent plates to capture and interrupt the movement of flare and spark, while also allowing for the rapid discharge of vent gas and air to prevent fire outbreaks.

Regulatory Compliance

Regulatory compliance plays a crucial role in ensuring the safety and reliability of blade batteries, particularly in the context of fire prevention mechanisms. As the adoption of blade batteries in electric vehicles and energy storage systems continues to grow, adherence to established regulations and standards becomes increasingly important.

In the United States, the National Highway Traffic Safety Administration (NHTSA) and the Federal Motor Vehicle Safety Standards (FMVSS) set forth guidelines for battery safety in electric vehicles. These regulations encompass various aspects of battery design, including thermal management systems, electrical isolation, and crash protection. Manufacturers must demonstrate compliance with these standards through rigorous testing and documentation.

The United Nations Economic Commission for Europe (UNECE) has developed the Global Technical Regulation No. 20 (GTR 20) on Electric Vehicle Safety, which addresses battery safety requirements for electric vehicles. This regulation includes provisions for thermal propagation prevention and fire resistance, directly impacting the design of safety mechanisms for blade batteries.

In the European Union, the European Commission has established the Battery Directive (2006/66/EC) and the End-of-Life Vehicles Directive (2000/53/EC), which set requirements for battery recycling and disposal. These regulations indirectly influence the design of safety mechanisms by promoting the use of recyclable materials and easily dismantlable battery systems.

China, a major player in the electric vehicle and battery market, has implemented the GB/T 31485-2015 standard for safety requirements and test methods of traction battery packs and systems for electric vehicles. This standard outlines specific requirements for thermal runaway prevention and fire safety in battery systems.

Compliance with international standards such as IEC 62619 for secondary cells and batteries containing alkaline or other non-acid electrolytes is essential for ensuring global market acceptance. This standard covers safety requirements for large format lithium-ion cells and batteries, including those used in industrial applications and electric road vehicles.

The Underwriters Laboratories (UL) has developed UL 9540A, a test method for evaluating thermal runaway fire propagation in battery energy storage systems. While not a regulatory requirement, compliance with this standard is often sought by manufacturers to demonstrate the effectiveness of their fire prevention mechanisms.

As the technology for blade batteries evolves, regulatory bodies are likely to update existing standards or introduce new ones to address specific safety concerns. Manufacturers must stay informed about these developments and proactively incorporate compliance measures into their safety mechanism designs.

In the United States, the National Highway Traffic Safety Administration (NHTSA) and the Federal Motor Vehicle Safety Standards (FMVSS) set forth guidelines for battery safety in electric vehicles. These regulations encompass various aspects of battery design, including thermal management systems, electrical isolation, and crash protection. Manufacturers must demonstrate compliance with these standards through rigorous testing and documentation.

The United Nations Economic Commission for Europe (UNECE) has developed the Global Technical Regulation No. 20 (GTR 20) on Electric Vehicle Safety, which addresses battery safety requirements for electric vehicles. This regulation includes provisions for thermal propagation prevention and fire resistance, directly impacting the design of safety mechanisms for blade batteries.

In the European Union, the European Commission has established the Battery Directive (2006/66/EC) and the End-of-Life Vehicles Directive (2000/53/EC), which set requirements for battery recycling and disposal. These regulations indirectly influence the design of safety mechanisms by promoting the use of recyclable materials and easily dismantlable battery systems.

China, a major player in the electric vehicle and battery market, has implemented the GB/T 31485-2015 standard for safety requirements and test methods of traction battery packs and systems for electric vehicles. This standard outlines specific requirements for thermal runaway prevention and fire safety in battery systems.

Compliance with international standards such as IEC 62619 for secondary cells and batteries containing alkaline or other non-acid electrolytes is essential for ensuring global market acceptance. This standard covers safety requirements for large format lithium-ion cells and batteries, including those used in industrial applications and electric road vehicles.

The Underwriters Laboratories (UL) has developed UL 9540A, a test method for evaluating thermal runaway fire propagation in battery energy storage systems. While not a regulatory requirement, compliance with this standard is often sought by manufacturers to demonstrate the effectiveness of their fire prevention mechanisms.

As the technology for blade batteries evolves, regulatory bodies are likely to update existing standards or introduce new ones to address specific safety concerns. Manufacturers must stay informed about these developments and proactively incorporate compliance measures into their safety mechanism designs.

Environmental Impact

The environmental impact of safety mechanisms for blade battery fire prevention is a critical consideration in the development and implementation of these technologies. As the automotive industry shifts towards electrification, the environmental footprint of battery production and safety systems becomes increasingly significant.

Blade batteries, known for their high energy density and improved safety features, already offer some environmental advantages over traditional lithium-ion batteries. However, the additional safety mechanisms required for fire prevention may introduce new environmental challenges. These mechanisms often involve the use of specialized materials and components, which can have varying degrees of environmental impact throughout their lifecycle.

One of the primary environmental concerns is the sourcing and production of materials used in fire prevention systems. Many of these materials, such as fire-resistant coatings and thermal management components, may require energy-intensive manufacturing processes or the use of rare earth elements. The extraction and processing of these materials can lead to increased carbon emissions and potential ecosystem disruption in mining areas.

On the other hand, effective fire prevention mechanisms can significantly reduce the environmental impact of battery fires. Battery fires not only pose immediate safety risks but also release harmful pollutants into the atmosphere and can contaminate soil and water sources. By preventing such incidents, these safety mechanisms contribute to overall environmental protection and reduce the carbon footprint associated with emergency response and cleanup efforts.

The recyclability and end-of-life management of blade batteries equipped with fire prevention mechanisms is another crucial environmental consideration. While blade batteries themselves are designed for improved recyclability, the addition of complex safety systems may complicate the recycling process. It is essential to develop fire prevention technologies that do not hinder the recyclability of the battery components, ensuring that valuable materials can be recovered and reused at the end of the battery's life cycle.

Furthermore, the environmental impact of these safety mechanisms extends to the operational phase of electric vehicles. Some fire prevention systems may add weight to the battery pack, potentially reducing the vehicle's energy efficiency and range. This could indirectly lead to increased energy consumption and associated environmental impacts. However, advancements in lightweight materials and efficient design are continually addressing this challenge.

In conclusion, while safety mechanisms for blade battery fire prevention are crucial for the widespread adoption of electric vehicles, their environmental impact must be carefully considered and mitigated. Balancing safety requirements with environmental sustainability will be key to the long-term success and acceptance of these technologies in the automotive industry.

Blade batteries, known for their high energy density and improved safety features, already offer some environmental advantages over traditional lithium-ion batteries. However, the additional safety mechanisms required for fire prevention may introduce new environmental challenges. These mechanisms often involve the use of specialized materials and components, which can have varying degrees of environmental impact throughout their lifecycle.

One of the primary environmental concerns is the sourcing and production of materials used in fire prevention systems. Many of these materials, such as fire-resistant coatings and thermal management components, may require energy-intensive manufacturing processes or the use of rare earth elements. The extraction and processing of these materials can lead to increased carbon emissions and potential ecosystem disruption in mining areas.

On the other hand, effective fire prevention mechanisms can significantly reduce the environmental impact of battery fires. Battery fires not only pose immediate safety risks but also release harmful pollutants into the atmosphere and can contaminate soil and water sources. By preventing such incidents, these safety mechanisms contribute to overall environmental protection and reduce the carbon footprint associated with emergency response and cleanup efforts.

The recyclability and end-of-life management of blade batteries equipped with fire prevention mechanisms is another crucial environmental consideration. While blade batteries themselves are designed for improved recyclability, the addition of complex safety systems may complicate the recycling process. It is essential to develop fire prevention technologies that do not hinder the recyclability of the battery components, ensuring that valuable materials can be recovered and reused at the end of the battery's life cycle.

Furthermore, the environmental impact of these safety mechanisms extends to the operational phase of electric vehicles. Some fire prevention systems may add weight to the battery pack, potentially reducing the vehicle's energy efficiency and range. This could indirectly lead to increased energy consumption and associated environmental impacts. However, advancements in lightweight materials and efficient design are continually addressing this challenge.

In conclusion, while safety mechanisms for blade battery fire prevention are crucial for the widespread adoption of electric vehicles, their environmental impact must be carefully considered and mitigated. Balancing safety requirements with environmental sustainability will be key to the long-term success and acceptance of these technologies in the automotive industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!