Schmitt Trigger in Oscillators: Enhancing Frequency Stability

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Schmitt Trigger Oscillator Evolution and Objectives

The Schmitt trigger, first introduced by Otto Schmitt in 1934, represents a significant milestone in electronic circuit design. Initially developed for biological research to detect nerve impulses, this hysteresis-based comparator circuit has evolved substantially over decades to become a fundamental component in oscillator design. The evolution trajectory of Schmitt trigger oscillators reflects broader electronic engineering advancements, transitioning from vacuum tube implementations to solid-state designs, and eventually to integrated circuit solutions.

Early Schmitt trigger oscillators suffered from frequency instability issues due to component tolerances, temperature variations, and power supply fluctuations. The 1960s marked a turning point with the introduction of operational amplifiers, enabling more precise and reliable Schmitt trigger oscillator configurations. By the 1980s, dedicated integrated circuits incorporating Schmitt trigger functionality emerged, significantly improving performance metrics while reducing implementation complexity.

Modern Schmitt trigger oscillators leverage advanced semiconductor manufacturing processes that allow for tighter component tolerances and reduced parasitic effects. Contemporary designs often incorporate temperature compensation mechanisms, precision voltage references, and sophisticated feedback networks to enhance frequency stability. The miniaturization trend has further enabled the integration of Schmitt trigger oscillators into complex systems-on-chip (SoC) solutions, supporting applications requiring precise timing signals in increasingly compact form factors.

The primary technical objective for Schmitt trigger oscillators centers on achieving superior frequency stability across varying operating conditions. This encompasses maintaining consistent oscillation frequency despite temperature fluctuations (typically -40°C to +125°C for industrial applications), power supply variations (±10% or better), and component aging effects. Secondary objectives include reducing phase noise, minimizing power consumption, and enhancing immunity to external electromagnetic interference.

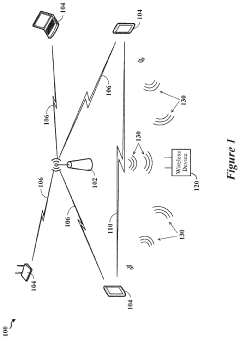

Emerging objectives reflect evolving market demands, particularly in IoT devices, wearable technology, and autonomous systems. These applications require oscillators that maintain stability while operating at ultra-low power levels, often in energy harvesting scenarios. Additionally, there is growing interest in developing adaptive Schmitt trigger oscillators capable of dynamically adjusting their characteristics based on operating conditions, potentially through digital calibration or machine learning algorithms.

The convergence of analog and digital design methodologies presents new opportunities for hybrid Schmitt trigger oscillator architectures. Research efforts increasingly focus on developing digitally-assisted analog oscillators that leverage the precision of digital calibration while maintaining the power efficiency of analog implementations. This approach aims to achieve unprecedented levels of frequency stability while addressing the constraints of emerging application domains.

Early Schmitt trigger oscillators suffered from frequency instability issues due to component tolerances, temperature variations, and power supply fluctuations. The 1960s marked a turning point with the introduction of operational amplifiers, enabling more precise and reliable Schmitt trigger oscillator configurations. By the 1980s, dedicated integrated circuits incorporating Schmitt trigger functionality emerged, significantly improving performance metrics while reducing implementation complexity.

Modern Schmitt trigger oscillators leverage advanced semiconductor manufacturing processes that allow for tighter component tolerances and reduced parasitic effects. Contemporary designs often incorporate temperature compensation mechanisms, precision voltage references, and sophisticated feedback networks to enhance frequency stability. The miniaturization trend has further enabled the integration of Schmitt trigger oscillators into complex systems-on-chip (SoC) solutions, supporting applications requiring precise timing signals in increasingly compact form factors.

The primary technical objective for Schmitt trigger oscillators centers on achieving superior frequency stability across varying operating conditions. This encompasses maintaining consistent oscillation frequency despite temperature fluctuations (typically -40°C to +125°C for industrial applications), power supply variations (±10% or better), and component aging effects. Secondary objectives include reducing phase noise, minimizing power consumption, and enhancing immunity to external electromagnetic interference.

Emerging objectives reflect evolving market demands, particularly in IoT devices, wearable technology, and autonomous systems. These applications require oscillators that maintain stability while operating at ultra-low power levels, often in energy harvesting scenarios. Additionally, there is growing interest in developing adaptive Schmitt trigger oscillators capable of dynamically adjusting their characteristics based on operating conditions, potentially through digital calibration or machine learning algorithms.

The convergence of analog and digital design methodologies presents new opportunities for hybrid Schmitt trigger oscillator architectures. Research efforts increasingly focus on developing digitally-assisted analog oscillators that leverage the precision of digital calibration while maintaining the power efficiency of analog implementations. This approach aims to achieve unprecedented levels of frequency stability while addressing the constraints of emerging application domains.

Market Applications and Demand Analysis for Stable Oscillators

The global market for stable oscillators has witnessed significant growth in recent years, driven primarily by the increasing demand for precision timing and frequency control in various electronic applications. The market size for frequency control products, including oscillators, was valued at approximately 8.2 billion USD in 2022 and is projected to reach 12.5 billion USD by 2028, growing at a CAGR of 7.3% during the forecast period.

Telecommunications represents the largest application segment for stable oscillators, accounting for nearly 35% of the total market share. The rollout of 5G networks worldwide has substantially increased the demand for high-stability oscillators, as these networks require precise timing synchronization to maintain data integrity and network performance. Telecom infrastructure providers are specifically seeking oscillators with frequency stability in the range of ±0.1 to ±0.5 ppm (parts per million).

The automotive sector has emerged as a rapidly growing market for stable oscillators, particularly with the advancement of autonomous driving technologies and vehicle-to-everything (V2X) communication systems. This sector is expected to grow at a CAGR of 9.8% through 2028, outpacing the overall market growth rate. Advanced driver-assistance systems (ADAS) require oscillators with excellent stability under varying temperature conditions and mechanical stress.

In the industrial automation sector, the Industry 4.0 revolution has created substantial demand for stable oscillators in precision control systems, robotics, and industrial IoT devices. This market segment values oscillators with low phase noise and high immunity to environmental variations, which are precisely the benefits that Schmitt trigger-enhanced oscillators provide.

The aerospace and defense sector, though smaller in volume, represents a high-value market for ultra-stable oscillators. Military communication systems, radar applications, and satellite navigation systems require oscillators with stability better than ±0.01 ppm and exceptional reliability under extreme conditions. This sector is willing to pay premium prices for oscillators that meet stringent performance specifications.

Consumer electronics constitutes another significant market segment, with smartphones, wearables, and IoT devices driving demand for miniaturized, low-power oscillators. The market trend in this segment is moving toward oscillators that combine high stability with ultra-low power consumption, as battery life becomes increasingly important in portable devices.

Regional analysis indicates that Asia-Pacific dominates the market with a 45% share, followed by North America (28%) and Europe (20%). China and Taiwan are the manufacturing hubs, while the United States leads in high-performance oscillator design and innovation. The fastest growth is observed in emerging economies of Southeast Asia and India, where telecommunications infrastructure development is accelerating.

Telecommunications represents the largest application segment for stable oscillators, accounting for nearly 35% of the total market share. The rollout of 5G networks worldwide has substantially increased the demand for high-stability oscillators, as these networks require precise timing synchronization to maintain data integrity and network performance. Telecom infrastructure providers are specifically seeking oscillators with frequency stability in the range of ±0.1 to ±0.5 ppm (parts per million).

The automotive sector has emerged as a rapidly growing market for stable oscillators, particularly with the advancement of autonomous driving technologies and vehicle-to-everything (V2X) communication systems. This sector is expected to grow at a CAGR of 9.8% through 2028, outpacing the overall market growth rate. Advanced driver-assistance systems (ADAS) require oscillators with excellent stability under varying temperature conditions and mechanical stress.

In the industrial automation sector, the Industry 4.0 revolution has created substantial demand for stable oscillators in precision control systems, robotics, and industrial IoT devices. This market segment values oscillators with low phase noise and high immunity to environmental variations, which are precisely the benefits that Schmitt trigger-enhanced oscillators provide.

The aerospace and defense sector, though smaller in volume, represents a high-value market for ultra-stable oscillators. Military communication systems, radar applications, and satellite navigation systems require oscillators with stability better than ±0.01 ppm and exceptional reliability under extreme conditions. This sector is willing to pay premium prices for oscillators that meet stringent performance specifications.

Consumer electronics constitutes another significant market segment, with smartphones, wearables, and IoT devices driving demand for miniaturized, low-power oscillators. The market trend in this segment is moving toward oscillators that combine high stability with ultra-low power consumption, as battery life becomes increasingly important in portable devices.

Regional analysis indicates that Asia-Pacific dominates the market with a 45% share, followed by North America (28%) and Europe (20%). China and Taiwan are the manufacturing hubs, while the United States leads in high-performance oscillator design and innovation. The fastest growth is observed in emerging economies of Southeast Asia and India, where telecommunications infrastructure development is accelerating.

Current Challenges in Oscillator Frequency Stability

Despite significant advancements in oscillator technology, frequency stability remains a persistent challenge across various applications. Modern electronic systems increasingly demand higher precision timing solutions, yet oscillators continue to face fundamental limitations that compromise their stability performance. Temperature variations represent one of the most significant challenges, causing frequency drift as components expand and contract, altering their electrical characteristics. Even temperature-compensated oscillators (TCXOs) and oven-controlled oscillators (OCXOs) cannot completely eliminate these effects, particularly in environments with rapid temperature fluctuations.

Power supply variations introduce another layer of instability, as voltage fluctuations directly impact oscillator frequency. While voltage regulators mitigate this issue to some extent, they cannot completely isolate oscillators from power supply noise, especially in compact or low-power designs where sophisticated power conditioning is impractical.

Aging effects present long-term stability challenges as crystal oscillators gradually shift in frequency over time due to mechanical stress relaxation, mass transfer within the resonator, and changes in electrode interfaces. These effects are particularly problematic in applications requiring sustained accuracy over years of operation, such as telecommunications infrastructure and scientific instrumentation.

Phase noise remains a critical limitation, manifesting as random frequency fluctuations that degrade signal quality. This becomes particularly problematic in high-frequency applications and communication systems where phase noise directly impacts bit error rates and channel separation capabilities. Traditional oscillator designs struggle to simultaneously achieve low phase noise and wide tuning ranges.

Load sensitivity introduces additional instability as external circuit conditions affect oscillator performance. Changes in capacitive loading can pull the oscillator frequency away from its nominal value, creating unpredictable behavior in complex systems where impedance matching may vary during operation.

Mechanical vibration and shock susceptibility represent significant challenges for oscillators in automotive, aerospace, and industrial environments. Even minor mechanical disturbances can induce frequency modulation through various mechanisms, including changes in component spacing and stress-induced alterations to material properties.

The miniaturization trend in electronics creates additional stability challenges as smaller oscillators become more susceptible to environmental influences and manufacturing variations. Reduced component sizes limit the implementation of traditional stability-enhancing techniques, forcing engineers to seek innovative approaches like the integration of Schmitt triggers to maintain acceptable performance within increasingly constrained dimensional requirements.

Power supply variations introduce another layer of instability, as voltage fluctuations directly impact oscillator frequency. While voltage regulators mitigate this issue to some extent, they cannot completely isolate oscillators from power supply noise, especially in compact or low-power designs where sophisticated power conditioning is impractical.

Aging effects present long-term stability challenges as crystal oscillators gradually shift in frequency over time due to mechanical stress relaxation, mass transfer within the resonator, and changes in electrode interfaces. These effects are particularly problematic in applications requiring sustained accuracy over years of operation, such as telecommunications infrastructure and scientific instrumentation.

Phase noise remains a critical limitation, manifesting as random frequency fluctuations that degrade signal quality. This becomes particularly problematic in high-frequency applications and communication systems where phase noise directly impacts bit error rates and channel separation capabilities. Traditional oscillator designs struggle to simultaneously achieve low phase noise and wide tuning ranges.

Load sensitivity introduces additional instability as external circuit conditions affect oscillator performance. Changes in capacitive loading can pull the oscillator frequency away from its nominal value, creating unpredictable behavior in complex systems where impedance matching may vary during operation.

Mechanical vibration and shock susceptibility represent significant challenges for oscillators in automotive, aerospace, and industrial environments. Even minor mechanical disturbances can induce frequency modulation through various mechanisms, including changes in component spacing and stress-induced alterations to material properties.

The miniaturization trend in electronics creates additional stability challenges as smaller oscillators become more susceptible to environmental influences and manufacturing variations. Reduced component sizes limit the implementation of traditional stability-enhancing techniques, forcing engineers to seek innovative approaches like the integration of Schmitt triggers to maintain acceptable performance within increasingly constrained dimensional requirements.

Contemporary Schmitt Trigger Implementation Techniques

01 Hysteresis control for frequency stability

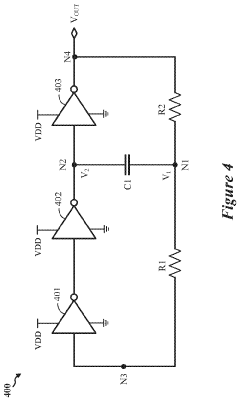

Controlling the hysteresis width in Schmitt trigger circuits is crucial for maintaining frequency stability. By adjusting the threshold voltage levels, the circuit can resist noise and prevent unwanted oscillations. Techniques include using resistor networks, feedback mechanisms, and voltage references to create precise and temperature-stable hysteresis windows that ensure consistent triggering points and stable output frequency.- Hysteresis control for frequency stability: Controlling the hysteresis width in Schmitt trigger circuits is crucial for maintaining frequency stability. By adjusting the threshold voltage levels, the circuit can resist noise and prevent unwanted oscillations. Techniques include using resistor networks, feedback mechanisms, and voltage references to set precise hysteresis windows that remain stable across temperature and voltage variations, ensuring consistent triggering behavior and reliable frequency output.

- Temperature compensation techniques: Temperature variations can significantly affect Schmitt trigger frequency stability. Various compensation techniques are employed to mitigate these effects, including the use of complementary semiconductor materials with opposing temperature coefficients, bandgap reference circuits, and thermally balanced layouts. These approaches help maintain consistent threshold voltages and switching characteristics across a wide temperature range, resulting in stable oscillation frequencies regardless of environmental conditions.

- Power supply noise rejection: Schmitt triggers used in frequency-critical applications must be immune to power supply variations and noise. Circuit designs incorporating voltage regulators, decoupling capacitors, and differential architectures help isolate the trigger thresholds from supply fluctuations. Some implementations use supply-independent reference voltages or ratio-based threshold setting to maintain consistent switching points regardless of supply voltage changes, thereby preserving frequency stability in noisy environments.

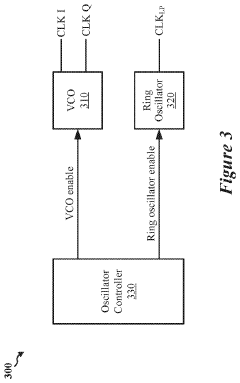

- Advanced circuit topologies: Novel Schmitt trigger architectures have been developed specifically to enhance frequency stability. These include differential designs with balanced current paths, regenerative feedback structures, and self-biasing configurations. Some implementations incorporate phase-locked loops or frequency compensation networks to actively correct drift. These advanced topologies minimize the impact of component variations and parasitic effects, resulting in more precise and stable oscillation frequencies for timing-critical applications.

- Process variation compensation: Manufacturing process variations can cause inconsistent behavior in Schmitt trigger circuits. Compensation techniques include auto-calibration circuits, digitally programmable thresholds, and adaptive biasing schemes. Some designs incorporate on-chip trimming capabilities to adjust threshold voltages post-production. These approaches help normalize the switching characteristics across different production batches and silicon dies, ensuring consistent frequency performance despite inherent semiconductor process variations.

02 Temperature compensation techniques

Temperature variations can significantly affect Schmitt trigger frequency stability. Various compensation techniques are employed to mitigate these effects, including the use of bandgap references, complementary temperature coefficient components, and specialized biasing circuits. These methods help maintain consistent threshold voltages and switching characteristics across a wide temperature range, ensuring stable oscillation frequency in timing applications.Expand Specific Solutions03 Power supply noise rejection

Schmitt triggers used in frequency-critical applications must be resistant to power supply variations and noise. Circuit designs incorporating differential structures, regulated internal voltage references, and supply filtering techniques help isolate the trigger thresholds from power supply fluctuations. These approaches ensure that the oscillation frequency remains stable even when the power supply experiences noise, ripple, or voltage changes.Expand Specific Solutions04 Feedback and stabilization circuits

Advanced feedback mechanisms are implemented to enhance the frequency stability of Schmitt trigger oscillators. These include negative feedback loops, phase-locked loops, and adaptive threshold adjustment circuits that continuously monitor and correct frequency drift. Such stabilization techniques compensate for component aging, environmental changes, and manufacturing variations to maintain precise timing characteristics over extended periods.Expand Specific Solutions05 Precision component selection and layout

The selection of high-precision components and careful circuit layout significantly impacts Schmitt trigger frequency stability. Using low-drift resistors, stable capacitors, and matched transistor pairs reduces variability in threshold voltages. Additionally, symmetrical layout techniques, proper grounding schemes, and isolation from noise sources minimize parasitic effects that could otherwise cause frequency instability in oscillator applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Schmitt Trigger oscillator market is currently in a growth phase, driven by increasing demand for stable frequency generation across multiple industries. The global market size is estimated to reach significant value due to applications in telecommunications, automotive electronics, and industrial automation. Leading semiconductor manufacturers like Texas Instruments, Analog Devices, and Renesas Electronics dominate with mature technology offerings, while companies such as ROHM, Microchip Technology, and Samsung Electronics are advancing innovation through enhanced stability solutions. Asian players including GigaDevice and SG Micro are rapidly gaining market share with cost-effective alternatives. The technology has reached moderate maturity, with established design principles, but continues to evolve as companies like Murata Manufacturing and MediaTek develop specialized implementations for emerging applications in IoT and wireless communications.

Renesas Electronics Corp.

Technical Solution: Renesas has developed advanced Schmitt trigger oscillator technology focused on integration and stability. Their RL78 microcontroller family incorporates high-precision Schmitt trigger oscillators with adaptive hysteresis control that automatically adjusts trigger thresholds based on operating conditions[9]. This approach enables frequency stability of ±0.5% across the full industrial temperature range without requiring external compensation components. Renesas' R8C series implements their proprietary "StableClock" technology that combines Schmitt trigger inputs with digital calibration to achieve exceptional frequency stability despite power supply fluctuations. Their oscillator designs feature integrated EMI filtering that maintains stable operation in electrically noisy automotive and industrial environments. Renesas has also pioneered ultra-low power Schmitt trigger oscillators for battery-powered IoT applications that maintain stability while consuming less than 80μA in active mode, utilizing their "GreenTrigger" technology that optimizes hysteresis windows for minimal power consumption while preserving noise immunity[10].

Strengths: Excellent integration capabilities with microcontrollers and system-on-chip solutions; strong performance in automotive environments; comprehensive design support with extensive reference designs. Weaknesses: Less specialized in ultra-high precision applications; higher power consumption in some product lines; more complex implementation requiring deeper technical expertise.

Analog Devices, Inc.

Technical Solution: Analog Devices has pioneered innovative Schmitt trigger oscillator solutions focused on ultra-high frequency stability. Their proprietary "PrecisionEdge" technology implements dynamically adjustable hysteresis thresholds that automatically calibrate to maintain optimal noise margins across varying environmental conditions[3]. ADI's LTC6993 TimerBlox oscillator incorporates an advanced Schmitt trigger with programmable hysteresis that can be precisely tuned to match specific crystal characteristics, reducing frequency drift to below 10ppm across industrial temperature ranges. Their oscillator designs feature integrated temperature compensation circuits that continuously adjust trigger thresholds to counteract temperature-induced frequency shifts. ADI has also developed specialized low-power Schmitt trigger oscillators for IoT applications that maintain frequency stability while consuming less than 100μA, utilizing their proprietary "SmartHysteresis" technology that optimizes trigger points based on real-time power supply conditions[4].

Strengths: Industry-leading precision with sub-10ppm stability; excellent performance in harsh environments with temperature compensation; comprehensive analog expertise enabling highly integrated solutions. Weaknesses: Higher cost structure compared to commodity alternatives; more complex implementation requiring deeper technical expertise; some solutions have limited operating frequency ranges.

Key Patents and Technical Innovations

Oscillator with schmitt trigger

PatentPendingUS20240235534A1

Innovation

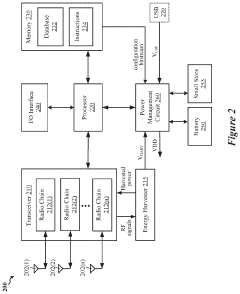

- A programmable ring oscillator incorporating a Schmitt trigger, CMOS inverters, resistors, and a capacitor, where the Schmitt trigger provides input hysteresis with threshold voltages adjustable based on supply voltage and configuration signals to maintain a constant oscillation frequency, reducing the impact of voltage variations.

Supply independent Schmitt trigger RC oscillator

PatentInactiveUS8208584B2

Innovation

- A modified Schmitt trigger RC oscillator design where the switching point is defined as a predetermined portion of the supply voltage, eliminating dependence on reference voltage and input voltage variations, resulting in a frequency that is only a function of the RC network values.

Temperature Compensation Methods in Schmitt Trigger Oscillators

Temperature variations significantly impact the performance of Schmitt trigger oscillators, causing frequency drift and instability. Effective temperature compensation methods are essential for maintaining consistent operation across varying environmental conditions. Several approaches have been developed to address this challenge, each with distinct advantages and implementation considerations.

Passive compensation techniques utilize components with opposing temperature coefficients to create a balanced system. For instance, combining negative temperature coefficient (NTC) resistors with positive temperature coefficient (PTC) capacitors can effectively neutralize thermal drift. This method is cost-effective and requires no additional power, making it suitable for low-power applications. However, passive compensation typically offers limited precision and may require careful component selection and calibration.

Active compensation methods employ temperature sensors and feedback circuits to dynamically adjust oscillator parameters. These systems continuously monitor ambient temperature and apply corrective signals to maintain stable frequency output. Common implementations include thermistor-based voltage dividers that modify threshold voltages or variable-gain amplifiers that adjust hysteresis width proportionally to temperature changes. Active compensation provides superior accuracy but increases power consumption and circuit complexity.

Crystal-referenced compensation techniques use temperature-stable crystal oscillators as reference sources. The Schmitt trigger oscillator's output is compared against this reference, and correction signals are generated to minimize deviation. This approach delivers excellent stability but at higher cost and complexity, typically reserved for precision applications where frequency accuracy is paramount.

Digital compensation represents the most advanced solution, incorporating microcontrollers or digital signal processors to implement sophisticated correction algorithms. Temperature sensors provide input to mathematical models that predict and counteract thermal effects. These systems can store calibration data across multiple temperature points, enabling precise compensation across wide operating ranges. Digital methods offer unparalleled flexibility and accuracy but require significant computational resources and careful calibration procedures.

Hybrid approaches combine multiple compensation techniques to leverage their respective strengths. For example, passive compensation might handle coarse adjustments while active or digital methods provide fine-tuning. These integrated solutions optimize performance while managing cost and complexity trade-offs.

Recent innovations include self-calibrating circuits that automatically characterize temperature response during initialization and periodically update compensation parameters during operation. Advanced materials with inherently stable thermal properties are also emerging as promising alternatives to traditional compensation methods.

Passive compensation techniques utilize components with opposing temperature coefficients to create a balanced system. For instance, combining negative temperature coefficient (NTC) resistors with positive temperature coefficient (PTC) capacitors can effectively neutralize thermal drift. This method is cost-effective and requires no additional power, making it suitable for low-power applications. However, passive compensation typically offers limited precision and may require careful component selection and calibration.

Active compensation methods employ temperature sensors and feedback circuits to dynamically adjust oscillator parameters. These systems continuously monitor ambient temperature and apply corrective signals to maintain stable frequency output. Common implementations include thermistor-based voltage dividers that modify threshold voltages or variable-gain amplifiers that adjust hysteresis width proportionally to temperature changes. Active compensation provides superior accuracy but increases power consumption and circuit complexity.

Crystal-referenced compensation techniques use temperature-stable crystal oscillators as reference sources. The Schmitt trigger oscillator's output is compared against this reference, and correction signals are generated to minimize deviation. This approach delivers excellent stability but at higher cost and complexity, typically reserved for precision applications where frequency accuracy is paramount.

Digital compensation represents the most advanced solution, incorporating microcontrollers or digital signal processors to implement sophisticated correction algorithms. Temperature sensors provide input to mathematical models that predict and counteract thermal effects. These systems can store calibration data across multiple temperature points, enabling precise compensation across wide operating ranges. Digital methods offer unparalleled flexibility and accuracy but require significant computational resources and careful calibration procedures.

Hybrid approaches combine multiple compensation techniques to leverage their respective strengths. For example, passive compensation might handle coarse adjustments while active or digital methods provide fine-tuning. These integrated solutions optimize performance while managing cost and complexity trade-offs.

Recent innovations include self-calibrating circuits that automatically characterize temperature response during initialization and periodically update compensation parameters during operation. Advanced materials with inherently stable thermal properties are also emerging as promising alternatives to traditional compensation methods.

Noise Immunity Advancements in Oscillator Design

Recent advancements in noise immunity for oscillator designs have significantly enhanced the performance and reliability of Schmitt trigger-based oscillators. Traditional oscillator circuits often suffer from noise susceptibility, which can lead to jitter, frequency instability, and false triggering. The implementation of Schmitt triggers has revolutionized this landscape by introducing hysteresis, which creates separate threshold levels for rising and falling signals.

The noise immunity capabilities of Schmitt trigger oscillators have been substantially improved through several key innovations. Advanced filtering techniques now complement the inherent hysteresis properties, creating multi-layered defense mechanisms against both common-mode and differential noise. These filters are strategically placed at input stages to prevent noise from propagating through the oscillator circuit while maintaining the desired signal integrity.

Material science breakthroughs have contributed to enhanced noise immunity through the development of specialized substrate materials with superior electromagnetic interference (EMI) shielding properties. When combined with Schmitt trigger designs, these materials create oscillator packages that demonstrate remarkable resilience against environmental noise factors, including radio frequency interference and power supply fluctuations.

Digital signal processing techniques have been integrated into modern Schmitt trigger oscillator designs, enabling adaptive threshold adjustment based on real-time noise conditions. This dynamic response capability allows oscillators to maintain stable frequency output even in environments with varying noise profiles. Machine learning algorithms are now being employed to predict noise patterns and preemptively adjust trigger thresholds, representing a significant leap forward in proactive noise immunity.

Power supply conditioning has emerged as another critical aspect of noise immunity advancement. Specialized voltage regulators and power filtering circuits designed specifically for Schmitt trigger oscillators ensure clean power delivery, eliminating a common source of noise that traditionally plagued oscillator performance. These power conditioning systems often incorporate their own Schmitt trigger circuits to maintain stable reference voltages.

Temperature compensation mechanisms have been refined to address thermal noise concerns, which previously limited the deployment of oscillators in extreme environments. Modern designs incorporate temperature sensors and feedback loops that dynamically adjust hysteresis windows to compensate for temperature-induced noise variations, maintaining consistent frequency stability across wide operating temperature ranges.

The cumulative effect of these advancements has been transformative for industries requiring precise timing signals in noisy environments. Telecommunications, automotive systems, industrial automation, and aerospace applications have all benefited from oscillators with superior noise immunity, enabling more reliable operation in challenging conditions while simultaneously reducing the need for external noise mitigation components.

The noise immunity capabilities of Schmitt trigger oscillators have been substantially improved through several key innovations. Advanced filtering techniques now complement the inherent hysteresis properties, creating multi-layered defense mechanisms against both common-mode and differential noise. These filters are strategically placed at input stages to prevent noise from propagating through the oscillator circuit while maintaining the desired signal integrity.

Material science breakthroughs have contributed to enhanced noise immunity through the development of specialized substrate materials with superior electromagnetic interference (EMI) shielding properties. When combined with Schmitt trigger designs, these materials create oscillator packages that demonstrate remarkable resilience against environmental noise factors, including radio frequency interference and power supply fluctuations.

Digital signal processing techniques have been integrated into modern Schmitt trigger oscillator designs, enabling adaptive threshold adjustment based on real-time noise conditions. This dynamic response capability allows oscillators to maintain stable frequency output even in environments with varying noise profiles. Machine learning algorithms are now being employed to predict noise patterns and preemptively adjust trigger thresholds, representing a significant leap forward in proactive noise immunity.

Power supply conditioning has emerged as another critical aspect of noise immunity advancement. Specialized voltage regulators and power filtering circuits designed specifically for Schmitt trigger oscillators ensure clean power delivery, eliminating a common source of noise that traditionally plagued oscillator performance. These power conditioning systems often incorporate their own Schmitt trigger circuits to maintain stable reference voltages.

Temperature compensation mechanisms have been refined to address thermal noise concerns, which previously limited the deployment of oscillators in extreme environments. Modern designs incorporate temperature sensors and feedback loops that dynamically adjust hysteresis windows to compensate for temperature-induced noise variations, maintaining consistent frequency stability across wide operating temperature ranges.

The cumulative effect of these advancements has been transformative for industries requiring precise timing signals in noisy environments. Telecommunications, automotive systems, industrial automation, and aerospace applications have all benefited from oscillators with superior noise immunity, enabling more reliable operation in challenging conditions while simultaneously reducing the need for external noise mitigation components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!