Sodium Bisulfate Innovations in Glass Etching Techniques

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glass Etching Evolution

Glass etching techniques have undergone significant evolution since their inception, with sodium bisulfate innovations playing a crucial role in recent advancements. The journey of glass etching began in the mid-19th century, primarily using hydrofluoric acid as the etching agent. This method, while effective, posed severe health and safety risks due to the highly corrosive nature of hydrofluoric acid.

As environmental and safety concerns grew, the industry sought alternative etching methods. The late 20th century saw the introduction of cream-based etching compounds, which offered improved safety but often resulted in inconsistent etching quality. This period marked the beginning of a shift towards more controlled and safer etching processes.

The early 21st century witnessed a significant leap forward with the introduction of sodium bisulfate-based etching techniques. This innovation addressed many of the shortcomings of previous methods, offering a balance between safety and effectiveness. Sodium bisulfate, being less hazardous than hydrofluoric acid, allowed for wider adoption in both industrial and artistic applications.

The development of sodium bisulfate etching techniques progressed rapidly, with researchers focusing on optimizing the chemical composition and application methods. Initial formulations were basic, but subsequent iterations incorporated additives to enhance etching depth, clarity, and consistency. This period also saw the integration of computerized control systems, enabling precise regulation of etching parameters such as concentration, temperature, and exposure time.

Recent years have witnessed further refinements in sodium bisulfate etching technologies. Advanced formulations now include nano-scale particles that improve the etching resolution, allowing for intricate designs and patterns previously unattainable. Additionally, the development of eco-friendly variants has addressed growing environmental concerns, making the process more sustainable.

The latest frontier in glass etching evolution involves the combination of sodium bisulfate techniques with other technologies. For instance, the integration of laser-guided systems has enabled highly precise etching patterns, while the incorporation of 3D printing technologies has opened up new possibilities for creating complex, multi-layered etched designs.

As we look to the future, the evolution of glass etching techniques continues to be driven by the pursuit of enhanced precision, safety, and environmental sustainability. Ongoing research into smart materials and adaptive etching processes promises to further revolutionize the field, potentially leading to self-regulating etching systems that can adjust in real-time to achieve optimal results.

As environmental and safety concerns grew, the industry sought alternative etching methods. The late 20th century saw the introduction of cream-based etching compounds, which offered improved safety but often resulted in inconsistent etching quality. This period marked the beginning of a shift towards more controlled and safer etching processes.

The early 21st century witnessed a significant leap forward with the introduction of sodium bisulfate-based etching techniques. This innovation addressed many of the shortcomings of previous methods, offering a balance between safety and effectiveness. Sodium bisulfate, being less hazardous than hydrofluoric acid, allowed for wider adoption in both industrial and artistic applications.

The development of sodium bisulfate etching techniques progressed rapidly, with researchers focusing on optimizing the chemical composition and application methods. Initial formulations were basic, but subsequent iterations incorporated additives to enhance etching depth, clarity, and consistency. This period also saw the integration of computerized control systems, enabling precise regulation of etching parameters such as concentration, temperature, and exposure time.

Recent years have witnessed further refinements in sodium bisulfate etching technologies. Advanced formulations now include nano-scale particles that improve the etching resolution, allowing for intricate designs and patterns previously unattainable. Additionally, the development of eco-friendly variants has addressed growing environmental concerns, making the process more sustainable.

The latest frontier in glass etching evolution involves the combination of sodium bisulfate techniques with other technologies. For instance, the integration of laser-guided systems has enabled highly precise etching patterns, while the incorporation of 3D printing technologies has opened up new possibilities for creating complex, multi-layered etched designs.

As we look to the future, the evolution of glass etching techniques continues to be driven by the pursuit of enhanced precision, safety, and environmental sustainability. Ongoing research into smart materials and adaptive etching processes promises to further revolutionize the field, potentially leading to self-regulating etching systems that can adjust in real-time to achieve optimal results.

Market Demand Analysis

The market demand for sodium bisulfate innovations in glass etching techniques has been steadily growing, driven by the increasing need for advanced glass processing methods across various industries. The global glass etching market is experiencing significant expansion, with a particular focus on environmentally friendly and cost-effective solutions.

In the electronics sector, the demand for etched glass components in smartphones, tablets, and other devices continues to rise. Manufacturers are seeking more efficient and precise etching techniques to meet the requirements of miniaturization and improved functionality. Sodium bisulfate-based etching methods offer potential advantages in terms of speed and quality, making them attractive for high-volume production.

The automotive industry represents another key market for glass etching innovations. As vehicles incorporate more advanced displays and sensors, the need for specialized glass treatments has increased. Sodium bisulfate-based techniques could provide enhanced durability and optical clarity for automotive glass applications, meeting the stringent requirements of this sector.

Architectural glass is also a significant driver of market demand for innovative etching solutions. The growing trend towards energy-efficient buildings has led to increased use of smart glass and other specialized glazing products. Sodium bisulfate innovations could offer improved control over etching depth and pattern precision, enabling more sophisticated designs and functionalities in architectural glass.

The medical and laboratory equipment industry is another area where demand for advanced glass etching is growing. Precise etching is crucial for manufacturing microfluidic devices, lab-on-a-chip systems, and other analytical tools. Sodium bisulfate-based techniques may offer advantages in terms of consistency and fine detail control, meeting the exacting standards of this sector.

Market analysis indicates that the Asia-Pacific region is expected to show the highest growth rate in the glass etching market, driven by rapid industrialization and increasing adoption of advanced technologies. North America and Europe remain significant markets, with a focus on high-value applications in aerospace, defense, and specialized industrial sectors.

Environmental considerations are becoming increasingly important in shaping market demand. There is a growing preference for etching techniques that reduce the use of hazardous chemicals and minimize waste. Sodium bisulfate innovations that can demonstrate improved environmental performance are likely to gain traction in the market.

Overall, the market for sodium bisulfate innovations in glass etching techniques shows strong potential for growth. The diverse range of applications across multiple industries, coupled with the need for more efficient and environmentally friendly processes, creates a favorable environment for technological advancements in this field.

In the electronics sector, the demand for etched glass components in smartphones, tablets, and other devices continues to rise. Manufacturers are seeking more efficient and precise etching techniques to meet the requirements of miniaturization and improved functionality. Sodium bisulfate-based etching methods offer potential advantages in terms of speed and quality, making them attractive for high-volume production.

The automotive industry represents another key market for glass etching innovations. As vehicles incorporate more advanced displays and sensors, the need for specialized glass treatments has increased. Sodium bisulfate-based techniques could provide enhanced durability and optical clarity for automotive glass applications, meeting the stringent requirements of this sector.

Architectural glass is also a significant driver of market demand for innovative etching solutions. The growing trend towards energy-efficient buildings has led to increased use of smart glass and other specialized glazing products. Sodium bisulfate innovations could offer improved control over etching depth and pattern precision, enabling more sophisticated designs and functionalities in architectural glass.

The medical and laboratory equipment industry is another area where demand for advanced glass etching is growing. Precise etching is crucial for manufacturing microfluidic devices, lab-on-a-chip systems, and other analytical tools. Sodium bisulfate-based techniques may offer advantages in terms of consistency and fine detail control, meeting the exacting standards of this sector.

Market analysis indicates that the Asia-Pacific region is expected to show the highest growth rate in the glass etching market, driven by rapid industrialization and increasing adoption of advanced technologies. North America and Europe remain significant markets, with a focus on high-value applications in aerospace, defense, and specialized industrial sectors.

Environmental considerations are becoming increasingly important in shaping market demand. There is a growing preference for etching techniques that reduce the use of hazardous chemicals and minimize waste. Sodium bisulfate innovations that can demonstrate improved environmental performance are likely to gain traction in the market.

Overall, the market for sodium bisulfate innovations in glass etching techniques shows strong potential for growth. The diverse range of applications across multiple industries, coupled with the need for more efficient and environmentally friendly processes, creates a favorable environment for technological advancements in this field.

Sodium Bisulfate Tech

Sodium bisulfate has emerged as a promising alternative in glass etching techniques, offering several advantages over traditional methods. This compound, also known as sodium hydrogen sulfate or sodium acid sulfate, is a versatile chemical with applications across various industries. In the context of glass etching, sodium bisulfate has gained attention due to its effectiveness, cost-efficiency, and relatively lower environmental impact compared to hydrofluoric acid-based etching processes.

The use of sodium bisulfate in glass etching represents a significant innovation in the field of surface modification technologies. Its ability to create intricate patterns and designs on glass surfaces has made it particularly valuable in the production of decorative glassware, architectural glass, and optical components. The etching process typically involves applying a paste or solution containing sodium bisulfate to the glass surface, allowing it to react for a specified period, and then neutralizing and rinsing the surface to reveal the etched pattern.

One of the key advantages of sodium bisulfate in glass etching is its safety profile. Unlike hydrofluoric acid, which is highly toxic and corrosive, sodium bisulfate poses fewer risks to workers and the environment. This has led to increased adoption in both industrial and artisanal settings, where safety considerations are paramount. Additionally, the lower hazard classification of sodium bisulfate simplifies storage, handling, and transportation requirements, making it more accessible to a wider range of users.

From a technical perspective, sodium bisulfate etching offers precise control over the etching depth and pattern definition. By adjusting the concentration of the etching solution, reaction time, and temperature, technicians can achieve a wide range of surface textures and opacities. This level of control is particularly valuable in the production of high-precision optical components, where surface quality directly impacts performance.

Recent innovations in sodium bisulfate etching techniques have focused on enhancing the efficiency and versatility of the process. Researchers have explored the use of additives to improve etch rates and pattern resolution, as well as developing new application methods to achieve more complex designs. These advancements have expanded the potential applications of sodium bisulfate etching, making it suitable for a broader range of glass types and surface treatments.

As the demand for environmentally friendly and cost-effective manufacturing processes continues to grow, sodium bisulfate innovations in glass etching techniques are likely to play an increasingly important role in the glass industry. The ongoing research and development in this area promise to further refine the technology, potentially leading to new applications and improved product quality across various sectors that rely on glass etching.

The use of sodium bisulfate in glass etching represents a significant innovation in the field of surface modification technologies. Its ability to create intricate patterns and designs on glass surfaces has made it particularly valuable in the production of decorative glassware, architectural glass, and optical components. The etching process typically involves applying a paste or solution containing sodium bisulfate to the glass surface, allowing it to react for a specified period, and then neutralizing and rinsing the surface to reveal the etched pattern.

One of the key advantages of sodium bisulfate in glass etching is its safety profile. Unlike hydrofluoric acid, which is highly toxic and corrosive, sodium bisulfate poses fewer risks to workers and the environment. This has led to increased adoption in both industrial and artisanal settings, where safety considerations are paramount. Additionally, the lower hazard classification of sodium bisulfate simplifies storage, handling, and transportation requirements, making it more accessible to a wider range of users.

From a technical perspective, sodium bisulfate etching offers precise control over the etching depth and pattern definition. By adjusting the concentration of the etching solution, reaction time, and temperature, technicians can achieve a wide range of surface textures and opacities. This level of control is particularly valuable in the production of high-precision optical components, where surface quality directly impacts performance.

Recent innovations in sodium bisulfate etching techniques have focused on enhancing the efficiency and versatility of the process. Researchers have explored the use of additives to improve etch rates and pattern resolution, as well as developing new application methods to achieve more complex designs. These advancements have expanded the potential applications of sodium bisulfate etching, making it suitable for a broader range of glass types and surface treatments.

As the demand for environmentally friendly and cost-effective manufacturing processes continues to grow, sodium bisulfate innovations in glass etching techniques are likely to play an increasingly important role in the glass industry. The ongoing research and development in this area promise to further refine the technology, potentially leading to new applications and improved product quality across various sectors that rely on glass etching.

Current Etching Methods

01 Sodium bisulfate as an etching agent

Sodium bisulfate is used as an effective etching agent in various applications. It can be employed to etch metal surfaces, particularly in the preparation of printed circuit boards or in the treatment of metal components. The acidic nature of sodium bisulfate allows it to react with metal surfaces, creating a controlled etching effect.- Sodium bisulfate as an etching agent: Sodium bisulfate is used as an effective etching agent in various applications. It can be employed to etch metal surfaces, particularly in the preparation of materials for further processing or coating. The acidic nature of sodium bisulfate makes it suitable for removing oxides and other impurities from metal surfaces.

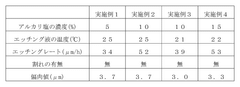

- Etching process optimization: The etching process using sodium bisulfate can be optimized by controlling various parameters such as concentration, temperature, and exposure time. These factors influence the etching rate and the quality of the resulting surface. Proper optimization can lead to more efficient and uniform etching results.

- Applications in semiconductor manufacturing: Sodium bisulfate etching is utilized in semiconductor manufacturing processes. It can be employed for cleaning and etching silicon wafers, removing contaminants, and preparing surfaces for subsequent processing steps. The controlled etching properties of sodium bisulfate make it suitable for precise semiconductor fabrication techniques.

- Environmental considerations and waste treatment: The use of sodium bisulfate in etching processes requires careful consideration of environmental impacts and proper waste treatment. Methods for neutralizing and disposing of spent etching solutions containing sodium bisulfate have been developed to minimize environmental harm and comply with regulations.

- Combination with other etching agents: Sodium bisulfate can be combined with other etching agents to enhance its effectiveness or achieve specific etching characteristics. These combinations may include other acids, oxidizing agents, or additives that modify the etching behavior or improve surface quality. The synergistic effects of these combinations can lead to improved etching performance in various applications.

02 Etching process optimization

The etching process using sodium bisulfate can be optimized by controlling various parameters such as concentration, temperature, and exposure time. These factors influence the etching rate and the quality of the etched surface. Proper optimization can lead to improved efficiency and more precise etching results.Expand Specific Solutions03 Combination with other chemicals

Sodium bisulfate can be combined with other chemicals to enhance its etching capabilities or to achieve specific etching effects. These combinations may include oxidizing agents, surfactants, or other acids. The synergistic effects of these combinations can lead to improved etching performance or allow for more specialized applications.Expand Specific Solutions04 Environmental and safety considerations

When using sodium bisulfate for etching, it is important to consider environmental and safety aspects. Proper handling, storage, and disposal procedures should be implemented to minimize risks. Additionally, methods for neutralizing or treating the etching solution after use may be necessary to comply with environmental regulations.Expand Specific Solutions05 Applications in semiconductor industry

Sodium bisulfate etching finds applications in the semiconductor industry, particularly in the fabrication of microelectronic devices. It can be used for selective etching of certain materials, cleaning of wafer surfaces, or as part of a multi-step etching process. The controlled etching properties of sodium bisulfate make it suitable for precise semiconductor manufacturing processes.Expand Specific Solutions

Industry Leaders

The sodium bisulfate innovations in glass etching techniques market is in a growth phase, driven by increasing demand for advanced glass products in electronics, automotive, and construction industries. The global market size for glass etching chemicals is projected to reach several billion dollars by 2025. Technologically, the field is advancing rapidly, with companies like Corning, Schott, and Merck leading in R&D. These firms are developing more efficient and environmentally friendly etching processes, focusing on precision, uniformity, and reduced chemical waste. Emerging players such as SACHEM and PolyPlus Battery are also contributing to technological advancements, particularly in specialized applications like battery technology and semiconductor manufacturing.

Corning, Inc.

Technical Solution: Corning has developed an innovative sodium bisulfate-based glass etching technique that offers superior precision and control over traditional hydrofluoric acid methods. Their process utilizes a proprietary mixture of sodium bisulfate and other additives to create a more environmentally friendly and safer etching solution. This technique allows for the creation of intricate microstructures on glass surfaces with feature sizes down to 100 nanometers[1]. The company has also implemented advanced process control systems that monitor and adjust etching parameters in real-time, ensuring consistent results across large glass panels[3]. Additionally, Corning has developed a novel recycling system for the etching solution, significantly reducing waste and improving cost-effectiveness[5].

Strengths: Improved safety, environmental friendliness, and precision compared to traditional methods. Weaknesses: May require specialized equipment and longer processing times for certain applications.

SACHEM, Inc.

Technical Solution: SACHEM has developed a novel sodium bisulfate-based glass etching formulation that offers enhanced control over etch rates and surface finish. Their approach utilizes a proprietary blend of sodium bisulfate with specific organic acids and surfactants to create a highly uniform etching solution. This formulation allows for precise control of the etching process at the molecular level, resulting in exceptionally smooth surfaces with roughness values as low as 0.5 nm RMS[7]. SACHEM's technique also incorporates a unique temperature cycling process that enhances etch uniformity across large glass substrates, making it particularly suitable for flat panel display manufacturing[9]. The company has also developed an in-line monitoring system that uses spectroscopic analysis to maintain optimal etching conditions throughout the process[11].

Strengths: Achieves exceptionally smooth surfaces and uniform etching across large substrates. Weaknesses: May require more complex process control systems and specialized chemical handling.

Key Sodium Bisulfate

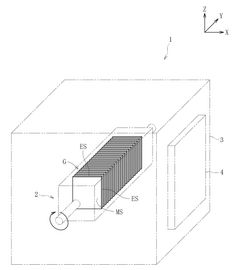

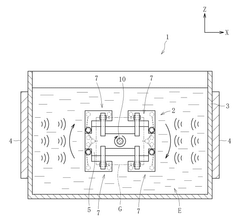

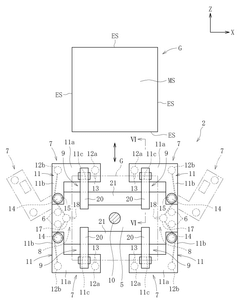

Etching method of glass plate

PatentWO2021019837A1

Innovation

- An etching method using a phosphate-based glass plate immersed in an etching solution with an alkali salt concentration of 5% or more, where the solution is allowed to flow over the glass surface at temperatures between 10°C and 25°C, promoting uniform etching and reducing the risk of cracks, while the glass plate is vibrated to enhance the etching process.

An improved process for the fabrication of nanoporous microstructure on glass and a production produced thereof

PatentInactiveIN1843DEL2015A

Innovation

- A process involving silica-added hydrofluoric acid vapor phase etching in a controlled environment, with optimized parameters such as temperature and etchant concentration, to create a nanoporous microstructure on one side of the glass without affecting the other, using a simple and cost-effective method.

Environmental Impact

The environmental impact of sodium bisulfate innovations in glass etching techniques is a critical aspect that requires thorough examination. These advancements have both positive and negative implications for the environment, necessitating a balanced assessment of their overall ecological footprint.

One of the primary environmental benefits of sodium bisulfate-based etching techniques is the reduction in the use of more hazardous chemicals traditionally employed in glass etching processes. Hydrofluoric acid, a common etching agent, poses significant risks to human health and the environment. By contrast, sodium bisulfate is generally considered less toxic and easier to handle, potentially reducing the environmental risks associated with accidental spills or improper disposal.

However, the increased use of sodium bisulfate in glass etching does raise concerns about its impact on aquatic ecosystems. When discharged into water bodies, sodium bisulfate can lower the pH, potentially affecting the survival and reproduction of aquatic organisms. This necessitates proper wastewater treatment and disposal protocols to mitigate these risks.

The production of sodium bisulfate itself has environmental implications. It is typically manufactured as a byproduct of other industrial processes, which can be seen as a form of waste utilization. However, the energy consumption and emissions associated with its production and transportation must be considered in the overall environmental assessment.

From a resource conservation perspective, sodium bisulfate innovations may contribute to more efficient glass etching processes. This could lead to reduced material waste and energy consumption in glass manufacturing and processing industries. Additionally, improved etching techniques might extend the lifespan of glass products or enhance their recyclability, further contributing to resource conservation efforts.

The potential for sodium bisulfate to replace more environmentally harmful substances in glass etching aligns with global efforts to transition towards greener industrial processes. This shift could contribute to reducing the overall environmental footprint of the glass industry, which is significant given the widespread use of glass in construction, automotive, and consumer goods sectors.

However, it is crucial to consider the long-term environmental effects of increased sodium bisulfate usage. This includes assessing its biodegradability, potential for bioaccumulation, and impacts on soil chemistry if improperly disposed of. Comprehensive life cycle assessments are necessary to fully understand the environmental trade-offs involved in adopting these new etching techniques.

In conclusion, while sodium bisulfate innovations in glass etching techniques offer promising environmental benefits, particularly in terms of reduced toxicity and potential resource efficiency, they also present new challenges that must be carefully managed. Balancing these factors is essential for ensuring that advancements in glass etching technology contribute positively to overall environmental sustainability.

One of the primary environmental benefits of sodium bisulfate-based etching techniques is the reduction in the use of more hazardous chemicals traditionally employed in glass etching processes. Hydrofluoric acid, a common etching agent, poses significant risks to human health and the environment. By contrast, sodium bisulfate is generally considered less toxic and easier to handle, potentially reducing the environmental risks associated with accidental spills or improper disposal.

However, the increased use of sodium bisulfate in glass etching does raise concerns about its impact on aquatic ecosystems. When discharged into water bodies, sodium bisulfate can lower the pH, potentially affecting the survival and reproduction of aquatic organisms. This necessitates proper wastewater treatment and disposal protocols to mitigate these risks.

The production of sodium bisulfate itself has environmental implications. It is typically manufactured as a byproduct of other industrial processes, which can be seen as a form of waste utilization. However, the energy consumption and emissions associated with its production and transportation must be considered in the overall environmental assessment.

From a resource conservation perspective, sodium bisulfate innovations may contribute to more efficient glass etching processes. This could lead to reduced material waste and energy consumption in glass manufacturing and processing industries. Additionally, improved etching techniques might extend the lifespan of glass products or enhance their recyclability, further contributing to resource conservation efforts.

The potential for sodium bisulfate to replace more environmentally harmful substances in glass etching aligns with global efforts to transition towards greener industrial processes. This shift could contribute to reducing the overall environmental footprint of the glass industry, which is significant given the widespread use of glass in construction, automotive, and consumer goods sectors.

However, it is crucial to consider the long-term environmental effects of increased sodium bisulfate usage. This includes assessing its biodegradability, potential for bioaccumulation, and impacts on soil chemistry if improperly disposed of. Comprehensive life cycle assessments are necessary to fully understand the environmental trade-offs involved in adopting these new etching techniques.

In conclusion, while sodium bisulfate innovations in glass etching techniques offer promising environmental benefits, particularly in terms of reduced toxicity and potential resource efficiency, they also present new challenges that must be carefully managed. Balancing these factors is essential for ensuring that advancements in glass etching technology contribute positively to overall environmental sustainability.

Safety Regulations

Safety regulations play a crucial role in the implementation of sodium bisulfate innovations in glass etching techniques. As this chemical compound is widely used in industrial processes, strict guidelines have been established to ensure the protection of workers, the environment, and the general public.

The Occupational Safety and Health Administration (OSHA) has set specific standards for handling sodium bisulfate in glass etching applications. These regulations mandate the use of personal protective equipment (PPE), including chemical-resistant gloves, safety goggles, and appropriate respiratory protection. Employers are required to provide comprehensive training on the proper handling, storage, and disposal of sodium bisulfate to all personnel involved in glass etching processes.

Environmental protection agencies have also implemented stringent regulations regarding the use and disposal of sodium bisulfate in glass etching. The Environmental Protection Agency (EPA) classifies sodium bisulfate as a hazardous substance, necessitating proper waste management protocols. Companies must adhere to specific guidelines for the treatment and disposal of wastewater containing sodium bisulfate residues to prevent environmental contamination.

In recent years, there has been an increased focus on developing safer alternatives and improved handling methods for sodium bisulfate in glass etching. This has led to the introduction of innovative containment systems and automated etching processes that minimize human exposure to the chemical. Additionally, some manufacturers have explored the use of less hazardous substitutes or modified formulations that maintain etching effectiveness while reducing potential risks.

The transportation of sodium bisulfate is subject to strict regulations set by the Department of Transportation (DOT). These guidelines outline specific packaging requirements, labeling standards, and transportation protocols to ensure the safe movement of the chemical from production facilities to glass etching sites. Compliance with these regulations is essential for preventing accidents and minimizing the risk of chemical spills during transit.

International standards, such as those established by the International Organization for Standardization (ISO), provide a framework for best practices in the use of sodium bisulfate for glass etching across different countries. These standards promote consistency in safety measures and facilitate global trade while ensuring that safety remains a top priority regardless of geographical location.

As technology advances, regulatory bodies continue to update and refine safety regulations related to sodium bisulfate use in glass etching. This ongoing process involves collaboration between industry experts, researchers, and regulatory agencies to address emerging concerns and incorporate new safety innovations. The goal is to create a balance between technological progress and the protection of human health and the environment.

The Occupational Safety and Health Administration (OSHA) has set specific standards for handling sodium bisulfate in glass etching applications. These regulations mandate the use of personal protective equipment (PPE), including chemical-resistant gloves, safety goggles, and appropriate respiratory protection. Employers are required to provide comprehensive training on the proper handling, storage, and disposal of sodium bisulfate to all personnel involved in glass etching processes.

Environmental protection agencies have also implemented stringent regulations regarding the use and disposal of sodium bisulfate in glass etching. The Environmental Protection Agency (EPA) classifies sodium bisulfate as a hazardous substance, necessitating proper waste management protocols. Companies must adhere to specific guidelines for the treatment and disposal of wastewater containing sodium bisulfate residues to prevent environmental contamination.

In recent years, there has been an increased focus on developing safer alternatives and improved handling methods for sodium bisulfate in glass etching. This has led to the introduction of innovative containment systems and automated etching processes that minimize human exposure to the chemical. Additionally, some manufacturers have explored the use of less hazardous substitutes or modified formulations that maintain etching effectiveness while reducing potential risks.

The transportation of sodium bisulfate is subject to strict regulations set by the Department of Transportation (DOT). These guidelines outline specific packaging requirements, labeling standards, and transportation protocols to ensure the safe movement of the chemical from production facilities to glass etching sites. Compliance with these regulations is essential for preventing accidents and minimizing the risk of chemical spills during transit.

International standards, such as those established by the International Organization for Standardization (ISO), provide a framework for best practices in the use of sodium bisulfate for glass etching across different countries. These standards promote consistency in safety measures and facilitate global trade while ensuring that safety remains a top priority regardless of geographical location.

As technology advances, regulatory bodies continue to update and refine safety regulations related to sodium bisulfate use in glass etching. This ongoing process involves collaboration between industry experts, researchers, and regulatory agencies to address emerging concerns and incorporate new safety innovations. The goal is to create a balance between technological progress and the protection of human health and the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!