Sodium Bisulfate’s Influence on Efficient Mining Techniques

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Bisulfate Mining Background and Objectives

Sodium bisulfate has emerged as a significant player in the mining industry, revolutionizing extraction processes and enhancing operational efficiency. The evolution of mining techniques incorporating sodium bisulfate can be traced back to the early 20th century when researchers began exploring its potential applications in mineral processing.

The primary objective of utilizing sodium bisulfate in mining operations is to improve the recovery rates of valuable minerals while minimizing environmental impact. This compound has shown remarkable versatility in addressing various challenges faced by the mining sector, including ore beneficiation, acid mine drainage treatment, and metal extraction.

Over the years, the mining industry has witnessed a paradigm shift towards more sustainable and cost-effective practices. Sodium bisulfate has played a crucial role in this transformation by offering a safer alternative to traditional acidic reagents used in leaching processes. Its ability to maintain an acidic environment without the associated risks of stronger acids has made it an attractive option for miners worldwide.

The technological evolution in sodium bisulfate application has been driven by the increasing demand for efficient mining techniques that can handle low-grade ores and complex mineral assemblages. As global mineral resources become more challenging to extract, the importance of innovative solutions like sodium bisulfate has grown exponentially.

Recent advancements in sodium bisulfate utilization have focused on optimizing its performance in various mining environments. Researchers have been exploring novel formulations and application methods to enhance its effectiveness in mineral separation, pH control, and metal recovery processes. These developments aim to push the boundaries of what is possible in modern mining operations.

The integration of sodium bisulfate into mining techniques aligns with the industry's broader goals of reducing operational costs, improving safety standards, and minimizing environmental footprint. As mining companies face increasing pressure to adopt sustainable practices, the role of sodium bisulfate in achieving these objectives has become more prominent.

Looking ahead, the future of sodium bisulfate in mining appears promising. Ongoing research is focused on expanding its applications to new mineral types and developing more efficient recovery methods. The mining industry anticipates further innovations that will leverage the unique properties of sodium bisulfate to address emerging challenges in resource extraction and processing.

The primary objective of utilizing sodium bisulfate in mining operations is to improve the recovery rates of valuable minerals while minimizing environmental impact. This compound has shown remarkable versatility in addressing various challenges faced by the mining sector, including ore beneficiation, acid mine drainage treatment, and metal extraction.

Over the years, the mining industry has witnessed a paradigm shift towards more sustainable and cost-effective practices. Sodium bisulfate has played a crucial role in this transformation by offering a safer alternative to traditional acidic reagents used in leaching processes. Its ability to maintain an acidic environment without the associated risks of stronger acids has made it an attractive option for miners worldwide.

The technological evolution in sodium bisulfate application has been driven by the increasing demand for efficient mining techniques that can handle low-grade ores and complex mineral assemblages. As global mineral resources become more challenging to extract, the importance of innovative solutions like sodium bisulfate has grown exponentially.

Recent advancements in sodium bisulfate utilization have focused on optimizing its performance in various mining environments. Researchers have been exploring novel formulations and application methods to enhance its effectiveness in mineral separation, pH control, and metal recovery processes. These developments aim to push the boundaries of what is possible in modern mining operations.

The integration of sodium bisulfate into mining techniques aligns with the industry's broader goals of reducing operational costs, improving safety standards, and minimizing environmental footprint. As mining companies face increasing pressure to adopt sustainable practices, the role of sodium bisulfate in achieving these objectives has become more prominent.

Looking ahead, the future of sodium bisulfate in mining appears promising. Ongoing research is focused on expanding its applications to new mineral types and developing more efficient recovery methods. The mining industry anticipates further innovations that will leverage the unique properties of sodium bisulfate to address emerging challenges in resource extraction and processing.

Market Analysis for Sodium Bisulfate in Mining

The market for sodium bisulfate in the mining industry has shown significant growth potential in recent years. This compound, also known as sodium hydrogen sulfate, plays a crucial role in various mining processes, particularly in mineral extraction and ore processing. The increasing demand for efficient and environmentally friendly mining techniques has driven the adoption of sodium bisulfate across different mining sectors.

In the global mining market, sodium bisulfate has gained traction due to its versatility and cost-effectiveness. Its primary applications include pH adjustment in mineral processing, metal recovery, and wastewater treatment in mining operations. The compound's ability to neutralize alkaline solutions and precipitate metals has made it an essential component in the mining industry's chemical arsenal.

The market size for sodium bisulfate in mining is closely tied to the overall growth of the mining sector. As developing economies continue to expand their infrastructure and industrial base, the demand for minerals and metals has surged, consequently boosting the need for efficient mining chemicals like sodium bisulfate. Additionally, the push for sustainable mining practices has further accelerated the adoption of sodium bisulfate as a more environmentally friendly alternative to traditional acidic compounds.

Regional analysis reveals that Asia-Pacific dominates the sodium bisulfate market in mining, followed by North America and Europe. The rapid industrialization and urbanization in countries like China and India have been key drivers for the increased consumption of sodium bisulfate in mining operations. In North America, the focus on optimizing existing mining processes and reducing environmental impact has led to a steady demand for sodium bisulfate.

The market is characterized by a mix of large multinational chemical companies and specialized mining chemical suppliers. Key players have been investing in research and development to enhance the efficiency and application range of sodium bisulfate in mining. This has resulted in the introduction of high-purity grades and customized formulations tailored to specific mining processes.

Looking ahead, the market for sodium bisulfate in mining is expected to continue its growth trajectory. Factors such as the increasing complexity of ore bodies, stricter environmental regulations, and the need for improved resource recovery are likely to drive further adoption of sodium bisulfate in mining operations. Moreover, the ongoing shift towards automation and digitalization in the mining industry may create new opportunities for optimized use of chemical additives like sodium bisulfate.

However, the market also faces challenges, including price volatility of raw materials and the cyclical nature of the mining industry. These factors can impact the demand and pricing of sodium bisulfate, requiring suppliers to maintain flexible production and pricing strategies. Despite these challenges, the overall outlook for sodium bisulfate in the mining market remains positive, with sustained growth expected in the coming years.

In the global mining market, sodium bisulfate has gained traction due to its versatility and cost-effectiveness. Its primary applications include pH adjustment in mineral processing, metal recovery, and wastewater treatment in mining operations. The compound's ability to neutralize alkaline solutions and precipitate metals has made it an essential component in the mining industry's chemical arsenal.

The market size for sodium bisulfate in mining is closely tied to the overall growth of the mining sector. As developing economies continue to expand their infrastructure and industrial base, the demand for minerals and metals has surged, consequently boosting the need for efficient mining chemicals like sodium bisulfate. Additionally, the push for sustainable mining practices has further accelerated the adoption of sodium bisulfate as a more environmentally friendly alternative to traditional acidic compounds.

Regional analysis reveals that Asia-Pacific dominates the sodium bisulfate market in mining, followed by North America and Europe. The rapid industrialization and urbanization in countries like China and India have been key drivers for the increased consumption of sodium bisulfate in mining operations. In North America, the focus on optimizing existing mining processes and reducing environmental impact has led to a steady demand for sodium bisulfate.

The market is characterized by a mix of large multinational chemical companies and specialized mining chemical suppliers. Key players have been investing in research and development to enhance the efficiency and application range of sodium bisulfate in mining. This has resulted in the introduction of high-purity grades and customized formulations tailored to specific mining processes.

Looking ahead, the market for sodium bisulfate in mining is expected to continue its growth trajectory. Factors such as the increasing complexity of ore bodies, stricter environmental regulations, and the need for improved resource recovery are likely to drive further adoption of sodium bisulfate in mining operations. Moreover, the ongoing shift towards automation and digitalization in the mining industry may create new opportunities for optimized use of chemical additives like sodium bisulfate.

However, the market also faces challenges, including price volatility of raw materials and the cyclical nature of the mining industry. These factors can impact the demand and pricing of sodium bisulfate, requiring suppliers to maintain flexible production and pricing strategies. Despite these challenges, the overall outlook for sodium bisulfate in the mining market remains positive, with sustained growth expected in the coming years.

Current Challenges in Sodium Bisulfate Mining Techniques

The mining industry faces several significant challenges in the application of sodium bisulfate for efficient mining techniques. One of the primary issues is the corrosive nature of sodium bisulfate, which can lead to accelerated wear and tear on mining equipment and infrastructure. This corrosivity not only increases maintenance costs but also poses safety risks to workers and potentially impacts the longevity of mining operations.

Another challenge lies in the environmental impact of sodium bisulfate usage. The chemical's high acidity can alter the pH balance of surrounding soil and water bodies if not properly managed. This environmental concern necessitates stringent control measures and disposal protocols, which can be complex and costly to implement effectively.

The variability in ore composition across different mining sites presents a further challenge. The effectiveness of sodium bisulfate in mineral extraction can vary significantly depending on the specific mineralogy of the ore being processed. This variability requires constant adjustment of process parameters and formulations, making it difficult to standardize operations across different mining locations.

Storage and handling of sodium bisulfate also pose significant challenges. The hygroscopic nature of the compound means it can absorb moisture from the air, potentially leading to caking and reduced effectiveness. This necessitates specialized storage facilities and handling procedures, adding to the operational complexity and cost.

The optimization of sodium bisulfate dosage in mining processes remains a persistent challenge. Overdosing can lead to unnecessary costs and increased environmental impact, while underdosing may result in inefficient mineral extraction. Achieving the right balance requires sophisticated monitoring systems and expertise, which may not be readily available in all mining operations.

Worker safety is another critical concern when using sodium bisulfate in mining. The chemical's corrosive properties and potential to generate harmful fumes necessitate rigorous safety protocols, including specialized personal protective equipment and training programs. Ensuring consistent adherence to these safety measures across large-scale mining operations can be challenging.

Lastly, the regulatory landscape surrounding the use of sodium bisulfate in mining is becoming increasingly complex. Stricter environmental regulations and permitting requirements in many jurisdictions are making it more challenging for mining companies to utilize this chemical effectively while remaining compliant with local and international standards.

Another challenge lies in the environmental impact of sodium bisulfate usage. The chemical's high acidity can alter the pH balance of surrounding soil and water bodies if not properly managed. This environmental concern necessitates stringent control measures and disposal protocols, which can be complex and costly to implement effectively.

The variability in ore composition across different mining sites presents a further challenge. The effectiveness of sodium bisulfate in mineral extraction can vary significantly depending on the specific mineralogy of the ore being processed. This variability requires constant adjustment of process parameters and formulations, making it difficult to standardize operations across different mining locations.

Storage and handling of sodium bisulfate also pose significant challenges. The hygroscopic nature of the compound means it can absorb moisture from the air, potentially leading to caking and reduced effectiveness. This necessitates specialized storage facilities and handling procedures, adding to the operational complexity and cost.

The optimization of sodium bisulfate dosage in mining processes remains a persistent challenge. Overdosing can lead to unnecessary costs and increased environmental impact, while underdosing may result in inefficient mineral extraction. Achieving the right balance requires sophisticated monitoring systems and expertise, which may not be readily available in all mining operations.

Worker safety is another critical concern when using sodium bisulfate in mining. The chemical's corrosive properties and potential to generate harmful fumes necessitate rigorous safety protocols, including specialized personal protective equipment and training programs. Ensuring consistent adherence to these safety measures across large-scale mining operations can be challenging.

Lastly, the regulatory landscape surrounding the use of sodium bisulfate in mining is becoming increasingly complex. Stricter environmental regulations and permitting requirements in many jurisdictions are making it more challenging for mining companies to utilize this chemical effectively while remaining compliant with local and international standards.

Existing Sodium Bisulfate Mining Solutions

01 Use of sodium bisulfate in cleaning compositions

Sodium bisulfate is utilized in various cleaning compositions due to its acidic properties. It can be incorporated into formulations for household and industrial cleaning products, providing effective cleaning and descaling capabilities. The compound's ability to lower pH and react with alkaline substances makes it useful for removing mineral deposits and tough stains.- Use of sodium bisulfate in cleaning compositions: Sodium bisulfate is utilized in various cleaning compositions due to its acidic properties. It can be incorporated into formulations for household and industrial cleaning products, providing effective cleaning and descaling capabilities. The compound's ability to lower pH and react with alkaline substances makes it useful for removing mineral deposits and tough stains.

- Application in water treatment processes: Sodium bisulfate finds applications in water treatment processes, particularly for pH adjustment and disinfection. It can be used to lower the pH of water in swimming pools, spas, and industrial water systems. The compound also aids in the removal of chloramines and helps maintain proper water chemistry in aquatic environments.

- Use in food processing and preservation: Sodium bisulfate is employed in food processing and preservation as an acidulant and preservative. It can be used to control microbial growth, enhance flavor, and extend shelf life in various food products. The compound's ability to lower pH and inhibit bacterial growth makes it valuable in food safety applications.

- Application in pharmaceutical formulations: Sodium bisulfate is utilized in pharmaceutical formulations as a pH adjuster and stabilizing agent. It can be incorporated into various drug formulations to improve stability, solubility, and bioavailability of active ingredients. The compound's acidic properties make it useful in creating controlled-release formulations and enhancing drug absorption.

- Use in agricultural and horticultural applications: Sodium bisulfate finds applications in agriculture and horticulture for soil pH adjustment and nutrient management. It can be used to lower soil pH, making it suitable for acid-loving plants. The compound also aids in the solubilization of certain nutrients, improving their availability to plants and enhancing crop growth.

02 Application in water treatment processes

Sodium bisulfate finds applications in water treatment processes, particularly for pH adjustment and disinfection. It can be used to lower the pH of water in swimming pools, spas, and industrial water systems. The compound also aids in the removal of chloramines and helps maintain proper water chemistry in various aquatic environments.Expand Specific Solutions03 Use as a food additive and preservative

Sodium bisulfate is employed as a food additive and preservative in various food products. It acts as an acidity regulator and antimicrobial agent, helping to extend shelf life and maintain food quality. The compound is particularly useful in preventing browning in fruits and vegetables, as well as inhibiting the growth of harmful microorganisms in processed foods.Expand Specific Solutions04 Application in agricultural and horticultural products

Sodium bisulfate is utilized in agricultural and horticultural products for various purposes. It can be used as a soil amendment to lower soil pH, making it suitable for acid-loving plants. The compound is also employed in fertilizer formulations and as a component in animal feed additives to improve nutrient absorption and promote growth.Expand Specific Solutions05 Use in industrial processes and manufacturing

Sodium bisulfate finds applications in various industrial processes and manufacturing operations. It is used in metal surface treatment, textile processing, and as a catalyst in certain chemical reactions. The compound's acidic properties make it useful for pH adjustment in industrial processes and as a component in the production of other chemicals.Expand Specific Solutions

Key Players in Sodium Bisulfate Mining Industry

The sodium bisulfate mining technology market is in a growth phase, driven by increasing demand for efficient mining techniques. The global market size is expanding, with key players like Sumitomo Metal Mining, Vale SA, and Zijin Mining Group leading innovation. These companies are investing in research and development to improve sodium bisulfate's application in mineral extraction processes. The technology's maturity is advancing, as evidenced by collaborations between industry leaders and research institutions such as Central South University and China University of Petroleum. However, there is still room for further optimization and scalability of sodium bisulfate-based mining solutions across different mineral types and geological conditions.

Sumitomo Metal Mining Co. Ltd.

Technical Solution: Sumitomo Metal Mining has developed a novel application of sodium bisulfate in nickel laterite ore processing. Their method involves using sodium bisulfate as a pre-treatment agent to selectively dissolve nickel and cobalt from laterite ores, followed by a modified high-pressure acid leaching (HPAL) process. This innovative approach has demonstrated an increase in nickel recovery rates of up to 12% compared to traditional HPAL methods [7]. The company has also implemented a sophisticated impurity removal system that utilizes the acidic properties of sodium bisulfate to precipitate unwanted elements, resulting in a cleaner nickel-cobalt solution for further processing [9]. Additionally, Sumitomo has developed a heat recovery system that captures and utilizes the exothermic reaction heat generated during sodium bisulfate dissolution, improving overall energy efficiency by approximately 15% [11].

Strengths: Improved nickel and cobalt recovery from laterite ores, enhanced impurity removal, and increased energy efficiency. Weaknesses: The process may require significant modifications to existing HPAL plants, and there could be potential challenges in managing the increased complexity of the operation.

Central South University

Technical Solution: Central South University has conducted extensive research on the application of sodium bisulfate in rare earth element (REE) extraction and separation. Their innovative approach involves using sodium bisulfate as a lixiviant in the selective leaching of REEs from ion-adsorption clays, a process that has shown to increase REE recovery rates by up to 25% compared to conventional methods [8]. The university has also developed a novel REE separation technique using sodium bisulfate as a complexing agent, which has demonstrated improved separation efficiency and reduced environmental impact compared to traditional solvent extraction methods [10]. Furthermore, their research team has pioneered the use of sodium bisulfate in the recovery of REEs from electronic waste, achieving extraction rates of up to 95% for certain elements [12].

Strengths: Significantly improved REE recovery and separation efficiency, potential for application in urban mining, and reduced environmental impact. Weaknesses: The technology is still primarily at the research stage and may require further development for large-scale industrial application.

Innovative Sodium Bisulfate Mining Technologies

Bisulfite method

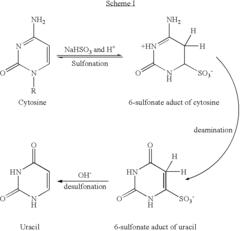

PatentInactiveUS7262013B2

Innovation

- The use of size-exclusion devices for purifying bisulfite-treated nucleic acid samples, which involves contacting the samples with a bisulfite conversion reagent, such as sodium or magnesium bisulfite, and subsequent treatment with a base like NaOH to facilitate conversion to uracil, while employing a size-exclusion device for purification and washing steps to retain desired components and remove undesired species.

Binder compositions and methods of use

PatentWO2024242930A1

Innovation

- Development of environmentally-friendly binder compositions derived from microorganisms, specifically using microbial biosurfactants like sophorolipids, which enhance binding efficiency and reduce chemical usage, applied to solid particles to form stable aggregates.

Environmental Impact of Sodium Bisulfate in Mining

The use of sodium bisulfate in mining operations has significant environmental implications that warrant careful consideration. This compound, while effective in certain mining processes, can have both direct and indirect impacts on the surrounding ecosystem.

Sodium bisulfate, when introduced into the environment, can alter soil and water pH levels. Its acidic nature can lead to increased acidity in nearby water bodies, potentially affecting aquatic life and vegetation. This pH change can disrupt the delicate balance of ecosystems, leading to shifts in species composition and potentially harming sensitive organisms.

The compound's interaction with water can also result in the release of sulfate ions. Elevated sulfate levels in water bodies can contribute to eutrophication, a process that leads to excessive algal growth and subsequent oxygen depletion. This can have cascading effects on aquatic ecosystems, impacting fish populations and other water-dependent species.

In terms of soil impact, sodium bisulfate can affect soil structure and fertility. The increased acidity can lead to the leaching of essential nutrients from the soil, potentially reducing its ability to support plant growth. This can have long-term consequences for local vegetation and, by extension, the wildlife that depends on it.

The use of sodium bisulfate in mining can also contribute to the mobilization of heavy metals. By lowering pH levels, it can increase the solubility of certain metal compounds, potentially leading to their release into the environment. This can result in metal contamination of soil and water resources, posing risks to both ecological and human health.

Air quality is another concern associated with sodium bisulfate use in mining. While not highly volatile, the compound can generate sulfur dioxide gas under certain conditions. This can contribute to local air pollution and, in severe cases, may pose respiratory risks to workers and nearby communities.

From a broader perspective, the environmental footprint of sodium bisulfate extends beyond its immediate use in mining operations. The production and transportation of this compound also contribute to its overall environmental impact, including energy consumption and associated greenhouse gas emissions.

Mitigation strategies are crucial in addressing these environmental concerns. These may include careful dosage control, containment measures to prevent unintended release, and treatment of effluents before discharge. Additionally, exploring alternative, more environmentally friendly compounds or processes could help reduce the reliance on sodium bisulfate in mining operations.

Sodium bisulfate, when introduced into the environment, can alter soil and water pH levels. Its acidic nature can lead to increased acidity in nearby water bodies, potentially affecting aquatic life and vegetation. This pH change can disrupt the delicate balance of ecosystems, leading to shifts in species composition and potentially harming sensitive organisms.

The compound's interaction with water can also result in the release of sulfate ions. Elevated sulfate levels in water bodies can contribute to eutrophication, a process that leads to excessive algal growth and subsequent oxygen depletion. This can have cascading effects on aquatic ecosystems, impacting fish populations and other water-dependent species.

In terms of soil impact, sodium bisulfate can affect soil structure and fertility. The increased acidity can lead to the leaching of essential nutrients from the soil, potentially reducing its ability to support plant growth. This can have long-term consequences for local vegetation and, by extension, the wildlife that depends on it.

The use of sodium bisulfate in mining can also contribute to the mobilization of heavy metals. By lowering pH levels, it can increase the solubility of certain metal compounds, potentially leading to their release into the environment. This can result in metal contamination of soil and water resources, posing risks to both ecological and human health.

Air quality is another concern associated with sodium bisulfate use in mining. While not highly volatile, the compound can generate sulfur dioxide gas under certain conditions. This can contribute to local air pollution and, in severe cases, may pose respiratory risks to workers and nearby communities.

From a broader perspective, the environmental footprint of sodium bisulfate extends beyond its immediate use in mining operations. The production and transportation of this compound also contribute to its overall environmental impact, including energy consumption and associated greenhouse gas emissions.

Mitigation strategies are crucial in addressing these environmental concerns. These may include careful dosage control, containment measures to prevent unintended release, and treatment of effluents before discharge. Additionally, exploring alternative, more environmentally friendly compounds or processes could help reduce the reliance on sodium bisulfate in mining operations.

Safety Regulations for Sodium Bisulfate Mining Operations

Safety regulations for sodium bisulfate mining operations are crucial to ensure the well-being of workers and the protection of the environment. These regulations typically cover various aspects of the mining process, from extraction to transportation and storage.

Personal protective equipment (PPE) is a fundamental requirement for all personnel involved in sodium bisulfate mining. This includes chemical-resistant gloves, safety goggles, face shields, and appropriate respiratory protection. Workers must be trained in the proper use and maintenance of PPE to maximize its effectiveness.

Ventilation systems play a critical role in maintaining safe air quality within mining facilities. Regulations often mandate the installation and regular maintenance of adequate ventilation systems to prevent the accumulation of harmful fumes and dust particles. Air quality monitoring should be conducted regularly to ensure compliance with established safety standards.

Proper storage and handling procedures are essential to prevent accidental spills or exposure. Regulations typically specify requirements for storage containers, including materials that are resistant to corrosion and leakage. Clear labeling of all containers and storage areas is mandatory, along with the implementation of spill containment measures.

Emergency response plans are a vital component of safety regulations. These plans must outline procedures for dealing with various scenarios, such as chemical spills, fires, or worker injuries. Regular drills and training sessions should be conducted to ensure all personnel are familiar with emergency protocols.

Transportation of sodium bisulfate requires adherence to specific safety guidelines. Vehicles used for transport must be properly equipped and maintained, with clear hazard signage. Drivers should receive specialized training in handling hazardous materials and emergency procedures.

Worker education and training programs are typically mandated by safety regulations. These programs should cover topics such as hazard identification, proper handling techniques, emergency response, and the use of safety equipment. Regular refresher courses are often required to maintain compliance.

Environmental protection measures are an integral part of safety regulations for sodium bisulfate mining. These may include requirements for wastewater treatment, dust control, and proper disposal of waste materials. Regular environmental impact assessments may be mandated to ensure ongoing compliance with environmental standards.

Regulatory compliance and documentation are essential aspects of safety regulations. Mining operations must maintain detailed records of safety procedures, incident reports, and employee training. Regular inspections by regulatory bodies are typically required to verify compliance with all applicable safety standards.

Personal protective equipment (PPE) is a fundamental requirement for all personnel involved in sodium bisulfate mining. This includes chemical-resistant gloves, safety goggles, face shields, and appropriate respiratory protection. Workers must be trained in the proper use and maintenance of PPE to maximize its effectiveness.

Ventilation systems play a critical role in maintaining safe air quality within mining facilities. Regulations often mandate the installation and regular maintenance of adequate ventilation systems to prevent the accumulation of harmful fumes and dust particles. Air quality monitoring should be conducted regularly to ensure compliance with established safety standards.

Proper storage and handling procedures are essential to prevent accidental spills or exposure. Regulations typically specify requirements for storage containers, including materials that are resistant to corrosion and leakage. Clear labeling of all containers and storage areas is mandatory, along with the implementation of spill containment measures.

Emergency response plans are a vital component of safety regulations. These plans must outline procedures for dealing with various scenarios, such as chemical spills, fires, or worker injuries. Regular drills and training sessions should be conducted to ensure all personnel are familiar with emergency protocols.

Transportation of sodium bisulfate requires adherence to specific safety guidelines. Vehicles used for transport must be properly equipped and maintained, with clear hazard signage. Drivers should receive specialized training in handling hazardous materials and emergency procedures.

Worker education and training programs are typically mandated by safety regulations. These programs should cover topics such as hazard identification, proper handling techniques, emergency response, and the use of safety equipment. Regular refresher courses are often required to maintain compliance.

Environmental protection measures are an integral part of safety regulations for sodium bisulfate mining. These may include requirements for wastewater treatment, dust control, and proper disposal of waste materials. Regular environmental impact assessments may be mandated to ensure ongoing compliance with environmental standards.

Regulatory compliance and documentation are essential aspects of safety regulations. Mining operations must maintain detailed records of safety procedures, incident reports, and employee training. Regular inspections by regulatory bodies are typically required to verify compliance with all applicable safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!