Sound quality enhancements in LM7 engine exhaust setups

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Exhaust Sound Evolution

The LM7 engine, a member of the GM LS engine family, has undergone significant evolution in its exhaust sound quality since its introduction in 1999. Initially designed for trucks and SUVs, the LM7's exhaust note was primarily focused on functionality rather than acoustic appeal. However, as automotive enthusiasts began to recognize the engine's potential, a growing demand for enhanced sound quality emerged.

In the early 2000s, aftermarket exhaust manufacturers started developing systems specifically tailored for the LM7. These early modifications primarily focused on increasing exhaust flow and reducing backpressure, which inadvertently resulted in a louder, more aggressive exhaust note. While popular among some enthusiasts, these systems often lacked refinement and could produce excessive drone at highway speeds.

As technology advanced, exhaust manufacturers began incorporating more sophisticated sound engineering techniques. By the mid-2000s, computer-aided design and flow simulation software allowed for more precise tuning of exhaust systems. This led to the development of exhaust setups that could enhance the LM7's natural V8 rumble while minimizing undesirable frequencies.

The late 2000s saw a shift towards variable exhaust systems for the LM7. These setups utilized vacuum-operated or electronically controlled valves to alter exhaust flow and sound characteristics based on driving conditions. This innovation allowed for a quieter, more subdued exhaust note during normal driving, with the ability to produce a more aggressive sound under heavy acceleration or at the driver's discretion.

In the 2010s, advancements in materials science contributed significantly to LM7 exhaust sound evolution. High-grade stainless steel and titanium alloys were increasingly used in premium exhaust systems, offering improved durability and unique tonal qualities. Additionally, the integration of resonators and Helmholtz chambers allowed for fine-tuning of specific frequencies, resulting in a more refined and balanced exhaust note.

Recent years have seen a focus on active sound design for LM7 exhaust setups. This approach combines traditional exhaust system engineering with electronic sound enhancement. By utilizing in-cabin speakers and sophisticated algorithms, these systems can augment the natural exhaust sound, providing a more immersive auditory experience for drivers and passengers alike.

Throughout this evolution, there has been a consistent trend towards achieving a balance between performance, sound quality, and regulatory compliance. Modern LM7 exhaust setups strive to deliver an engaging auditory experience while meeting increasingly stringent noise and emissions standards. This ongoing development continues to push the boundaries of exhaust technology, ensuring that the LM7 engine remains a favorite among enthusiasts seeking both performance and acoustic satisfaction.

In the early 2000s, aftermarket exhaust manufacturers started developing systems specifically tailored for the LM7. These early modifications primarily focused on increasing exhaust flow and reducing backpressure, which inadvertently resulted in a louder, more aggressive exhaust note. While popular among some enthusiasts, these systems often lacked refinement and could produce excessive drone at highway speeds.

As technology advanced, exhaust manufacturers began incorporating more sophisticated sound engineering techniques. By the mid-2000s, computer-aided design and flow simulation software allowed for more precise tuning of exhaust systems. This led to the development of exhaust setups that could enhance the LM7's natural V8 rumble while minimizing undesirable frequencies.

The late 2000s saw a shift towards variable exhaust systems for the LM7. These setups utilized vacuum-operated or electronically controlled valves to alter exhaust flow and sound characteristics based on driving conditions. This innovation allowed for a quieter, more subdued exhaust note during normal driving, with the ability to produce a more aggressive sound under heavy acceleration or at the driver's discretion.

In the 2010s, advancements in materials science contributed significantly to LM7 exhaust sound evolution. High-grade stainless steel and titanium alloys were increasingly used in premium exhaust systems, offering improved durability and unique tonal qualities. Additionally, the integration of resonators and Helmholtz chambers allowed for fine-tuning of specific frequencies, resulting in a more refined and balanced exhaust note.

Recent years have seen a focus on active sound design for LM7 exhaust setups. This approach combines traditional exhaust system engineering with electronic sound enhancement. By utilizing in-cabin speakers and sophisticated algorithms, these systems can augment the natural exhaust sound, providing a more immersive auditory experience for drivers and passengers alike.

Throughout this evolution, there has been a consistent trend towards achieving a balance between performance, sound quality, and regulatory compliance. Modern LM7 exhaust setups strive to deliver an engaging auditory experience while meeting increasingly stringent noise and emissions standards. This ongoing development continues to push the boundaries of exhaust technology, ensuring that the LM7 engine remains a favorite among enthusiasts seeking both performance and acoustic satisfaction.

Market Demand Analysis

The market demand for sound quality enhancements in LM7 engine exhaust setups has been steadily growing in recent years. This trend is driven by several factors, including increasing consumer expectations for vehicle performance and comfort, stricter noise regulations, and the automotive industry's focus on differentiation through sound engineering.

In the performance vehicle segment, enthusiasts are seeking exhaust systems that not only improve engine output but also deliver a satisfying auditory experience. The LM7 engine, commonly found in GM trucks and SUVs, has a large aftermarket following, with owners looking to enhance both performance and sound characteristics. This has led to a surge in demand for high-quality exhaust components and systems specifically designed for LM7 applications.

The luxury vehicle market has also been a significant driver of sound quality enhancement technologies. Manufacturers are investing heavily in active sound design and noise cancellation systems to create unique and premium audio experiences for their customers. This trend is gradually trickling down to mid-range vehicles, expanding the potential market for LM7 engine sound enhancements.

Environmental regulations and noise pollution concerns have paradoxically contributed to the demand for sound quality improvements. As vehicles are required to meet stricter noise emission standards, manufacturers are turning to advanced exhaust technologies that can maintain performance while reducing overall noise levels. This has created a market for sophisticated muffler designs and electronic sound management systems compatible with LM7 engines.

The automotive aftermarket industry has responded to this demand by developing a wide range of products, from performance exhaust systems to electronic sound modulators. These products cater to various consumer preferences, from those seeking a more aggressive engine note to those desiring a quieter, more refined driving experience.

Market research indicates that the global automotive exhaust system market is expected to grow significantly in the coming years, with a substantial portion attributed to sound quality enhancements. The LM7 engine segment, given its popularity in North American markets, is poised to capture a notable share of this growth.

Furthermore, the rise of electric and hybrid vehicles has created a unique opportunity for sound enhancement technologies in traditional combustion engines like the LM7. As these quieter alternatives become more prevalent, there is a growing appreciation for the distinctive sound of well-tuned gasoline engines, driving demand for exhaust systems that can deliver an optimal acoustic signature.

In the performance vehicle segment, enthusiasts are seeking exhaust systems that not only improve engine output but also deliver a satisfying auditory experience. The LM7 engine, commonly found in GM trucks and SUVs, has a large aftermarket following, with owners looking to enhance both performance and sound characteristics. This has led to a surge in demand for high-quality exhaust components and systems specifically designed for LM7 applications.

The luxury vehicle market has also been a significant driver of sound quality enhancement technologies. Manufacturers are investing heavily in active sound design and noise cancellation systems to create unique and premium audio experiences for their customers. This trend is gradually trickling down to mid-range vehicles, expanding the potential market for LM7 engine sound enhancements.

Environmental regulations and noise pollution concerns have paradoxically contributed to the demand for sound quality improvements. As vehicles are required to meet stricter noise emission standards, manufacturers are turning to advanced exhaust technologies that can maintain performance while reducing overall noise levels. This has created a market for sophisticated muffler designs and electronic sound management systems compatible with LM7 engines.

The automotive aftermarket industry has responded to this demand by developing a wide range of products, from performance exhaust systems to electronic sound modulators. These products cater to various consumer preferences, from those seeking a more aggressive engine note to those desiring a quieter, more refined driving experience.

Market research indicates that the global automotive exhaust system market is expected to grow significantly in the coming years, with a substantial portion attributed to sound quality enhancements. The LM7 engine segment, given its popularity in North American markets, is poised to capture a notable share of this growth.

Furthermore, the rise of electric and hybrid vehicles has created a unique opportunity for sound enhancement technologies in traditional combustion engines like the LM7. As these quieter alternatives become more prevalent, there is a growing appreciation for the distinctive sound of well-tuned gasoline engines, driving demand for exhaust systems that can deliver an optimal acoustic signature.

Current Challenges

The current challenges in sound quality enhancements for LM7 engine exhaust setups are multifaceted and complex. One of the primary obstacles is achieving an optimal balance between performance and noise reduction. As emissions regulations become increasingly stringent, manufacturers must find innovative ways to maintain engine efficiency while simultaneously reducing exhaust noise levels.

Another significant challenge lies in the inherent design limitations of the LM7 engine. The V8 configuration, while powerful, presents unique acoustic properties that can be difficult to manage. The firing order and exhaust pulse timing contribute to a distinctive sound signature that enthusiasts often desire, but which may not align with noise regulations or consumer preferences for quieter vehicles.

Material selection poses an additional hurdle in exhaust system design. Traditional materials like stainless steel offer durability but may not provide the ideal acoustic properties for sound enhancement. Advanced materials such as titanium or inconel alloys show promise but come with increased costs and manufacturing complexities.

The integration of active noise control systems presents both opportunities and challenges. While these systems can effectively reduce unwanted frequencies, they add complexity to the exhaust setup, increase overall system weight, and may impact fuel efficiency. Moreover, tuning these systems to work seamlessly across various driving conditions and engine loads remains a significant technical challenge.

Packaging constraints within modern vehicle designs further complicate exhaust system enhancements. As vehicles become more compact and aerodynamic, finding adequate space for larger mufflers or resonators becomes increasingly difficult. This spatial limitation often forces engineers to compromise between sound quality and overall vehicle design.

The subjective nature of sound quality adds another layer of complexity to the enhancement process. What constitutes a desirable exhaust note can vary greatly among consumers, making it challenging to develop a universally appealing sound profile. This subjectivity necessitates extensive market research and consumer testing, which can be time-consuming and costly.

Lastly, the advent of electric and hybrid vehicles has shifted industry focus, potentially limiting resources and innovation in traditional combustion engine exhaust systems. This shift may result in reduced investment in LM7 engine exhaust enhancements, making it more challenging to address existing sound quality issues.

Another significant challenge lies in the inherent design limitations of the LM7 engine. The V8 configuration, while powerful, presents unique acoustic properties that can be difficult to manage. The firing order and exhaust pulse timing contribute to a distinctive sound signature that enthusiasts often desire, but which may not align with noise regulations or consumer preferences for quieter vehicles.

Material selection poses an additional hurdle in exhaust system design. Traditional materials like stainless steel offer durability but may not provide the ideal acoustic properties for sound enhancement. Advanced materials such as titanium or inconel alloys show promise but come with increased costs and manufacturing complexities.

The integration of active noise control systems presents both opportunities and challenges. While these systems can effectively reduce unwanted frequencies, they add complexity to the exhaust setup, increase overall system weight, and may impact fuel efficiency. Moreover, tuning these systems to work seamlessly across various driving conditions and engine loads remains a significant technical challenge.

Packaging constraints within modern vehicle designs further complicate exhaust system enhancements. As vehicles become more compact and aerodynamic, finding adequate space for larger mufflers or resonators becomes increasingly difficult. This spatial limitation often forces engineers to compromise between sound quality and overall vehicle design.

The subjective nature of sound quality adds another layer of complexity to the enhancement process. What constitutes a desirable exhaust note can vary greatly among consumers, making it challenging to develop a universally appealing sound profile. This subjectivity necessitates extensive market research and consumer testing, which can be time-consuming and costly.

Lastly, the advent of electric and hybrid vehicles has shifted industry focus, potentially limiting resources and innovation in traditional combustion engine exhaust systems. This shift may result in reduced investment in LM7 engine exhaust enhancements, making it more challenging to address existing sound quality issues.

Existing Sound Solutions

01 Exhaust system design for sound quality

The design of the exhaust system plays a crucial role in determining the sound quality of the LM7 engine. This includes the configuration of pipes, mufflers, and resonators to achieve the desired acoustic characteristics. Proper design can enhance the engine's sound while meeting noise regulations.- Exhaust system design for sound quality: The design of the exhaust system plays a crucial role in determining the sound quality of the LM7 engine. This includes the configuration of pipes, mufflers, and resonators to achieve the desired acoustic characteristics. Proper design can enhance the engine's sound while meeting noise regulations.

- Active noise control systems: Implementation of active noise control systems can significantly improve the sound quality of the LM7 engine exhaust. These systems use electronic components to generate sound waves that cancel out unwanted noise, allowing for a more refined and controlled exhaust note.

- Tuning exhaust components for optimal sound: Careful tuning of exhaust components such as resonators, baffles, and chambers can enhance the sound quality of the LM7 engine. This involves adjusting the dimensions and materials of these components to achieve the desired frequency response and tonal characteristics.

- Variable exhaust systems: Incorporating variable exhaust systems allows for dynamic control of the LM7 engine's sound quality. These systems can adjust the exhaust flow and acoustics based on engine speed, load, or driver preferences, providing a range of sound profiles from quiet to sporty.

- Material selection for exhaust components: The choice of materials for exhaust components significantly impacts the sound quality of the LM7 engine. Using materials with specific acoustic properties, such as stainless steel or titanium, can enhance sound characteristics while also improving durability and performance.

02 Electronic sound enhancement

Electronic systems can be used to modify and enhance the exhaust sound of the LM7 engine. These systems may include active noise control, sound generators, or audio processing techniques to create a more desirable engine sound profile without physical modifications to the exhaust system.Expand Specific Solutions03 Muffler and resonator tuning

Specific tuning of mufflers and resonators can significantly impact the sound quality of the LM7 engine exhaust. This involves adjusting the internal structure, materials, and dimensions of these components to achieve the desired tone, volume, and frequency characteristics of the exhaust note.Expand Specific Solutions04 Variable exhaust systems

Implementing variable exhaust systems allows for dynamic control of the LM7 engine's sound quality. These systems may include adjustable valves or flaps that can alter the exhaust flow path or backpressure, enabling different sound profiles based on driving conditions or user preferences.Expand Specific Solutions05 Material selection for exhaust components

The choice of materials for exhaust system components can significantly affect the sound quality of the LM7 engine. Different materials, such as stainless steel, titanium, or composite materials, can influence the acoustic properties, heat dissipation, and overall performance of the exhaust system.Expand Specific Solutions

Key Industry Players

The sound quality enhancement market for LM7 engine exhaust setups is in a mature stage, with a significant global market size driven by increasing demand for high-performance automotive solutions. The technology has reached a high level of sophistication, with key players like Tenneco GmbH, Faurecia Emissions Control Technologies, and Ford Global Technologies leading innovation. These companies, along with others such as Toyota Motor Corp. and BMW AG, are continuously refining their offerings to meet stringent emissions standards while improving sound quality. The competitive landscape is characterized by a mix of established automotive giants and specialized exhaust system manufacturers, all vying for market share through technological advancements and strategic partnerships.

Tenneco GmbH

Technical Solution: Tenneco GmbH has developed advanced sound quality enhancement technologies for LM7 engine exhaust setups. Their approach includes active noise control systems that use electronic sound generators to counteract unwanted exhaust noise[1]. They have also implemented passive acoustic tuning techniques, such as Helmholtz resonators and quarter-wave tubes, to target specific frequencies[2]. Tenneco's exhaust systems incorporate variable valve technology that can adjust exhaust flow and sound characteristics based on driving conditions and user preferences[3]. Additionally, they have developed advanced materials and manufacturing processes to optimize exhaust system weight and thermal management, which indirectly contribute to improved sound quality[4].

Strengths: Comprehensive approach combining active and passive technologies; customizable sound profiles. Weaknesses: Complexity and cost of active systems; potential reliability issues with electronic components.

Toyota Motor Corp.

Technical Solution: Toyota has implemented a multi-faceted approach to enhance sound quality in LM7 engine exhaust setups. They have developed a proprietary Active Noise Control (ANC) system that uses engine data and cabin microphones to generate anti-noise through the vehicle's audio system, effectively canceling out undesirable exhaust frequencies[1]. Toyota also employs advanced computational fluid dynamics (CFD) simulations to optimize exhaust system geometry for improved sound quality[2]. Their exhaust systems feature variable valve technology that can modify exhaust flow paths and acoustic characteristics based on engine load and speed[3]. Furthermore, Toyota has invested in high-precision manufacturing techniques to ensure tight tolerances in exhaust components, reducing unwanted resonances and vibrations[4].

Strengths: Integration of ANC with vehicle infotainment systems; data-driven design approach. Weaknesses: Reliance on electronic systems for noise cancellation; potential for increased complexity in maintenance.

Core Sound Innovations

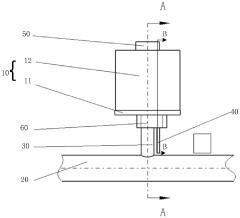

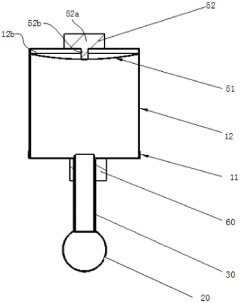

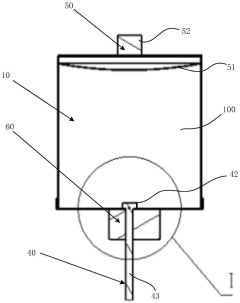

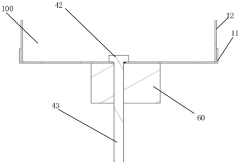

Exhaust system sound quality adjustment device and method

PatentActiveCN111720189B

Innovation

- An exhaust system sound quality adjustment device is designed, which includes a sound-generating housing with a resonant cavity on the exhaust tail pipe, a connecting pipe and a frequency modulator. The vibration membrane and controller are used to realize the frequency adjustment of the resonant cavity. The frequency is transmitted through the ECU. The noise frequency and vibration amplitude signals control the movement of the frequency modulator and the diaphragm, and adjust the sound compensation and silencing functions of the exhaust tail pipe.

Emissions Regulations

Emissions regulations play a crucial role in shaping the development of sound quality enhancements for LM7 engine exhaust setups. These regulations, primarily aimed at reducing harmful emissions and noise pollution, have a significant impact on the design and implementation of exhaust systems.

In recent years, environmental concerns have led to increasingly stringent emissions standards worldwide. The United States Environmental Protection Agency (EPA) and the European Union's Euro standards are at the forefront of these regulations. These standards set limits on various pollutants, including carbon monoxide, nitrogen oxides, and particulate matter, which directly influence the design of exhaust systems.

For LM7 engine exhaust setups, meeting these emissions standards while maintaining or enhancing sound quality presents a unique challenge. Manufacturers must balance the need for effective exhaust gas treatment with the desire for an appealing engine sound. This has led to the development of innovative technologies such as active noise control systems and variable exhaust valve systems.

The California Air Resources Board (CARB) has implemented some of the most stringent emissions regulations in the world. These regulations have a ripple effect on the automotive industry, often setting the benchmark for other states and countries. As a result, exhaust system designers must consider CARB standards when developing sound quality enhancements for LM7 engines, even if the vehicles are not initially intended for the California market.

Noise regulations also play a significant role in exhaust system design. Many countries and local jurisdictions have specific limits on vehicle noise levels, which directly impact the sound quality enhancements that can be implemented. For example, the European Union's regulation UN/ECE R51 sets strict limits on vehicle pass-by noise, requiring manufacturers to carefully tune their exhaust systems to meet these standards.

The push towards electrification and hybrid powertrains has introduced new challenges and opportunities in exhaust system design. While these technologies aim to reduce emissions, they also change the sound profile of vehicles. For LM7 engines, which are primarily used in internal combustion vehicles, this shift in the market has led to increased focus on creating distinctive and appealing exhaust notes within the constraints of emissions regulations.

As emissions regulations continue to evolve, the future of sound quality enhancements in LM7 engine exhaust setups will likely see a greater emphasis on advanced materials and smart technologies. These may include the use of lightweight, high-performance catalytic converters, adaptive sound systems, and even artificial sound generation to meet both emissions standards and consumer expectations for engine sound quality.

In recent years, environmental concerns have led to increasingly stringent emissions standards worldwide. The United States Environmental Protection Agency (EPA) and the European Union's Euro standards are at the forefront of these regulations. These standards set limits on various pollutants, including carbon monoxide, nitrogen oxides, and particulate matter, which directly influence the design of exhaust systems.

For LM7 engine exhaust setups, meeting these emissions standards while maintaining or enhancing sound quality presents a unique challenge. Manufacturers must balance the need for effective exhaust gas treatment with the desire for an appealing engine sound. This has led to the development of innovative technologies such as active noise control systems and variable exhaust valve systems.

The California Air Resources Board (CARB) has implemented some of the most stringent emissions regulations in the world. These regulations have a ripple effect on the automotive industry, often setting the benchmark for other states and countries. As a result, exhaust system designers must consider CARB standards when developing sound quality enhancements for LM7 engines, even if the vehicles are not initially intended for the California market.

Noise regulations also play a significant role in exhaust system design. Many countries and local jurisdictions have specific limits on vehicle noise levels, which directly impact the sound quality enhancements that can be implemented. For example, the European Union's regulation UN/ECE R51 sets strict limits on vehicle pass-by noise, requiring manufacturers to carefully tune their exhaust systems to meet these standards.

The push towards electrification and hybrid powertrains has introduced new challenges and opportunities in exhaust system design. While these technologies aim to reduce emissions, they also change the sound profile of vehicles. For LM7 engines, which are primarily used in internal combustion vehicles, this shift in the market has led to increased focus on creating distinctive and appealing exhaust notes within the constraints of emissions regulations.

As emissions regulations continue to evolve, the future of sound quality enhancements in LM7 engine exhaust setups will likely see a greater emphasis on advanced materials and smart technologies. These may include the use of lightweight, high-performance catalytic converters, adaptive sound systems, and even artificial sound generation to meet both emissions standards and consumer expectations for engine sound quality.

NVH Considerations

Noise, Vibration, and Harshness (NVH) considerations play a crucial role in enhancing sound quality for LM7 engine exhaust setups. The LM7, a 5.3-liter V8 engine commonly found in General Motors vehicles, presents unique challenges and opportunities for exhaust system optimization.

One of the primary NVH concerns in LM7 exhaust setups is the management of low-frequency drone. This phenomenon, typically occurring between 1500-3000 RPM, can create an unpleasant resonance inside the vehicle cabin. To address this issue, engineers often employ Helmholtz resonators or quarter-wave tubes strategically placed within the exhaust system. These devices are tuned to specific frequencies, effectively canceling out unwanted drone without compromising overall exhaust flow.

Vibration isolation is another critical aspect of NVH management in LM7 exhaust systems. The V8 configuration of the LM7 engine produces significant vibration, which can be transmitted through the exhaust system to the vehicle body. Advanced hangers and isolators, often utilizing materials like silicone or fluoroelastomers, are employed to dampen these vibrations. These components are carefully designed to provide optimal isolation while maintaining proper exhaust system alignment.

The exhaust note of the LM7 engine is a key factor in perceived vehicle quality and driver satisfaction. Sound engineers focus on enhancing the characteristic V8 rumble while minimizing harsh or unpleasant frequencies. This is often achieved through careful design of the muffler internals, including the use of multiple chambers, perforated tubes, and sound-absorbing materials. Advanced computational fluid dynamics (CFD) and acoustic modeling software are utilized to predict and fine-tune exhaust sound characteristics before physical prototyping.

Thermal management is an often-overlooked aspect of NVH in exhaust systems. Excessive heat can lead to material expansion and contraction, potentially causing rattles or changes in acoustic properties over time. High-quality heat shields and thermal wraps are employed to manage temperature distribution throughout the exhaust system, ensuring consistent performance and longevity of NVH-related components.

Lastly, the integration of active noise control technologies is an emerging trend in LM7 exhaust system development. These systems use electronic sound generation or cancellation to further refine the exhaust note, allowing for adaptive sound profiles based on driving conditions or user preferences. While still in the early stages of widespread adoption, active systems show promise in providing unprecedented levels of sound quality control in LM7 and similar engine applications.

One of the primary NVH concerns in LM7 exhaust setups is the management of low-frequency drone. This phenomenon, typically occurring between 1500-3000 RPM, can create an unpleasant resonance inside the vehicle cabin. To address this issue, engineers often employ Helmholtz resonators or quarter-wave tubes strategically placed within the exhaust system. These devices are tuned to specific frequencies, effectively canceling out unwanted drone without compromising overall exhaust flow.

Vibration isolation is another critical aspect of NVH management in LM7 exhaust systems. The V8 configuration of the LM7 engine produces significant vibration, which can be transmitted through the exhaust system to the vehicle body. Advanced hangers and isolators, often utilizing materials like silicone or fluoroelastomers, are employed to dampen these vibrations. These components are carefully designed to provide optimal isolation while maintaining proper exhaust system alignment.

The exhaust note of the LM7 engine is a key factor in perceived vehicle quality and driver satisfaction. Sound engineers focus on enhancing the characteristic V8 rumble while minimizing harsh or unpleasant frequencies. This is often achieved through careful design of the muffler internals, including the use of multiple chambers, perforated tubes, and sound-absorbing materials. Advanced computational fluid dynamics (CFD) and acoustic modeling software are utilized to predict and fine-tune exhaust sound characteristics before physical prototyping.

Thermal management is an often-overlooked aspect of NVH in exhaust systems. Excessive heat can lead to material expansion and contraction, potentially causing rattles or changes in acoustic properties over time. High-quality heat shields and thermal wraps are employed to manage temperature distribution throughout the exhaust system, ensuring consistent performance and longevity of NVH-related components.

Lastly, the integration of active noise control technologies is an emerging trend in LM7 exhaust system development. These systems use electronic sound generation or cancellation to further refine the exhaust note, allowing for adaptive sound profiles based on driving conditions or user preferences. While still in the early stages of widespread adoption, active systems show promise in providing unprecedented levels of sound quality control in LM7 and similar engine applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!